Polymers - INEOS Chlor

Polymers - INEOS Chlor

Polymers - INEOS Chlor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FactFile<br />

English

Since its creation in 1986, EVC has been committed to polyvinyl<br />

chloride. As a responsible member of the industry, we have a strong<br />

interest in ensuring that people everywhere benefit from the safe use<br />

of PVC products.<br />

As a result, we are engaged in a constant quest for improvements,<br />

including more efficient processing techniques, more cost-effective<br />

manufacturing, safer working conditions, and products that more<br />

accurately meet customer needs.<br />

Our objective is to build an organisation that is profitable and sus-<br />

tainable, working for the ultimate long-term benefit of our busi-<br />

ness, our employees and our world.<br />

Calum MacLean<br />

CEO<br />

EVC International N.V.

EVC MANUFACTURING AROUND THE GLOBE

Profile<br />

EVC - European Vinyls Corporation - is the leading European polyvinyl chloride (PVC) manufacturer,<br />

number five in the world, and the largest producer of credit card plastic in Europe.<br />

EVC’s manufacturing and marketing activity is vertically integrated through most of the PVC chain and<br />

includes ethylene dichloride (EDC), vinyl chloride monomer (VCM), VCM catalysts, additives for<br />

PVC polymerisation, and PVC resins, compounds and films.<br />

The EVC Group employs around 3,000 people with production sites in Germany, India, Italy,<br />

Switzerland and the United Kingdom. Production capacity stands at 1.4 million tonnes per annum of<br />

PVC resins and 1.1 million tonnes per annum of VCM.<br />

Key raw materials, ethylene and chlorine, are obtained externally through long-term supply agreements.<br />

EVC’s integration downstream into compounds and films provides an outlet for a significant portion of<br />

its production of PVC resins. External sales of EVC’s products are global in nature with a concentration<br />

in the areas where the EVC Group’s operations are located.<br />

All PVC resins from EVC are marketed under the name EVIPOL.<br />

EVICOM is the brand name of the PVC compounds products.<br />

EVICAS is the trademark of Inovyl’s build-up supressants.<br />

A range of PVC additives is marketed under the brand name INOVOL.<br />

Key Tradenames<br />

1

2<br />

Snapshot<br />

• Business Manufacturer of EDC, VCM and PVC resins, compounds and films<br />

• Turnover 1.1 billion<br />

• Personnel 3,000<br />

• Shares Majority shareholding <strong>INEOS</strong><br />

• Volume 1.1 million tonnes VCM, 1.4 million tonnes PVC<br />

• Tradenames EVIPOL, EVICOM, EVICAS, INOVOL<br />

History<br />

• 1986 EVC formed through a 50/50 joint venture between ICI and EniChem<br />

• 1988 Acquisition of VKW rigid film operations from ICI and of the PVC compounding<br />

assets in the UK, Italy and Switzerland<br />

• 1989 Acquisition of the vinyls technology and licensing business of the Stauffer<br />

Chemical Company of America<br />

• 1990 Acquisition of Mazzucchelli Vinyls and Savinil<br />

Transfer of production assets from ICI and EniChem<br />

• 1994 EVC floated on the Amsterdam Stock Exchange<br />

• 1996 Acquisition of the VCM plant in Runcorn, UK from ICI, to be rejuvenated and<br />

expanded<br />

• 1997 Acquisition of the packaging film plant at Weißandt-Gölzau, Germany, and of a<br />

majority shareholding in the Indian PVC film producer, Caprihans<br />

• 1998 Acquisition of BSL’s PVC assets at Schkopau, Germany<br />

• 2001 <strong>INEOS</strong> acquires a majority shareholding in EVC<br />

EVC International N.V.

