Introduction To The SERCOS interface⢠- Sercos N.A.

Introduction To The SERCOS interface⢠- Sercos N.A.

Introduction To The SERCOS interface⢠- Sercos N.A.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

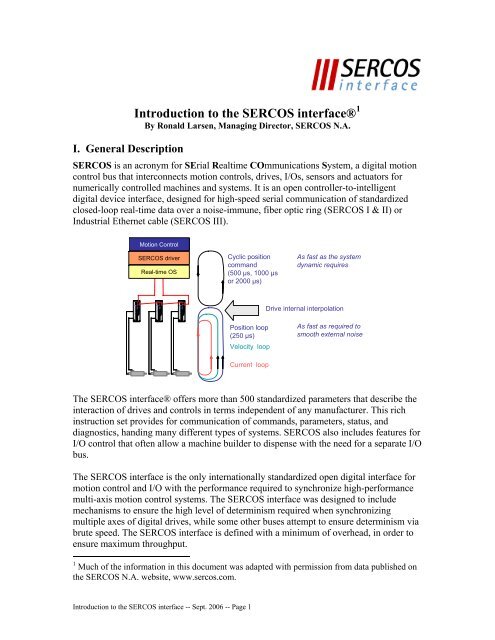

I. General Description<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface® 1<br />

By Ronald Larsen, Managing Director, <strong>SERCOS</strong> N.A.<br />

<strong>SERCOS</strong> is an acronym for SErial Realtime COmmunications System, a digital motion<br />

control bus that interconnects motion controls, drives, I/Os, sensors and actuators for<br />

numerically controlled machines and systems. It is an open controller-to-intelligent<br />

digital device interface, designed for high-speed serial communication of standardized<br />

closed-loop real-time data over a noise-immune, fiber optic ring (<strong>SERCOS</strong> I & II) or<br />

Industrial Ethernet cable (<strong>SERCOS</strong> III).<br />

Motion Control<br />

<strong>SERCOS</strong> driver<br />

Real-time OS<br />

Cyclic position<br />

command<br />

(500 µs, 1000 µs<br />

or 2000 µs)<br />

As fast as the system<br />

dynamic requires<br />

Drive internal interpolation<br />

Position loop<br />

(250 µs)<br />

Velocity loop<br />

As fast as required to<br />

smooth external noise<br />

Current loop<br />

<strong>The</strong> <strong>SERCOS</strong> interface® offers more than 500 standardized parameters that describe the<br />

interaction of drives and controls in terms independent of any manufacturer. This rich<br />

instruction set provides for communication of commands, parameters, status, and<br />

diagnostics, handing many different types of systems. <strong>SERCOS</strong> also includes features for<br />

I/O control that often allow a machine builder to dispense with the need for a separate I/O<br />

bus.<br />

<strong>The</strong> <strong>SERCOS</strong> interface is the only internationally standardized open digital interface for<br />

motion control and I/O with the performance required to synchronize high-performance<br />

multi-axis motion control systems. <strong>The</strong> <strong>SERCOS</strong> interface was designed to include<br />

mechanisms to ensure the high level of determinism required when synchronizing<br />

multiple axes of digital drives, while some other buses attempt to ensure determinism via<br />

brute speed. <strong>The</strong> <strong>SERCOS</strong> interface is defined with a minimum of overhead, in order to<br />

ensure maximum throughput.<br />

1 Much of the information in this document was adapted with permission from data published on<br />

the <strong>SERCOS</strong> N.A. website, www.sercos.com.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 1

<strong>The</strong> <strong>SERCOS</strong> interface greatly reduces connectivity problems in control systems. It can<br />

connect up to 254 drives to a control using one fiber optic cable ring or a single daisychained<br />

