Technical Services - Southwest Research Institute

Technical Services - Southwest Research Institute

Technical Services - Southwest Research Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

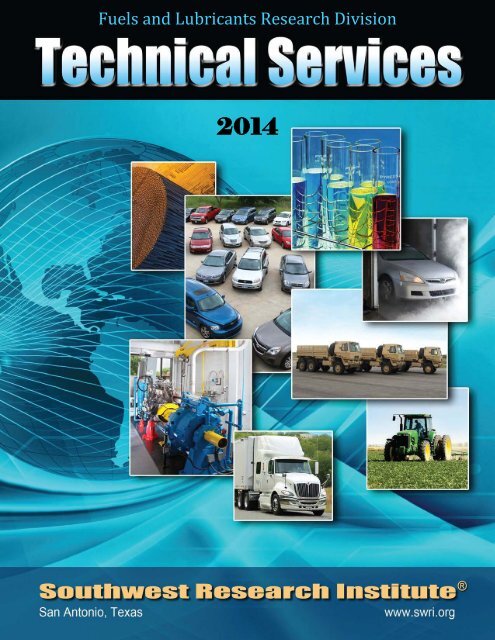

Fuels and Lubricants <strong>Research</strong> Division<br />

2014<br />

22

The Fuels and Lubricants <strong>Research</strong> Division of <strong>Southwest</strong> <strong>Research</strong><br />

<strong>Institute</strong> ® includes extensive engines, fuels and lubricants research,<br />

development and evaluation activities.<br />

Fuels and<br />

Lubricants<br />

<strong>Research</strong><br />

Division<br />

<strong>Technical</strong><br />

<strong>Services</strong><br />

The result is unequaled capabilities for automotive product research,<br />

development, testing and evaluation. A client-driven and technologyoriented<br />

staff of more than 400 provides a broad range of services<br />

for research, development, qualification, demonstration, certification,<br />

or evaluation of automotive components and petroleum products<br />

used in cars, trucks, buses, locomotives, tractors, motorcycles and<br />

outboard engines, or any other internal combustion engine<br />

application.<br />

Our services include bench, laboratory or field demonstrations and<br />

include worldwide specifications. We provide all relevant and<br />

applicable ASTM, OEM and other recognized procedures. An even<br />

greater variety and range of services is provided for specific<br />

applications and special needs. This publication contains a partial list<br />

of the services available, organized by department. We welcome<br />

your inquiries and will provide price quotes on request at no<br />

obligation. Key personnel are listed at the beginning of each section.<br />

Steven D. Marty, P.E., Vice President<br />

Fuels and Lubricants <strong>Research</strong> Division<br />

<strong>Southwest</strong> <strong>Research</strong> <strong>Institute</strong><br />

6220 Culebra Road<br />

P.O. Drawer 28510<br />

San Antonio, Texas USA 78228-0510<br />

(210) 522-5929<br />

smarty@swri.org<br />

www.flrd.swri.org<br />

www.swri.org<br />

The Fuels and Lubricants <strong>Research</strong> Division is:<br />

• Certified to ISO 9001:2008, “Quality Management Systems -<br />

Requirements”<br />

• Accredited to ISO/IEC 17025:2005, “General Requirements for the<br />

Competence of Testing and Calibration Laboratories”<br />

• Certified to ISO 14001:2004, “Environmental Management<br />

Systems”<br />

The Division also has achieved Ford Tier 1 status for providing<br />

engineering services and has received the Ford Q1 Quality Award.<br />

In conjunction with these Divisional quality system accomplishments:<br />

• The Petroleum Products <strong>Research</strong> Department is a Nuclear<br />

Procurement Issues Committee (NUPIC)-Approved Laboratory.<br />

• The Fuels and Lubricants <strong>Research</strong> Department has maintained its<br />

status as an American Chemistry Council (ACC)-Approved<br />

Laboratory.<br />

i

Table of Contents<br />

ENGINE LUBRICANTS RESEARCH DEPARTMENT ................................................... 1<br />

ENGINE LUBRICANTS RESEARCH DEPARTMENT ................................................... 2<br />

Gasoline Engine Lubricant Certification Testing ................................................................... 2<br />

Calibrated Sequence IIIF Lubricant Test .................................................................................................. 2<br />

Calibrated Sequence IIIFHD Lubricant Test ............................................................................................. 2<br />

Calibrated Sequence IIIG Lubricant Test .................................................................................................. 2<br />

Calibrated Sequence IIIGA Lubricant Test ............................................................................................... 2<br />

Calibrated Sequence IIIGB Lubricant Test ............................................................................................... 2<br />

Calibrated Sequence IVA Lubricant Test .................................................................................................. 2<br />

Calibrated Sequence VG Lubricant Test .................................................................................................. 2<br />

Calibrated Sequence VIB Lubricant Test .................................................................................................. 2<br />

Calibrated Sequence VID Lubricant Test .................................................................................................. 2<br />

Calibrated Sequence VIII Lubricant Test .................................................................................................. 2<br />

Calibrated Ball Rust Test .......................................................................................................................... 2<br />

Diesel Engine Lubricant Certification Testing ....................................................................... 2<br />

Caterpillar 1K Lubricant Test..................................................................................................................... 2<br />

Caterpillar 1M-PC Lubricant Test .............................................................................................................. 3<br />

Caterpillar 1N Lubricant Test .................................................................................................................... 3<br />

Caterpillar 1P Lubricant Test..................................................................................................................... 3<br />

Caterpillar 1R Lubricant Test .................................................................................................................... 3<br />

Caterpillar C13 Lubricant Test .................................................................................................................. 3<br />

Mack T8/T8A/T8E Lubricant Test ............................................................................................................. 3<br />

Mack T10A Lubricant Test ........................................................................................................................ 3<br />

Mack T11 Lubricant Test ........................................................................................................................... 3<br />

Mack T12 Lubricant Test ........................................................................................................................... 3<br />

Roller Follower Wear Test (RFWT) ........................................................................................................... 3<br />

Engine Oil Aeration Test (EOAT) .............................................................................................................. 3<br />

Cummins ISB Lubricant Test .................................................................................................................... 3<br />

Cummins ISM Lubricant Test .................................................................................................................... 4<br />

Specialized Diesel Engine Testing .......................................................................................... 4<br />

Railroad and Marine .................................................................................................................................. 4<br />

Fuel Additives ............................................................................................................................................ 4<br />

Fuel Consumption ..................................................................................................................................... 4<br />

Alternative Fuels ....................................................................................................................................... 4<br />

Fuel System Wear ..................................................................................................................................... 4<br />

Durability ................................................................................................................................................... 4<br />

Injector Deposit/Coking ............................................................................................................................. 4<br />

Engine Hardware ...................................................................................................................................... 4<br />

Oil Consumption ........................................................................................................................................ 4<br />

New Engine vs. Available Lubricants ........................................................................................................ 4<br />

Valve Guttering ......................................................................................................................................... 4<br />

Destructive Evaluations ............................................................................................................................. 4<br />

Oil Consumption Apparatus ...................................................................................................................... 4<br />

Parts Analysis ........................................................................................................................................... 4<br />

Ratings ...................................................................................................................................................... 5<br />

ii

Turbocharger Durability/Lubrication .......................................................................................................... 5<br />

Tribology and Advanced Lubricant Evaluations ................................................................... 5<br />

Plint TE-77 Reciprocating Test Rig ........................................................................................................... 5<br />

High-Pressure, -Temperature and -Frequency Reciprocating Rig ........................................................... 5<br />

Falex Block-on-Ring Test Rig ................................................................................................................... 5<br />

