SIROLLCIS CM Solutions for cold rolling mills - Industry - Siemens

SIROLLCIS CM Solutions for cold rolling mills - Industry - Siemens

SIROLLCIS CM Solutions for cold rolling mills - Industry - Siemens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Coupled pickling lines and tandem <strong>cold</strong> <strong>mills</strong><br />

High-capacity production <strong>for</strong> high-quality products<br />

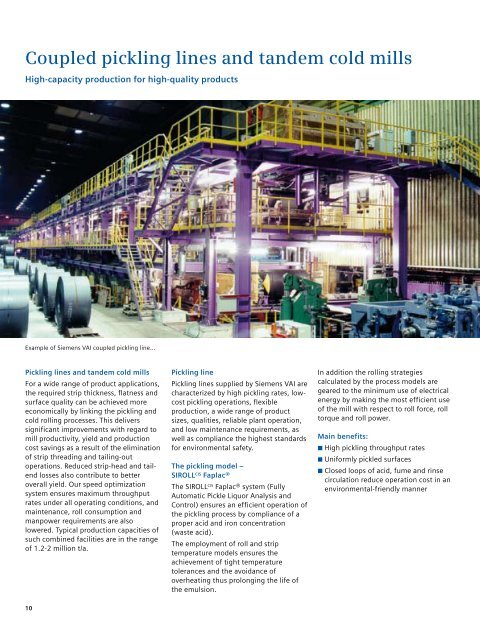

Example of <strong>Siemens</strong> VAI coupled pickling line...<br />

Pickling lines and tandem <strong>cold</strong> <strong>mills</strong><br />

For a wide range of product applications,<br />

the required strip thickness, flatness and<br />

surface quality can be achieved more<br />

economically by linking the pickling and<br />

<strong>cold</strong> <strong>rolling</strong> processes. This delivers<br />

significant improvements with regard to<br />

mill productivity, yield and production<br />

cost savings as a result of the elimination<br />

of strip threading and tailing-out<br />

operations. Reduced strip-head and tailend<br />

losses also contribute to better<br />

overall yield. Our speed optimization<br />

system ensures maximum throughput<br />

rates under all operating conditions, and<br />

maintenance, roll consumption and<br />

manpower requirements are also<br />

lowered. Typical production capacities of<br />

such combined facilities are in the range<br />

of 1.2-2 million t/a.<br />

Pickling line<br />

Pickling lines supplied by <strong>Siemens</strong> VAI are<br />

characterized by high pickling rates, lowcost<br />

pickling operations, flexible<br />

production, a wide range of product<br />

sizes, qualities, reliable plant operation,<br />

and low maintenance requirements, as<br />

well as compliance the highest standards<br />

<strong>for</strong> environmental safety.<br />

The pickling model –<br />

SIROLL CIS Faplac®<br />

The SIROLL CIS Faplac® system (Fully<br />

Automatic Pickle Liquor Analysis and<br />

Control) ensures an efficient operation of<br />

the pickling process by compliance of a<br />

proper acid and iron concentration<br />

(waste acid).<br />

The employment of roll and strip<br />

temperature models ensures the<br />

achievement of tight tempera ture<br />

tolerances and the avoidance of<br />

overheating thus prolonging the life of<br />

the emulsion.<br />

In addition the <strong>rolling</strong> strategies<br />

calculated by the process models are<br />

geared to the minimum use of electrical<br />

energy by making the most efficient use<br />

of the mill with respect to roll <strong>for</strong>ce, roll<br />

torque and roll power.<br />

Main benefits:<br />

High pickling throughput rates<br />

Uni<strong>for</strong>mly pickled surfaces<br />

Closed loops of acid, fume and rinse<br />

circulation reduce operation cost in an<br />

environmental-friendly manner<br />

10