Industrial Ethernet cable, and multiple rings may be used in a system.<br />

Control unit<br />

Master 1<br />

Ring 1<br />

max. 254 drives<br />

Master 2<br />

Ring 2<br />

max. 254 drives<br />

Slave Slave Slave<br />

Single<br />

Drive<br />

Group of<br />

Drives<br />

Single<br />

Drive<br />

Slave<br />

Single<br />

Drive<br />

Slave<br />

Group of<br />

Drives<br />

A comparable traditional analog servo system with 8 axes of motion may require over<br />

100 wires between the drive and control. This reduces system cost, eliminates many types<br />

of noise problems and helps machine designers get motion control systems up and<br />

running quickly.<br />

<strong>The</strong> <strong>SERCOS</strong> interface was created in the 1980s by a group of European machine tool<br />

builders and control/drive vendors to specify a digital open interface that would ease the<br />

transition from analog to digital drive technology. It was originally intended to be a drive<br />

interface for advanced machine tool applications, but today is in wide use in all servocontrolled<br />

automation disciplines. <strong>The</strong> <strong>SERCOS</strong> interface standard covers control topics<br />

that are common to all servo applications, as well as topics that are industry specific. It is<br />

estimated that the majority of <strong>SERCOS</strong> interface axes in the field today are on<br />

applications such as web-fed printing presses; packaging, converting & food processing<br />

machines; assembly, handling and robots; semiconductor processing equipment;<br />

metalforming and welding machines; textile processing; fiber winding; simulators and<br />

test equipment; plastics machines and many other types of special machines.<br />

II. <strong>SERCOS</strong> interface is an International Standard<br />

<strong>The</strong> <strong>SERCOS</strong> interface is a set of standard specifications that may be incorporated into<br />

any company’s products, with each control and drive maintaining its own functions and<br />

features. Because it is an international IEC standard, it allows any manufacturer’s<br />

<strong>SERCOS</strong> interface-compatible digital control to talk to any other <strong>SERCOS</strong> interfacecompatible<br />

digital servo drive, digital spindle drive, hydraulic system, digital I/O or<br />

sensors over a well-defined fiber optic link or standard Ethernet technology. Controls and<br />

drives conforming to the standard comply with a standard medium for transmission,<br />

topology, connection techniques, signal levels, message (telegram) structures, timing and<br />

data formats.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 2

III. Three Generations of the <strong>SERCOS</strong> interface<br />

<strong>The</strong>re have been three generations of the <strong>SERCOS</strong> interface:<br />

• <strong>The</strong> first generation – <strong>SERCOS</strong> I -- operated at 2 and 4 Mbit/sec, using the<br />

SERCON410B ASIC and fiber optic transmitters/receivers and cabling. <strong>The</strong><br />

SERCON410B is no longer produced.<br />

• <strong>The</strong> second (current) generation – <strong>SERCOS</strong> II -- operates at 2/4/8/16 Mbit/sec, using<br />

the SERCON816 ASIC and fiber optics. <strong>The</strong> SERCON816 is downward compatible<br />

with the SERCON410B.<br />

• <strong>The</strong> new third generation – <strong>SERCOS</strong> III -- operates at up to 100 Mbit/sec utilizing a<br />

Field Programmable Gate Array (FPGA) or a General Purpose Communication<br />

Controller (GPCC) and is based on standard Industrial Ethernet hardware. <strong>SERCOS</strong><br />

III maintains backward compatibility with previous versions in regard to profiles,<br />

synchronization, message structures and the standardized parameter set that describes<br />

all aspects of real-time motion and I/O control.<br />

More than 50 control manufacturers and 30 drive manufacturers worldwide offer first and<br />

second generation <strong>SERCOS</strong> interface products, with hundreds of thousands of systems<br />

installed. Several manufacturers offer <strong>SERCOS</strong> interface I/O stations plus hardware and<br />

software development tools. <strong>The</strong> first <strong>SERCOS</strong> III products were introduced in late 2005<br />

and 2006, with many more in development.<br />

IV. Functions of the <strong>SERCOS</strong> interface<br />

• Exchanges data between control and drives, transmitting command and actual<br />

values with extremely short cycle times.<br />

• Guarantees exact synchronization for precise coordinated moves with as many<br />