PCS Instruments Mini Traction Machine (MTM2) ..................................................................................... 5<br />

JASO Diesel Engine Lubricant Testing .................................................................................. 5<br />

Mitsubishi 4D34T4 Valve Train Wear JASO M354:1999 .......................................................................... 5<br />

ASTM-TC Procedures for Two-Stroke, Air-Cooled Engines .................................................. 5<br />

D4857-12 TC Seq. I (Y350M2 Detergency) .............................................................................................. 5<br />

D4863-13 TC Seq. II (CE50S Lubricity) .................................................................................................... 5<br />

D4858-13 TC Seq. III (CE50S Pre-Ignition) .............................................................................................. 5<br />

NMMA TC-W3 ® Procedures for Two-Cycle Outboard Engines ............................................. 6<br />

CE50S Lubricity ........................................................................................................................................ 6<br />

NMMA TC-W3 AF-27 Lubricity.................................................................................................................. 6<br />

OMC 40 HP General Performance ........................................................................................................... 6<br />

OMC 70 HP Detergency ........................................................................................................................... 6<br />

Mercury 15 HP Detergency ....................................................................................................................... 6<br />

Pre-Ignition ................................................................................................................................................ 6<br />

NMMA FC-W ® and FC-W Catalyst Compatible ® Procedures for Four-Cycle Outboard<br />

Engines ..................................................................................................................................... 6<br />

NMMA FC-W 115 HP General Performance Engine Test ........................................................................ 6<br />

JASO FB, FC, FD, EGB, EGC & EGD Procedures for Two-Stroke Lubricant Engine Testing<br />

.................................................................................................................................................. 6<br />

M 342-92 Smoke ....................................................................................................................................... 6<br />

M 343-92 Exhaust System Blocking ......................................................................................................... 6<br />

M 341-92 Detergency ................................................................................................................................ 6<br />

M 340-92 Lubricity ..................................................................................................................................... 6<br />

M 341-02 Three-Hour Detergency ............................................................................................................ 6<br />

Field Test Engine – Complete New Powerhead Inspection ...................................................................... 6<br />

Field Test Engine – Block and Piston Inspection ...................................................................................... 6<br />

Component, Product and Additive Testing ............................................................................ 7<br />

Engine Rating and Measurements ............................................................................................................ 7<br />

Aircraft Product Testing ............................................................................................................................. 7<br />

Additive Testing ......................................................................................................................................... 7<br />

Sequence Test Development .................................................................................................................... 7<br />

Gaskets and Seals .................................................................................................................................... 7<br />

Two-Stroke Cycle Tests ............................................................................................................................ 7<br />

Test Equipment, Fabrication and Training Export <strong>Services</strong> ...................................................................... 7<br />

Natural Gas Lubricant Evaluations ........................................................................................................... 7<br />

FUELS AND DRIVELINE LUBRICANTS RESEARCH DEPARTMENT......................... 8<br />

FUELS AND DRIVELINE LUBRICANTS RESEARCH DEPARTMENT......................... 9<br />

Transmission Fluid Testing ..................................................................................................... 9<br />

General Motors Automatic Transmission Fluids Testing ...................................................... 9<br />

iii

DEXRON ® -VI Chemical and Bench Tests (DEXRON ® -VI Items A-M, and O-U) ...................................... 9<br />

DEXRON ® -VI Oxidation Test .................................................................................................................... 9<br />

DEXRON ® -VI Cycling Test ........................................................................................................................ 9<br />

DEXRON ® -VI Plate Clutch Friction Test ................................................................................................... 9<br />

DEXRON ® -VI Wear Test ........................................................................................................................... 9<br />

DEXRON ® -VI Aeration Test ...................................................................................................................... 9<br />

DEXRON ® -VI Low Speed Clutch Friction and Torque Capacity Test ....................................................... 9<br />

Ford Automatic Transmission Fluid Testing .......................................................................... 9<br />

MERCON ® V Chemical and Bench Tests (MERCON ® V items 3.1 thru 3.7, 3.9 and 3.10) ..................... 9<br />

MERCON ® V Wear Tests ........................................................................................................................ 10<br />

MERCON ® V Aluminum Beaker Oxidation Test (ABOT) ........................................................................ 10<br />

MERCON ® V Clutch Friction Durability Test ........................................................................................... 10<br />

MERCON ® V Anti-Shudder Durability ..................................................................................................... 10<br />

Ford Over-Running Clutch (AX4N OWC) Wear Test Procedure ............................................................ 10<br />

Allison Severe Duty, Extended Drain Interval Automatic Transmission Fluid Testing ......10<br />

Allison TES-295 Chemical and Bench Tests .......................................................................................... 10<br />

Allison TES-295 Oxidation Test .............................................................................................................. 10<br />

Allison TES-295 Wear Tests ................................................................................................................... 10<br />

Allison TES-295 Frictional Properties Tests ........................................................................................... 10<br />

Allison On-Highway Automatic Transmission Fluid Testing ...............................................10<br />

Allison TES-389 Chemical and Bench Tests .......................................................................................... 10<br />

Allison TES-389 Wear Test ..................................................................................................................... 10<br />

Allison TES-389 Oxidation Resistance Test ........................................................................................... 10<br />

Allison TES-389 Friction Tests ................................................................................................................ 11<br />

Allison Heavy-Duty Automatic Transmission Fluid Testing ................................................11<br />

Allison TES-439 Chemical and Bench Test ............................................................................................ 11<br />

Allison TES-439 Oxidation Test .............................................................................................................. 11<br />

Allison TES-439 Graphite High-Energy Friction Test ............................................................................. 11<br />

JASO SAE #2 Testing .............................................................................................................11<br />

JASO T903:2011 and M348:2002 Clutch Friction Test .......................................................................... 11<br />

Caterpillar Transmission and Drivetrain Fluid Testing ........................................................11<br />

TO-4 Physical Properties ........................................................................................................................ 11<br />

TO-4 Elastomer Compatibility ................................................................................................................. 11<br />

TO-4 Oxidation Stability .......................................................................................................................... 11<br />

TO-4 Gear Wear Test (ASTM D4998) .................................................................................................... 11<br />

TO-4 Pump Wear Test ............................................................................................................................ 11<br />

TO-4 Friction Properties .......................................................................................................................... 11<br />

Hydraulic Fluid Testing ..........................................................................................................12<br />

DIN 51389-2 Vane Pump Wear Test ...................................................................................................... 12<br />

Conestoga Pump Test (ASTM D7043) ................................................................................................... 12<br />

Eaton 35VQ25A Pump Test .................................................................................................................... 12<br />

Denison T6H20C Hybrid Pump - Phase I ............................................................................................... 12<br />

Manual Transmission and Rear Axle Gear Lubricant Performance Testing .......................12<br />

L-20 High-Torque Test ............................................................................................................................ 12<br />

L-33-1 Moisture Corrosion Test (ASTM D7038) ..................................................................................... 12<br />

iv

L-37 High-Torque Test (ASTM D6121) ................................................................................................... 12<br />

L-42 High-Speed Shock Axle Test (ASTM D7452) ................................................................................. 12<br />

L-60-1 Thermal and Oxidative Stability Test (ASTM D5704) .................................................................. 12<br />

FZG Gear Wear Test (ASTM D4998) ..................................................................................................... 13<br />

FZG Load Stage Test (ASTM D5182) .................................................................................................... 13<br />

Axle Efficiency Test ................................................................................................................................. 13<br />

FZG Pitting Test with Type C Gear ......................................................................................................... 13<br />