EVC consists of three product groups: <strong>Polymers</strong>, PVC Compounds and PVC Films.<br />

<strong>Polymers</strong> PVC Compounds PVC Films<br />

• EDC / VCM<br />

• Suspension PVC<br />

Homopolymers, Copolymers<br />

• Emulsion PVC<br />

Microsuspension, Emulsion,<br />

Seeded Emulsion,<br />

Mini-Emulsion,<br />

Continuous Emulsion<br />

• Catalysts and Additives<br />

Europe<br />

Asia<br />

• Rigid<br />

Powder (Extrusion)<br />

• Granules<br />

Blow Moulding, Extrusion,<br />

Moulding<br />

• Flexible<br />

Extrusion, Moulding<br />

Organisation<br />

• Pharmaceutical and Medical<br />

Packaging<br />

• Non-Pharmaceutical<br />

Packaging<br />

Food and Non-Food<br />

• Cards<br />

• Specialties<br />

Manufacturing Sites<br />

<strong>Polymers</strong> PVC Compounds PVC Films<br />

EDC / VCM<br />

• Porto Marghera (Italy)<br />

• Porto Torres (Italy)<br />

• Ravenna (Italy)<br />

• Wilhelmshaven (Germany)<br />

• Runcorn (UK)<br />

S-PVC<br />

• Porto Marghera (Italy)<br />

• Ravenna (Italy)<br />

• Wilhelmshaven (Germany)<br />

• Schkopau (Germany)<br />

• Runcorn (UK)<br />

• Barry (UK)<br />

E-PVC<br />

• Porto Torres (Italy)<br />

• Schkopau (Germany)<br />

• Hillhouse (UK)<br />

• Argenta (Italy)<br />

• Frosinone (Italy)<br />

• Pavia (Italy)<br />

• Porto Marghera (Italy)<br />

• Helsby (UK)<br />

• Sins (Switzerland)<br />

• Weißandt-Gölzau<br />

(Germany)<br />

• Castiglione Olona (Italy)<br />

• Cagliari (Italy)<br />

• Bötzingen (Germany)<br />

• Staufen (Germany)<br />

• Weißandt-Gölzau<br />

(Germany)<br />

• Nasik (India)<br />

• Thane (India)<br />

3

4<br />

PVC Processes and Applications<br />

EVC International N.V.<br />

Oil<br />

Natural Gas<br />

Salt<br />

Processes<br />

Ethylene<br />

<strong>Chlor</strong>ine<br />

EDC VCM<br />

PVC<br />

+ Additives<br />

+ Stabilisers<br />

+ Additives<br />

+ Stabilisers

PVC Compounds<br />

PVC Films<br />

Applications<br />

Pipes / Tubes<br />

Window frames<br />

Wire and cable sheathing<br />

Flooring and wallcoverings<br />

Automotive parts<br />

Packaging<br />

Bottles and containers<br />

Medical applications<br />

Smart cards, identity cards<br />

Stationery and office equipment<br />

Printing and decoration<br />

Footwear<br />

Computer housing<br />

Coatings<br />

5

6<br />

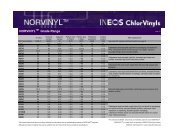

<strong>Polymers</strong><br />

EDC / VCM<br />

Vinyl chloride monomer (VCM) is the major raw material used in the manufacture of PVC. It is produced<br />

from the basic raw materials of ethylene and chlorine.<br />

Ethylene, one of the most important building blocks of the petrochemical industry, is produced by the<br />

thermal cracking of hydrocarbons. <strong>Chlor</strong>ine is produced by the electrolysis of salt (sodium chloride),<br />

and is a co-product of the manufacture of caustic soda. Ethylene and chlorine are reacted together to<br />

form the important process intermediate, ethylene dichloride (EDC).<br />

A complete VCM production plant consists of the following major units:<br />

• A direct chlorination unit in which ethylene and chlorine are combined in a continuous process to<br />

form EDC<br />

• An EDC cracking unit in which EDC is thermally decomposed into VCM and hydrogen chloride<br />

