Fasteners - hdgasa

Fasteners - hdgasa

Fasteners - hdgasa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Contribution from South America<br />

Bob’s BANTER:<br />

What readers have<br />

to say...<br />

Hello Bob,<br />

I wrote to you last year re using<br />

your “Cleaner Fish” article in the<br />

GALVANIZING magazine. I have<br />

spoken to Terry Smith, the editor.<br />

He is delighted to hear we read<br />

his magazine! He said I may send<br />

it on to others. Obviously with<br />

your email details.<br />

Coincidentally our sons were<br />

friends at school and still<br />

maintain contact.<br />

Please send me a copy.<br />

Thanks a lot.<br />

George Savage<br />

Picasso Digital Graphics<br />

Hi Bob<br />

After 15 years’ of retirement I find<br />

that the pure scientific articles are<br />

getting less interesting, or is it<br />

understandable. Your Bob’s Banter,<br />

with its often philosophic slant, is<br />

however always great reading. I<br />

especially enjoyed your latest one<br />

based on Darwin’s evolution<br />

theory. Thanks. Best wishes for a<br />

lovely 2012 and many more to<br />

come.<br />

Regards<br />

Wim Skinner<br />

Hi Bob,<br />

Just read your article “Bob’s<br />

Banter” in HD Galvanizing Today<br />

no. 47 – what an inspirational way<br />

to start my day.<br />

Hope to see more of your<br />

writings in the magazine in the<br />

future.<br />

tx<br />

Conrad Hubbe<br />

for STATIC Structural Engineers<br />

cc (In association with Geni<br />

Consulting Engineers cc)<br />

Motivation and methodology<br />

of hot dip galvanizing steel<br />

railway sleepers for Vale Do<br />

Rio Doce, Brazil<br />

Introduction<br />

Due to thermodynamic laws, steel<br />

when left unprotected will in time<br />

return to its natural state of iron ore.<br />

This means that insufficient corrosion<br />

protection, will result in premature<br />

corrosion, ultimately reducing the<br />

mechanical properties and strength of<br />

the steel.<br />

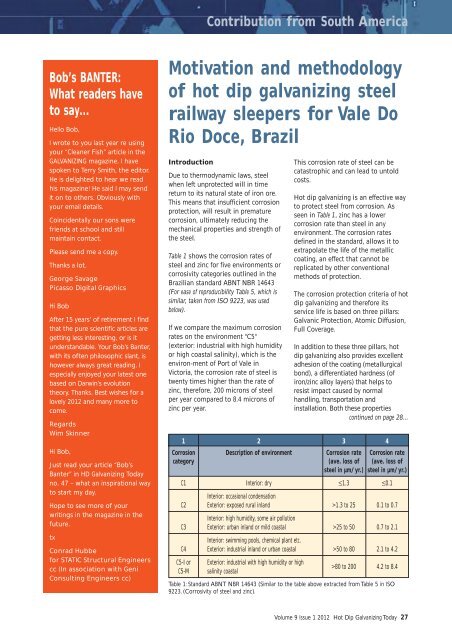

Table 1 shows the corrosion rates of<br />

steel and zinc for five environments or<br />

corrosivity categories outlined in the<br />

Brazilian standard ABNT NBR 14643<br />

(For ease of reproducibility Table 5, which is<br />

similar, taken from ISO 9223, was used<br />

below).<br />

If we compare the maximum corrosion<br />

rates on the environment "C5"<br />

(exterior: industrial with high humidity<br />

or high coastal salinity), which is the<br />

environ-ment of Port of Vale in<br />

Victoria, the corrosion rate of steel is<br />

twenty times higher than the rate of<br />

zinc, therefore, 200 microns of steel<br />

per year compared to 8.4 microns of<br />

zinc per year.<br />

This corrosion rate of steel can be<br />

catastrophic and can lead to untold<br />

costs.<br />

Hot dip galvanizing is an effective way<br />

to protect steel from corrosion. As<br />

seen in Table 1, zinc has a lower<br />

corrosion rate than steel in any<br />

environment. The corrosion rates<br />

defined in the standard, allows it to<br />

extrapolate the life of the metallic<br />

coating, an effect that cannot be<br />

replicated by other conventional<br />

methods of protection.<br />

The corrosion protection criteria of hot<br />

dip galvanizing and therefore its<br />

service life is based on three pillars:<br />

Galvanic Protection, Atomic Diffusion,<br />

Full Coverage.<br />

In addition to these three pillars, hot<br />

dip galvanizing also provides excellent<br />

adhesion of the coating (metallurgical<br />

bond), a differentiated hardness (of<br />

iron/zinc alloy layers) that helps to<br />

resist impact caused by normal<br />

handling, transportation and<br />

installation. Both these properties<br />

continued on page 28...<br />

1 2 3 4<br />

Corrosion Description of environment Corrosion rate Corrosion rate<br />

category (ave. loss of (ave. loss of<br />

steel in µm/yr.) steel in µm/yr.)<br />

C1 Interior: dry ≤1.3 ≤0.1<br />

Interior: occasional condensation<br />

C2 Exterior: exposed rural inland >1.3 to 25 0.1 to 0.7<br />

Interior: high humidity, some air pollution<br />

C3 Exterior: urban inland or mild coastal >25 to 50 0.7 to 2.1<br />

Interior: swimming pools, chemical plant etc.<br />

C4 Exterior: industrial inland or urban coastal >50 to 80 2.1 to 4.2<br />

C5-I or<br />

C5-M<br />

Exterior: industrial with high humidity or high<br />

salinity coastal<br />

>80 to 200 4.2 to 8.4<br />

Table 1: Standard ABNT NBR 14643 (Similar to the table above extracted from Table 5 in ISO<br />

9223, (Corrosivity of steel and zinc).<br />

Volume 9 Issue 1 2012 Hot Dip Galvanizing Today 27