FZG Step Load (A10/16.6R/90:120) ....................................................................................................... 13<br />

Manual Transmission High-Temperature Cyclic Durability Test (ASTM D5579) .................................... 13<br />

SSP 180 Synchronizer ............................................................................................................................ 13<br />

Mack GO-J/J+ and Eaton PS-163 Test Procedures ............................................................................... 13<br />

Manual Transmission and Dry Clutch Transmission (dDCT) Fluid Testing ........................14<br />

General Motors Dry Dual Clutch Transmissions Fluids Testing .........................................14<br />

DEXRON ® -dDCT Chemical and Bench Tests ........................................................................................ 14<br />

DEXRON ® -dDCT Wear Test ................................................................................................................... 14<br />

DEXRON ® -dDCT Scuffing Protection Test ............................................................................................. 14<br />

DEXRON ® -dDCT Synchronizer Function Test ....................................................................................... 14<br />

Tractor Testing ........................................................................................................................14<br />

Tractor Field Tests .................................................................................................................................. 14<br />

Tractor Fluids Specification Testing......................................................................................14<br />

Tractor Hydraulic Fluid Testing ............................................................................................................... 14<br />

JDQ-84 Dynamic Corrosion Sauer-Danfoss Pump Test ........................................................................ 14<br />

JDQ-94 Powershift Transmission Clutch Friction Test ........................................................................... 14<br />

JDQ-102 Shear Stability .......................................................................................................................... 14<br />

JDQ-95 Spiral Bevel/Final Drive Wear Test ............................................................................................ 15<br />

JDQ-96B Torque Variation and Brake Friction Retention Test ............................................................... 15<br />

John Deere Hydraulic Pump Shear Stability ........................................................................................... 15<br />

JDQ-95A Spiral Bevel Gear Wear .......................................................................................................... 15<br />

John Deere High Energy Clutch ............................................................................................................. 15<br />

John Deere TZT Oxidation ...................................................................................................................... 15<br />

Automotive Fleet Testing .......................................................................................................15<br />

Axle and Axle Lubricant Evaluations, Heavy-Duty .................................................................................. 15<br />

Axle and Axle Lubricant Evaluations, Light-Duty .................................................................................... 15<br />

Truck Axle Lubricant Fuel Economy ....................................................................................................... 15<br />

Crankcase Engine Lubricant Fuel Economy ........................................................................................... 15<br />

Truck Fuel Economy Improvements ....................................................................................................... 16<br />

Durability and Reliability Evaluation of Engine/Vehicle Compatibility ..................................................... 16<br />

Road Simulators/Mileage Accumulation Dynamometers ........................................................................ 16<br />

Vehicle Test Tracks ................................................................................................................................. 16<br />

Off-Highway Evaluations ......................................................................................................................... 16<br />

John Deere Engine Coolant Cavitation Test ........................................................................................... 16<br />

Specialized Fuel Testing ........................................................................................................16<br />

Vehicle Evaluations for Fuel Injector Plugging........................................................................................ 16<br />

Intake System and Combustion Chamber Deposits ............................................................................... 16<br />

Intake Valve-Sticking Evaluations ........................................................................................................... 16<br />

Vehicle Driveability and Performance Testing ........................................................................................ 16<br />

v

Vehicle Octane Requirement and ORI Evaluations ................................................................................ 17<br />

Alternative Fuels Testing (Methanol, Ethanol, Natural Gas and others) ................................................ 17<br />

Octane Requirement Increase (ORI) ...................................................................................................... 17<br />

Gasoline Direct Injection GDI) Fuel Injector Deposits ............................................................................ 17<br />

Sequential Central Port Injection Fouling Test........................................................................................ 17<br />

PETROLEUM PRODUCTS RESEARCH DEPARTMENT ............................................ 18<br />

PETROLEUM PRODUCTS RESEARCH DEPARTMENT ............................................ 19<br />

Fuel, Lubricant and Fluid Inspection ....................................................................................................... 19<br />

Metals Analyses ...................................................................................................................................... 19<br />

Fuel Conformance/Fuel Surveys/Field Studies....................................................................................... 19<br />

Trace Organic Analysis ........................................................................................................................... 19<br />

Laboratory Engine Technology ............................................................................................................... 19<br />

SwRI-developed Instruments .................................................................................................................. 19<br />

Petroleum Products <strong>Research</strong> ................................................................................................................ 20<br />

Used Lubricant Field Studies .................................................................................................................. 20<br />

Procedural Development ......................................................................................................................... 20<br />

Trend Analysis ........................................................................................................................................ 20<br />

Lubricants and Fluid Evaluations ............................................................................................................ 20<br />

Engine Lubricants ................................................................................................................................... 20<br />

Gear Lubricants ....................................................................................................................................... 20<br />

Transmission Fluids ................................................................................................................................ 20<br />

Industrial Lubricants ................................................................................................................................ 20<br />

Engine Coolants ...................................................................................................................................... 20<br />

FUELS AND LUBRICANTS TECHNOLOGY DEPARTMENT ..................................... 21<br />

FUELS AND LUBRICANTS TECHNOLOGY DEPARTMENT ..................................... 22<br />

Automotive Filtration Performance Testing ............................................................................................. 22<br />

Fluids Filtration and Handling <strong>Research</strong> ................................................................................................. 22<br />

Fuels, Lubricants, and Fluids Applications .............................................................................................. 22<br />

Fuel Systems and Contamination <strong>Research</strong> ........................................................................................... 23<br />

Filtration and Fine Particle Technology ................................................................................................... 23<br />

vi

Engine Lubricants <strong>Research</strong> Department<br />

Ben Weber, Executive Director ................................................................... (210) 522-5911<br />

William A. Buscher III, Manager, Gasoline Lubricant Evaluations ...............................(210) 522-6802<br />

Jim McCord, Manager, Diesel Engine Lubricants ........................................................(210) 522-3439<br />

Dr. Peter Lee, Principal Engineer, Tribology ................................................................(210) 522-5545<br />

Dr. Sylvain Kouame, <strong>Research</strong> Engineer, Advanced Lubricant Evaluations ...............(210) 522-5271<br />