• An oxychlorination unit in which recycled hydrogen chloride is reacted with further ethylene feedstock<br />

in the presence of copper chloride catalyst and oxygen.<br />

EVC’s VCM and PVC resins facilities are located on large integrated sites. VCM is produced principally<br />

for use within EVC with any surplus being sold on the external market. Production capacity of VCM<br />

stands at 1.1 million tonnes per annum.<br />

Ethylene<br />

Oxygen<br />

Ethylene<br />

<strong>Chlor</strong>ine<br />

EVC International N.V.<br />

Oxychlorination<br />

Direct<br />

<strong>Chlor</strong>ination<br />

Hydrogen <strong>Chlor</strong>ide Recycle<br />

EDC Purification<br />

EDC Recycle<br />

Water By Products<br />

EDC Cracking<br />

VCM

S-PVC<br />

PVC resin is formed by the polymerisation of VCM. PVC is made as a number of different product<br />

types, each subdivided into a range of grades to meet the requirements of specific applications. EVC’s<br />

PVC resins products are marketed under the name EVIPOL. Production facilities are located in<br />

Germany, Italy and the United Kingdom.<br />

S-PVC represents almost 90% of the PVC output of EVC, and is the type used for virtually all extrusion,<br />

injection moulding and film making processes. Individual grades produced are characterised by their<br />

melt flow properties and suitability for rigid (unplasticised) or flexible (plasticised) applications.<br />

The PVC process involves the polymerisation of VCM in large scale batch reactors in the presence of<br />

water together with initiators (catalysts) and other additives. In the case of the suspension process, the<br />

suspended droplets of liquid monomer are progressively converted to solid or porous PVC particles<br />

depending on grade. Once the reaction is essentially complete, unreacted VCM is removed and the<br />

polymer is isolated by centrifuging and drying.<br />

VCM<br />

VCM<br />

Water<br />

Additives<br />

Polymerisation Stripping<br />

Centrifuging Drying S-PVC<br />

Water<br />

Water<br />

7

8<br />

This type of polymer is used in the major fabrication areas of extrusion, injection moulding and blow<br />

moulding, and for the manufacture of films and foils. Typical applications include potable and gravity<br />

pipes, window frames, cable insulation, food and pharmaceutical packaging, automotive and domestic<br />

appliance components, medical applications such as tubing and blood bags.<br />

Copolymer grades are also produced, for example with up to 15% vinyl acetate being copolymerised<br />

with vinyl chloride, in a process which is essentially similar to that used for S-PVC. Copolymer grades<br />

have increased toughness compared with S-PVC and are used for high quality film and foil applications.<br />

EVC International N.V.

E-PVC<br />

E-PVC represents approximately 10% of PVC produced by EVC.<br />

It is used in a wide range of speciality applications involving coating,<br />

dipping and spreading operations, for which S-PVC cannot be<br />

used. It is generally converted into a usable form by the addition<br />

of plasticisers to form a ‘plastisol’ or paste.<br />

The polymerisation stage involves an emulsion of very fine<br />

droplets of VCM in water, and the polymerisation process takes<br />

place to form a stable emulsion, or latex, of polymer in water. After<br />

the removal of unreacted monomer, the water is removed by evaporation<br />

in spray drying equipment.<br />

Applications for E-PVC include coated fabrics, conveyor belting,<br />

cushion and wear layers of flooring, and wallcoverings.<br />

EVC’s E-PVC production sites are located in Germany, Italy and the<br />

United Kingdom. Annual capacity of emulsion PVC stands at 160 kt.<br />

VCM<br />

VCM<br />

Water<br />

Additives<br />

Polymerisation<br />

Stripping<br />

Water<br />

Spray Drying<br />

E-PVC<br />

<strong>Polymers</strong><br />

At a Glance...<br />

Annual Capacities<br />

VCM 1.1m tonnes<br />

S-PVC 1.2m tonnes<br />

E-PVC 160 kt<br />

Main End-Uses<br />

Pipes<br />

Window frames<br />

Flooring<br />

Wallcoverings<br />

Wire and cable sheathing<br />

Domestic appliances<br />

Automotive parts<br />

Packaging, food and non-food<br />

Medical applications<br />

Pharmaceutical applications<br />

Stationery and office equipment<br />

Coated fabrics<br />

Footwear<br />

9

10<br />

PVC Compounds<br />

PVC compounds are prepared by blending PVC resin with stabilisers, pigments and other additives to<br />

give the required properties in the fabricated finished product. In the case of compounds for flexible<br />

