ATW catalog - Evapco

ATW catalog - Evapco

ATW catalog - Evapco

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

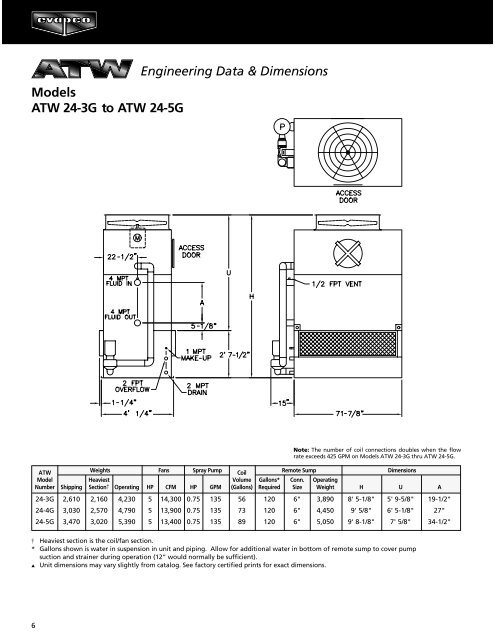

Models<strong>ATW</strong> 24-3G to <strong>ATW</strong> 24-5GEngineering Data & DimensionsNote: The number of coil connections doubles when the flowrate exceeds 425 GPM on Models <strong>ATW</strong> 24-3G thru <strong>ATW</strong> 24-5G.<strong>ATW</strong>Weights Fans Spray Pump CoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H U A24-3G 2,610 2,160 4,230 5 14,300 0.75 135 56 120 6" 3,890 8' 5-1/8" 5' 9-5/8" 19-1/2"24-4G 3,030 2,570 4,790 5 13,900 0.75 135 73 120 6" 4,450 9' 5/8" 6' 5-1/8" 27"24-5G 3,470 3,020 5,390 5 13,400 0.75 135 89 120 6" 5,050 9' 8-1/8" 7' 5/8" 34-1/2"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.6

Models<strong>ATW</strong> 36-3F to <strong>ATW</strong> 36-5F<strong>ATW</strong> 48-3F to <strong>ATW</strong> 48-5GEngineering Data & DimensionsNote: The number of coil connections doubles when the flowrate exceeds 425 GPM on Models <strong>ATW</strong> 36-3F thru <strong>ATW</strong> 48-5G.<strong>ATW</strong>Weights Fans Spray PumpCoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U A36-3F 3,720 3,110 6,060 (2) 3 20,400 1 200 82 180 6" 5,580 8' 5-1/8" 8' 11-1/2" 5' 9-5/8" 19-1/2"36-4F 4,330 3,730 6,900 (2) 3 19,800 1 200 107 180 6" 6,420 9' 5/8" 8' 11-1/2" 6' 5-1/8" 27"36-5F 4,990 4,380 7,780 (2) 3 19,100 1 200 133 180 6" 7,300 9' 8-1/8" 8' 11-1/2" 7' 5/8" 34-1/2"48-3F 4,750 3,980 7,910 (2) 3 25,300 1.5 270 108 230 8" 7,290 8' 5-1/8" 11' 11-3/4" 5' 9-5/8" 19-1/2"48-3G 4,750 3,980 7,910 (2) 5 28,580 1.5 270 108 230 8" 7,390 8' 5-1/8" 11' 11-3/4" 5' 9-5/8" 19-1/2"48-4G 5,620 4,840 9,080 (2) 5 27,700 1.5 270 143 230 8" 8,460 9' 5/8" 11' 11-3/4" 6' 5-1/8" 27"48-5G 6,450 5,680 10,210 (2) 5 26,900 1.5 270 177 230 8" 9,590 9' 8-1/8" 11' 11-3/4" 7' 5/8" 34-1/2"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.7

Models<strong>ATW</strong> 64-3H to <strong>ATW</strong> 64-6JEngineering Data & DimensionsNote: The number of coil connections doubles when the flowrate exceeds 900 GPM on Models <strong>ATW</strong> 64-3H thru <strong>ATW</strong> 64-6J.<strong>ATW</strong>Weights Fans Spray Pump CoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H U A64-3H 7,190 5,890 10,580 7.5 33,420 2 340 140 220 8" 9,350 10' 6-1/2" 6' 6-3/8" 19-1/2"64-3I 7,220 5,920 10,610 10 36,580 2 340 140 220 8" 9,380 10' 6-1/2" 6' 6-3/8" 19-1/2"64-4H 8,290 6,990 12,040 7.5 32,440 2 340 184 220 8" 10,810 11' 2" 7' 1-7/8" 27"64-4I 8,320 7,020 12,070 10 35,520 2 340 184 220 8" 10,840 11' 2" 7' 1-7/8" 27"64-5I 9,490 8,190 13,590 10 34,450 2 340 226 220 8" 12,360 11' 9-1/2" 7' 9-3/8" 34-1/2"64-5J 9,550 8,250 13,650 15 38,590 2 340 226 220 8" 12,420 11' 9-1/2" 7' 9-3/8" 34-1/2"64-6I 10,660 9,360 15,120 10 33,390 2 340 268 220 8" 13,890 12' 5" 8' 4-7/8" 42"64-6J 10,720 9,420 15,180 15 37,400 2 340 268 220 8" 13,950 12' 5" 8' 4-7/8" 42"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.8

Models<strong>ATW</strong> 77-3I to <strong>ATW</strong> 77-6K<strong>ATW</strong> 89-3I to <strong>ATW</strong> 89-6LEngineering Data & DimensionsNote: The number of coil connections doubles when the flowrate exceeds 900 GPM on Models <strong>ATW</strong> 77-3I thru <strong>ATW</strong> 89-6L.<strong>ATW</strong>Weights Fans Spray PumpCoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U A77-3I 8,290 6,850 12,430 10 41,450 2 410 184 250 8" 11,060 11' 2-5/8" 8' 11-1/2" 6' 10-7/8" 19-1/2"77-3J 8,360 6,920 12,500 15 46,630 2 410 184 250 8" 11,130 11' 2-5/8" 8' 11-1/2" 6' 10-7/8" 19-1/2"77-4I 9,560 8,120 14,170 10 40,240 2 410 240 250 8" 12,800 11' 10-1/8" 8' 11-1/2" 7' 6-3/8" 27"77-4J 9,630 8,190 14,240 15 45,270 2 410 240 250 8" 12,870 11' 10-1/8" 8' 11-1/2" 7' 6-3/8" 27"77-5I 10,940 9,500 16,020 10 39,030 2 410 296 250 8" 14,650 12' 5-5/8" 8' 11-1/2" 8' 1-7/8" 34-1/2"77-5J 11,010 9,570 16,090 15 43,910 2 410 296 250 8" 14,720 12' 5-5/8" 8' 11-1/2" 8' 1-7/8" 34-1/2"77-6J 12,350 10,910 17,900 15 42,550 2 410 352 250 8" 16,530 13' 1-1/8" 8' 11-1/2" 8' 9-3/8" 42"77-6K 12,400 10,960 17,950 20 46,120 2 410 352 250 8" 16,580 13' 1-1/8" 8' 11-1/2" 8' 9-3/8" 42"89-3I 9,520 7,860 14,380 10 45,960 3 500 212 290 10" 12,770 11' 2-5/8" 10' 5-1/2" 6' 10-7/8" 19-1/2"89-3J 9,590 7,930 14,450 15 52,130 3 500 212 290 10" 12,840 11' 2-5/8" 10' 5-1/2" 6' 10-7/8" 19-1/2"89-4I 11,000 9,340 16,410 10 44,620 3 500 278 290 10" 14,800 11' 10-1/8" 10' 5-1/2" 7' 6-3/8" 27"89-4J 11,070 9,410 16,480 15 50,610 3 500 278 290 10" 14,870 11' 10-1/8" 10' 5-1/2" 7' 6-3/8" 27"89-5J 12,690 11,030 18,650 15 49,090 3 500 344 290 10" 17,040 12' 5-5/8" 10' 5-1/2" 8' 1-7/8" 34-1/2"89-5K 12,740 11,080 18,700 20 53,210 3 500 344 290 10" 17,090 12' 5-5/8" 10' 5-1/2" 8' 1-7/8" 34-1/2"89-6K 14,300 12,640 20,810 20 51,570 3 500 410 290 10" 19,200 13' 1-1/8" 10' 5-1/2" 8' 9-3/8" 42"89-6L 14,330 12,670 20,840 25 54,890 3 500 410 290 10" 19,230 13' 1-/18" 10' 5-1/2" 8' 9-3/8" 42"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.9

