Polymers - INEOS Chlor

Polymers - INEOS Chlor

Polymers - INEOS Chlor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

E-PVC<br />

E-PVC represents approximately 10% of PVC produced by EVC.<br />

It is used in a wide range of speciality applications involving coating,<br />

dipping and spreading operations, for which S-PVC cannot be<br />

used. It is generally converted into a usable form by the addition<br />

of plasticisers to form a ‘plastisol’ or paste.<br />

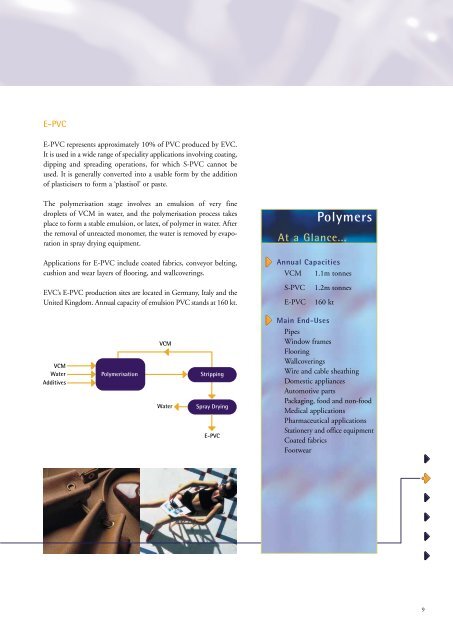

The polymerisation stage involves an emulsion of very fine<br />

droplets of VCM in water, and the polymerisation process takes<br />

place to form a stable emulsion, or latex, of polymer in water. After<br />

the removal of unreacted monomer, the water is removed by evaporation<br />

in spray drying equipment.<br />

Applications for E-PVC include coated fabrics, conveyor belting,<br />

cushion and wear layers of flooring, and wallcoverings.<br />

EVC’s E-PVC production sites are located in Germany, Italy and the<br />

United Kingdom. Annual capacity of emulsion PVC stands at 160 kt.<br />

VCM<br />

VCM<br />

Water<br />

Additives<br />

Polymerisation<br />

Stripping<br />

Water<br />

Spray Drying<br />

E-PVC<br />

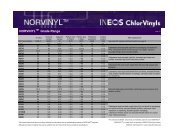

<strong>Polymers</strong><br />

At a Glance...<br />

Annual Capacities<br />

VCM 1.1m tonnes<br />

S-PVC 1.2m tonnes<br />

E-PVC 160 kt<br />

Main End-Uses<br />

Pipes<br />

Window frames<br />

Flooring<br />

Wallcoverings<br />

Wire and cable sheathing<br />

Domestic appliances<br />

Automotive parts<br />

Packaging, food and non-food<br />

Medical applications<br />

Pharmaceutical applications<br />

Stationery and office equipment<br />

Coated fabrics<br />

Footwear<br />

9