Sieve Shakers - MEP Instruments

Sieve Shakers - MEP Instruments

Sieve Shakers - MEP Instruments

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

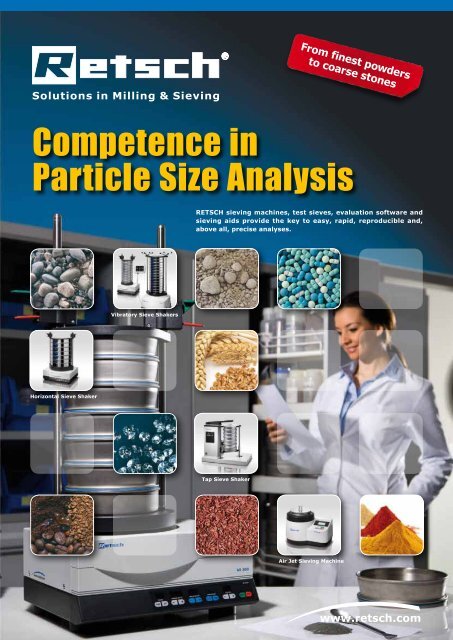

From finest powders<br />

to coarse stones<br />

Competence in<br />

Particle Size Analysis<br />

RETSCH sieving machines, test sieves, evaluation software and<br />

sieving aids provide the key to easy, rapid, reproducible and,<br />

above all, precise analyses.<br />

Vibratory <strong>Sieve</strong> <strong>Shakers</strong><br />

Horizontal <strong>Sieve</strong> Shaker<br />

Tap <strong>Sieve</strong> Shaker<br />

Air Jet Sieving Machine

The widest<br />

sieving equi<br />

RETSCH’s line of sieving machines not only<br />

covers a wide measuring range. Thanks to<br />

various sieving motions and sieve sizes it is<br />

possible to select the ideal instrument for<br />

practically any bulk material. The instruments<br />

produce exact and reproducible results<br />

and comply with the requirements for<br />

the test materials monitoring according to<br />

DIN EN ISO 9000 ff.<br />

Vibratory SIEVE ShakERS<br />

Innovative technology that sets<br />

standards worldwide<br />

■ Patented electromagnetic drive produces<br />

3-D throwing motion for optimum separation<br />

efficiency<br />

■ For sieves from 100 mm to 450 mm Ø<br />

■ Suitable for dry and wet sieving<br />

■ Digital amplitude adjustment allows for sharp<br />

fractionizing even after very short sieving times<br />

■ Measuring instruments according to<br />

DIN EN ISO 9000 ff<br />

www.retsch.com/as<br />

All Vibratory <strong>Sieve</strong><br />

<strong>Shakers</strong> are suitable<br />

for dry and wet<br />

sieving<br />

Calibration ensures<br />

100% reproducibility<br />

of sieving results<br />

(“control” series)<br />

Software Easy<strong>Sieve</strong> ®<br />

for control through<br />

RS232 serial interface,<br />

easy evaluation and<br />

documentation of<br />

results<br />

With patented<br />

CET Technology<br />

Performance data AS 200 AS 200 AS 200 AS 300 AS 450<br />

basic digit control control control<br />

Applications: <br />

Feed material: <br />

Motion of product to be sieved: <br />

with angular momentum<br />

Measuring range*: 20 µm to 40 mm 20 μm to 125 mm<br />

Max. batch / feed capacity: 6 kg 25 kg<br />

Adjustment of analog analog digital digital digital<br />

amplitude / speed: 0 – 3 mm 0 – 3 mm 0.2 – 3 mm 0.2 – 2 mm 0.2 – 2.2 mm<br />

Suitable sieve diameters: 100 mm to 315 mm 400 mm to 450 mm<br />

*depending on feed material and used sieve set

Product videos at<br />

range of<br />

pment in the world<br />

www.retsch.com/videos<br />

Horizontal, TAP AND AIR JET SIEVINg MACHINES<br />

Horizontal <strong>Sieve</strong> Shaker AS 400 control<br />

■ Excellent separation efficiency even with short sieving times<br />

■ Digital process parameter setting, memory for<br />

up to 9 Standard Operating Procedures (SOPs)<br />

■ For sieves up to 400 mm Ø<br />

■ Easy operation, ergonomic design<br />

■ Can be recalibrated<br />

www.retsch.com/as400control<br />

Digital Image PROCESSINg<br />

Dynamic digital image processing is<br />

one of the most accurate methods<br />

to determine the particle size and<br />

particle shape of bulk goods. The<br />

optical particle analyzers CAMSIZER<br />

and CAMSIZER XT from Retsch<br />

Technology are equipped with a<br />

patented two-camera-system and<br />

provide precise and reliable measuring<br />

results with additional information<br />

such as particle number and<br />

density. If required the measurement<br />

results are 100% compatible<br />

to sieve analysis.<br />

Tap <strong>Sieve</strong> Shaker AS 200 tap<br />

■ Horizontal, circular movement with taps in accordance with relevant standards<br />