applications, plasticisers are also included in the formulations.<br />

PVC compounds are produced in two physical forms:<br />

• Granules: PVC resin blended with the appropriate additives is fed to melt processing or extrusion<br />

equipment. The molten composition is then pelletised and cooled, producing PVC compound in<br />

granular form. Almost 90% of EVC’s compound production is of this type.<br />

• Dry Blends: PVC resin is blended with the appropriate additives and is screened and packed as a dry<br />

powder.<br />

Plasticiser PVC Compound<br />

(Dry Blend)<br />

PVC<br />

Pigments<br />

Additives<br />

EVC International N.V.<br />

Blender<br />

Cooler<br />

Melt Processor<br />

Pelletizer<br />

PVC Compound<br />

(Granules)

EVC is active in all sectors of the compounds market and produces<br />

thousands of different formulations of PVC compounds used in a<br />

variety of industries. Its production is split equally between rigid<br />

compounds, mainly used by pipe, rolling-shutter, bottle and window<br />

profile manufacturers, and flexible compounds, mainly used<br />

for cables, profiles, medical and footwear applications.<br />

EVC operates four compounds plants in Italy, one in Germany,<br />

one in Switzerland and one in the United Kingdom.<br />

The PVC compounds products are marketed under the name<br />

EVICOM.<br />

PVC Compounds<br />

At a Glance...<br />

Annual capacity<br />

200 kt<br />

Main End-Uses<br />

Pipes<br />

Rolling-shutters<br />

Bottles and containers<br />

Cables and wires<br />

Electrical plugs and sockets<br />

Tubes and profiles<br />

Computer housing<br />

Footwear<br />

11

12<br />

PVC Films<br />

PVC Films are produced by blending PVC resin with appropriate additives, followed by melt processing<br />

and film formation using calendering equipment. In the calendering process the PVC mixture is initially<br />

melted in the gap between two heated metal cylinders rotating in opposite directions. Further cylinders<br />

control the consistency and thickness of the films, which typically range between 0.06 and 1.2 mm.<br />

Following the calendering process, a sophisticated range of finishing processes can be applied in-house<br />

including coating, laminating and stretching of the films. The finished films are cut to size and either<br />

wound onto reels or kept totally flat, depending on the final application requirements.<br />

The Films business focuses on manufacturing and supplying rigid films to four major application markets:<br />

• Coated and uncoated films for pharmaceutical and medical packaging - such as blister packaging<br />

• Magnetic stripes and smart cards - such as bank cards, identity systems and telecommunication cards<br />

• Films for applications such as printing and decoration, furniture, office supplies and special technical<br />

applications<br />

• Food and non-food packaging films<br />

EVC operates PVC rigid film plants in Germany and Italy and is the largest producer of films for credit<br />

cards in Europe. In addition, EVC holds a majority interest in Caprihans India Limited, the Indian<br />

producer of rigid, flexible and extruded films. This venture reinforces EVC’s commercial presence in the<br />

region and the neighbouring markets of Asia Pacific. It also strengthens our competitive position in<br />

rigid films across the global marketplace.<br />

EVC International N.V.

At a Glance...<br />

Annual capacity<br />

150 kt<br />

PVC Films<br />

Main End-Uses<br />

Pharmaceutical packaging<br />

Medical packaging<br />

Food and non-food packaging<br />

Magnetic stripes<br />

Smart cards<br />

Identity cards<br />

Telecommunication cards<br />

Printing and decoration<br />

Furniture<br />

Bottle capsules and sleeves<br />

Office supplies<br />

Technical applications<br />

13

14<br />

Manufacturing<br />

EVC operates 20 manufacturing facilities in five different countries and is able to offer customers<br />

throughout the world a high standard of service as well as products of consistent quality.<br />

Having <strong>INEOS</strong> as a majority shareholder allows EVC to benchmark all of its manufacturing facilities against<br />

<strong>INEOS</strong> plants worldwide and in doing so, achieve best practice in production and efficiency processes.<br />

Each of the operating units aims to achieve world-class manufacturing and Safety, Health and Environmental<br />

standards, all maintained and audited through our Manufacturing Excellence programme.<br />

Manufacturing Excellence is a rigorous programme that benchmarks all EVC plants across the company,<br />

ensuring that the highest standards are met. The programme instils a common set of procedures that<br />

enable best practices to be implemented across a broad range of the company’s manufacturing activities.<br />

Manufacturing Excellence is a critical factor at EVC - it is focused on delivering a quality and cost-effective<br />

product to customers, and ensuring safe and efficient operations at every plant in every country.<br />

EVC International N.V.