1

Engine Lubricants<br />

<strong>Research</strong> Department<br />

Ben Weber, Executive Director<br />

(210) 522-5911<br />

William A. Buscher III, Manager<br />

Gasoline Lubricant Evaluations<br />

(210) 522-6802<br />

Jim McCord, Manager<br />

Diesel Engine Lubricants<br />

(210) 522-3439<br />

Dr. Peter Lee, Principal Engineer<br />

Tribology<br />

(210) 522-5545<br />

Dr. Sylvain Kouame, <strong>Research</strong> Engineer<br />

Advanced Lubricant Evaluations<br />

(210) 522-5271<br />

Gasoline Engine Lubricant<br />

Certification Testing<br />

Calibrated Sequence IIIF Lubricant Test<br />

This 80-hour engine dynamometer lubricant test<br />

evaluates a lubricant’s ability to prevent<br />

camshaft lobe wear, valve lifter wear, and hightemperature<br />

oxidation. In addition, varnish and<br />

piston deposits are evaluated.<br />

Calibrated Sequence IIIFHD Lubricant Test<br />

This 60-hour test measures high temperature<br />

oxidation performance of a lubricant. Test<br />

conditions are identical to the Sequence IIIF test<br />

with the exception of test length.<br />

Calibrated Sequence IIIG Lubricant Test<br />

This 100-hour test evaluates a lubricant’s ability<br />

to prevent camshaft lobe wear, valve lifter wear<br />

and high temperature oxidation. In addition,<br />

varnish and piston deposits are evaluated.<br />

Operational conditions are similar to the<br />

Sequence IIIF but at a more severe level.<br />

Calibrated Sequence IIIGA Lubricant Test<br />

This 100-hour test evaluates the cold<br />

temperature viscosity of a lubricant after<br />

operation at high temperature test conditions.<br />

Test conditions are identical to the Sequence<br />

IIIG test.<br />

Calibrated Sequence IIIGB Lubricant Test<br />

This 100-hour test evaluates phosphorus<br />

retention of a lubricant after operation at high<br />

temperature test conditions. Test conditions are<br />

identical to the Sequence IIIG test.<br />

Calibrated Sequence IVA Lubricant Test<br />

This 100-hour engine dynamometer lubricant<br />

test is designed to evaluate low temperature<br />

camshaft lobe wear. It evaluates the VE wear<br />

aspect that has been eliminated from the VG<br />

test.<br />

Calibrated Sequence VG Lubricant Test<br />

This 216-hour engine dynamometer lubricant<br />

test is designed to evaluate a lubricant’s<br />

performance in combating low temperature<br />

sludge and varnish formation.<br />

Calibrated Sequence VIB Lubricant Test<br />

This 133-hour engine dynamometer lubricant<br />

test measures the effects of lubricants on fuel<br />

economy of gasoline engine passenger cars and<br />

light-duty trucks.<br />

Calibrated Sequence VID Lubricant Test<br />

This 153-hour engine dynamometer lubricant<br />

test measures the effects of lubricants on fuel<br />

economy of gasoline engine passenger cars and<br />

light-duty trucks equipped with a “low-friction”<br />

engine.<br />

Calibrated Sequence VIII Lubricant Test<br />

This 40-hour test measures lubricant shear<br />

stability and evaluates a lubricant’s ability to<br />

inhibit bearing corrosion.<br />

Calibrated Ball Rust Test<br />

This 18-hour bench test is designed to simulate<br />

the Sequence IID test. This test evaluates a<br />

lubricant’s ability to prevent rust formation on<br />

critical engine components.<br />

Diesel Engine Lubricant Certification<br />

Testing<br />

Caterpillar 1K Lubricant Test<br />

This test evaluates the piston deposits, liner<br />

wear, and oil consumption associated with test<br />

lubricants using 0.4 percent sulfur fuel. Run on a<br />

Caterpillar 1Y540 single-cylinder direct injection<br />

engine, the procedure is steady state at 2,100<br />

rpm and 8,000 BTU per minute fuel rate for 252<br />

2

hours. This test is required by CI-4, CH-4 and<br />

MIL-L-2104F.<br />

Caterpillar 1M-PC Lubricant Test<br />

This 120-hour lubricant test is conducted on a<br />

1Y73 indirect injection single-cylinder engine at<br />

1,800 rpm and 42 hp. The test evaluates piston<br />

deposits, ring sticking, ring and cylinder liner<br />

wear, and piston, ring, and liner scuffing.<br />

Caterpillar 1N Lubricant Test<br />

This 252-hour lubricant test is conducted on a<br />

calibrated 1Y540 engine, exactly like the 1K test<br />

except 0.05 percent sulfur fuel is used. This test<br />

is required for the CJ-4 category.<br />

Caterpillar 1P Lubricant Test<br />

This test evaluates piston deposits, ring sticking,<br />

ring and cylinder liner wear, and piston, ring and<br />

liner scuffing, as well as lubricant consumption.<br />

The test is required for the CH-4 API category.<br />

This 360-hour lubricant test is conducted on a<br />

calibrated 1Y3700 single-cylinder overhead<br />

cam, electronically-controlled, direct injection<br />

engine using 0.05 percent sulfur fuel and a twopiece<br />

piston with a steel crown and aluminum<br />

skirt.<br />

Caterpillar 1R Lubricant Test<br />

The purpose of this 504-hour test is to evaluate<br />

the performance of crankcase lubricants with<br />

respect to piston deposits, ring sticking, ring and<br />

cylinder wear, piston, ring and liner scuffing, as<br />

well as lubricant consumption. This test is<br />

required for the CI-4 category and uses a<br />

calibrated 1Y3700 engine with 0.05 percent<br />

sulfur fuel.<br />

Caterpillar C13 Lubricant Test<br />

This 500-hour test uses a Caterpillar C13 engine<br />

with all steel pistons operated at 1,800 rpm and<br />

1,200 grams per minute fuel rate to evaluate the<br />

performance of crankcase lubricants with regard<br />

to piston deposits and lubricant consumption.<br />

The test is required for the CJ-4 category.<br />

Mack T8/T8A/T8E Lubricant Test<br />

Test lubricants are evaluated for their ability to<br />

minimize viscosity increase and oil filter plugging<br />

associated with soot loading. The test, required<br />

for API classifications CH-4, CI-4, and Mack<br />

EOL/M specifications, uses a 1991 in-line, sixcylinder,<br />

Mack E7-350, turbocharged, charge<br />

air-cooled, direct-injection diesel engine at 1,800<br />

rpm. The engine is operated at rated load for<br />

250 hours for the T8, 150 hours for the T8A, and<br />

300 hours for the T8E.<br />

Mack T10A Lubricant Test<br />

This 75-hour test evaluates the ability of an<br />

engine lubricant to control its low temperature<br />

viscometrics. A prototype E-Tech engine is<br />

used. This test is required for the CI-4 category.<br />

Mack T11 Lubricant Test<br />

This 252-hour test uses a Mack prototype E-<br />

Tech engine operating at 1,800 rpm with noncondensing<br />

cooled EGR and production 2002<br />

heads, injectors and pistons, to evaluate a<br />

lubricant’s ability to limit viscosity increase with<br />

high soot loading. This test is part of Mack<br />

engine lubricant specifications EON+ 03, CI-4+<br />

and CJ-4.<br />

Mack T12 Lubricant Test<br />

This 300-hour test uses much the same<br />

hardware as the T10 test, but now has a<br />

variable geometry turbocharger and production<br />

EGR cooling heat exchangers. To simulate 2007<br />

engine operation, EGR rates are increased<br />

significantly from the T10 levels. Test objectives<br />

are the same; to minimize cylinder liner, ring and<br />

bearing wear. This test is required for the CJ-4<br />

category.<br />

Roller Follower Wear Test (RFWT)<br />

This high-soot engine test is used to evaluate<br />

how well test lubricants limit axle wear in the<br />

roller cam lifter. For the test, a 6.5-liter, eightcylinder,<br />

naturally aspirated, indirect-injection<br />

diesel engine is operated at 1,000 rpm with a<br />

high load for 50 hours. The test is required for<br />

CH-4, CI-4, and CJ-4 qualifications.<br />

Engine Oil Aeration Test (EOAT)<br />

This 20-hour test, using an International truck,<br />

7.3-liter engine running at 3,000 rpm and wideopen<br />

throttle, evaluates an engine lubricant’s<br />

resistance to aeration. This test is required for<br />

CH-4, CI-4, and CJ-4 qualifications.<br />