Models<strong>ATW</strong> 153-3I to <strong>ATW</strong> 153-6K<strong>ATW</strong> 179-3I to <strong>ATW</strong> 179-6LEngineering Data & DimensionsNote: The number of coil connections doubles when the flowrate exceeds 900 GPM on Models <strong>ATW</strong> 153-3I thru <strong>ATW</strong> 179-6L.<strong>ATW</strong>Weights Fans Spray PumpCoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U A153-3I 15,780 12,980 24,260 (2) 10 83,180 5 800 356 510 12" 21,460 11' 11" 18' 6' 10-7/8" 19-1/2"153-3J 15,920 13,120 24,400 (2) 15 93,600 5 800 356 510 12" 21,600 11' 11" 18' 6' 10-7/8" 19-1/2"153-4I 18,400 15,600 27,830 (2) 10 80,760 5 800 472 510 12" 25,030 12' 6-1/2" 18' 7' 6-3/8" 27"153-4J 18,540 15,740 27,970 (2) 15 90,880 5 800 472 510 12" 25,170 12' 6-1/2" 18' 7' 6-3/8" 27"153-5I 20,950 18,150 31,330 (2) 10 78,340 5 800 586 510 12" 28,530 13' 2" 18' 8' 1-7/8" 34-1/2"153-5J 21,090 18,290 31,470 (2) 15 88,150 5 800 586 510 12" 28,670 13' 2" 18' 8' 1-7/8" 34-1/2"153-6J 23,780 20,980 35,120 (2) 15 85,430 5 800 700 510 12" 32,320 13' 9-1/2" 18' 8' 9-3/8" 42"153-6K 23,880 21,080 35,220 (2) 20 92,590 5 800 700 510 12" 32,420 13' 9-1/2" 18' 8' 9-3/8" 42"179-3I 17,840 14,730 27,820 (2) 10 92,190 7.5 1,050 414 590 12" 24,550 11' 11" 21' 6' 10-7/8" 19-1/2"179-3J 17,980 14,870 27,960 (2) 15 104,600 7.5 1,050 414 590 12" 24,690 11' 11" 21' 6' 10-7/8" 19-1/2"179-4I 20,890 17,780 31,980 (2) 10 89,500 7.5 1,050 548 590 12" 28,710 12' 6-1/2" 21' 7' 6-3/8" 27"179-4J 21,030 17,920 32,120 (2) 15 101,550 7.5 1,050 548 590 12" 28,850 12' 6-1/2" 21' 7' 6-3/8" 27"179-5J 24,000 20,890 36,210 (2) 15 98,500 7.5 1,050 682 590 12" 32,940 13' 2" 21' 8' 1-7/8" 34-1/2"179-5K 24,100 20,990 36,310 (2) 20 106,770 7.5 1,050 682 590 12" 33,040 13' 2" 21' 8' 1-7/8" 34-1/2"179-6K 27,220 24,110 40,540 (2) 20 103,460 7.5 1,050 816 590 12" 37,270 13' 9-1/2" 21' 8' 9-3/8" 42"179-6L 27,280 24,170 40,600 (2) 25 110,130 7.5 1,050 816 590 12" 37,330 13' 9-1/2" 21' 8' 9-3/8" 42"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.11

Models<strong>ATW</strong> 204-3J to <strong>ATW</strong> 204-6L<strong>ATW</strong> 238-3J to <strong>ATW</strong> 238-6MEngineering Data & Dimensions<strong>ATW</strong>Weights Fans Spray Pump Coil Remote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U E A204-3J 20,780 8,580 32,060 (2) 15 114,970 (2)3 1,100 484 660 (2)10" 28,360 11' 11" 11' 11-3/4" 6' 10-7/8" 5' 1/8" 19-1/2"204-3K 20,860 8,620 32,140 (2) 20 124,620 (2)3 1,100 484 660 (2)10" 28,440 11' 11" 11' 11-3/4" 6' 10-7/8" 5' 1/8" 19-1/2"204-4J 24,240 10,310 36,780 (2) 15 111,620 (2)3 1,100 632 660 (2)10" 33,080 12' 6-1/2" 11' 11-3/4" 7' 6-3/8" 5' 1/8" 27"204-4K 24,320 10,350 36,860 (2) 20 120,990 (2)3 1,100 632 660 (2)10" 33,160 12' 6-1/2" 11' 11-3/4" 7' 6-3/8" 5' 1/8" 27"204-5K 27,780 12,080 41,580 (2) 20 117,360 (2)3 1,100 784 660 (2)10" 37,880 13' 2" 11' 11-3/4" 8' 1-7/8" 5' 1/8" 34-1/2"204-5L 27,820 12,100 41,620 (2) 25 124,930 (2)3 1,100 784 660 (2)10" 37,920 13' 2" 11' 11-3/4" 8' 1-7/8" 5' 1/8" 34-1/2"204-6K 31,360 13,870 46,420 (2) 20 113,730 (2)3 1,100 936 660 (2)10" 42,720 13' 9-1/2" 11' 11-3/4" 8' 9-3/8" 5' 1/8" 42"204-6L 31,400 13,890 46,460 (2) 25 119,710 (2)3 1,100 936 660 (2)10" 42,760 13' 9-1/2" 11' 11-3/4" 8' 9-3/8" 5' 1/8" 42"238-3J 23,520 9,740 36,620 (2) 15 127,690 (2)3 1,200 560 760 (2)10" 32,300 12' 5" 13' 11-3/4" 6' 10-7/8" 5' 6-1/8" 19-1/2"238-3K 23,600 9,780 36,700 (2) 20 139,290 (2)3 1,200 560 760 (2)10" 32,380 12' 5" 13' 11-3/4" 6' 10-7/8" 5' 6-1/8" 19-1/2"238-4K 27,600 11,780 42,180 (2) 20 135,230 (2)3 1,200 736 760 (2)10" 37,860 13' 1/2" 13' 11-3/4" 7' 6-3/8" 5' 6-1/8" 27"238-4L 27,640 11,800 42,220 (2) 25 143,950 (2)3 1,200 736 760 (2)10" 37,900 13' 1/2" 13' 11-3/4" 7' 6-3/8" 5' 6-1/8" 27"238-5K 29,760 12,860 45,820 (2) 20 131,170 (2)3 1,200 912 760 ((2)10" 41,500 13' 8" 13' 11-3/4" 8' 1-7/8" 5' 6-1/8" 34-1/2"238-5L 29,800 12,880 45,860 (2) 25 139,630 (2)3 1,200 912 760 (2)10" 41,540 13' 8" 13' 11-3/4" 8' 1-7/8" 5' 6-1/8" 34-1/2"238-6L 35,820 15,890 53,360 (2) 25 135,310 (2)3 1,200 1,092 760 (2)10" 49,040 14' 3-1/2" 13' 11-3/4" 8' 9-3/8" 5' 6-1/8" 42"238-6M 35,860 15,910 53,400 (2) 30 142,400 (2)3 1,200 1,092 760 (2)10" 49,080 14' 3-1/2" 13' 11-3/4" 8' 9-3/8" 5' 6-1/8" 42"12Note: The number of coil connections doubles when the flow rateexceeds 1,800 GPM on Models <strong>ATW</strong> 204-3J thru <strong>ATW</strong> 238-6M.† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.

Models<strong>ATW</strong> 144-3K to <strong>ATW</strong> 144-6N<strong>ATW</strong> 168-3L to <strong>ATW</strong> 168-6NEngineering Data & DimensionsNote: The number of coil connections doubles when the flowrate exceeds 900 GPM on Models <strong>ATW</strong> 144-3K thru <strong>ATW</strong> 168-6N.<strong>ATW</strong>Weights Fans Spray PumpCoilRemote Sump DimensionsModel Heaviest Gallons Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U E A144-3K 14,710 12,140 23,580 20 79,800 5 800 342 490 12" 21,510 13' 4-3/4" 11' 11-3/4" 8' 2-5/8" 5' 2-1/8" 22-1/4"144-3L 14,760 12,190 23,630 25 85,040 5 800 342 490 12" 21,560 13' 4-3/4" 11' 11-3/4" 8' 2-5/8" 5' 2-1/8" 22-1/4"144-4K 17,200 14,630 26,970 20 77,470 5 800 450 490 12" 24,900 14' 1-1/4" 11' 11-3/4" 8'11-1/8" 5' 2-1/8" 30-3/4"144-4L 17,250 14,680 27,020 25 82,560 5 800 450 490 12" 24,950 14' 1-1/4" 11' 11-3/4" 8'11-1/8" 5' 2-1/8" 30-3/4"144-4M 17,350 14,780 27,120 30 86,890 5 800 450 490 12" 25,050 14' 1-1/4" 11' 11-3/4" 8'11-1/8" 5' 2-1/8" 30-3/4"144-5L 19,590 17,020 30,260 25 80,090 5 800 556 490 12" 28,190 14' 9-3/4" 11' 11-3/4" 9' 7-5/8" 5' 2-1/8" 39-1/4"144-5M 19,690 17,120 30,360 30 84,280 5 800 556 490 12" 28,290 14' 9-3/4" 11' 11-3/4" 9' 7-5/8" 5' 2-1/8" 39-1/4"144-6M 22,450 19,880 34,010 30 81,680 5 800 664 490 12" 31,940 15' 6-1/4" 11' 11-3/4" 10' 4-1/8" 5' 2-1/8" 47-3/4"144-6N 22,700 20,130 34,260 40 88,530 5 800 664 490 12" 32,190 15' 6-1/4" 11' 11-3/4" 10' 4-1/8" 5' 2-1/8" 47-3/4"168-3L 16,730 13,810 27,140 25 95,050 5 900 396 570 12" 24,720 13' 10-3/4"13' 11-3/4" 8' 2-5/8" 5' 8-1/8" 22-1/4"168-3M 16,800 13,880 27,210 30 100,030 5 900 396 570 12" 24,790 13' 10-3/4"13' 11-3/4" 8' 2-5/8" 5' 8-1/8" 22-1/4"168-4L 19,630 16,710 31,090 25 92,280 5 900 522 570 12" 28,670 14' 7-1/4" 13' 11-3/4" 8'11-1/8" 5' 8-1/8" 30-3/4"168-4M 19,700 16,780 31,160 30 97,110 5 900 522 570 12" 28,740 14' 7-1/4" 13' 11-3/4" 8'11-1/8" 5' 8-1/8" 30-3/4"168-5M 22,410 19,490 34,920 30 94,200 5 900 648 570 12" 32,500 15' 3-3/4" 13' 11-3/4" 9' 7-5/8" 5' 8-1/8" 39-1/4"168-5N 22,670 19,750 35,180 40 102,100 5 900 648 570 12" 32,760 15' 3-3/4" 13' 11-3/4" 9' 7-5/8" 5' 8-1/8" 39-1/4"168-6M 25,620 22,700 39,180 30 91,290 5 900 774 570 12" 36,760 16' 1/4" 13' 11-3/4" 10' 5-1/8" 5' 8-1/8" 47-3/4"168-6N 25,880 22,960 39,440 40 98,940 5 900 774 570 12" 37,020 16' 1/4" 13' 11-3/4" 10' 5-1/8" 5' 8-1/8" 47-3/4"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.13