Research and Technical Services<br />

EVC’s involvement with all aspects of VCM / PVC technology and products, and the wide technological<br />

background built over the years, places the Research and Technical Services team (R&TS) in an unrivalled<br />

position from which to develop the best products.<br />

R&TS has a broad range of facilities which are used by trained chemists, process engineers and material<br />

scientists. Semi technical scale production facilities are employed which simulate the VCM / PVC cycle<br />

from monomer production to the final processing of PVC resins. Laboratories contain a comprehensive<br />

range of processing equipment and product characterisation facilities to provide information on the<br />

composition, properties and performance of PVC products.<br />

Meeting the technical needs and requirements of existing and future customers is the aim of all<br />

Technical Service activities. Technical Service staff provide expertise in PVC processing technologies and<br />

application areas and they initiate and support market development opportunities as they arise. In order<br />

to provide direct customer support, EVC has fully equipped Research and Technical Service centres in<br />

Germany, Italy and the United Kingdom.<br />

15

16<br />

Safety, Health and Environment<br />

Protecting the environment is central to EVC’s commitment. The goal of sustainable development is<br />

seen as key to the long-term, successful operation of the business and the efficient use of resources<br />

and the manufacture of products that do not damage the environment are essential requirements for<br />

business success.<br />

EVC’s approach is based on the principle of ‘Responsible Care’, and this is achieved through participation<br />

in the programmes of the Responsible Care ® initiatives in the territories in which the company operates.<br />

This commitment is summarised as an obligation to:<br />

• Protect the environment<br />

• Protect the health and safety of all engaged in the business<br />

• Protect and support communities in which EVC operates<br />

• Achieve commercial success in its business operations.<br />

In 1995, European Council of Vinyl Manufacturers (ECVM) member companies signed a voluntary<br />

Charter, committing themselves to meet demanding environmental standards for the production of<br />

VCM and S-PVC. In 1999, the scope of the Charter was extended to meet further demanding targets<br />

in the production of E-PVC by no later than 2003. In addition, in 2000, an integrated approach to<br />

deliver responsible cradle-to-grave PVC product management was set out in a ‘Voluntary Commitment<br />

of the PVC Industry’. The commitment, which has been signed by the four major industry associations,<br />

is a ground-breaking move by the European PVC industry, the first of its kind for the plastics industry.<br />

EVC International N.V.

EVC’s comprehensive Safety Management System has been derived from systems developed by the<br />

internationally respected survey and risk management group, Det Norske Veritas (DNV). Further<br />

developed to reflect the specific hazards and priorities of EVC’s business, this management system has<br />

been known since 1998 as the ‘EVC Rating System’.<br />

EVC Rating System is focused on achieving:<br />

• A clear definition of all activities and responsibilities<br />

• Recognised training and qualifications for all personnel<br />

• Required standards through internally and externally verified auditing<br />

• Ongoing improvement in engineering and safety standards<br />

• Medium and long-term improvements in occupational health standards<br />

• Openness and transparency in all environmental and safety matters.<br />

EVC Rating System forms the basis for EVC meeting the most demanding of international standards,<br />

including the requirements of the European Commission ‘Seveso II’ Directive, and the eco-management<br />

and audit standards (EMAS) required for certification to ISO 14001.<br />

EVC is committed to the achievement of ISO 14001 standards at its entire polymer and rigid films<br />

manufacturing sites in Europe. In order to achieve these standards, challenging targets have been set for<br />

each business within EVC.<br />

EVC continues to improve its Environmental Management Systems with the Wilhelmshaven site securing<br />

its EN ISO 14001 and EMAS certification. Porto Marghera certified to ISO 14001, and all UK plants<br />

achieving ISO 14001 certification. The remaining sites are targeting accreditation during 2003.<br />

17

18<br />

EVC International N.V.

