Biturox® Multigrade Bitumen - Pörner Group

Biturox® Multigrade Bitumen - Pörner Group

Biturox® Multigrade Bitumen - Pörner Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BITUMEN BY BITUROX ®<br />

10/2008

© OMV<br />

„<strong>Bitumen</strong> is a black,<br />

sticky and, when hot,<br />

smelling material.“<br />

The world of today and tomorrow needs more and<br />

better roads...<br />

Roads have to be inexpensive both in construction and maintenance. In the same sense, they have to proof<br />

maximum durability. And finally, used road paving material should be easily and completely reprocessable<br />

and reusable.<br />

Bituminous binders of highest quality, as a component of road pavement formulations, meet all the criteria<br />

listed above. Furthermore, they perform excellently under extreme climatic conditions and thus can stand<br />

heaviest traffic loads. Under these aspects, bitumen production presents itself as an increasingly attractive<br />

and profitable sector of downstream business.<br />

<strong>Biturox®</strong> Paramo<br />

Pardubice,<br />

Czech Republic<br />

Refineries need more than only crude processing<br />

Today’s petroleum product marketers are more often confronted with the need to supply top bitumen binder<br />

qualities to the construction industry at a reasonable price level. Another business-line of interest is the chemical<br />

specialities industry. Frequently an initial bitumen business is the key-opener for new valuable business<br />

relations in the field of premium lubricants, fuels, process products etc.<br />

The main effort of any large-scale refinery in the world is to produce million of tons of fast moving products<br />

(e.g. gasoline, diesel fuel, kerosene, feedstocks for the petrochemistry etc.) at the least possible overall costs.<br />

Mainly this goal is met by selecting the proper crude mix and using sophisticated refinery technology. This<br />

approach generally has the consequence that a straight production of high quality bitumen is impracticable.<br />

The name of the tool to optimally reconcile the market-demand for top-grade bitumen with the upstream cost<br />

controlling effort is<br />

biturox ®<br />

2

<strong>Pörner</strong>: <strong>Bitumen</strong> Upgrading Specialists<br />

The world largest<br />

Biturox ® plant at<br />

Płock, Poland.<br />

The <strong>Pörner</strong> <strong>Group</strong> with a work force of 350 experts in the field of chemical and refinery engineering is specialised<br />

in bitumen technology. <strong>Pörner</strong> only and alone built the largest number of bitumen processing plants of all<br />

dimensions and all over the world. This achievement enabled <strong>Pörner</strong> <strong>Group</strong> to accumulate the most comprehensive<br />

expert knowledge in engineering, design, construction, start-up and operation of bitumen plants.<br />

Know How – Three columns of competence<br />

The Biturox ® Process represents the modern and proven solution to produce top bitumen qualities from a<br />

great variety of raw materials. The expertise of <strong>Pörner</strong> staff covers technological, economical and market<br />

related aspects. Biturox ® plants have been built according to various national quality standards (conventional<br />

or performance based - such as SHRP).<br />

• Technology<br />

The core piece of the Biturox ® Process is the unequalled loop reactor. In this perfect aeration reactor the thermo-chemical<br />

conversion of selected raw material blends by air-oxygen takes place continuously and under<br />

repeatable conditions. The process allows controlling all important process parameters (pressure, temperature,<br />

flow rates, residence time etc.) with high accuracy. Biturox ® technology proofs that the oxidation process<br />

can run both effectively and very softly: The valuable aromatic components are formed and preserved in the<br />

reaction mixture and, at the same time, the degradation of organic compounds to coke and the build-up of<br />

deposits is minimised. Deriving from the process fundamentals, the features of safe and automated operation<br />

as well as low turnaround and maintenance requirements, make the Biturox ® process to the most attractive<br />

solution for a modern bitumen producer.<br />

Biturox ® Pilot Plant in<br />

Schwechat, Austria.<br />

• Design, Research and Pilot Testing<br />

A satisfying bitumen quality depends on the harmonised balance of its chemical components: saturates, aromatics,<br />

naphthenes, resins, asphaltenes. In more than 30 years and supported by several Hundred of research<br />

laboratory and pilot tests on almost any crude type, <strong>Pörner</strong>, together with its partner OMV, developed methods<br />

how to formulate and to process bitumen: All findings were filed in a comprehensive database of know-how.<br />