axes as required.<br />

• Supports four operating modes: torque, velocity, position control and block<br />

mode. <strong>The</strong> transmission of nominal position has proven to be the best solution for<br />

fast, highly precise applications.<br />

• Includes a service channel for non-cyclic data transmission, such as internal<br />

parameters, data and diagnostics. A complete set of drive parameters can be<br />

downloaded and uploaded for storage via the service channel.<br />

• Enables the use of controls and drives from different manufacturers in a system,<br />

by standardizing all data, parameters, commands and feedbacks exchanged<br />

between drives and controls.<br />

V. Advantages<br />

<strong>The</strong> <strong>SERCOS</strong> interface allows drive and control manufacturers to create intelligent<br />

digital drives with vastly improved capabilities and flexibility. A single drive can be<br />

designed to handle multiple motors, such as permanent magnet servomotors, high<br />

horsepower induction servomotors (vector drives) and linear motors, with the<br />

configuration set-up parametrically.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 3

Types of products using the <strong>SERCOS</strong> interface include:<br />

• AC and DC servo positioning drives<br />

• Spindle and main drives<br />

• Stepper indexer/drives<br />

• Vector drives<br />

• Linear motor drives<br />

• Inverters/variable frequency drives<br />

• Multi-axis motion controllers<br />

• I/O modules<br />

• PLC interfaces<br />

• Numerical controls<br />

• Electrohydraulic valves and positioning systems<br />

<strong>The</strong> <strong>SERCOS</strong> interface provides the flexibility of configuring multi-vendor control<br />

systems with plug and play interoperability. Designers are not limited to products from<br />

one manufacturer, but are free to choose the best-in-breed to solve their individual motion<br />

and I/O control problems.<br />

<strong>The</strong> <strong>SERCOS</strong> interface reduces system cost, eliminates many types of noise problems<br />

and helps machine designers get motion control systems up and running quickly.<br />

Even more importantly, the <strong>SERCOS</strong> interface has facilitated great advances in machine<br />

productivity. End users have realized incredible timesaving advantages with <strong>SERCOS</strong> on<br />

their machines -- faster delivery, faster installation, faster setup, faster product<br />

changeover, and faster production speeds.<br />

VI. <strong>SERCOS</strong> III<br />

Industrial Ethernet has become the de facto standard for manufacturing information<br />

networking, and the market is requesting Ethernet connectivity for servo drives. <strong>The</strong><br />

problem is that Industrial Ethernet is characterized by high bandwidth and low hardware<br />

costs, but is not deterministic.<br />

<strong>The</strong> <strong>SERCOS</strong> interface, on the other hand, is optimized for high-speed deterministic<br />

motion control, which is required for the exact synchronization of multiple drives.<br />

<strong>SERCOS</strong> also defines a protocol structure and includes an ample variety of profile<br />

definitions for control for most motion and I/O devices. It has been successfully used on<br />

over 300,000 applications. <strong>SERCOS</strong> III combines the proven mechanisms and properties<br />

of the original <strong>SERCOS</strong> interface with the high speed and low cost of the Industrial<br />

Ethernet physics, thus creating an advanced version of the most successful open motion<br />

control communications interface.<br />

Many technologies have been added to the Ethernet stack simply by adding a new<br />

protocol. But rather than put motion under TCP/IP (transmission control protocol-<br />

/Internet protocol), resulting in less determinism and the added expense of switching<br />

devices, the <strong>SERCOS</strong> solution was to put the standard Ethernet TCP/IP under control of<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 4

the motion bus, and use Ethernet hardware with its lower cost twisted-pair copper cable.<br />

(However, Ethernet fiber optics will be supported by <strong>SERCOS</strong> III.)<br />

This maintains the deterministic motion control of <strong>SERCOS</strong>, allows links to the existing<br />

manufacturing communications infrastructure, provides for the possibility of new features<br />

and lowers hardware costs. And noise immunity will not be a major problem, as<br />