Directory<br />

Contents<br />

Chemical Technologies<br />

Raw Materials Handled<br />

Physical Processes<br />

Chemicals and Structures<br />

Addresses<br />

19

20<br />

Chemical Technologies<br />

<strong>Chlor</strong>ination<br />

Co-polymerisation<br />

Hydrogenation<br />

Neutralisation<br />

Oxyhydrochlorination<br />

Raw Materials Handled<br />

Additives<br />

Catalysts<br />

<strong>Chlor</strong>ine<br />

Ethylene<br />

Ethylene Dichloride<br />

Hydrogen<br />

Hydrogen <strong>Chlor</strong>ide<br />

Natural Gas<br />

Physical Processes<br />

Absorption / Desorption<br />

Agitation<br />

Bagging<br />

Blending<br />

Clariflocculation<br />

Compression<br />

Compounding<br />

Condensation<br />

Conveying<br />

Dewatering<br />

Distillation<br />

Drying<br />

Extrusion<br />

Filtration<br />

Granulation<br />

Heat Transfer<br />

EVC International N.V.<br />

Polymerisation - Emulsion<br />

Polymerisation - Suspension<br />

Pyrolysis<br />

Thermal Oxidation<br />

Oxygen<br />

Polyvinyl <strong>Chlor</strong>ide<br />

PVC Fillers<br />

PVC Plasticisers<br />

PVC Stabilisers<br />

Sodium Hydroxide<br />

Vinyl <strong>Chlor</strong>ide<br />

Water<br />

Mass Transfer<br />

Mechanical Handling<br />

Milling<br />

Mixing<br />

Palletisation<br />

Pelletisation<br />

Pumping<br />

Quenching<br />

Reaction<br />

Refrigeration<br />

Screening<br />

Separation<br />

Solid Handling<br />

Steam Raising<br />

Stripping<br />

Vaporisation

Vinyl <strong>Chlor</strong>ide Monomer (VCM)<br />

Cl<br />

C C<br />

H<br />

H<br />

Polyvinyl <strong>Chlor</strong>ide (PVC)<br />

Cl<br />

H<br />

C C<br />

H<br />

H<br />

H n<br />

Chemicals and Structures<br />

21

22<br />

Addresses<br />

Registered Office<br />

EVC International N.V.<br />

Ir Rocourstraat 28<br />

6245 AD Eijsden<br />

The Netherlands<br />

Tel +31-43-4099191<br />

Fax +31-43-4099198<br />

SALES OFFICES<br />

<strong>Polymers</strong><br />

GERMANY European Vinyls<br />

Corporation (Deutschland) GmbH<br />

Inhausersieler Straße 25<br />

26388 Wilhelmshaven<br />

Germany<br />

Tel +49-4425-98-01<br />

Fax +49-4425-98-2217<br />

UK European Vinyls<br />

Corporation (UK) Limited<br />

P.O. Box 9<br />

Runcorn<br />

Cheshire WA7 4JE<br />

United Kingdom<br />

Tel +44-1928-512918<br />

Fax +44-1928-560972<br />

USA EVC Americas, Inc.<br />

7275 Goodlett Farms Parkway<br />

Cordova, Tennessee 38016<br />

USA<br />

Tel +1-901-381-2150<br />

Fax +1-901-381-2244<br />

PVC Compounds<br />

ITALY EVC Compounds<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via Leonardo Da Vinci 5<br />

44011 Argenta (FE)<br />

Italy<br />

Tel +39-0532-315511<br />

Fax +39-0532-315703<br />

UK EVC Compounds Ltd<br />

Chester Road, Helsby<br />

Frodsham<br />

Cheshire WA6 0DF<br />

United Kingdom<br />

Tel +44-1928-725311<br />

Fax +44-1928-725101<br />

EVC International N.V.<br />

Business Centre<br />

European Vinyls Corporation (UK) Limited<br />

Hawkslease<br />

Chapel Lane, Lyndhurst<br />

Hampshire SO43 7FG<br />

United Kingdom<br />

Tel +44-2380-287043<br />

Fax +44-2380-287046<br />

www.evc-int.com<br />

BELGIUM EVC Belgium S.A./N.V.<br />

Excelsiorlaan 3<br />

1930 Zaventem<br />

Belgium<br />

Tel +32-2-709-1310<br />

Fax +32-2-709-1322/23<br />

ITALY European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via della Chimica 14<br />

