SRS Product Brochure - Evapco

SRS Product Brochure - Evapco

SRS Product Brochure - Evapco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DESCRIPTION OF OPERATION<br />

Liquid refrigerant is fed into the recirculator to maintain a<br />

controlled liquid level. The liquid is mechanically pumped<br />

to the evaporators at a rate exceeding the evaporation rate.<br />

The liquid and vapor leaving the evaporators return to the<br />

recirculator where they are separated. The liquid is<br />

recirculated through the pump to the evaporators and the<br />

dry suction gas passes to the compressors.<br />

SYSTEM ADVANTAGES OF THE <strong>SRS</strong> RECIRCULATOR<br />

• Excess feed rate optimizes evaporator performance by<br />

completely wetting the internal tube surface and<br />

maximizing heat transfer coefficients.<br />

• Recirculator vessel protects compressor(s) from liquid<br />

carryover and allows for hot gas defrosting into wet<br />

suction lines.<br />

• Excess feed rate and hot gas defrosting help to wash oil<br />

from evaporators. Oil flows with the refrigerant to the<br />

recirculator where it can be drained from one centralized<br />

location.<br />

• Pumps provide uniform flow of refrigerant to the plant<br />

regardless of condensing pressure.<br />

• Factory packaging reduces installation costs.<br />

• Vertical recirculator saves floor space in the equipment<br />

room.<br />

SELECTION PROCEDURE<br />

From TABLE 1, select a model with a capacity equal to or<br />

greater than the required capacity at the given saturated<br />

suction temperature.<br />

In TABLE 2, check available surge volume for model<br />

selected against required system surge volume. If<br />

available surge volume is inadequate, select next larger<br />

model with sufficient surge volume (or contact factory).<br />

Determine required pump capacity from TABLE 3.<br />

Select pump with sufficient capacity and head from<br />

TABLE 4.<br />

WHEN ORDERING PLEASE SPECIFY:<br />

Recirculator model number and pump. Please include<br />

required capacity in tons of refrigeration, saturated suction<br />

temperature, recirculation rate, surge volume, liquid feed<br />

temperature, and voltage/frequency. Also, please indicate<br />

right hand or left hand pumped liquid connection.<br />

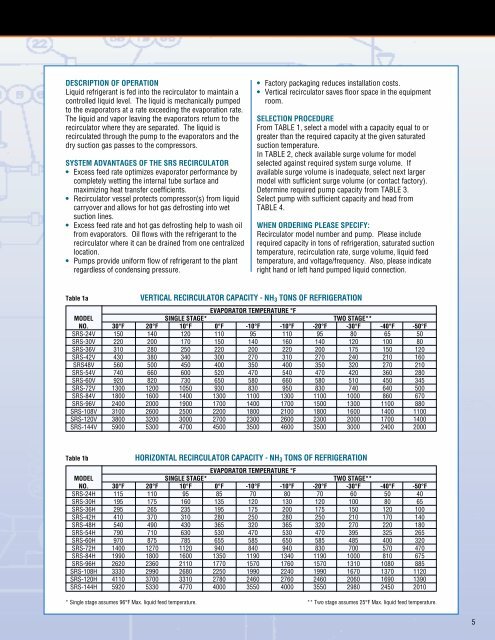

Table 1a<br />

VERTICAL RECIRCULATOR CAPACITY - NH 3 TONS OF REFRIGERATION<br />

EVAPORATOR TEMPERATURE °F<br />

MODEL SINGLE STAGE* TWO STAGE**<br />

NO. 30°F 20°F 10°F 0°F -10°F -10°F -20°F -30°F -40°F -50°F<br />

<strong>SRS</strong>-24V 150 140 120 110 95 110 95 80 65 50<br />

<strong>SRS</strong>-30V 220 200 170 150 140 160 140 120 100 80<br />

<strong>SRS</strong>-36V 310 280 250 220 200 220 200 175 150 120<br />

<strong>SRS</strong>-42V 430 380 340 300 270 310 270 240 210 160<br />

<strong>SRS</strong>48V 560 500 450 400 350 400 350 320 270 210<br />

<strong>SRS</strong>-54V 740 660 600 520 470 540 470 420 360 280<br />

<strong>SRS</strong>-60V 920 820 730 650 580 660 580 510 450 345<br />

<strong>SRS</strong>-72V 1300 1200 1050 930 830 950 830 740 640 500<br />

<strong>SRS</strong>-84V 1800 1600 1400 1300 1100 1300 1100 1000 860 670<br />

<strong>SRS</strong>-96V 2400 2000 1900 1700 1400 1700 1500 1300 1100 880<br />

<strong>SRS</strong>-108V 3100 2600 2500 2200 1800 2100 1800 1600 1400 1100<br />

<strong>SRS</strong>-120V 3800 3200 3000 2700 2300 2600 2300 2000 1700 1400<br />

<strong>SRS</strong>-144V 5900 5300 4700 4500 3500 4600 3500 3000 2400 2000<br />

Table 1b<br />

HORIZONTAL RECIRCULATOR CAPACITY - NH 3 TONS OF REFRIGERATION<br />

EVAPORATOR TEMPERATURE °F<br />

MODEL SINGLE STAGE* TWO STAGE**<br />

NO. 30°F 20°F 10°F 0°F -10°F -10°F -20°F -30°F -40°F -50°F<br />

<strong>SRS</strong>-24H 115 110 95 85 70 80 70 60 50 40<br />

<strong>SRS</strong>-30H 195 175 160 135 120 130 120 100 80 65<br />

<strong>SRS</strong>-36H 295 265 235 195 175 200 175 150 120 100<br />

<strong>SRS</strong>-42H 410 370 310 280 250 280 250 210 170 140<br />

<strong>SRS</strong>-48H 540 490 430 365 320 365 320 270 220 180<br />

<strong>SRS</strong>-54H 790 710 630 530 470 530 470 395 325 265<br />

<strong>SRS</strong>-60H 970 875 785 655 585 650 585 485 400 320<br />

<strong>SRS</strong>-72H 1400 1270 1120 940 840 940 830 700 570 470<br />

<strong>SRS</strong>-84H 1990 1800 1600 1350 1190 1340 1190 1000 810 675<br />

<strong>SRS</strong>-96H 2620 2360 2110 1770 1570 1760 1570 1310 1080 885<br />

<strong>SRS</strong>-108H 3330 2990 2680 2250 1990 2240 1990 1670 1370 1120<br />

<strong>SRS</strong>-120H 4110 3700 3310 2780 2460 2760 2460 2060 1690 1390<br />

<strong>SRS</strong>-144H 5920 5330 4770 4000 3550 4000 3550 2980 2450 2010<br />

* Single stage assumes 96°F Max. liquid feed temperature. ** Two stage assumes 25°F Max. liquid feed temperature.<br />

5