SIROLLCIS CM Solutions for cold rolling mills - Industry - Siemens

SIROLLCIS CM Solutions for cold rolling mills - Industry - Siemens

SIROLLCIS CM Solutions for cold rolling mills - Industry - Siemens

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SIROLL CIS SIAS – Surface inspection and allocation<br />

Surface quality under control<br />

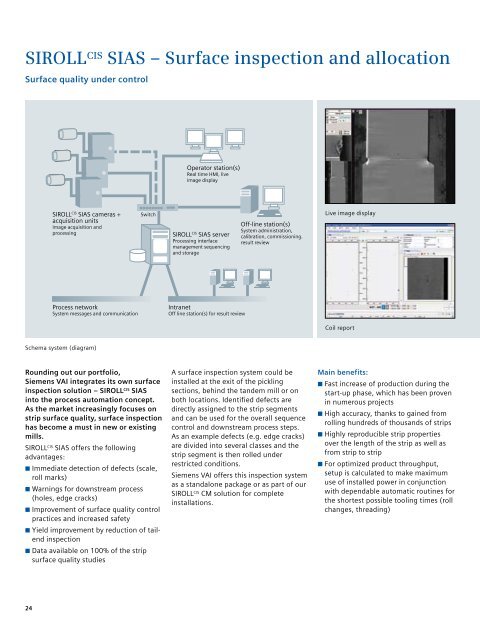

Operator station(s)<br />

Real time HMI, live<br />

image display<br />

SIROLL CIS SIAS cameras +<br />

acquisition units<br />

Image acquisition and<br />

processing<br />

Switch<br />

SIROLL CIS SIAS server<br />

Processing interface<br />

management sequencing<br />

and storage<br />

Off-line station(s)<br />

System administration,<br />

calibration, commissioning.<br />

result review<br />

Live image display<br />

Process network<br />

System messages and communication<br />

Intranet<br />

Off line station(s) <strong>for</strong> result review<br />

Coil report<br />

Schema system (diagram)<br />

Rounding out our portfolio,<br />

<strong>Siemens</strong> VAI integrates its own surface<br />

inspection solution – SIROLL CIS SIAS<br />

into the process automation concept.<br />

As the market increasingly focuses on<br />

strip surface quality, surface inspection<br />

has become a must in new or existing<br />

<strong>mills</strong>.<br />

SIROLL CIS SIAS offers the following<br />

advantages:<br />

Immediate detection of defects (scale,<br />

roll marks)<br />

Warnings <strong>for</strong> downstream process<br />

(holes, edge cracks)<br />

Improvement of surface quality control<br />

practices and increased safety<br />

Yield improvement by reduction of tailend<br />

inspection<br />

Data available on 100% of the strip<br />

surface quality studies<br />

A surface inspection system could be<br />

installed at the exit of the pickling<br />

sections, behind the tandem mill or on<br />

both locations. Identified defects are<br />

directly assigned to the strip segments<br />

and can be used <strong>for</strong> the overall sequence<br />

control and downstream process steps.<br />

As an example defects (e.g. edge cracks)<br />

are divided into several classes and the<br />

strip segment is then rolled under<br />

restricted conditions.<br />

<strong>Siemens</strong> VAI offers this inspection system<br />

as a standalone package or as part of our<br />

SIROLL CIS <strong>CM</strong> solution <strong>for</strong> complete<br />

installations.<br />

Main benefits:<br />

Fast increase of production during the<br />

start-up phase, which has been proven<br />

in numerous projects<br />

High accuracy, thanks to gained from<br />

<strong>rolling</strong> hundreds of thousands of strips<br />

Highly reproducible strip properties<br />

over the length of the strip as well as<br />

from strip to strip<br />

For optimized product throughput,<br />

setup is calculated to make maximum<br />

use of installed power in conjunction<br />

with dependable automatic routines <strong>for</strong><br />

the shortest possible tooling times (roll<br />

changes, threading)<br />

24