30175 Porto Marghera<br />

Italy<br />

Tel +39-041-2912668<br />

Fax +39-041-2912213<br />

ITALY EVC Compounds<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via Morolense 16<br />

03100 Frosinone<br />

Italy<br />

Tel +39-0775-291763<br />

Fax +39-0775-294034<br />

SWITZERLAND EVC European Vinyls<br />

Corporation (Switzerland) A.G.<br />

Postfach 32, Bremgartenstrasse<br />

5643 Sins<br />

Switzerland<br />

Tel +41-41-789-8000<br />

Fax +41-41-789-8888

PVC Films<br />

GERMANY EVC Rigid Film GmbH<br />

Radebeulstraße 1<br />

79219 Staufen<br />

Germany<br />

Tel +49-7633-811-0<br />

Fax +49-7633-811-330<br />

INDIA Caprihans India Limited<br />

Block D, Shivsagar Estate<br />

Dr. Annie Besant Road, Worli<br />

Mumbai 400 018<br />

India<br />

Tel +91-22-2-492-1900-05<br />

Fax +91-22-2-493-4042<br />

+91-22-2-496-0693<br />

Catalysts and Additives<br />

BELGIUM EVC Belgium S.A./N.V.<br />

Inovyl, Division of<br />

EVC Belgium S.A./N.V.<br />

Excelsiorlaan 3<br />

1930 Zaventem<br />

Belgium<br />

Tel +32-2-709-1315<br />

Fax +32-2-709-1324<br />

MANUFACTURING SITES<br />

<strong>Polymers</strong><br />

GERMANY European Vinyls<br />

Corporation (Deutschland) GmbH<br />

Werk Schkopau, Gebäude O 160<br />

06258 Schkopau<br />

Germany<br />

Tel +49-3461-7717-0<br />

Fax +49-3461-7717-2819<br />

ITALY European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via della Chimica 5<br />

30175 Porto Marghera<br />

Italy<br />

Tel +39-041-2912023<br />

Fax +39-041-938145<br />

ITALY European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Zona Industriale La Marinella<br />

07046 Porto Torres (SS)<br />

Italy<br />

Tel +39-079-509770<br />

Fax +39-079-509453<br />

UK European Vinyls<br />

Corporation (UK) Limited<br />

Hillhouse International<br />

Bourne Road, Thornton-Cleveleys<br />

Lancashire FY5 4QD<br />

United Kingdom<br />

Tel +44-1253-898700<br />

Fax +44-1253-858215<br />

USA EVC Americas, Inc.<br />

7275 Goodlett Farms Parkway<br />

Cordova, Tennessee 38016<br />

USA<br />

Tel. +1-901-381-2150<br />

Fax +1-901-381-2244<br />

ITALY EVC Rigid Film<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via XXIV Maggio 1<br />

21043 Castiglione Olona (Varese)<br />

Italy<br />

Tel +39-0331-853111<br />

Fax +39-0331-853213<br />

GERMANY European Vinyls<br />

Corporation (Deutschland) GmbH<br />

Inhausersieler Straße 25<br />

26388 Wilhelmshaven<br />

Germany<br />

Tel +49-4425-98-01<br />

Fax +49-4425-98-2217<br />

ITALY European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via Baiona 107/111<br />