Models<strong>ATW</strong> 216-3L to <strong>ATW</strong> 216-6O<strong>ATW</strong> 240-3M to <strong>ATW</strong> 240-6PEngineering Data & Dimensions<strong>ATW</strong>Weights Fans Spray PumpCoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U A216-3L 21,010 17,210 34,330 25 116,390 7.5 1,200 506 720 12" 31,200 14' 4-3/4" 18' 8' 2-5/8" 22-1/4"216-3M 21,120 17,320 34,440 30 123,680 7.5 1,200 506 720 12" 31,310 14' 4-3/4" 18' 8' 2-5/8" 22-1/4"216-4L 24,700 20,900 39,370 25 113,000 7.5 1,200 668 720 12" 36,240 15' 1-1/4" 18' 8' 11-1/8" 30-3/4"216-4M 24,810 21,010 39,480 30 120,070 7.5 1,200 668 720 12" 36,350 15' 1-1/4" 18' 8' 11-1/8" 30-3/4"216-4N 25,070 21,270 39,740 40 130,320 7.5 1,200 668 720 12" 36,610 15' 1-1/4" 18' 8' 11-1/8" 30-3/4"216-5M 28,400 24,600 44,420 30 116,470 7.5 1,200 832 720 12" 41,290 15' 9-3/4" 18' 9' 7-5/8" 39-1/4"216-5N 28,660 24,860 44,680 40 126,410 7.5 1,200 832 720 12" 41,550 15' 9-3/4" 18' 9' 7-5/8" 39-1/4"216-6N 32,740 28,940 50,120 40 122,500 7.5 1,200 994 720 12" 46,990 16' 6-1/4" 18' 10' 4-1/8" 47-3/4"216-6O 32,800 29,000 50,180 50 130,400 7.5 1,200 994 720 12" 47,050 16' 6-1/4" 18' 10' 4-1/8" 47-3/4"240-3M 23,320 19,020 38,210 30 132,680 10 1,400 562 800 14" 34,720 14' 4-3/4" 20' 8' 2-5/8" 22-1/4"240-3N 23,580 19,280 38,470 40 144,810 10 1,400 562 800 14" 34,980 14' 4-3/4" 20' 8' 2-5/8" 22-1/4"240-4M 27,400 23,100 43,800 30 128,820 10 1,400 742 800 14" 40,310 15' 1-1/4" 20' 8' 11-1/8" 30-3/4"240-4N 27,660 23,360 44,060 40 140,600 10 1,400 742 800 14" 40,570 15' 1-1/4" 20' 8' 11-1/8" 30-3/4"240-5N 31,640 27,340 49,550 40 136,380 10 1,400 922 800 14" 46,060 15' 9-3/4" 20' 9' 7-5/8" 39-1/4"240-5O 31,700 27,400 49,610 50 145,170 10 1,400 922 800 14" 46,120 15' 9-3/4" 20' 9' 7-5/8" 39-1/4"240-6O 36,160 31,860 55,580 50 140,680 10 1,400 1,104 800 14" 52,090 16' 6-1/4" 20' 10' 4-1/8" 47-3/4"240-6P 36,270 31,970 55,690 60 148,050 10 1,400 1,104 800 14" 52,200 16' 6-1/4" 20' 10' 4-1/8" 47-3/4"14Note: The number of coil connections doubles when the flowrate exceeds 900 GPM on Models <strong>ATW</strong> 216-3L thru <strong>ATW</strong> 240-6P.† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.

Models<strong>ATW</strong> 286-3K to <strong>ATW</strong> 286-6N<strong>ATW</strong> 334-3L to <strong>ATW</strong> 334-6NEngineering Data & DimensionsNote: The number of coil connections doubles when the flow rateexceeds 1,800 GPM on Models <strong>ATW</strong> 286-3K thru <strong>ATW</strong> 334-6N.<strong>ATW</strong>Weights Fans Spray Pump CoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U E A286-3K 29,380 12,140 47,120 (2) 20 159,590 (2) 5 1,600 684 980 (2)12" 42,980 14' 4-3/4" 24' 2" 8' 2-5/8" 6' 2-1/8" 22-1/4"286-3L 29,480 12,190 47,220 (2) 25 170,080 (2) 5 1,600 684 980 (2)12" 43,080 14' 4-3/4" 24' 2" 8' 2-5/8" 6' 2-1/8" 22-1/4"286-4L 34,460 14,680 54,000 (2) 25 165,130 (2) 5 1,600 900 980 (2)12" 49,860 15' 1-1/4" 24' 2" 8' 11-1/8" 6' 2-1/8" 30-3/4"286-4M 34,660 14,780 54,200 (2) 30 173,780 (2) 5 1,600 900 980 (2)12" 50,060 15' 1-1/4" 24' 2" 8' 11-1/8" 6' 2-1/8" 30-3/4"286-5L 39,140 17,020 60,480 (2) 25 160,170 (2) 5 1,600 1,112 980 (2)12" 56,340 15' 9-3/4" 24' 2" 9' 7-5/8" 6' 2-1/8" 39-1/4"286-5M 39,340 17,120 60,680 (2) 30 168,560 (2) 5 1,600 1,112 980 (2)12" 56,540 15' 9-3/4" 24' 2" 9' 7-5/8" 6' 2-1/8" 39-1/4"286-6M 44,860 19,880 67,980 (2) 30 163,350 (2) 5 1,600 1,328 980 (2)12" 63,840 16' 6-1/4" 24' 2" 10' 4-1/8" 6' 2-1/8" 47-3/4"286-6N 45,360 20,130 68,480 (2) 40 177,050 (2) 5 1,600 1,328 980 (2)12" 64,340 16' 6-1/4" 24' 2" 10' 4-1/8" 6' 2-1/8" 47-3/4"334-3L 33,500 13,810 54,320 (2) 25 190,090 (2) 5 1,800 792 1,140 (2)12" 49,480 15' 4-3/4" 28' 2" 8' 2-5/8" 7' 2-1/8" 22-1/4"334-3M 33,640 13,880 54,460 (2) 30 200,050 (2) 5 1,800 792 1,140 (2)12" 49,620 15' 4-3/4" 28' 2" 8' 2-5/8" 7' 2-1/8" 22-1/4"334-4L 39,300 16,710 62,220 (2) 25 184,560 (2) 5 1,800 1,044 1,140 (2)12" 57,380 16' 1-1/4" 28' 2" 8' 11-1/8" 7' 2-1/8" 30-3/4"334-4M 39,440 16,780 62,360 (2) 30 194,220 (2) 5 1,800 1,044 1,140 (2)12" 57,520 16' 1-1/4" 28' 2" 8' 11-1/8" 7' 2-1/8" 30-3/4"334-5M 44,860 19,490 69,880 (2) 30 188,400 (2) 5 1,800 1,296 1,140 (2)12" 65,040 16' 9-3/4" 28' 2" 9' 7-5/8" 7' 2-1/8" 39-1/4"334-5N 45,380 19,750 70,400 (2) 40 204,200 (2) 5 1,800 1,296 1,140 (2)12" 65,560 16' 9-3/4" 28' 2" 9' 7-5/8" 7' 2-1/8" 39-1/4"334-6M 51,280 22,700 78,400 (2) 30 182,570 (2) 5 1,800 1,548 1,140 (2)12" 73,560 17' 6-1/4" 28' 2" 10' 4-1/8" 7' 2-1/8" 47-3/4"334-6N 51,800 22,960 78,920 (2) 40 197,880 (2) 5 1,800 1,548 1,140 (2)12" 74,080 17' 6-1/4" 28' 2" 10' 4-1/8" 7' 2-1/8" 47-3/4"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.15