Ethernet’s twisted pair cable is generally extremely noise immune because it uses a<br />

differential driver and receiver.<br />

<strong>SERCOS</strong> III offers the following advantages:<br />

• Protection of investment due to high compatibility with previous <strong>SERCOS</strong><br />

interface (topology, profiles, telegram structures, synchronization)<br />

• Reduction of hardware costs for a <strong>SERCOS</strong> III interface connection down to the<br />

level of an analog interface<br />

• Integration of IP protocols<br />

• Cross communication between slaves<br />

• Synchronization of several motion controls<br />

• A double ring structure with regard to signal flow for fault tolerance in case of a<br />

break in the ring<br />

• Hot plugging for connection and removal of nodes during operation<br />

• Safe communication for drive-integrated safety functions<br />

• Half the minimum cycle time of the previous <strong>SERCOS</strong> interface (31.25 μs vs 62.5<br />

μs)<br />

VII. How the <strong>SERCOS</strong> interface Works<br />

A. <strong>To</strong>pology<br />

Components in a generation I and II <strong>SERCOS</strong> interface-based motion control system are<br />

connected via fiber optic rings using a master/slave configuration. A typical system may<br />

include several rings, with up to 254 devices per ring. A <strong>SERCOS</strong> interface master<br />

controls each ring, assigning timeslots to ensure deterministic and collision-free access<br />

for all slaves.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 5

<strong>SERCOS</strong> I and II <strong>To</strong>pology<br />

<strong>SERCOS</strong> III communicates over industrial Ethernet and offers both a line and ring<br />

logical structure within the cable. <strong>The</strong> double ring structure offers the possibility of<br />

redundant data transfer. With <strong>SERCOS</strong> III, in case of a break at any point in the ring, the<br />

protocol automatically switches over to the line structure, so that the communication and<br />

manufacturing will continue while the integrated diagnostics tool signals the break, which<br />

can be repaired without interfering with the plants’ performance.<br />

<strong>SERCOS</strong> III doesn’t use the star topology of the standard Ethernet. No hubs or switches<br />

are needed.<br />

Ring structure<br />

(double ring)<br />

M1<br />

Master<br />

M2<br />

Line structure<br />

(single ring)<br />

M1<br />

Master<br />

M2<br />

Slave<br />

1<br />

Slave<br />

2<br />

Slave<br />

n<br />

Slave<br />

1<br />

Slave<br />

2<br />

Slave<br />

n<br />

With hardware redundancy<br />

<strong>SERCOS</strong> III <strong>To</strong>pologies<br />

Without hardware redundancy<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 6

B. Communications Structure<br />

In order to ensure strict synchronization of multiple axes and a predictable update time at<br />

each axis, the <strong>SERCOS</strong> interface utilizes a master/slave communication structure, where<br />

the motion control acts as a master, the drives act as slaves. <strong>SERCOS</strong> I and II drives are<br />

only permitted to respond to queries from the motion control, so direct communication<br />

between slaves isn’t possible. However, this feature is advantageous in some motion<br />

control applications and the Ethernet physics enable such a slave-to-slave data transfer,<br />

so <strong>SERCOS</strong> III supports this feature.<br />

C. Physical Layer<br />

With <strong>SERCOS</strong> I and II one fiber optic ring is used to exchange full 32-bit data between<br />

controllers, drives, I/O and sensors. This includes commands, status, parameters and<br />

diagnostics. In <strong>SERCOS</strong> III, standard industrial Ethernet is used for this purpose. Note<br />

that Ethernet fiber optics can be used for communication with <strong>SERCOS</strong> III.<br />