Thus <strong>Pörner</strong> is able to recommend for almost any feed stock-product combination the most efficient and least<br />

costly way to make top-bitumen quality.<br />

• Experience<br />

<strong>Pörner</strong> knows much about bitumen: A visco-elastic, complex mixture of chemical compounds, difficult to<br />

handle. Based on <strong>Pörner</strong>‘s engineering expertise the most perfect bitumen plants have been realised. Applying<br />

all principles of efficiency to blending, heating, cooling of bitumen, to optimise instrumentation and automation,<br />

to minimise by-products and emissions, to save and recover energy, to keep maintenance and downtimes<br />

low. Selecting, the ideally suited equipment, minimising delivery times and making construction fast<br />

and easy and to taking care of personnel training, commissioning and start-up.<br />

<strong>Pörner</strong> designs and realises <strong>Bitumen</strong> Plants including all infrastructures out of one hand:<br />

production units of high availability, easy to operate and designed for a long lifetime.<br />

3 3

Modern world of bitumen<br />

Roads are connecting people. <strong>Bitumen</strong> is the most versatile and qualified material for fast construction of<br />

long-life and inexpensive roads. The process product industry is another consumer of extra bitumen qualities<br />

for roofing felts, construction coating, bitumen emulsions etc.<br />

Biturox ® bitumen products contribute to have a „world-wide growing network of perfect roads“ and to have<br />

„tight roofs everywhere“.<br />

Changes - Challenges - Chances<br />

Almost every day crude prices, qualities and availability undergo radical changes. The number of bitumen<br />

producers fall off, as smaller, non-profitable producers have to close their books anywhere. New performance<br />

oriented bitumen standards (e.g. SHRP) show up frequently. Flexibility and rapid response to new demands<br />

are a must in the petroleum industry‘s every day fight for market shares.<br />

The modern refineries generally need to improve the bitumen processing technology, which should fit into<br />

their completely automated manufacturing pattern and contribute to the plant’s economic efficiency by higher<br />

production flexibility combined with an almost complete independence of the crude type available.<br />

The Biturox ® Process offers the solution to produce both multigrade road construction bitumen and high PEN<br />

Index bitumen using a continuous, fully automated operation and achieving nearly full independence from<br />

feedstock quality and price.<br />

Highlight<br />

The Biturox ® Process guarantees the user almost complete independence from crude types, simultaneously<br />

allowing to make the best qualities of bitumen.<br />

The name is the Biturox ® paradoxon: Better quality from cheaper feedstock components.<br />

Biturox ® : High Quality – Efficient – Large Quantities<br />

High PI <strong>Bitumen</strong><br />

Low PI <strong>Bitumen</strong><br />

<strong>Multigrade</strong>:<br />

combined and improved<br />

product characterists<br />

at high as well<br />

as low temperatures.<br />

Stiffness<br />

low temperature limit<br />

for performance<br />

high temperature limit<br />

for performance<br />

Low PI<br />

High PI<br />

temperature range<br />

for compaction<br />

(High PI)<br />

maximum viscosity for<br />

satisfactory compaction<br />

Viscosity<br />

minimum viscosity for<br />

satisfactory compaction<br />

temperature range<br />

for compaction<br />

(Low PI)<br />

4<br />

-50 0 50 100 150<br />

TEMPERATURE ° C<br />

Biturox ® <strong>Multigrade</strong> <strong>Bitumen</strong><br />

© <strong>Pörner</strong> Ingenieurgesellschaft m.b.H.

Biturox ® - <strong>Multigrade</strong> <strong>Bitumen</strong><br />

The designation <strong>Multigrade</strong> used in this leaflet has the same meaning as in the lubricating oil terminology.<br />

<strong>Multigrade</strong> oils are characterised by a reduced dependence of viscosity with temperature. They are able<br />

to do their services over a wider temperature range and are characterised by a high viscosity index. The<br />

same system fits to bitumen products: <strong>Multigrade</strong> can be used in the above sense, viscosity index should be<br />

replaced by penetration index - PI.<br />

• The Feedstock<br />

High molecular weight components of all chemical configuration types, present in most crude oils are suited<br />

as feedstock for the Biturox ® Process. The only exception is, when in the starting material for bitumen the<br />

paraffinic hydrocarbons predominate. In this case the Paratox ® process, a two-step Biturox ® Process, has to<br />

be used. The following products of refining activities are on the list of bitumen raw material:<br />