Models<strong>ATW</strong> 430-3L to <strong>ATW</strong> 430-6O<strong>ATW</strong> 478-3M to <strong>ATW</strong> 478-6PEngineering Data & Dimensions<strong>ATW</strong>Weights Fans Spray PumpCoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U A430-3L 42,280 17,210 68,920 (2) 25 232,770 (2) 7.5 2,400 1,012 1,440 (2) 12" 62,660 15' 4-3/4" 36' 2-1/2" 8' 2-5/8" 22-1/4"430-3M 42,500 17,320 69,140 (2) 30 247,350 (2) 7.5 2,400 1,012 1,440 (2) 12" 62,880 15' 4-3/4" 36' 2-1/2" 8' 2-5/8" 22-1/4"430-4L 49,660 20,900 79,000 (2) 25 225,990 (2) 7.5 2,400 1,336 1,440 (2) 12" 72,740 16' 1-1/4" 36' 2-1/2" 8' 11-1/8" 30-3/4"430-4M 49,880 21,010 79,220 (2) 30 240,150 (2) 7.5 2,400 1,336 1,440 (2) 12" 72,960 16' 1-1/4" 36' 2-1/2" 8' 11-1/8" 30-3/4"430-4N 50,400 21,270 79,740 (2) 40 260,630 (2) 7.5 2,400 1,336 1,440 (2) 12" 73,480 16' 1-1/4" 36' 2-1/2" 8' 11-1/8" 30-3/4"430-5M 57,060 24,600 89,100 (2) 30 232,940 (2) 7.5 2,400 1,664 1,440 (2) 12" 82,840 16' 9-3/4" 36' 2-1/2" 9' 7-5/8" 39-1/4"430-5N 57,580 24,860 89,620 (2) 40 252,810 (2) 7.5 2,400 1,664 1,440 (2) 12" 83,360 16' 9-3/4" 36' 2-1/2" 9' 7-5/8" 39-1/4"430-6N 65,740 28,940 100,500 (2) 40 244,990 (2) 7.5 2,400 1,988 1,440 (2) 12" 94,240 17' 6-1/4" 36' 2-1/2" 10' 4-1/8" 47-3/4"430-6O 65,860 29,000 100,620 (2) 50 260,790 (2) 7.5 2,400 1,988 1,440 (2) 12" 94,360 17' 6-1/4" 36' 2-1/2" 10' 4-1/8" 47-3/4"478-3M 46,860 19,020 76,640 (2) 30 265,370 (2)10 2,800 1,124 1,600 (2) 14" 69,660 15' 4-3/4" 40' 2-1/2" 8' 2-5/8" 22-1/4"478-3N 47,380 19,280 77,160 (2) 40 289,630 (2)10 2,800 1,124 1,600 (2) 14" 70,180 15' 4-3/4" 40' 2-1/2" 8' 2-5/8" 22-1/4"478-4M 55,020 23,100 87,820 (2) 30 257,640 (2)10 2,800 1,484 1,600 (2) 14" 80,840 16' 1-1/4" 40' 2-1/2" 8' 11-1/8" 30-3/4"478-4N 55,540 23,360 88,340 (2) 40 281,190 (2)10 2,800 1,484 1,600 (2) 14" 81,360 16' 1-1/4" 40' 2-1/2" 8' 11-1/8" 30-3/4"478-5N 63,500 27,340 99,320 (2) 40 272,750 (2)10 2,800 1,844 1,600 (2) 14" 92,340 16' 9-3/4" 40' 2-1/2" 9' 7-5/8" 39-1/4"478-5O 63,620 27,400 99,440 (2) 50 290,340 (2)10 2,800 1,844 1,600 (2) 14" 92,460 16' 9-3/4" 40' 2-1/2" 9' 7-5/8" 39-1/4"478-6O 72,540 31,860 111,380 (2) 50 281,360 (2)10 2,800 2,208 1,600 (2) 14" 104,400 17' 6-1/4" 40' 2-1/2" 10' 4-1/8" 47-3/4"478-6P 72,760 31,970 111,600 (2) 60 296,090 (2)10 2,800 2,208 1,600 (2) 14" 104,620 17' 6-1/4" 40' 2-1/2" 10' 4-1/8" 47-3/4"16Note: The number of coil connections doubles when the flowrate exceeds 1,800 GPM on Models <strong>ATW</strong> 430-3L thru <strong>ATW</strong> 478-6P.† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.

Models<strong>ATW</strong> 290-3K to <strong>ATW</strong> 290-6N<strong>ATW</strong> 338-3L to <strong>ATW</strong> 338-6NEngineering Data & DimensionsNote: The number of coil connections doubles when the flow rateexceeds 1,800 GPM on Models <strong>ATW</strong> 290-3K thru <strong>ATW</strong> 338-6N.<strong>ATW</strong>Weights Fans Spray PumpCoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U E A290-3K 29,360 12,140 47,100 (2) 20 159,590 (2) 5 1,600 684 980 (2)12" 42,960 14' 4-3/4" 11' 11-3/4" 8' 2-5/8" 6' 2-1/8" 22-1/4"290-3L 29,460 12,190 47,200 (2) 25 170,080 (2) 5 1,600 684 980 (2)12" 43,060 14' 4-3/4" 11' 11-3/4" 8' 2-5/8" 6' 2-1/8" 22-1/4"290-4L 34,440 14,680 53,980 (2) 25 165,130 (2) 5 1,600 900 980 (2)12" 49,840 15' 1-1/4" 11' 11-3/4" 8'11-1/8" 6' 2-1/8" 30-3/4"290-4M 34,640 14,780 54,180 (2) 30 173,780 (2) 5 1,600 900 980 (2)12" 50,040 15' 1-1/4" 11' 11-3/4" 8'11-1/8" 6' 2-1/8" 30-3/4"290-5L 39,120 17,020 60,460 (2) 25 160,170 (2) 5 1,600 1,112 980 (2)12" 56,320 15' 9-3/4" 11' 11-3/4" 9' 7-5/8" 6' 2-1/8" 39-1/4"290-5M 39,320 17,120 60,660 (2) 30 168,560 (2) 5 1,600 1,112 980 (2)12" 56,520 15' 9-3/4" 11' 11-3/4" 9' 7-5/8" 6' 2-1/8" 39-1/4"290-6M 44,840 19,880 67,960 (2) 30 163,350 (2) 5 1,600 1,328 980 (2)12" 63,820 16' 6-1/4" 11' 11-3/4" 10' 4-1/8" 6' 2-1/8" 47-3/4"290-6N 45,340 20,130 68,460 (2) 40 177,050 (2) 5 1,600 1,328 980 (2)12" 64,320 16' 6-1/4" 11' 11-3/4" 10' 4-1/8" 6' 2-1/8" 47-3/4"338-3L 33,540 13,810 54,360 (2) 25 190,090 (2) 5 1,800 792 1,140 (2)12" 49,520 15' 4-3/4" 13' 11-3/4" 8' 2-5/8" 7' 2-1/8" 22-1/4"338-3M 33,680 13,880 54,500 (2) 30 200,050 (2) 5 1,800 792 1,140 (2)12" 49,660 15' 4-3/4" 13' 11-3/4" 8' 2-5/8" 7' 2-1/8" 22-1/4"338-4L 39,340 16,710 62,260 (2) 25 184,560 (2) 5 1,800 1,044 1,140 (2)12" 57,420 16' 1-1/4" 13' 11-3/4" 8'11-1/8" 7' 2-1/8" 30-3/4"338-4M 39,480 16,780 62,400 (2) 30 194,220 (2) 5 1,800 1,044 1,140 (2)12" 57,560 16' 1-1/4" 13' 11-3/4" 8'11-1/8" 7' 2-1/8" 30-3/4"338-5M 44,900 19,490 69,920 (2) 30 188,400 (2) 5 1,800 1,296 1,140 (2)12" 65,080 16' 9-3/4" 13' 11-3/4" 9' 7-5/8" 7' 2-1/8" 39-1/4"338-5N 45,420 19,750 70,440 (2) 40 204,200 (2) 5 1,800 1,296 1,140 (2)12" 65,600 16' 9-3/4" 13' 11-3/4" 9' 7-5/8" 7' 2-1/8" 39-1/4"338-6M 51,320 22,700 78,440 (2) 30 182,570 (2) 5 1,800 1,548 1,140 (2)12" 73,600 17' 6-1/4" 13' 11-3/4" 10' 4-1/8" 7' 2-1/8" 47-3/4"338-6N 51,840 22,960 78,960 (2) 40 197,880 (2) 5 1,800 1,548 1,140 (2)12" 74,120 17' 6-1/4" 13' 11-3/4" 10' 4-1/8" 7' 2-1/8" 47-3/4"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.17