D. Communications Controllers<br />

ASIC (<strong>SERCOS</strong> I & II) or FPGA or GPCC (<strong>SERCOS</strong> III)-based <strong>SERCOS</strong> interface<br />

controllers are normally integrated into master motion controls as well as drives,<br />

amplifiers and I/O modules. <strong>The</strong>y simplify the task of the designer by automatically<br />

handling most <strong>SERCOS</strong> interface communication functions.<br />

E. Timing<br />

Timing is critical in serial networks because motion controls cannot accurately<br />

reconstruct the state of the machine unless everything is precisely synchronized –<br />

measurements, transmissions and replies. Many of the messages that controls and drives<br />

send each other are for timing and synchronization.<br />

In CNC position loop software, the position error is determined in a software routine that<br />

takes time. <strong>The</strong> system works because the position error updates are designed to occur at<br />

predictable points in time. <strong>The</strong> same logic is applied in the <strong>SERCOS</strong> interface. Methods<br />

are specified to keep the jitter on the serial link down to a low level, then an internal<br />

timing sequence is used to ensure that all drives in a loop act upon their command signal<br />

at the exact same moment, and all acquire their feedback information at the exact same<br />

moment. <strong>The</strong> result is transparent to the user.<br />

F. <strong>SERCOS</strong> interface IDNs<br />

All motion control and drive communication is performed via a set of <strong>SERCOS</strong> interface<br />

telegrams, which each have an identification, or “Ident” (IDN) number. All parametric<br />

data, such as scaling and loop gains, and real-time loop closure information is set up this<br />

way. This allows the <strong>SERCOS</strong> interface to standardize the most common interface data.<br />

Over 500 IDNs are presently used to define a comprehensive set of motion control and<br />

I/O commands. All <strong>SERCOS</strong> interface products must incorporate a subset of these, but<br />

do not necessarily need to include all IDNs.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 7

<strong>The</strong> format used for an IDN plus a sample IDN are shown in the following illustration.<br />

IDN<br />

Name (abbreviation)<br />

Function/description<br />

Length in bytes<br />

Minimum input value<br />

Maximum input value<br />

Scaling/resolution<br />

Units<br />

S-00047<br />

Position command value<br />

During the position control drive operation mode, the position command values are transferred<br />

from the control unit to the drive according to the time pattern of the control unit cycle.<br />

4 Min. ≥ -2 31<br />

Max. ≤ +2 31 -1<br />

Scaling type: IDN00076<br />

Scaling factor: IDN 00077<br />

Scaling exponent: IDN 00078<br />

Rotational position resolution: IDN 00079<br />

G. Cycle Times<br />

<strong>The</strong> <strong>SERCOS</strong> interface cycle time is specified in a flexible format of 62.5 microseconds,<br />

125, 250, 500, and then multiples of 1 millisecond. <strong>SERCOS</strong> III cycle times begin at<br />

31.25 microseconds. <strong>The</strong> amount & type of data contained in a cycle is also variable.<br />

This flexibility permits a designer to vary cycle time, content and number of drives to<br />

achieve a particular project’s requirements. More data can be sent faster to a smaller<br />

number of drives. Slowing the rate down permits a higher density of drives per ring. For<br />

example, with generations I and II, 4 to 8 axes are common on a ring in machine tool<br />

applications where intense communication is required to control a high-speed tool path.<br />

Up to 40 axes may be controlled on a ring in packaging applications, and up to 100 axes<br />

may be found in web-fed printing applications, where electronic line shafting is utilized<br />

to synchronize a number of print cylinders and auxiliary axes. When necessary, multiple<br />

rings can be employed in an application.<br />

H. Error Correction/Diagnostics<br />

<strong>The</strong> <strong>SERCOS</strong> interface offers extensive diagnostic reporting and produces detailed<br />

reports on fault conditions. This allows vendors to incorporate detailed context-sensitive<br />

troubleshooting procedures in their motion controls. An operator can go to his control<br />

panel and acquire instant diagnosis of every axis motor and drive at every section of the<br />

machine. Failures can be immediately pinpointed by the control system and quickly and<br />

easily be repaired as opposed to hit and miss troubleshooting.<br />

I. Service and IP Channels<br />

Generations I and II <strong>SERCOS</strong> interface include a service channel, which can be used for<br />

the transfer of communication data as well as parameter or diagnostic data in non-realtime.<br />