• Vacuum residue (short residue) VR<br />

• Pitch from bright stock de-asphalting PDA-P<br />

• Aromatic extracts from lubricating oil processing EXT<br />

• Atmospheric residue (long residue)<br />

• Heavy vacuum gas oil HVGO<br />

• Heavy cycle oils from cracking, visbreaking, coking<br />

• The Method<br />

High quality bitumen must show a harmonic distribution of saturates, aromatics, resins and asphaltenes.<br />

Biturox ® multigrade bitumen is made by the method of composition control.<br />

Several raw material components of different chemical nature are selected and combined to an adequate<br />

feed composition. This composition is forwarded to the Biturox ® Process where it is integrated by air oxidation<br />

under clearly defined and absolutely controlled processing conditions.<br />

• Biturox ® -controlled operation<br />

The Biturox ® reactor is the perfect tool for such operation:<br />

efficient, controllable and safe. The feed composition is processed<br />

very gently under elevated pressure and the polarity of<br />

the aromatic components is increased minimising the risks of<br />

local overheating and coke build-up. Internal reactor cooling<br />

allows exact temperature control. The process runs continuously<br />

resulting in a consistent and homogenous finished product<br />

quality.<br />

ANALYSIS OF<br />

FEED COMPONENTS<br />

BY SCANNING<br />

VR<br />

PDA-P<br />

EXT<br />

HVGO<br />

OPTIMIZED FEED<br />

COMPOSITION BY<br />

PILOT TESTING<br />

<strong>Biturox®</strong> Process Scheme<br />

PROCESSING UNDER<br />

SPECIFIC PRESSURE<br />

AND TEMPERATURE<br />

OPTIMIZED FINAL<br />

PRODUCT MEETING<br />

TARGET SPECIFICATION<br />

(MULTIGRADE)<br />

© <strong>Pörner</strong> Ingenieurgesellschaft m.b.H.<br />

Conclusion<br />

<strong>Bitumen</strong> as the residue of crude is chemically very complex. Taking advantage from its research database<br />

and many hundreds of pilot tests carried out on crudes from all over the world, <strong>Pörner</strong> has gained the experience<br />

to optimise feedstock compositions and to design the process most adequate to make a quality product -<br />

even from cheaper feed components.<br />

The Biturox ® Process creates and preserves the valuable medium molecular weight aromatics<br />

in bitumen improving the elastic properties as well as adhesion on the aggregate. The<br />

result is a product with tailored chemical structure and optimum quality characteristics:<br />

Biturox ® <strong>Multigrade</strong> <strong>Bitumen</strong>.<br />

5 5

The Biturox ® pla<br />

Product Storage<br />

and Loading<br />

Product storage designed to keep<br />

the product homogeneous.<br />

Feedstock Section<br />

Circulation in the tanks to establish<br />

an uniform temperature profile.<br />

“BituFil” stations for automated<br />

loading of product to rail wagon or<br />

tank trucks.<br />

Utilities<br />

Plant and instrument<br />

air.<br />

Electrical power, steam,<br />

water<br />

Product Section<br />

6<br />

Product blending for tailor-made<br />

products (optional).<br />

Heat recovery for pre-heating.

nt<br />

Reactor<br />

Inner loop type reactor<br />

design warrants optimised<br />

but also very gentle treatment<br />

of the medium.<br />

Operation is very safe due to<br />

total utilisation of air oxygen.<br />

Pre-heating<br />

Pre-heating of feedstock<br />

blend to processing temperature.<br />

© <strong>Pörner</strong> Ingenieurgesellschaft<br />

7 7

Research and Piloting<br />

Biturox ® Research Facilities<br />

For more than 30 years the Biturox ® Research Centre is an excellently performing service provider to the<br />

whole industry, making or using bitumen. Up to date laboratory and semi-technical research and development<br />

facilities, analytical methods of newest standard and the backup of the nearby OMV refinery enabled and<br />

promoted <strong>Pörner</strong>‘s efforts to stock-up the most comprehensive expertise on bitumen making world-wide.<br />

Two Biturox ® pilot plants are available for practical testing of feedstock or composition of several components<br />

in batch or continuous operating mode. The results of pilot tests are used as design basis for Biturox ® plants<br />