Cummins ISB Lubricant Test<br />

This 350-hour test uses a Cummins ISB engine<br />

and is used to evaluate a crankcase lubricant’s<br />

ability to reduce camshaft lobe and sliding cam<br />

follower wear. After an initial 100 hours of steady<br />

state operation at 1,600 rpm to accumulate 3.25<br />

percent soot in the oil, the engine is operated for<br />

250 hours on a 28-second cycle simulating front-<br />

3

end loader operation. This test is required for<br />

CJ-4 qualifications.<br />

Cummins ISM Lubricant Test<br />

This 200-hour test uses a Cummins ISM engine<br />

and is intended as a replacement test for the<br />

M11 EGR, using newer hardware. The engine<br />

has variable geometry turbo-charging,<br />

production EGR coolers and EGR valve. It<br />

evaluates a lubricant’s effectiveness at reducing<br />

soot related overhead wear, sludge and filter<br />

plugging. This test is required for CJ-4, as well<br />

as being an alternative to the M-11 EGR for the<br />

CI-4 category.<br />

Specialized Diesel Engine Testing<br />

SwRI uses many single- and multi-cylinder<br />

engines to improve the understanding of fuel,<br />

lubricant and special hardware behavior.<br />

Standard, experimental and modified test<br />

procedures are employed. The <strong>Institute</strong> offers an<br />

array of services and will prepare proposals and<br />

facilities for experimental work. Examples of<br />

developmental activities include:<br />

Railroad and Marine<br />

SwRI helps develop and conduct screening tests<br />

and procedures that correlate with large-scale<br />

tests to save time and money.<br />

Fuel Additives<br />

Using a variety of test engines, SwRI evaluates<br />

how fuel additives affect combustion deposits,<br />

fuel consumption, power loss and gain, lubricant<br />

additive reactions, etc. Fuel additive clean-up<br />

and keep-clean tests are performed on the GM<br />

6.5-liter engines.<br />

Fuel Consumption<br />

Special testing techniques are used to evaluate<br />

how lubricants or fuel property changes affect<br />

engine fuel consumption.<br />

Alternative Fuels<br />

Evaluations include optional fuels in a diesel<br />

engine and extended fuel evaluations. For<br />

example, appropriate engine and power<br />

analyses are conducted for diesel fuels mixed<br />

with alcohols or with esters of cottonseed or<br />

sunflower oil.<br />

Fuel System Wear<br />

New techniques are used to rapidly access the<br />

wear of fuel-lubricated fuel system components,<br />

especially pumps.<br />

Durability<br />

Durability evaluations are conducted around the<br />

clock under steady-state or cyclic conditions.<br />

Injector Deposit/Coking<br />

Evaluation and product experiments are<br />

developed to meet specific requirements using a<br />

range of engines and coking/deposit<br />

mechanisms.<br />

Engine Hardware<br />

Evaluations of engine hardware (pistons, rings,<br />

cylinder liners, bearings, injectors, etc.) can be<br />

tailored to meet specific requirements. Tests can<br />

include special durability procedures and<br />

evaluation of how metallurgy, surface finish, etc.<br />

affect part performance.<br />

Oil Consumption<br />

SwRI has designed specific programs to<br />

correlate oil consumption to cylinder liner finish,<br />

piston ring design, piston design, turbocharger<br />

effects or other engine parameters in any diesel<br />

engine.<br />

New Engine vs. Available Lubricants<br />

The <strong>Institute</strong> develops and conducts procedures<br />

to evaluate the compatibility of available<br />

lubricants to newly designed engines.<br />

Valve Guttering<br />

Evaluations related to this aspect of lubricant<br />

performance are available on a selection of twocycle<br />

engines. SwRI is experienced in the<br />

experimental procedures that enhance valve<br />

guttering.<br />

Destructive Evaluations<br />

Tests to find the “weakest link” are performed<br />

under maximum power or over-fuel conditions.<br />

Oil Consumption Apparatus<br />

SwRI fabricates and evaluates various oil<br />

consumption measurement devices for diesel<br />

engines.<br />

Parts Analysis<br />

Specialized equipment is used to evaluate and<br />

screen parts to understand how they can affect<br />

4

lubricant testing and to determine parts durability<br />

and predicted service life. SwRI offers<br />

metallurgical analysis, including electron<br />

microscopic analysis.<br />

Ratings<br />

<strong>Institute</strong> staff members rate pistons, rings, liners<br />

and other engine parts to industry standards.<br />

Specialized ratings, including rating procedure<br />

development, are available to meet specific or<br />

unique applications.<br />

Turbocharger Durability/Lubrication<br />

Turbocharger durability or engine lubricant<br />

suitability tests are performed for turbocharged<br />

engines.<br />

Tribology and Advanced Lubricant<br />

Evaluations<br />

Plint TE-77 Reciprocating Test Rig<br />

Standard ASTM D5706, D5707, D6079 and<br />

ISO/DIN 12156-2 procedures as well as customdesigned<br />

test services are performed using a<br />

Plint TE-77 test rig to investigate the frictional<br />

response and wear properties of materials and<br />

lubricants. Test components can be<br />

manufactured from specific materials of interest<br />

and surface finished or textured as desired.<br />

Post-test wear scar analysis and component<br />

surface film analysis provide in-depth<br />

understanding of wear.<br />

High-Pressure, -Temperature and -Frequency<br />

Reciprocating Rig<br />

A modified High-Frequency Reciprocating Rig<br />

that also provides high pressure and high<br />

temperature is used to measure the lubricity, or<br />

ability of a fluid to affect friction and wear,<br />

between surfaces in relative motion under load.<br />

The system uses an electromagnetic vibrator to<br />

oscillate a moving steel ball specimen over a<br />

small amplitude while pressing it against a<br />

stationary steel disk. This rig is capable of<br />

operating up to 300°C and high pressure,<br />

enabling testing of highly volatile fuels. ASTM<br />

D6079 and D7688 tests can also be performed.<br />

Falex Block-on-Ring Test Rig<br />

Several ASTM standard tests including D2509,<br />

D2714, D2782, D2981, D3704 and G77 as well<br />

as customized investigations are conducted<br />

using the Falex Block-on-Ring device to quantify<br />

frictional response and wear properties of<br />

materials and lubricants. Test components can<br />

be manufactured from specific materials of<br />

interest and surface finished or textured as<br />

desired. Post-test wear scar analysis and<br />

component surface film analysis provide indepth<br />

understanding of wear mechanisms.<br />

PCS Instruments Mini Traction Machine<br />

(MTM2)<br />

A PCS Instruments Mini Traction Machine is yet<br />

another method used to investigate the frictional<br />

response and wear properties of materials and<br />

lubricants. This machine utilizes a disk and<br />

ball/barrel that can be rotated at different<br />

speeds, giving slide roll rations from 0 to 100<br />

percent. The SwRI rig has been modified to<br />

allow extended temperature and load ranges.<br />

There is also a pin-on-disk attachment, disc<br />

reciprocating mode and real-time wear<br />

measurement capability.<br />

JASO Diesel Engine Lubricant<br />

Testing<br />

Mitsubishi 4D34T4 Valve Train Wear<br />

JASO M354:1999<br />

This 160-hour test evaluates wear resistance on<br />

valve operating systems for automotive diesel<br />

engine lubricants using the Mitsubishi 4D34T4<br />

engine.<br />

ASTM-TC Procedures for Two-Stroke,<br />

Air-Cooled Engines<br />

D4857-12 TC Seq. I (Y350M2 Detergency)<br />

This 20-hour test primarily evaluates a<br />

lubricant’s ability to inhibit piston ring sticking<br />

and piston deposit formation. The fuel to<br />

lubricant ratio is 50:1. The reference lubricant is<br />