<strong>To</strong> maintain downward compatibility, <strong>SERCOS</strong> III also has the service channel.<br />

<strong>SERCOS</strong> III also offers an optional IP channel for transfer of real-time and non-real-time<br />

data via standard Ethernet frames. <strong>The</strong> service channel and IP channel are configurable.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 8

VIII. Differences and Similarities with other Communication Busses<br />

Fieldbus protocols (DeviceNet, Profibus and others) were designed for I/O and are<br />

intended for low-level devices -- such as sensors, motor starters and inverters -- which are<br />

mainly turned on and off, or which require an asynchronous analog command value. A<br />

number of these busses can be used for control of loosely coupled drives – but motion<br />

control is not their primary function.<br />

On the other hand, the <strong>SERCOS</strong> interface was designed for high-speed control of tightly<br />

coupled motion axes, where deterministic control is of high importance. In a high-speed<br />

packaging line or multi-axis machine tool, sub-microsecond synchronization accuracy of<br />

multiple axes in the system is required.<br />

Although the <strong>SERCOS</strong> interface was not designed primarily to be a fieldbus, it has the<br />

ability to decentralize I/O via multiple I/O nodes that connect to the field devices. <strong>The</strong><br />

I/O requirements may be satisfied via the <strong>SERCOS</strong> interface, negating the need for a<br />

separate fieldbus. However, in high-power applications, such as flexible machine<br />

systems, both a fieldbus and <strong>SERCOS</strong> interface often exist in the same control system.<br />

<strong>The</strong> decision of whether to use a fieldbus, <strong>SERCOS</strong> interface, or both, depends on the<br />

application. If only loose coupling between axes is required, a series of single-axis<br />

position drives connected via a fieldbus may be adequate. However, in a synchronized<br />

motion application, the <strong>SERCOS</strong> interface is required; and I/O can be handled over the<br />

<strong>SERCOS</strong> interface, depending on the requirements and complexity of the system. A<br />

number of manufacturers offer <strong>SERCOS</strong> interface I/O systems.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 9

This figure illustrates a system with communication to a higher-level factory network, a fieldbus<br />

for I/O and the <strong>SERCOS</strong> II interface for real-time motion control.<br />

XI. Conformance Testing for <strong>SERCOS</strong> interface Products<br />

Products with the <strong>SERCOS</strong> interface are tested at the Institute for Control Engineering of<br />

Machine <strong>To</strong>ols and Manufacturing Units (ISW) at the University of Stuttgart. <strong>The</strong> aim of<br />

the conformance test is to ensure the compatibility and interoperability of <strong>SERCOS</strong><br />

interface devices from different vendors in multiple vendor environments. Testing to the<br />

<strong>SERCOS</strong> I & II Conformance Class A and B levels, plus testing for conformance to the<br />

<strong>SERCOS</strong> Packaging Profile, are presently available. Conformance tests for <strong>SERCOS</strong> III<br />

are now in development.<br />

Only products that have passed the conformance test are allowed to carry<br />

the <strong>SERCOS</strong> Conformance-tested logo.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 10

X. Ideal for Distributed Multi-axis Control Systems<br />

<strong>The</strong> <strong>SERCOS</strong> interface is a foundation for building distributed multi-axis control systems<br />

for a myriad of applications. Distributed control improves machine flexibility by moving<br />

processing power and decision making from the CNC or motion control down into the<br />

drives and sensors. <strong>The</strong>se devices then become intelligent building blocks that can easily<br />

be added to a machine or production line without major changes in hardware and<br />

software.<br />

<strong>The</strong> <strong>SERCOS</strong> interface is well suited for distributed control because it places axisdependent<br />

control functions, such as loop closures, interpolation and registration, in the<br />

drives, not in the motion controller. Thus, motion controllers can concentrate on motion<br />

control profiles and toolpaths independent of the axes. In operation, the control issues a<br />

position command to the drive, which then closes its own loops and micro-interpolates its<br />

trajectory, based on previously downloaded parameters. <strong>The</strong> <strong>SERCOS</strong> interface also<br />

integrates input/output functions such as limit switches, pushbuttons and various sensors.<br />