(i.e. reactor rating). Reference samples can be produced from defined feed compositions ready for further<br />

applied testing by the client.<br />

All results of basic and applied research work, the experience gathered during design, construction, start-up<br />

and routine operation of the numerous Biturox ® plants, the information feedback from the Biturox ® licensees,<br />

the newest findings of the Biturox ® Enhancement Technique (chemical upgrading of bitumen) and, obviously,<br />

the performance reports on application of Biturox ® bitumen have been collected in a most comprehensive<br />

database.<br />

Target<br />

Many bitumen research institutes over-emphasise the significance of crude oil provenance and compositional<br />

classification, simultaneously neglecting to notice and to review the chances, which lie in the thermo-chemical<br />

modification of an almost unlimited palette of crude oil derived feedstock.<br />

The main objective of the Biturox ® Research Facilities is therefore, to find methods how to optimise the chemical<br />

composition of bitumen, namely reaction conditions, which promote the synthesis of polar, aromatic compounds<br />

and suppress the decomposition of asphaltenes to coke.<br />

But finally the goals of the said efforts have to be to satisfy the market demand for bitumen qualities with<br />

outstanding and superior application characteristics at a reasonable low price.<br />

Desired characteristics<br />

Fatique resistance<br />

Ability for emulsion<br />

Stiffness<br />

Good short- and long-term aging properties<br />

Compatibility with polymers<br />

Problems to solve<br />

Chemical composition<br />

Life time<br />

Cracking at low temperatures<br />

Rutting at high temperatures<br />

Optimise adhesive properties<br />

Stability<br />

Result<br />

The Biturox ® technology is a representative example how applied and scientific research can be conducted<br />

effectively, rewarding and to the benefit of many people, driving on good roads, living in comfortable accommodations<br />

and both under cost-saving conditions.<br />

Biturox ® MBW<br />

Mitteldeutsches <strong>Bitumen</strong>werk<br />

Granschütz, Germany<br />

8

Project realization<br />

The <strong>Pörner</strong> <strong>Group</strong> is, as documented in this brochure, the most experienced bitumen plant designer and constructor<br />

worldwide. The volume of data in the electronic files is the basis for an expedient and cost-saving<br />

project realisation in every single step. The table below gives a general overview of the scope and steps of the<br />

realisation of a “turn-key grass-root” project:<br />

• Preliminary studies, information & data collection<br />

• Feasibility study<br />

• Evaluation of raw material, laboratory & pilot-plant testing<br />

• Evaluation of the technical, commercial, legal and<br />

ecological conditions<br />

• Presentation of the recommendations to and<br />

acknowledgement by the client<br />

• Action planning, scheduling, project cost assessment<br />

• Chemical, mechanical, civil basic and detail<br />

engineering<br />

• Approval of the final project documents by the<br />

client and by the supervising authorities<br />

• Procurement & logistics of equipment and material<br />

• Engagement and supervision of contractors<br />

• General on-site supervision of the construction work<br />

• Project progress reporting and documentation<br />

• Commission of the completed plant<br />

• Presentation of the plant and operation manuals to the client<br />

• Test run & staff training<br />

• Project post-completion auditing and services<br />

Biturox ® ESHA,<br />

Amsterdam, Netherlands<br />

From Lab Tests to<br />

Turn Key Realization<br />

<strong>Pörner</strong> has learned a lot about bitumen<br />

in more than 35 years.<br />

Make advantage not to repeat any mistake from which <strong>Pörner</strong> has learned in three decades of plant construction!<br />

With <strong>Pörner</strong> the world of<br />

Biturox ® bitumen is yours.<br />

9 9

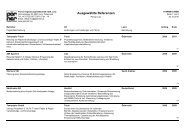

The Proof: Bitur<br />

Project Client Operator Location Country Year<br />

Biturox ® Wörth Mobil Oil Wörth Mobil Oil Wörth Wörth Germany 1978<br />

Biturox ® Esfahan NIOC NIOC Esfahan Iran 1988<br />

Biturox ® Kaoshiung CPC CPC Kaohsiung Taiwan 1990<br />

Biturox ® Bandar Abbas NIOC NIOC Bandar Abbas Iran 1991<br />

Biturox ® Adelaide Mobil Oil Australia Mobil Adelaide Australia 1992<br />

Biturox ® Plock PKN Orlen Orlen Asfalt Plock Poland 1994<br />

Biturox ® Madras CPCL CPCL Refinery Chennai India 1994<br />

Biturox ® OMV<br />

Schwechat, Austria<br />

Bitukomb Lisichansk Lisichanskij NPZ Lisichanskij NPZ Lisichansk Ukraine 1995<br />