48100 Ravenna<br />

Italy<br />

Tel +39-0544-513111<br />

Fax +39-0544-513691<br />

UK European Vinyls<br />

Corporation (UK) Limited<br />

P.O. Box 9, Runcorn<br />

Cheshire WA7 4JE<br />

United Kingdom<br />

Tel +44-1928-512918<br />

Fax +44-1928-560972<br />

UK European Vinyls<br />

Corporation (UK) Limited<br />

Sully Moors Road<br />

Sully, Penarth<br />

South Glamorgan CF64 5RP<br />

United Kingdom<br />

Tel +44-1446-724200<br />

Fax +44-1446-745810<br />

23

24<br />

PVC Compounds<br />

ITALY EVC Compounds<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via Leonardo Da Vinci 5<br />

44011 Argenta (FE)<br />

Italy<br />

Tel +39-0532-315511<br />

Fax +39-0532-315703<br />

ITALY EVC Compounds<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via Della Chimica 14<br />

30175 Porto Marghera<br />

Italy<br />

Tel +39-041-2912633<br />

Fax +39-041-2913918<br />

SWITZERLAND EVC European Vinyls<br />

Corporation (Switzerland) A.G.<br />

Postfach 32, Bremgartenstrasse<br />

5643 Sins<br />

Switzerland<br />

Tel +41-41-789-8000<br />

Fax +41-41-789-8888<br />

GERMANY EVC Packaging Film GmbH<br />

Radegaster Straße 14<br />

06369 Weißandt-Gölzau<br />

Germany<br />

Tel +49-3497-8258-0<br />

Fax +49-3497-8258-11<br />

PVC Films<br />

INDIA Caprihans India Limited<br />

Plot No. 76, MIDC Industrial Estate<br />

Trimbak Road<br />

Satpur, Nasik 422007<br />

India<br />

Tel +91-25-335-0377<br />

Fax +91-22-582-2422<br />

ITALY EVC Rigid Film<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via S.e.P. Mazzucchelli 7<br />

21043 Castiglione Olona (Varese)<br />

Italy<br />

Tel +39-0331-853111<br />

Fax +39-0331-853213<br />

GERMANY EVC Packaging Film GmbH<br />

Radegaster Straße 14<br />

06369 Weißandt-Gölzau<br />

Germany<br />

Tel +49-3497-8258-0<br />

Fax +49-3497-8258-11<br />

GERMANY EVC Rigid Film GmbH<br />

Schloßmattenstraße 2<br />

79268 Bötzingen<br />

Germany<br />

Tel +49-7663-63-0<br />

Fax +49-7663-63-546<br />

EVC International N.V.<br />

ITALY EVC Compounds<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via Stazione 2<br />

27030 Villanova d’Ardenghi (PV)<br />

Italy<br />

Tel +39-0382-400544<br />

Fax +39-0382-400042<br />

ITALY EVC Compounds<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Via Morolense 16<br />

03100 Frosinone<br />

Italy<br />

Tel +39-0775-291763<br />

Fax +39-0775-294034<br />

UK EVC Compounds Ltd<br />

Chester Road, Helsby<br />

Frodsham<br />

Cheshire WA6 0DF<br />

United Kingdom<br />

Tel +44-1928-725-311<br />

Fax +44-800-220-613<br />

INDIA Caprihans India Limited<br />

Plot No. C-13/16, Road No. 16T<br />

Wagle Industrial Estate<br />

Thane 400604<br />

India<br />

Tel +91-22-582-1285<br />

Fax +91-22-582-2422<br />

ITALY EVC Packaging Film<br />

A division of European Vinyls<br />

Corporation (Italia) S.p.A.<br />

Località Macchiareddu Str. 3a<br />

09032 Assemini (Cagliari)<br />

Italy<br />

Tel +39-070-246-11<br />

Fax +39-070-246-1342<br />

GERMANY EVC Rigid Film GmbH<br />

Radebeulstraße 1<br />

79219 Staufen<br />

Germany<br />

Tel +49-7633-811-0<br />

Fax +49-7633-811-330

<strong>INEOS</strong> CHART

© EVC International N.V. 2003. All rights reserved.

EVC International N.V.<br />

Ir Rocourstraat 28<br />

6245 AD Eijsden<br />

The Netherlands<br />

Tel +31-43-4099191<br />

Fax +31-43-4099198<br />

EVC FFE 2003.01<br />

EVC FactFile English<br />

waypointdesign.be