XI. <strong>SERCOS</strong> interface Packaging Profile<br />

Packaging applications have benefited greatly from the adoption of the <strong>SERCOS</strong><br />

interface in controls and drives. Many packaging machinery manufacturers are shipping<br />

machines today that were designed from the ground up using servo technology, in which<br />

hundreds of mechanical components have been eliminated, costs have been reduced and<br />

flexibility has been maximized.<br />

<strong>The</strong> OMAC (Open Modular Architecture Controls) Packaging Workgroup published a<br />

recommendation in November 2001 to use <strong>SERCOS</strong> interface (IEC 61491) as an open<br />

drive interface for packaging machines. In this context, the group challenged the<br />

<strong>SERCOS</strong> organization to further improve the multi-vendor interoperability of servo<br />

controls and drives on the basis of a packaging profile.<br />

<strong>The</strong> <strong>SERCOS</strong> organizations responded by creating a packaging profile that defines a<br />

subset of the <strong>SERCOS</strong> interface parameters that are applicable to packaging machines.<br />

<strong>The</strong> <strong>SERCOS</strong> interface specifies more than 500 standardized parameters that define the<br />

interaction between controls and drives in a vendor-independent manner. <strong>The</strong> <strong>SERCOS</strong><br />

specification supports the interoperability of controls, drives and I/O devices from<br />

different manufacturers on the basis of an open real-time communication system.<br />

However, in practice, issues arise which make the idea of “plug and play” more difficult<br />

to implement. Only a subset of all existing parameters is needed for most applications, as<br />

some parameters have been designed for very specific use only (i.e., spindle positioning<br />

in machine tools), or they deal with optional interfaces (e.g., position feedback value of<br />

an external feedback). Thus, not all vendors implement all parameters in every device<br />

they produce.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 11

Another issue is that motion control functions can be integrated centrally in the control as<br />

well as decentrally in the drives. This depends on the functionality of the servo drives,<br />

which may vary from manufacturer to manufacturer. Machine builders have different<br />

philosophies and preferences with regard to control architecture. Thus, depending on the<br />

drive functions that are used by a control, a different set of <strong>SERCOS</strong> parameters is<br />

required.<br />

<strong>To</strong> keep this complexity manageable and to ensure the highest interoperability of controls<br />

and drives, it was decided to implement packaging application-specific profiles as subsets<br />

to the <strong>SERCOS</strong> specification. Existing <strong>SERCOS</strong> function groups and the corresponding<br />

parameters have been mapped into profiles for three of the six OMAC-defined<br />

application classes. <strong>The</strong> profiles consist of mandatory and optional parameters for simple<br />

servo drives and frequency converters, and also for intelligent drives, which can be<br />

commanded by any of position, velocity or torque values. Thus, any servo drives/-<br />

controllers that implement the pack profile will be interoperable.<br />

It’s important to note that the pack profile doesn't restrict drives/controls<br />

to only the defined parameters; but it does require that the drive/control<br />

implement the defined parameters in the defined manner in order insure<br />

compatibility.<br />

XII. Synchronization of Motion Controls<br />

<strong>SERCOS</strong> III specifies a Controller-to-Controller (C2C) profile for distributed control<br />

functions in modular machines and systems, providing for controller-to-controller<br />

synchronization between distributed motion controls. This addresses the increased need<br />

in manufacturing systems engineering in which individual machine modules not only<br />

need to be connected mechanically, but also need to be integrated into communication<br />

networks and coupled in hard real-time.<br />

For example, consider printing and packaging machines with a modular structure. Often<br />

each module of the machine has its own PLC or motion control, but the axes in each<br />

module must work synchronously, such as in four-color (or more) printing. With the C2C<br />

profile, every module in a machine or entire line can perform a data exchange with every<br />