Biturox ® Mangalore Toyo Engineering MRPL Mangalore India 1995<br />

Biturox ® Baku<br />

Azerneftyag<br />

Azerneftyag<br />

Refinery<br />

Baku Azerbaidjan 1995<br />

Biturox ® Krasnovodsk NEKRA NEKRA Turkmenbashi Turkmenistan 1995<br />

Configuration<br />

Capacity<br />

Image<br />

Fact Sheet<br />

1 Reactor, Feedstock heating/cooling<br />

through direct<br />

heat exchange, Scrubber,<br />

Offgas-Incinerator<br />

1,080 tons/day<br />

Configuration<br />

Capacity<br />

Image<br />

Configuration<br />

Capacity<br />

Image<br />

Fact Sheet<br />

1 Reactor, Feedstock<br />

heating/Product cooling<br />

through direct heat<br />

exchange, Knock Out Drum,<br />

Offgas-Incinerator, Pipeline,<br />

truck-, drum- and bag filling<br />

400 tons/day<br />

Fact Sheet<br />

1 Reactor, Feedstock heating/Product<br />

cooling through<br />

spiral heat exchanger and<br />

hot oil<br />

circulation, Scrubber and<br />

Offgas-Incinerator<br />

192 tons/day<br />

10

ox ® References<br />

Project Client Operator Location Country Year<br />

Biturox ® Rayong LGEN IPRC PCL Rayong Thailand 1996<br />

Biturox ® Visakh HPCL Visakh Refinery Visakhapatnam India 1998<br />

Biturox ® Amsterdam ESHA ESHA Amsterdam Netherlands 1998<br />

Biturox ® Myanmar Fritz Werner MPE Yangon Myanmar 1999<br />

Biturox ® Chelyabinsk Dept. Car Roads Dept. Car Roads Chelyabinsk Russia 2000<br />

Biturox ® Bharat BPCL Mumbai Refinery Mumbai India 2000<br />

Biturox ® Jarbit Jarbit Jarbit Jaroslavl Russia 2002<br />

Biturox ® Taiwan Simosa Oil Corp. Simosa Oil Corp. Mailiao Taiwan 2002<br />

Biturox ® Gujarat IOCL Gujarat Refinery Vadodara India 2002<br />

Biturox ® plant<br />

Jaroslavl, Russia<br />

Biturox ® Lavéra Innovene Innovene Lavéra France 2004<br />

Biturox ® Gdansk Grupa Lotos Lotos Asfalt Gdansk Poland 2005<br />

Biturox ® Schwechat OMV OMV Schwechat Austria 2006<br />

Biturox ® Nizhnekamsk TAIF-NK TAIF-NK Nizhnekamsk Russia 2007<br />

Biturox ® Cochin BPCL Kochi Refinery Cochin India 2008<br />

Scope of<br />

services<br />

Capacity<br />

Image<br />

Fact Sheet<br />

Basic design for the process<br />

and off-plot units, detailed<br />

engineering, procurement<br />

and supply of the plant<br />

equipment and material, site<br />

supervision, start-up, training<br />

and documentation (general<br />

contracting)<br />

480 tons/day<br />

Scope of<br />

services<br />

Capacity<br />

Image<br />

Fact Sheet<br />

Basic design, detailed<br />

engineering, procurement<br />

and supply of the process<br />

unit, site su pervision,<br />

start-up assistance, training<br />

and documentation<br />

1,032 tons/day<br />

11 11

WWW.BITUROX.COM<br />

<strong>Pörner</strong> Ingenieurgesellschaft mbH<br />

Hamburgerstraße 9<br />

A-1050 Vienna<br />

Austria<br />

Tel.: +43 (1) 589 90-0<br />

Fax: +43 (1) 589 90-99<br />

Email: vienna@poerner.at<br />

Web: www.poerner.at<br />

www.biturox.com