Models<strong>ATW</strong> 434-3L to <strong>ATW</strong> 434-6O<strong>ATW</strong> 482-3M to <strong>ATW</strong> 482-6PEngineering Data & Dimensions<strong>ATW</strong>Weights Fans Spray Pump CoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U A434-3L 42,320 17,210 68,960 (2) 25 232,770 (2) 7.5 2,400 1,012 1,440 (2) 12" 62,700 16' 4-3/4" 18' 8' 2-5/8" 22-1/4"434-3M 42,540 17,320 69,180 (2) 30 247,350 (2) 7.5 2,400 1,012 1,440 (2) 12" 62,920 16' 4-3/4" 18' 8' 2-5/8" 22-1/4"434-4L 49,700 20,900 79,040 (2) 25 225,990 (2) 7.5 2,400 1,336 1,440 (2) 12" 72,780 17' 1-1/4" 18' 8' 11-1/8" 30-3/4"434-4M 49,920 21,010 79,260 (2) 30 240,150 (2) 7.5 2,400 1,336 1,440 (2) 12" 73,000 17' 1-1/4" 18' 8' 11-1/8" 30-3/4"434-4N 50,440 21,270 79,780 (2) 40 260,630 (2) 7.5 2,400 1,336 1,440 (2) 12" 73,520 17' 1-1/4" 18' 8' 11-1/8" 30-3/4"434-5M 57,100 24,600 89,140 (2) 30 232,940 (2) 7.5 2,400 1,664 1,440 (2) 12" 82,880 17' 9-3/4" 18' 9' 7-5/8" 39-1/4"434-5N 57,620 24,860 89,660 (2) 40 252,810 (2) 7.5 2,400 1,664 1,440 (2) 12" 83,400 17' 9-3/4" 18' 9' 7-5/8" 39-1/4"434-6N 65,780 28,940 100,540 (2) 40 244,990 (2) 7.5 2,400 1,988 1,440 (2) 12" 94,280 18' 6-1/4" 18' 10' 4-1/8" 47-3/4"434-6O 65,900 29,000 100,660 (2) 50 260,790 (2) 7.5 2,400 1,988 1,440 (2) 12" 94,400 18' 6-1/4" 18' 10' 4-1/8" 47-3/4"482-3M 46,680 19,020 76,460 (2) 30 265,370 (2) 10 2,800 1,124 1,600 (2) 14" 69,480 16' 4-3/4" 20' 8' 2-5/8" 22-1/4"482-3N 47,200 19,280 76,980 (2) 40 289,630 (2) 10 2,800 1,124 1,600 (2) 14" 70,000 16' 4-3/4" 20' 8' 2-5/8" 22-1/4"482-4M 54,840 23,100 87,640 (2) 30 257,640 (2) 10 2,800 1,484 1,600 (2) 14" 80,660 17' 1-1/4" 20' 8' 11-1/8" 30-3/4"482-4N 55,360 23,360 88,160 (2) 40 281,190 (2) 10 2,800 1,484 1,600 (2) 14" 81,180 17' 1-1/4" 20' 8' 11-1/8" 30-3/4"482-5N 63,320 27,340 99,140 (2) 40 272,750 (2) 10 2,800 1,844 1,600 (2) 14" 92,160 17' 9-3/4" 20' 9' 7-5/8" 39-1/4"482-5O 63,440 27,400 99,260 (2) 50 290,340 (2) 10 2,800 1,844 1,600 (2) 14" 92,280 17' 9-3/4" 20' 9' 7-5/8" 39-1/4"482-6O 72,360 31,860 111,200 (2) 50 281,360 (2) 10 2,800 2,208 1,600 (2) 14" 104,220 18' 6-1/4" 20' 10' 4-1/8" 47-3/4"482-6P 72,580 31,970 111,420 (2) 60 296,090 (2) 10 2,800 2,208 1,600 (2) 14" 104,440 18' 6-1/4" 20' 10' 4-1/8" 47-3/4"18Note: The number of coil connections doubles when the flowrate exceeds 1,800 GPM on Models <strong>ATW</strong> 434-3L thru <strong>ATW</strong> 482-6P.† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.

Models<strong>ATW</strong> 578-3K to <strong>ATW</strong> 578-6N<strong>ATW</strong> 672-3L to <strong>ATW</strong> 672-6NEngineering Data & DimensionsNote: The number of coil connections doubles when the flow rateexceeds 3,600 GPM on Models <strong>ATW</strong> 578-3K thru <strong>ATW</strong> 672-6N.<strong>ATW</strong>Weights Fans Spray Pump CoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U A578-3K 59,280 12,140 94,780 (4) 20 319,180 (4) 5 3,200 1,368 1,960 (4) 12" 86,340 16' 4-3/4" 24' 2" 8' 2-5/8" 22-1/4"578-3L 59,480 12,190 94,980 (4) 25 340,160 (4) 5 3,200 1,368 1,960 (4) 12" 86,540 16' 4-3/4" 24' 2" 8' 2-5/8" 22-1/4"578-4K 69,240 14,630 108,340 (4) 20 309,880 (4) 5 3,200 1,800 1,960 (4) 12" 99,900 17' 1-1/4" 24' 2" 8' 11-1/8" 30-3/4"578-4L 69,440 14,680 108,540 (4) 25 330,260 (4) 5 3,200 1,800 1,960 (4) 12" 100,100 17' 1-1/4" 24' 2" 8' 11-1/8" 30-3/4"578-4M 69,840 14,780 108,940 (4) 30 347,550 (4) 5 3,200 1,800 1,960 (4) 12" 100,500 17' 1-1/4" 24' 2" 8' 11-1/8" 30-3/4"578-5L 78,800 17,020 121,500 (4) 25 320,350 (4) 5 3,200 2,224 1,960 (4) 12" 113,060 17' 9-3/4" 24' 2" 9' 7-5/8" 39-1/4"578-5M 79,200 17,120 121,900 (4) 30 337,130 (4) 5 3,200 2,224 1,960 (4) 12" 113,460 17' 9-3/4" 24' 2" 9' 7-5/8" 39-1/4"578-6M 90,240 19,880 136,500 (4) 30 326,700 (4) 5 3,200 2,656 1,960 (4) 12" 128,060 18' 6-1/4" 24' 2" 10' 4-1/8" 47-3/4"578-6N 91,240 20,130 137,500 (4) 40 354,100 (4) 5 3,200 2,656 1,960 (4) 12" 129,060 18' 6-1/4" 24' 2" 10' 4-1/8" 47-3/4"672-3L 67,460 13,810 109,240 (4) 25 380,190 (4) 5 3,600 1,584 2,280 (4) 12" 99,380 16' 4-3/4" 28' 2" 8' 2-5/8" 22-1/4"672-3M 67,740 13,880 109,520 (4) 30 400,100 (4) 5 3,600 1,584 2,280 (4) 12" 99,660 16' 4-3/4" 28' 2" 8' 2-5/8" 22-1/4"672-4L 79,060 16,710 125,040 (4) 25 369,110 (4) 5 3,600 2,088 2,280 (4) 12" 115,180 17' 1-1/4" 28' 2" 8' 11-1/8" 30-3/4"672-4M 79,340 16,780 125,320 (4) 30 388,440 (4) 5 3,600 2,088 2,280 (4) 12" 115,460 17' 1-1/4" 28' 2" 8' 11-1/8" 30-3/4"672-5M 90,180 19,490 140,360 (4) 30 376,790 (4) 5 3,600 2,592 2,280 (4) 12" 130,500 17' 9-3/4" 28' 2" 9' 7-5/8" 39-1/4"672-5N 91,220 19,750 141,400 (4) 40 408,400 (4) 5 3,600 2,592 2,280 (4) 12" 131,540 17' 9-3/4" 28' 2" 9' 7-5/8" 39-1/4"672-6M 103,020 22,700 157,400 (4) 30 365,140 (4) 5 3,600 3,096 2,280 (4) 12" 147,540 18' 6-1/4" 28' 2" 10' 4-1/8" 47-3/4"672-6N 104,060 22,960 158,440 (4) 40 395,770 (4) 5 3,600 3,096 2,280 (4) 12" 148,580 18' 6-1/4" 28' 2" 10' 4-1/8" 47-3/4"† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.19