other module to insure synchronization, independent of the master or the physical order<br />

of the modules in the <strong>SERCOS</strong> ring.<br />

<strong>The</strong> specification of communication and synchronization mechanisms between<br />

distributed motion controls takes into consideration the hardware redundancy and hotplugging<br />

features of <strong>SERCOS</strong> III. In addition, the data and commands exchanged<br />

between controls are defined based on the existing <strong>SERCOS</strong> parameter model. This<br />

data includes control and state information, as well as relevant command values and<br />

actual values. In this context, a convergence with the CIP Motion Profile and the<br />

development of a <strong>SERCOS</strong>/CIP-Gateway is planned.<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 12

Typical applications for such a profile are in printing, packaging and processing<br />

machines; as well as machine tools with special requirements for control systems and<br />

synchronization, e.g., machine concepts with gantry axes or rotary transfer tables.<br />

XIII. Keeping the interface Up to Date<br />

Updates to the <strong>SERCOS</strong> interface standard are defined by multi-company Technical<br />

Working Groups (TWGs) in both North America and Europe, which ensure that the latest<br />

enhancements proposed by <strong>SERCOS</strong> member companies are incorporated into the<br />

specification. Updates that have been accepted by the TWGs since official adoption of<br />

the IEC standard are published by the <strong>SERCOS</strong> interface member organizations and<br />

made available to anyone for a modest fee.<br />

XIV. Support Organizations<br />

<strong>The</strong> many <strong>SERCOS</strong> interface vendors have formed <strong>SERCOS</strong> interface trade association<br />

groups in Europe, North America and Japan. <strong>The</strong>se organizations promote the use of the<br />

digital <strong>SERCOS</strong> interface, and coordinate and disseminate general and technical<br />

information. Membership is open to any individual, organization or company interested in<br />

establishing knowledge of the <strong>SERCOS</strong> interface, applications, technical implementation<br />

and/or operation.<br />

For literature and information on <strong>SERCOS</strong> interface trade association membership<br />

contact:<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 13

<strong>SERCOS</strong> International<br />

Landhausstrasse 20<br />

D-70190 Stuttgart, Germany<br />

Phone: +49 711 / 28 457 50<br />

Fax: +49 711 / 28 457 55<br />

Email: info@sercos.de<br />

www.sercos.de<br />

<strong>SERCOS</strong> North America<br />

405 Loblolly Bay Drive<br />

Santa Rosa Beach, Florida 32459<br />

<strong>To</strong>ll-free Tel: 800/573-7267<br />

Local Tel & Fax: 850/269-0908<br />

E-mail: info@sercos.com<br />

www.sercos.com<br />

<strong>SERCOS</strong> Japan<br />

Katsuyuki Nakata<br />

Attn. Mr. Shigeru Ueki<br />

2-7-6 Hirakawa-cho, Chiyoda-ku<br />

<strong>To</strong>kyo, 102-0093, Japan<br />

Tel: +81-3-5210-4457 ● Fax: +81-3-5210-4458<br />

E-mail: knakata@eos.ocn.ne.jp<br />

XV. Sources for More Information<br />

<strong>SERCOS</strong> interface Standard (IEC 61491)<br />

• Available from Global Engineering Documents, a source for technical standards -<br />

- http//global.his.com.<br />

• Available from IEC - International Electrotechnical Commission in Switzerland –<br />

www.iec.ch<br />

Note that the title of the standard is Electrical Equipment of Industrial Machines –<br />

Serial Data Link for Real-time Communication Between Controls and Drives.<br />

Searching for the word <strong>SERCOS</strong> will not locate the standard.<br />

Other Documentation and Information<br />

You can find more detailed technical descriptions, download free documentation and<br />

purchase the <strong>SERCOS</strong> specification, profiles and reference manuals on:<br />

• www.sercos.de<br />

• www.sercos.com<br />

###<br />

<strong>Introduction</strong> to the <strong>SERCOS</strong> interface -- Sept. 2006 -- Page 14