run in one cylinder, and the candidate lubricant<br />

is run in the other.<br />

D4863-13 TC Seq. II (CE50S Lubricity)<br />

This test evaluates a lubricant’s ability to prevent<br />

scuffing. The fuel to lubricant ratio is 150:1.<br />

D4858-13 TC Seq. III (CE50S Pre-Ignition)<br />

This 50-hour test evaluates a lubricant’s ability<br />

to prevent damage from deposit-induced preignition.<br />

The fuel to lubricant ratio is 20:1.<br />

5

NMMA TC-W3 ®<br />

Procedures for Two-Cycle<br />

Outboard Engines<br />

CE50S Lubricity<br />

This test evaluates how effectively a lubricant<br />

prevents scuffing. The fuel to lubricant ratio is<br />

150:1.<br />

NMMA TC-W3 AF-27 Lubricity<br />

This test enhances the ability to evaluate the<br />

lubricity of lubricating oils in two-stroke cycle<br />

gasoline engines using a refinement of the<br />

JASO M340-92 and TC-W3 CE-50S lubricity<br />

tests.<br />

OMC 40 HP General Performance<br />

This 98-hour test evaluates how well lubricants<br />

inhibit piston deposits, ring sticking and general<br />

engine deposits. The fuel to lubricant ratio is<br />

100:1.<br />

OMC 70 HP Detergency<br />

This 100-hour test evaluates piston ring sticking<br />

and piston deposits associated with a special<br />

ring sticking fuel. The fuel to lubricant ratio is<br />

50:1.<br />

Mercury 15 HP Detergency<br />

This 100-hour test evaluates how well lubricants<br />

inhibit scuffing, ring sticking and wrist pin needle<br />

bearing gum. The fuel to lubricant ratio is 100:1.<br />

Pre-Ignition<br />

This 100-hour test evaluates a lubricant’s ability<br />

to prevent damage from combustion chamber<br />

deposit-induced pre-ignition. The fuel to<br />

lubricant ratio is 20:1.<br />

NMMA FC-W ® and FC-W Catalyst<br />

Compatible ® Procedures for Four-<br />

Cycle Outboard Engines<br />

NMMA FC-W 115 HP General Performance<br />

Engine Test<br />

This procedure evaluates the general<br />

performance of a four-stroke cycle water-cooled<br />

marine engine lubricant when subjected to fuel<br />

dilution levels above 7 percent during the course<br />

of operation.<br />

JASO FB, FC, FD, EGB, EGC & EGD<br />

Procedures for Two-Stroke Lubricant<br />

Engine Testing<br />

M 342-92 Smoke<br />

This eight-hour test evaluates the visible smoke<br />

level emitted from an engine exhaust system<br />

operating at 10:1 fuel to lubricant ratio.<br />

Candidate performance is evaluated against a<br />

known quality reference lubricant.<br />

M 343-92 Exhaust System Blocking<br />

This test, which is run until the exhaust system<br />

deposit formation causes a specified decrease<br />

in intake vacuum, is run at a fuel to lubricant<br />

ratio of 5:1. Typical reference test length is 8 to<br />

12 hours. Candidate performance is evaluated<br />

against a known quality reference lubricant.<br />

M 341-92 Detergency<br />

This test evaluates a lubricant for piston deposit<br />

formation and ring sticking resistance. The fuel<br />

to lubricant ratio is 100:1. Candidate<br />

performance is evaluated against a known<br />

quality reference lubricant.<br />

M 340-92 Lubricity<br />

This eight-hour test measures engine lubricant<br />

performance with minimal cooling. Candidate<br />

performance is evaluated against a known<br />

quality reference lubricant. The fuel to lubricant<br />

ratio is 50:1.<br />

M 341-02 Three-Hour Detergency<br />

This test is based on the one-hour JASO<br />

detergency test. The engine is operated at a<br />

higher temperature for the increased duration of<br />

three hours. The results are more severe than<br />

those collected during the one-hour test. The<br />

fuel to lubricant ratio is 50:1.<br />

Field Test Engine – Complete New<br />

Powerhead Inspection<br />

Post-test service is available and can include<br />

teardown, rating, photos and/or measurement if<br />

required.<br />

Field Test Engine – Block and Piston<br />

Inspection<br />

Post-test service is available and can include<br />

teardown, rating, photos and/or measurement if<br />

required.<br />

6

Component, Product and Additive<br />

Testing<br />

Engine Rating and Measurements<br />

SwRI offers a wide and varying range of engine<br />

parts rating, blueprinting and/or measurements<br />

to meet customer requirements. Engines can be<br />

removed from vehicles at the test sponsor’s site,<br />

where work is performed, and then replaced in<br />

the vehicle, or the engine can be crated and<br />

shipped to SwRI. The engines can be<br />

disassembled and the required parts rated,<br />

measured and weighed. Engines can then be<br />

reassembled and reinstalled in the vehicle or<br />

shipped to the sponsor. Any combination of<br />

parts rating/measurements and the frequency of<br />

these inspections can be arranged.<br />

Aircraft Product Testing<br />

<strong>Services</strong> include lubricant testing according to<br />

Federal Test Method 3407 “Navy Hot” and<br />

materials certification according to FAA 150-<br />

hour flight simulation test.<br />

Additive Testing<br />

The performance of fuel and lubricant additives<br />

is evaluated for improvements and/or<br />

detrimental effects. Additives with a base<br />

reference fluid can be tested per military<br />

guidelines or other <strong>Institute</strong>/client-developed<br />

techniques.<br />

Sequence Test Development<br />

When current sequence tests are inappropriate,<br />

SwRI can develop proprietary or industry-shared<br />

lubricant test techniques.<br />

Gaskets and Seals<br />

Using engine dynamometer test stands, SwRI<br />

assesses the durability of engine sealing<br />

components. These materials are analyzed for<br />

size change, deformation, leakage, corrosion,<br />

etc.<br />

Two-Stroke Cycle Tests<br />

Engine and component durability, power<br />

determination, fuel and lubricant investigation,<br />

and other specialized tests are conducted on<br />

engine dynamometer test stands.<br />

Test Equipment, Fabrication and Training<br />

Export <strong>Services</strong><br />

SwRI’s charter encourages the worldwide<br />

exchange of technology. One of the many<br />

services provided by the <strong>Institute</strong> is the design<br />

and fabrication of custom test equipment and<br />

engine dynamometer apparatus used to<br />

evaluate fuels and lubricants. This equipment is<br />

tailored for the end user’s laboratory facilities<br />

and uses state-of-the-art computer controls and<br />

electronic data acquisition. An important feature<br />

of this service is the training of the end user’s<br />

personnel in ASTM test procedures, test engine<br />

rebuild, test equipment operations and<br />

evaluation of test results. Through technology<br />

transfer, SwRI helps domestic and foreign<br />

clients meet the ever-increasing demands on<br />

petroleum and related products. With complex,<br />

fired-engine, microprocessor-controlled<br />

evaluation equipment, the <strong>Institute</strong> assists<br />

clients in new lubricant formulation. Such<br />

technology transfer requires appropriate training<br />

in the safe and proper operation of all<br />

equipment, bench tests, instruments, bench<br />

apparatus, and ancillary laboratory equipment.<br />

Natural Gas Lubricant Evaluations<br />

SwRI has utilized various engine platforms for<br />

the evaluation and study of crankcase lubricants<br />

utilizing natural gas. The evaluations include<br />

chemical analysis to measure the lubricant<br />

degradation throughout the duration of the<br />

engine test, as well as a measurement of the<br />

piston deposit formations, engine lubricant<br />

consumption and engine component durability.<br />

7

Fuels and Driveline Lubricants<br />

<strong>Research</strong> Department<br />

Mike Lochte, Director .................................................................................. (210) 522-5430<br />

Brent Shoffner, Manager, Fuels Performance Evaluations .......................................... (210) 522-6986<br />