Models<strong>ATW</strong> 866-3L to <strong>ATW</strong> 866-6O<strong>ATW</strong> 960-3M to <strong>ATW</strong> 960-6PEngineering Data & DimensionsNote: The number of coil connections doubles when the flowrate exceeds 3,600 GPM on Models <strong>ATW</strong> 866-3L thru <strong>ATW</strong> 960-6P.<strong>ATW</strong>Weights Fans Spray PumpCoilRemote Sump DimensionsModel Heaviest Volume Gallons* Conn. OperatingNumber Shipping Section† Operating HP CFM HP GPM (Gallons) Required Size Weight H L U A866-3L 84,920 17,210 138,400 (4) 25 465,540 (4) 7.5 4,800 2,024 2,880 (4) 12" 125,700 16' 4-3/4" 36' 2-1/2" 8' 2-5/8" 22-1/4"866-3M 85,360 17,320 138,840 (4) 30 494,700 (4) 7.5 4,800 2,024 2,880 (4) 12" 126,140 16' 4-3/4" 36' 2-1/2" 8' 2-5/8" 22-1/4"866-4L 99,680 20,900 158,560 (4) 25 451,980 (4) 7.5 4,800 2,672 2,880 (4) 12" 145,860 17' 1-1/4" 36' 2-1/2" 8' 11-1/8" 30-3/4"866-4M 100,120 21,010 159,000 (4) 30 480,300 (4) 7.5 4,800 2,672 2,880 (4) 12" 146,300 17' 1-1/4" 36' 2-1/2" 8' 11-1/8" 30-3/4"866-5M 114,480 24,600 178,760 (4) 30 465,890 (4) 7.5 4,800 3,328 2,880 (4) 12" 166,060 17' 9-3/4" 36' 2-1/2" 9' 7-5/8" 39-1/4"866-5N 115,520 24,860 179,800 (4) 40 505,630 (4) 7.5 4,800 3,328 2,880 (4) 12" 167,100 17' 9-3/4" 36' 2-1/2" 9' 7-5/8" 39-1/4"866-6N 131,840 28,940 201,560 (4) 40 489,990 (4) 7.5 4,800 3,976 2,880 (4) 12" 188,860 18' 6-1/4" 36' 2-1/2" 10' 4-1/8" 47-3/4"866-6O 132,080 29,000 201,800 (4) 50 521,580 (4) 7.5 4,800 3,976 2,880 (4) 12" 189,100 18' 6-1/4" 36' 2-1/2" 10' 4-1/8" 47-3/4"960-3M 93,580 19,020 153,320 (4) 30 530,730 (4) 10 5,600 2,248 3,200 (4) 14" 139,200 16' 4-3/4" 40' 2-1/2" 8' 2-5/8" 22-1/4"960-3N 94,620 19,280 154,360 (4) 40 579,250 (4) 10 5,600 2,248 3,200 (4) 14" 140,240 16' 4-3/4" 40' 2-1/2" 8' 2-5/8" 22-1/4"960-4M 109,900 23,100 175,680 (4) 30 515,270 (4) 10 5,600 2,968 3,200 (4) 14" 161,560 17' 1-1/4" 40' 2-1/2" 8' 11-1/8" 30-3/4"960-4N 110,940 23,360 176,720 (4) 40 562,380 (4) 10 5,600 2,968 3,200 (4) 14" 162,600 17' 1-1/4" 40' 2-1/2" 8' 11-1/8" 30-3/4"960-5N 126,860 27,340 198,680 (4) 40 545,510 (4) 10 5,600 3,688 3,200 (4) 14" 184,560 17' 9-3/4" 40' 2-1/2" 9' 7-5/8" 39-1/4"960-5O 127,100 27,400 198,920 (4) 50 580,680 (4) 10 5,600 3,688 3,200 (4) 14" 184,800 17' 9-3/4" 40' 2-1/2" 9' 7-5/8" 39-1/4"960-6O 144,940 31,860 222,800 (4) 50 562,720 (4) 10 5,600 4,416 3,200 (4) 14" 208,680 18' 6-1/4" 40' 2-1/2" 10' 4-1/8" 47-3/4"960-6P 145,380 31,970 223,240 (4) 60 592,190 (4) 10 5,600 4,416 3,200 (4) 14" 209,120 18' 6-1/4" 40' 2-1/2" 10' 4-1/8" 47-3/4"20† Heaviest section is the coil/fan section.* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pumpsuction and strainer during operation (12” would normally be sufficient).▲ Unit dimensions may vary slightly from <strong>catalog</strong>. See factory certified prints for exact dimensions.

Recommended Steel SupportThe recommended support for EVAPCO Closed CircuitCoolers is structural “I”beams located under the outerflanges and running the entire length of the unit. Theunit should be elevated to allow access underneath theunit and to the roof below. Mounting holes, 3/4” indiameter are located in the bottom flanges of the pansection to provide for bolting to the structural steel.(Refer to certified drawings from the factory for bolthole locations.)Beams should be level before setting the unit in place.Do not level the unit by shimming between the unit andthe structural steel. Dimensions, weights, and data aresubject to change without notice. Refer to the factorycertified drawings for exact dimensions.Plan ViewsA<strong>ATW</strong> SUPPORTING STEEL DIMENSIONS4' Wide Models A B<strong>ATW</strong> 24 5’ 11-7/8”4’ 1/4”<strong>ATW</strong> 36 8’ 11-1/2”4’ 1/4”<strong>ATW</strong> 48 11’ 11-3/4”4’ 1/4”8-1/2' Wide Models A B<strong>ATW</strong> 64 8’ 5-1/2”7’ 5-7/8”<strong>ATW</strong> 77 8’ 11-1/2”8’ 5-1/2”<strong>ATW</strong> 89 10’ 5-1/2”8’ 5-1/2”<strong>ATW</strong> 102 11’ 11-3/4”8’ 5-1/2”<strong>ATW</strong> 119 13’ 11-3/4”8’ 5-1/2”<strong>ATW</strong> 153 18’ 0”8’ 5-1/2”<strong>ATW</strong> 179 21’ 0”8’ 5-1/2”4' to 12' WIDE MODELS12' Wide Models A B<strong>ATW</strong> 144 11’ 11-3/4”11’ 10”A17' and 24' WIDE MODELS<strong>ATW</strong> 168 13’ 11-3/4”11’ 10”<strong>ATW</strong> 216 18’ 0”11’ 10”<strong>ATW</strong> 240 20’ 0”11’ 10”<strong>ATW</strong> 286 24’ 2”11’ 10”<strong>ATW</strong> 334 28’ 2”11’ 10”<strong>ATW</strong> 430 36’ 2-1/2”11’ 10”<strong>ATW</strong> 478 40’ 2-1/2”11’ 10”17' Wide Models A BEnd ElevationsB4' to 12' WIDEMODELS<strong>ATW</strong> 204 11’ 11-3/4”17’ 1-1/2”<strong>ATW</strong> 238 13’ 11-3/4”17’ 1-1/2”24' Wide Models A B<strong>ATW</strong> 290 11’ 11-3/4”24’ 1-1/8”<strong>ATW</strong> 338 13’ 11-3/4”24’ 1-1/8”<strong>ATW</strong> 434 18’ 0”24’ 1-1/8”<strong>ATW</strong> 482 20’ 0”24’ 1-1/8”B<strong>ATW</strong> 578 24’ 2”24’ 1-1/8”<strong>ATW</strong> 672 28’ 2”24’ 1-1/8”<strong>ATW</strong> 866 36’ 2-1/2”24’ 1-1/8”<strong>ATW</strong> 960 40’ 2-1/2”24’ 1-1/8”17' and 24' WIDE MODELS21