■ Robust, maintenance-free<br />

■ For sieves 200 mm / 203 mm (8”) Ø<br />

■ Digital time setting<br />

www.retsch.com/as200tap<br />

Air Jet Sieving Machine AS 200 jet<br />

■ Reproducible results due to Open Mesh Function<br />

■ High flexibility through adjustable nozzle speed<br />

■ Operation with RETSCH sieves 200 mm / 203 mm (8”) Ø<br />

■ Automatic vacuum regulation (option)<br />

■ Memory for up to 10 SOPs<br />

■ Silent operation due to integrated silencer<br />

www.retsch.com/as200jet<br />

CAMSIZER ® –<br />

Particle analysis in a range<br />

from 30 µm to 30 mm<br />

■ Very high resolution,<br />

extreme depth of sharpness<br />

■ Short measurement time<br />

(2 – 3 minutes)<br />

■ Excellent compatibility to sieve<br />

analysis<br />

■ Highest reproducibility of<br />

measuring results<br />

■ Particle counting and determination<br />

of density possible<br />

■ FDA conformity: 21 CFR Part 11<br />

www.retsch.com/camsizer<br />

AS 400 AS 200 AS 200<br />

control tap jet<br />

<br />

<br />

horizontal circular horizontal circular dispersion<br />

motion motion with taps by air jet<br />

45 µm to 63 mm 20 µm to 25 mm 10 µm to 4 mm<br />

5 kg 3 kg 0.1 kg<br />

digital fixed digital<br />

50 – 300 min -1 280 min -1 , 150 taps 5 – 55 min -1<br />

100 mm to 400 mm 200 mm / 203 mm (8”) 200 mm / 203 mm (8”)<br />

www.retsch.com<br />

CAMSIZER XT –<br />

Particle analysis of fine<br />

powders in a range<br />

from 1 µm to 3 mm<br />

■ Newly developed optical system<br />

with ultra-strong LEDs for highest<br />

resolution and excellent depth of<br />

sharpness<br />

■ Dry and wet measurement possible<br />

■ Reliable detection of smallest<br />

amounts of “undersize” and<br />

“oversize”<br />

■ Very short measurement<br />

time of 1 – 3 minutes<br />

www.retsch.com/camsizerxt

AnalyTICAl TEST SIEVES<br />

Unique manufacturing process<br />

RETSCH has developed a unique manufacturing<br />

process that guarantees a<br />

previously unattained quality and consistency<br />

in sieve production. Each<br />

sieve that leaves our company includes<br />

a test report or, upon request,<br />

a special inspection certificate or a<br />

calibration certificate in conformity<br />

with ISO 3310-1.<br />

Free test measurements<br />

As part of RETSCH’s professional<br />

customer support we offer our<br />

customers the individual advice<br />

required to find the optimum<br />

solution for their sample<br />

preparation task. To achieve this<br />

our application laboratories<br />

process and measure samples<br />

free-of-charge and provide a<br />

recommendation for the most<br />

suitable method and instrument.<br />

For more information<br />

please visit our website<br />

www.retsch.com/testmeasurement<br />

100% optical<br />

inspection ensures<br />

high product quality<br />

Rotary Tube<br />

Divider PK 1000<br />

Inspection and<br />

calibration certificates<br />

available<br />

Sample Divider<br />

PT 100<br />

Sample<br />

Splitters<br />

1. One piece construction and fabrictransition<br />

without any grooves to<br />

prevent cross contamination<br />

2. A high degree of corrosion resistance<br />

and ease of cleaning due to high-alloy<br />

stainless steel (specification: 316)<br />

3. 15% lighter than traditional sieves while<br />

at the same time increasing the free<br />

sieve area<br />

4. Previously unattained product quality<br />

due to fully automatic production and<br />

extensive optical inspection with<br />

optimum design<br />

5. Innovative resistance welding<br />

technology guarantees permanently<br />

tight sieve fabric<br />

6. Maximum stability and optimum sealing<br />

when used in sieve stacks<br />

7. Clear and precise labeling of the sieves<br />

with full traceability based on<br />

individualized laser engraving<br />

www.retsch.com/sieves<br />

RETSCH offers a wide range of sieve accessories such as collecting pans, covers,<br />

sieving aids and a test sieve rack.<br />

Solutions FOR MORE EFFICIENT SIEVE ANAlySES<br />

The Key to greater efficiency in the laboratory<br />

RETSCH products are used in the quality control of solids for a reason. From representative<br />

sample division for precise particle size analysis to professional maintenance of the test<br />

sieves – RETSCH offers a complete equipment range for perfect results.<br />

www.retsch.com/assisting<br />

Fluid Bed Dryer<br />

TG 200<br />

Ultrasonic Baths<br />

UR 1/UR 3<br />

Product Range<br />

Milling<br />

■ Jaw Crushers<br />

■ Rotor Mills<br />

■ Cutting Mills<br />

■ Knife Mills<br />

■ Mortar Grinders<br />

■ Disc Mills<br />

■ Mixer Mills<br />

■ Planetary Ball Mills<br />

Sieving<br />

■ <strong>Sieve</strong> <strong>Shakers</strong><br />

■ Evaluation Software<br />

■ Test <strong>Sieve</strong>s<br />

Assisting<br />

■ Sample Dividers<br />

■ Feeders<br />

■ Dryers<br />

■ Cleaners<br />

■ Pellet Presses<br />

Retsch GmbH<br />

Rheinische Str. 36<br />

42781 Haan ∙ Germany<br />

Phone +49 (0)2129/5561-0<br />

Fax +49 (0)2129/8702<br />

E-Mail mk@retsch.com<br />

Web www.retsch.com<br />

Subject to technical modification and errors · 99.100.1062/E-06-2011

![Rice, size measurement of broken grains [pdf] - MEP Instruments](https://img.yumpu.com/46724497/1/184x260/rice-size-measurement-of-broken-grains-pdf-mep-instruments.jpg?quality=85)