Larry Eckhard, Manager, Fleet and Field Evaluations ................................................. (210) 522-2980<br />

Matt Jackson, Manager, Specialty and Driveline Fluid Evaluations ............................. (210) 522-6981<br />

8

Fuels and Driveline<br />

Lubricants <strong>Research</strong><br />

Department<br />

Mike Lochte, Director<br />

(210) 522-5430<br />

Brent Shoffner, Manager<br />

Fuels Performance Evaluations<br />

(210) 522-6986<br />

Larry Eckhard, Manager<br />

Fleet and Field Evaluations<br />

(210) 522-2980<br />

Matt Jackson, Manager<br />

Specialty and Driveline Fluid Evaluations<br />

(210) 522-6981<br />

Transmission Fluid Testing<br />

General Motors Automatic<br />

Transmission Fluids Testing<br />

SwRI conducts the following procedures<br />

associated with the General Motors automatic<br />

transmission service fill fluid specification,<br />

DEXRON ® -VI.<br />

DEXRON ® -VI Chemical and Bench Tests<br />

(DEXRON ® -VI Items A-M, and O-U)<br />

These procedures include tests to evaluate<br />

automatic transmission fluids for color,<br />

elemental content, fluid profile, miscibility,<br />

density, high- and low-temperature viscosity,<br />

flash and fire points, copper strip corrosion, antifoaming<br />

properties, corrosion and rust<br />

protection, film thickness, and effects on seals.<br />

DEXRON ® -VI Oxidation Test<br />

This test is run with an electric motor-driven<br />

General Motors Powertrain 4L60-E automatic<br />

transmission. The 450-hour test is used to<br />

determine the oxidation resistance, thermal<br />

stability, and corrosion protection characteristics<br />

of a fluid.<br />

DEXRON ® -VI Cycling Test<br />

This procedure determines the performance of<br />

an automatic transmission fluid with respect to<br />

frictional stability, viscosity stability, lubricating<br />

properties, oxidation resistance, and corrosion<br />

protection. The test is run for 42,000 cycles in a<br />

V-8 engine-driven General Motors 4L60E<br />

automatic transmission.<br />

DEXRON ® -VI Plate Clutch Friction Test<br />

Using the SAE No. 2 Friction Test Machine, this<br />

test determines the friction characteristics and<br />

durability of an automatic transmission fluid with<br />

plate clutch operation. Fluids must provide<br />

satisfactory performance for 200 hours (36,000<br />

cycles) of continuous operation.<br />

DEXRON ® -VI Wear Test<br />

This test determines the anti-wear properties of<br />

automatic transmission fluids using an electric<br />

motor-driven model 104C hydraulic pump. Antiwear<br />

performance is determined by measuring<br />

the weight loss of the pump’s vanes and cam<br />

ring after 100 hours of continuous operation.<br />

DEXRON ® -VI Aeration Test<br />

The DEXRON ® -VI Aeration Test Rig utilizes a<br />

VTi pump, operated under load, to determine the<br />

air entrainment and density properties of<br />

automatic transmission fluid as a function of<br />

temperature.<br />

DEXRON ® -VI Low Speed Clutch Friction and<br />

Torque Capacity Test<br />

The DEXRON ® -VI Low Speed Clutch and<br />

Torque Capacity Test Rig utilizes a 30 hp<br />

variable speed electric drive that provides input<br />

power to a Greening SAE No. 2 Universal Wet<br />

Friction Material Test Machine through a speedreducing<br />

gearbox. The purpose of the test is to<br />

determine the torque capacity and shudder<br />

tendency of automatic transmission fluid on<br />

torque converter carbon fiber friction material at<br />

low rotational speeds.<br />

Ford Automatic Transmission Fluid<br />

Testing<br />

SwRI conducts the following Ford Motor<br />

Company automatic transmission service fill fluid<br />

MERCON ® V specification procedures:<br />

MERCON ® V Chemical and Bench Tests<br />

(MERCON ® V items 3.1 thru 3.7, 3.9 and 3.10)<br />

These procedures evaluate automatic<br />

transmission fluids for miscibility, high- and lowtemperature<br />

viscosity, color, flash point, copper<br />

strip corrosion, corrosion and rust protection,<br />

cleanliness level, anti-foaming properties and<br />

elastomer compatibility.<br />

9

MERCON ® V Wear Tests<br />

The anti-wear properties of an automatic<br />

transmission fluid are determined by the Vickers<br />

Vane Pump Wear Test, FZG Wear Test, Four-<br />

Ball Wear Test, Falex EP Test, and Timken<br />

Wear Test.<br />

MERCON ® V Aluminum Beaker Oxidation<br />

Test (ABOT)<br />

This bench test determines the oxidation stability<br />

of automatic transmission fluids in the presence<br />

of materials used in automatic transmissions.<br />

The 300-hour test is conducted in an aluminum<br />

beaker heated by an aluminum block test fixture.<br />

MERCON ® V Clutch Friction Durability Test<br />

This test determines the static and dynamic<br />

torque capacity of an automatic transmission<br />

fluid when new and after 30,000 cycles of<br />

continuous operation. The test uses the SAE<br />

No. 2 Friction Test Machine.<br />

MERCON ® V Anti-Shudder Durability<br />

The MERCON ® SP Anti-Shudder Durability<br />

(ASD) Test Rig utilizes a Greening SAE No. 2<br />

Universal Wet Friction Test Machine test head,<br />

operated to determine the frictional<br />

characteristics of a fluid through high-speed<br />

clutch engagements, low-speed aging and<br />

torque sweeps, as well as static breakaway<br />

measurements. A copper coupon is immersed in<br />

the test fluid, which is pumped into the test head<br />

along with instrument air.<br />

Ford Over-Running Clutch (AX4N OWC)<br />

Wear Test Procedure<br />

The goal of this test is to determine the ability of<br />

a fluid to protect the inner race of the<br />

overrunning clutch in a free-wheeling situation.<br />

The test result will be “no trenching” (inner race<br />

intact) or “trenching” (rollers have worn a visible<br />

grove in the inner race).<br />

Allison Severe Duty, Extended Drain<br />

Interval Automatic Transmission<br />

Fluid Testing<br />

SwRI evaluates automatic transmissions for<br />

severe duty and extended drain interval use<br />

according to the Allison Transmission TES-295<br />

specification.<br />

Allison TES-295 Chemical and Bench Tests<br />

These tests evaluate fluids for elemental<br />

content, infrared spectrum, viscosity, flash point,<br />

fire point, foam resistance, copper strip<br />

corrosion, corrosion and rust protection, and<br />

elastomer compatibility.<br />

Allison TES-295 Oxidation Test<br />

This test is conducted using an electric motordriven<br />

GM 4L60-E transmission. The 600-hour<br />

test is used to determine the oxidation<br />

resistance, thermal stability and corrosion<br />

protection characteristics of a fluid.<br />

Allison TES-295 Wear Tests<br />

These tests asses the antiwear performance of<br />

a fluid utilizing the ASTM D5182 gear scuffing<br />

wear test and a modified version of the ASTM<br />

D7043 vane pump wear test.<br />

Allison TES-295 Frictional Properties Tests<br />

Utilizing the SAE No. 2 Friction Test Machine,<br />

these tests assess the friction and durability<br />

characteristics of a fluid utilizing two friction<br />

materials. The graphitic material is evaluated for<br />

5,500 continuous test cycles. The paper<br />

material is evaluated for 30,000 continuous<br />

cycles.<br />

Allison On-Highway Automatic<br />

Transmission Fluid Testing<br />

SwRI evaluates automatic transmissions for onhighway<br />

use according to the Allison<br />