SpecificationsFurnish and install as shown on the plans an EVAPCO Model_________ induced draft counterflow closed circuit cooler.Each unit shall have the capacity to cool _________ GPM of_______ from ______ °F to ______ °F with a _____ °F enteringwet bulb temperature.Basin and CasingThe basin and casing shall be constructed of G-235 hot-dipgalvanized steel for long life and durability. Standard basinaccessories shall include overflow, drain, type 304 stainlesssteel strainers, and brass make-up valve with plastic float.Direct Drive Models 4’ WideFan Motor_________ horsepower totally enclosed fan cooled fanmotor(s), with 1.25 service factor shall be furnished suitable foroutdoor service on ________ volts, _________ hertz, and_________ phase.DriveThe fan shall be mounted on the motor in a direct driveconfiguration.Belt Drive Models 8-1/2’ & 17’ WideFan Motor_________ horsepower totally enclosed fan cooled motorswith 1.15 service factor shall be furnished suitable for outdoorservice on _________ volts, _________ hertz, and _________phase. Motor(s) shall be mounted on an adjustable basewhich is accessible from the outside of the unit for service. Aswing away protective cover shall shield the motor andsheave from the weather.DriveThe fan drive shall be multigroove, solid back V-belt typewith taper lock sheaves designed for 150% of the motornameplate horsepower. The belt material shall be neoprenereinforced with polyester cord and specifically designed forevaporative cooler service. Fan sheave shall be aluminumalloy construction. The fans and the fan sheaves shall bemounted on the shaft with a specially coated bushing toprovide maximum corrosion protection. Belt adjustmentshall be accomplished from the exterior of the unit. Bearinglube lines shall be extended to the exterior of the unit foreasy maintenance.Belt Drive Models 12’ & 24’ WideFan Motor_________ horsepower totally enclosed air over ball bearingfan motor(s), with 1.15 service factor shall be furnishedsuitable for service on _________ volts, _________ hertz, and_________ phase. Motor(s) shall be mounted on an adjustablebase which allows the motor to swing to the outside of theunit for servicing.DriveThe fan drive shall be a multigroove, solid back V-belt typewith taper lock sheaves designed for 150% of the motornameplate horsepower. The belt material shall be neoprenereinforced with polyester cord and specifically designed forevaporative cooler service. Fan and motor sheaves shall bealuminum alloy construction. The fans and fan sheaves shallbe mounted on the shaft with a specially coated bushing toprovide maximum corrosion protection. Belt adjustmentshall be accomplished from the exterior of the unit. Bearinglube lines shall be extended to the exterior of the unit foreasy maintenance.Axial Propeller FansFans shall be heavy duty axial propeller type staticallybalanced. The fans shall be constructed of aluminum alloyblades, installed in a closely fitted cowl with venturi air inlet.Fan screens shall be galvanized steel mesh and frame, boltedto the fan cowl.Fan Shaft BearingsFan shaft bearings shall be heavy duty self-aligning ball typewith grease fittings extended to the outside of the unit.Materials shall be stainless steel balls with chrome steel racesand zinc plated housing for corrosion resistance. Bearingsshall be designed for a minimum L-10 life of 75,000 hours.Water Recirculation PumpThe pump(s) shall be a close-coupled, centrifugal type withmechanical seal, installed vertically at the factory to allow freedrainage on shut down. _________ horsepower totallyenclosed motor(s) shall be furnished suitable for outdoorservice on _________ volts, _________ hertz, and _________phase.Heat Transfer CoilCooling coil(s) shall be all prime surface steel, encased in asteel framework and hot-dip galvanized after fabrication as acomplete assembly. The tubes shall be arranged in a selfspacing,staggered pattern in the direction of airflow formaximum heat transfer efficiency and minimum pressuredrop, without the use of additional spacers between the coiltubes. The coil(s) shall be pneumatically tested at 400 psig,under water.Water Distribution SystemThe system shall provide a water flow rate of not less than 6GPM over each square foot of unit plan area to ensure properflooding of the coil. The spray header shall be constructed ofschedule 40 polyvinyl chloride pipe for corrosion resistance. Allspray branches shall be removable for cleaning. The watershall be distributed over the entire coil surface by precisionmolded ABS spray nozzles (1-1/4” x 5/16” orifice) with internalsludge ring to eliminate clogging. Nozzles shall be threadedinto spray header to provide easy removal for maintenance.EliminatorsThe eliminators shall be constructed entirely of inert polyvinylchloride (PVC) in easily handled sections. The eliminatordesign shall incorporate three changes in air direction toassure complete removal of all entrained moisture from thedischarge air stream. Maximum drift rate shall be less than0.001% of the circulating water rate.LouversThe louvers shall be constructed from polyvinyl chloride(PVC). The louvers shall be mounted in easily removableframes for access to the pan for maintenance. The louversshall have a minimum of two changes in air direction toprevent splashout and block direct sunlight.FinishAll basin and casing materials shall be constructed of G-235heavy gauge mill hot-dip galvanized steel. Duringfabrication, all panel edges shall be coated with a 95% purezinc-rich compound for superior protection againstcorrosion.24

ApplicationsDesignEVAPCO units are of heavy-duty construction and designedfor long trouble-free operation. Proper equipment selection,installation and maintenance is, however, necessary toensure full unit performance. Some of the majorconsiderations in the application of a cooler are presentedbelow. For additional information, contact the factory.Air CirculationIt is important that proper air circulation be provided. Thebest location is on an unobstructed roof top or on groundlevel away from walls and other barriers. Those closed circuitcoolers located in wells, enclosures or adjacent to high wallsmust be properly located to avoid the problems associatedwith recirculation.Recirculation raises the wet bulb temperature of the enteringair causing the water temperature to rise above the design.For these cases, the discharge of the fan should be located ata height even with the adjacent wall, thereby reducing thechance of recirculation. For additional information, see theEVAPCO Equipment Layout Manual.Good engineering practice dictates that the closed circuitcooler discharge air not be directed or located close to or inthe vicinity of building air intakes.PipingCooler piping should be designed and installed in accordancewith generally accepted engineering practices. The pipinglayout should be symmetrical on multiple unit systems, andsized for a reasonably low water velocity and pressure drop.The standard closed circuit cooler is recommended only on aclosed, pressurized system. The piping system should includean expansion tank to allow for fluid expansion and purgingair from the system.Note: Closed Circuit Coolers should never be used on anopen type system. An open type system with a cooler mayresult in premature coil failure.The piping system should be designed to permit completedrainage of the heat exchanger coil. This will require avacuum breaker or air vent to be installed at the high pointand a drain valve installed at the low point of the pipingsystem. Both must be adequately sized.All piping should be securely anchored by properly designedhangers and supports. No external loads should be placedupon the cooler connections, nor should any of the pipesupports be anchored to the cooler framework.Recirculating Water SystemThe surest way to protect the recirculating water system fromfreezing is with a remote sump. The remote sump should belocated inside the building and below the unit. When aremote sump arrangement is selected, the spray pump isprovided by others and installed at the remote sump. Allwater in the closed circuit cooler basin should drain to theremote sump when the spray pump cycles off. Refer to page23 for concept illustration.Other freeze protection methods are available when a remotesump is not feasible. Electric pan heaters, steam or hot watercoils can be used to keep the pan water from freezing whenthe unit cycles off. Water lines to and from the unit, spraypump and related piping should be heat traced and insulatedup to the overflow level in order to protect from freezing.The unit should not be operated dry (fans on, pump off) unlessthe basin is completely drained and the unit has beendesigned for dry operation. Consult the factory when dryoperation is a requirement.Freeze ProtectionIf the units are installed in a cold climate and operated yearround,freeze protection must be provided for the heatexchanger coil in the unit as well as for the recirculatingwater system.Heat Exchanger CoilThe simplest and most foolproof method of protecting theheat exchanger coil from freeze-up is to use a glycol solution.If this is not possible, an auxiliary heat load must bemaintained on the coil at all times so that the watertemperature does not drop below 50°F when the cooler isshut down. Also, a minimum recommended flow rate mustbe maintained. Refer to Heat Loss Data Table on page 27 forheat loss data.Minimum Flows4' Wide Models GPM<strong>ATW</strong> 24, 36, 48 708-1/2' Wide Models<strong>ATW</strong> 64, 77, 89, 102,175119, 153, 17912' Wide Models<strong>ATW</strong> 144, 168, 216, 240,286, 334, 430, 47840017' Wide Models<strong>ATW</strong> 204, 238 35024' Wide Models<strong>ATW</strong> 290, 338, 434, 482 400<strong>ATW</strong> 578, 672, 866, 960 800Water TreatmentIn some cases the make-up water will be so high in mineralcontent that a normal bleed-off will not prevent scaling. Inthis case, water treatment will be required and a reputablewater treatment company familiar with the local waterconditions should be consulted.Any chemical water treatment used must be compatible withthe galvanized construction of the unit. If acid is used fortreatment, it should be accurately metered and theconcentration properly controlled. The pH of the water shouldbe maintained between 6.5 and 8.0. Batch chemical feeding isnot recommended because it does not afford the properdegree of control. If acid cleaning is required, extreme cautionmust be exercised and only inhibited acids recommended foruse with galvanized construction should be used.Control of Biological ContaminationWater quality should be checked regularly for biologicalcontamination. If biological contamination is detected, amore aggressive water treatment and mechanical cleaningprogram should be undertaken. The water treatmentprogram should be performed in conjunction with a qualifiedwater treatment company. It is important that all internalsurfaces be kept clean of accumulated dirt and sludge. Inaddition, the drift eliminators should be maintained in goodoperating condition.Units constructed of galvanized steel operating withcirculating water having a pH of 8.3 or higher will requireperiodic passivation of the galvanized steel to prevent theformation of “white rust”.25

Discharge Hoods with PositiveClosure DampersWhen a closed circuit cooler is used in a water-to-air heatpump system or in certain process cooling applications, amethod of reducing the heat loss during idle periods ofwintertime operation may be required. For these cases, anoptional discharge hood with positive closure dampers anddamper actuator is available.The discharge hood with dampers is designed to minimizethe heat loss from convective airflow through an idle cooler.Further reductions in heat loss may be obtained with theaddition of insulation to the hood and casing, minimizingconductive heat losses. Insulation may be factory installedon the hood and casing or field installed by an insulationcontractor.The discharge hood and dampers are constructed of hot-dipgalvanized steel. Hoods are equipped with access panels tofacilitate maintenance of the eliminators and waterdistribution system. The dampers, damper actuator andlinkage are all factory assembled. Actuator controls andwiring are field supplied by others. Damper actuatorsrequire 120 volt power supply.The system control sequence should provide for dampers tobe fully open before the fans are running and closed whenthe fans are off; the damper actuator must be interlockedwith the temperature control system for this purpose.Heat loss data is provided for standard units without hoods,with hoods and with hoods and insulation. Table ratings arebased on 50°F water in the coil, -10°F ambient and 45 MPHwinds (fan and pump off). Refer to page 27.Discharge Hood DimensionsNumberModel L H* W Weight of Hoods<strong>ATW</strong> 24 5’ 11-7/8”1’ 6” 4’ 1/4” 400 1<strong>ATW</strong> 36 8’ 11-1/2”1’ 6” 4’ 1/4” 560 1<strong>ATW</strong> 48 11’ 11-3/4”1’ 6” 4’ 1/4” 710 1<strong>ATW</strong> 64 7’ 5-7/8”1’ 4”8’ 5-1/2”830 1<strong>ATW</strong> 77 8’ 11-1/2”1’ 4”8’ 5-1/2”1,000 1<strong>ATW</strong> 89 8’ 11-1/2”1’ 4”8’ 5-1/2”1,000 1<strong>ATW</strong> 102 8’ 11-1/2”1’ 4”8’ 5-1/2”1,000 1<strong>ATW</strong> 119 8’ 11-1/2”1’ 4”8’ 5-1/2”1,000 1<strong>ATW</strong> 153 8’ 11-1/2”1’ 4”8’ 5-1/2”2,000 2<strong>ATW</strong> 179 8’ 11-1/2”1’ 4”8’ 5-1/2”2,000 2<strong>ATW</strong> 204 8’ 11-1/2”1’ 4”8’ 5-1/2”2,000 2<strong>ATW</strong> 238 8’ 11-1/2”1’ 4”8’ 5-1/2”2,000 2<strong>ATW</strong> 144 11’ 11-3/4”1’ 2” 11’ 10” 1,700 1<strong>ATW</strong> 168 11’ 11-3/4”1’ 2” 11’ 10” 1,700 1<strong>ATW</strong> 216 11’ 11-3/4”1’ 2” 11’ 10” 1,700 1<strong>ATW</strong> 240 11’ 11-3/4”1’ 2” 11’ 10” 1,700 1<strong>ATW</strong> 286 11’ 11-3/4”1’ 2” 11’ 10” 3,400 2<strong>ATW</strong> 290 11’ 11-3/4”1’ 2” 11’ 10” 3,400 2<strong>ATW</strong> 334 11’ 11-3/4”1’ 2” 11’ 10” 3,400 2<strong>ATW</strong> 338 11’ 11-3/4”1’ 2” 11’ 10” 3,400 2<strong>ATW</strong> 430 11’ 11-3/4”1’ 2” 11’ 10” 3,400 2<strong>ATW</strong> 434 11’ 11-3/4”1’ 2” 11’ 10” 3,400 2<strong>ATW</strong> 478 11’ 11-3/4”1’ 2” 11’ 10” 3,400 2<strong>ATW</strong> 482 11’ 11-3/4”1’ 2” 11’ 10” 3,400 2<strong>ATW</strong> 578 11’ 11-3/4”1’ 2” 11’ 10” 6,800 4<strong>ATW</strong> 672 11’ 11-3/4”1’ 2” 11’ 10” 6,800 4<strong>ATW</strong> 866 11’ 11-3/4”1’ 2” 11’ 10” 6,800 4<strong>ATW</strong> 960 11’ 11-3/4”1’ 2” 11’ 10” 6,800 4* Overall unit height will be height of the base unit plus the Hdimension.LWH26

Heat Loss Data, MBHStandard With Hood andModel Unit Hood Insulation<strong>ATW</strong> 24-3 67 57 36<strong>ATW</strong> 24-4 81 61 39<strong>ATW</strong> 24-5 91 65 42<strong>ATW</strong> 36-3 102 72 46<strong>ATW</strong> 36-4 123 77 50<strong>ATW</strong> 36-5 138 83 53<strong>ATW</strong> 48-3 137 94 60<strong>ATW</strong> 48-4 165 101 65<strong>ATW</strong> 48-5 186 108 69<strong>ATW</strong> 64-3 192 109 70<strong>ATW</strong> 64-4 232 116 74<strong>ATW</strong> 64-5 261 123 79<strong>ATW</strong> 64-6 279 129 83<strong>ATW</strong> 77-3 224 122 78<strong>ATW</strong> 77-4 270 129 83<strong>ATW</strong> 77-5 304 137 88<strong>ATW</strong> 77-6 324 144 92<strong>ATW</strong> 89-3 262 132 85<strong>ATW</strong> 89-4 316 140 90<strong>ATW</strong> 89-5 356 148 95<strong>ATW</strong> 89-6 380 156 100<strong>ATW</strong> 102-3 300 142 91<strong>ATW</strong> 102-4 363 151 97<strong>ATW</strong> 102-5 408 160 102<strong>ATW</strong> 102-6 435 168 108<strong>ATW</strong> 119-3 352 156 100<strong>ATW</strong> 119-4 425 165 106<strong>ATW</strong> 119-5 478 175 112<strong>ATW</strong> 119-6 509 184 118<strong>ATW</strong> 153-3 454 200 128<strong>ATW</strong> 153-4 548 211 135<strong>ATW</strong> 153-5 617 222 142<strong>ATW</strong> 153-6 658 234 150<strong>ATW</strong> 179-3 530 220 141<strong>ATW</strong> 179-4 641 233 149<strong>ATW</strong> 179-5 724 245 157<strong>ATW</strong> 179-6 769 258 165<strong>ATW</strong> 204-3 600 284 182<strong>ATW</strong> 204-4 726 302 194<strong>ATW</strong> 204-5 816 320 194<strong>ATW</strong> 204-6 870 336 216<strong>ATW</strong> 238-3 704 312 200<strong>ATW</strong> 238-4 850 330 212<strong>ATW</strong> 238-5 956 350 224<strong>ATW</strong> 238-6 1018 368 236<strong>ATW</strong> 144-3 427 199 127<strong>ATW</strong> 144-4 516 210 135<strong>ATW</strong> 144-5 580 221 142<strong>ATW</strong> 144-6 619 233 149Standard With Hood andModel Unit Hood Insulation<strong>ATW</strong> 168-3 500 216 138<strong>ATW</strong> 168-4 604 228 146<strong>ATW</strong> 168-5 679 241 154<strong>ATW</strong> 168-6 725 253 162<strong>ATW</strong> 216-3 645 251 161<strong>ATW</strong> 216-4 779 265 170<strong>ATW</strong> 216-5 877 279 179<strong>ATW</strong> 216-6 935 294 188<strong>ATW</strong> 240-3 718 268 172<strong>ATW</strong> 240-4 867 283 182<strong>ATW</strong> 240-5 976 299 191<strong>ATW</strong> 240-6 1,041 314 201<strong>ATW</strong> 286-3 & 290-3 854 398 254<strong>ATW</strong> 286-4 & 290-4 1,032 420 270<strong>ATW</strong> 286-5 & 290-5 1,160 442 284<strong>ATW</strong> 286-6 & 290-6 1,238 466 298<strong>ATW</strong> 334-3 & 338-3 1,000 432 276<strong>ATW</strong> 334-4 & 338-4 1,208 456 292<strong>ATW</strong> 334-5 & 338-5 1,358 482 308<strong>ATW</strong> 334-6 & 338-6 1,450 506 324<strong>ATW</strong> 430-3 & 434-3 1,290 502 322<strong>ATW</strong> 430-4 & 434-4 1,558 530 340<strong>ATW</strong> 430-5 & 434-5 1,754 558 358<strong>ATW</strong> 430-6 & 434-6 1,870 588 376<strong>ATW</strong> 478-3 & 482-3 1,436 536 344<strong>ATW</strong> 478-4 & 482-4 1,734 566 364<strong>ATW</strong> 478-5 & 482-5 1,952 598 382<strong>ATW</strong> 478-6 & 482-6 2,082 628 402<strong>ATW</strong> 578-3 1,708 796 508<strong>ATW</strong> 578-4 2,064 840 540<strong>ATW</strong> 578-5 2,320 884 568<strong>ATW</strong> 578-6 2,476 932 596<strong>ATW</strong> 672-3 2,000 864 552<strong>ATW</strong> 672-4 2,416 912 584<strong>ATW</strong> 672-5 2,716 964 616<strong>ATW</strong> 672-6 2,900 1,012 648<strong>ATW</strong> 866-3 2,580 1,004 644<strong>ATW</strong> 866-4 3,116 1,060 680<strong>ATW</strong> 866-5 3,508 1,116 716<strong>ATW</strong> 866-6 3,740 1,176 752<strong>ATW</strong> 960-3 2,872 1,072 688<strong>ATW</strong> 960-4 3,468 1,132 728<strong>ATW</strong> 960-5 3,904 1,196 764<strong>ATW</strong> 960-6 4,164 1,256 80427