Transmission TES-389 specification.<br />

Allison TES-389 Chemical and Bench Tests<br />

These tests evaluate fluids for color, elemental<br />

content, flash point, cleanliness, miscibility,<br />

water content, viscosity, shear stability, copper<br />

strip corrosion, corrosion and rust protection,<br />

foam resistance and elastomer compatibility.<br />

Allison TES-389 Wear Test<br />

This test determines the anti-wear properties of<br />

a fluid using an electric motor-driven model<br />

104C hydraulic pump. Antiwear performance is<br />

determined by measuring the weight loss of the<br />

pump’s vanes and cam ring after 100 hours of<br />

continuous operation.<br />

Allison TES-389 Oxidation Resistance Test<br />

This 300-hour test determines the oxidation<br />

resistance, thermal stability and corrosion<br />

10

protection characteristics of a fluid through a<br />

modified aluminum beaker oxidation test<br />

procedure.<br />

Allison TES-389 Friction Tests<br />

These tests utilize the SAE No. 2 Friction Test<br />

Machine to assess the friction characteristics<br />

and durability of a fluid. Fluids are evaluated<br />

using two different friction materials, each for<br />

150 hours.<br />

Allison Heavy-Duty Automatic<br />

Transmission Fluid Testing<br />

SwRI evaluates heavy-duty diesel engine<br />

lubricants and higher viscosity automatic<br />

transmission fluids according to the Allison<br />

Transmission TES-439 Off-Highway<br />

Transmission Fluid Specification.<br />

Allison TES-439 Chemical and Bench Test<br />

These tests evaluate fluids for elemental<br />

content, total acid number, flash point, high- and<br />

low-temperature viscosity, antifoaming<br />

properties, copper strip corrosion, corrosion and<br />

rust protection, glycol response and elastomeric<br />

compatibility.<br />

Allison TES-439 Oxidation Test<br />

This 300-hour test determines the oxidation<br />

resistance, thermal stability and corrosion<br />

protection characteristics of fluids. This test is<br />

conducted as a modified aluminum beaker<br />

oxidation test.<br />

Allison TES-439 Graphite High-Energy<br />

Friction Test<br />

Using the SAE No. 2 Friction Test Machine, the<br />

friction characteristics and durability of fluids are<br />

determined on heavy-duty graphite clutch plates.<br />

Fluids must provide satisfactory performance for<br />

5,500 cycles of continuous operation.<br />

JASO SAE #2 Testing<br />

JASO T903:2011 and M348:2002 Clutch<br />

Friction Test<br />

These tests determine a fluid’s friction<br />

characteristics and durability. The procedures<br />

simulate satisfactory performance in a normally<br />

functioning transmission under service<br />

conditions. Performance of these tests requires<br />

the SAE No. 2 Friction Test Machine. Test<br />

duration is 1,000 cycles for T903:2011 and<br />

5,000 cycles for M348:2002. Clutches are<br />

engaged once each cycle and absorb 24,500<br />

joules of total energy. Fluid temperature is<br />

maintained at 100°C. The steel and composition<br />

plates are evaluated. Both test procedures are<br />

considered “modified,” as they are conducted<br />

using a sump size of 750 ml.<br />

Caterpillar Transmission and<br />

Drivetrain Fluid Testing<br />

SwRI conducts the following Caterpillar, Inc.,<br />

powershift transmission and drivetrain fluid test<br />

procedures:<br />

TO-4 Physical Properties<br />

These tests evaluate fluids for homogeneity,<br />

fluid compatibility, foaming characteristics,<br />

humidity, corrosion, copper corrosion, lowtemperature<br />

storage, flash and fire points, pour<br />

point and water content.<br />

TO-4 Elastomer Compatibility<br />

These tests evaluate compatibility with<br />

fluoroelastomer compounds, seals, O-rings and<br />

other elastomeric materials.<br />

TO-4 Oxidation Stability<br />

This 300-hour test determines the oxidation<br />

resistance, thermal stability, and corrosion<br />

protection characteristics of fluids. This test,<br />

conducted with an electric motor-driven 4L60-E<br />

automatic transmission, is similar to the test<br />

specified by DEXRON ® -II(E).<br />

TO-4 Gear Wear Test (ASTM D4998)<br />

Using the FZG rig, the gear-wear protection<br />

provided by lubricants is evaluated according to<br />

ASTM D4998.<br />

TO-4 Pump Wear Test<br />

This test evaluates the anti-wear characteristics<br />

of hydraulic fluids by measuring cam ring and<br />

vane weight loss for a 35VQ25A pump. The<br />

pump operates for 50 hours at an outlet<br />

pressure of 3,000 psi and an inlet fluid<br />

temperature of 203°F. This test is the same as<br />

the Vickers (Eaton) 35VQ25A wear test. The<br />

first three or four of five tests must pass.<br />

TO-4 Friction Properties<br />

Using six different materials and seven total<br />

tests, the frictional characteristics of lubricating<br />

fluids are evaluated using the Link Engineering<br />

Model M1158 Test Machine.<br />

11

Hydraulic Fluid Testing<br />

DIN 51389-2 Vane Pump Wear Test<br />

The purpose of this test is to determine the antiwear<br />

properties of hydraulic fluids. The fluid is<br />

run through an electric-driven vane pump for<br />

250 hours at an inlet temperature selected to<br />

maintain a kinematic viscosity of 13 mm 2 /sec.<br />

The pump components are weighed before and<br />

after the test. Weight loss determines the fluid<br />

performance.<br />

Conestoga Pump Test (ASTM D7043)<br />

The purpose of this test is to determine the antiwear<br />

properties of hydraulic fluids. The fluid is<br />

run through an electric-driven Model 104C<br />

hydraulic pump for 100 hours. The pump’s<br />

vanes and cam ring are weighed before and<br />

after the test. Weight loss determines the fluid<br />

performance.<br />

Eaton 35VQ25A Pump Test<br />

This test evaluates the anti-wear characteristics<br />

of hydraulic fluids by measuring cam ring and<br />

vane weight loss for a 35VQ25A pump. The<br />

pump operates for 50 hours at an outlet<br />

pressure of 3,000 psi and an inlet fluid<br />

temperature of 203°F. This test is the same as<br />

the Vickers 35VQ25A wear test. The first three<br />

or four of five tests must pass.<br />

Denison T6H20C Hybrid Pump - Phase I<br />

Denison T6H20C Hybrid Pump - Phase II<br />

These tests sponsored by Denison evaluate the<br />

effect of hydraulic fluid on flow, pressure loss<br />

and wear using a hybrid T6H style piston and<br />

vane pump run near rated conditions. The tests<br />

are made up of a break-in phase, a dry fluid<br />

testing phase (no water added), and a wet fluid<br />

(water added) testing phase. The dry and wet<br />

phases are a little over 300 hours long each and<br />

are priced separately. These are cyclic tests with<br />

the outlet pressures for both pumps changing<br />

every two seconds. The same test pump is used<br />

for both wet and dry phases.<br />

Manual Transmission and Rear Axle<br />

Gear Lubricant Performance Testing<br />

Required bench and performance tests are<br />

conducted to qualify automotive gear lubricants<br />

under various specifications. Numerous other<br />

test procedures for the lubricant and additive<br />

industries may be conducted, as well as custom<br />

programs tailored to clients’ individual needs.<br />

L-20 High-Torque Test<br />

This test determines the load-carrying, wear,<br />

and extreme pressure characteristics of gear<br />

lubricants under low-speed, high-torque<br />