permit application review summary - New Hampshire Department of ...

permit application review summary - New Hampshire Department of ...

permit application review summary - New Hampshire Department of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

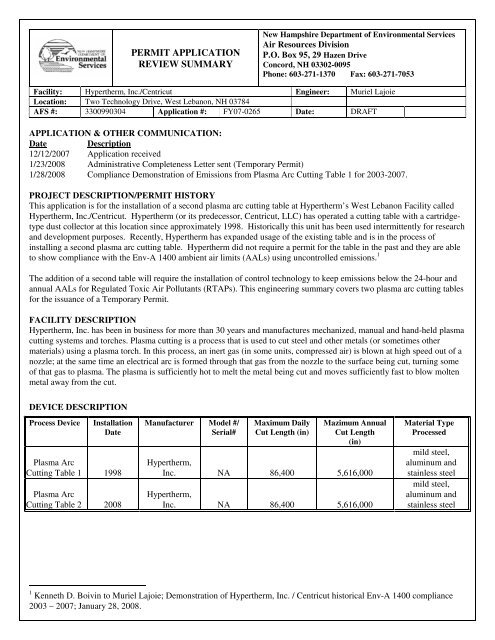

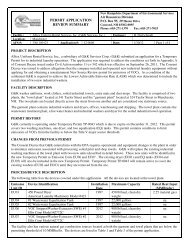

PERMIT APPLICATION<br />

REVIEW SUMMARY<br />

<strong>New</strong> <strong>Hampshire</strong> <strong>Department</strong> <strong>of</strong> Environmental Services<br />

Air Resources Division<br />

P.O. Box 95, 29 Hazen Drive<br />

Concord, NH 03302-0095<br />

Phone: 603-271-1370 Fax: 603-271-7053<br />

Facility: Hypertherm, Inc./Centricut Engineer: Muriel Lajoie<br />

Location: Two Technology Drive, West Lebanon, NH 03784<br />

AFS #: 3300990304 Application #: FY07-0265 Date: DRAFT<br />

APPLICATION & OTHER COMMUNICATION:<br />

Date Description<br />

12/12/2007 Application received<br />

1/23/2008 Administrative Completeness Letter sent (Temporary Permit)<br />

1/28/2008 Compliance Demonstration <strong>of</strong> Emissions from Plasma Arc Cutting Table 1 for 2003-2007.<br />

PROJECT DESCRIPTION/PERMIT HISTORY<br />

This <strong>application</strong> is for the installation <strong>of</strong> a second plasma arc cutting table at Hypertherm’s West Lebanon Facility called<br />

Hypertherm, Inc./Centricut. Hypertherm (or its predecessor, Centricut, LLC) has operated a cutting table with a cartridgetype<br />

dust collector at this location since approximately 1998. Historically this unit has been used intermittently for research<br />

and development purposes. Recently, Hypertherm has expanded usage <strong>of</strong> the existing table and is in the process <strong>of</strong><br />

installing a second plasma arc cutting table. Hypertherm did not require a <strong>permit</strong> for the table in the past and they are able<br />

to show compliance with the Env-A 1400 ambient air limits (AALs) using uncontrolled emissions. 1<br />

The addition <strong>of</strong> a second table will require the installation <strong>of</strong> control technology to keep emissions below the 24-hour and<br />

annual AALs for Regulated Toxic Air Pollutants (RTAPs). This engineering <strong>summary</strong> covers two plasma arc cutting tables<br />

for the issuance <strong>of</strong> a Temporary Permit.<br />

FACILITY DESCRIPTION<br />

Hypertherm, Inc. has been in business for more than 30 years and manufactures mechanized, manual and hand-held plasma<br />

cutting systems and torches. Plasma cutting is a process that is used to cut steel and other metals (or sometimes other<br />

materials) using a plasma torch. In this process, an inert gas (in some units, compressed air) is blown at high speed out <strong>of</strong> a<br />

nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some<br />

<strong>of</strong> that gas to plasma. The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten<br />

metal away from the cut.<br />

DEVICE DESCRIPTION<br />

Process Device<br />

Installation<br />

Date<br />

Plasma Arc<br />

Cutting Table 1 1998<br />

Plasma Arc<br />

Cutting Table 2 2008<br />

Manufacturer Model #/<br />

Serial#<br />

Maximum Daily<br />

Cut Length (in)<br />

Mazimum Annual<br />

Cut Length<br />

(in)<br />

Hypertherm,<br />

Inc. NA 86,400 5,616,000<br />

Hypertherm,<br />

Inc. NA 86,400 5,616,000<br />

Material Type<br />

Processed<br />

mild steel,<br />

aluminum and<br />

stainless steel<br />

mild steel,<br />

aluminum and<br />

stainless steel<br />

1 Kenneth D. Boivin to Muriel Lajoie; Demonstration <strong>of</strong> Hypertherm, Inc. / Centricut historical Env-A 1400 compliance<br />

2003 – 2007; January 28, 2008.

PERMIT APPLICATION<br />

REVIEW SUMMARY<br />

<strong>New</strong> <strong>Hampshire</strong> <strong>Department</strong> <strong>of</strong> Environmental Services<br />

Air Resources Division<br />

P.O. Box 95, 29 Hazen Drive<br />

Concord, NH 03302-0095<br />

Phone: 603-271-1370 Fax: 603-271-7053<br />

Facility: Hypertherm, Inc./Centricut Engineer: Muriel Lajoie<br />

Location: Two Technology Drive, West Lebanon, NH 03784<br />

AFS #: 3300990304 Application #: FY07-0265 Date: DRAFT<br />

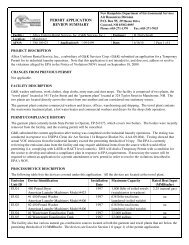

PROCESS DESCRIPTION<br />

Hypertherm’s plasma arc cutting torches utilize an ionized gas stream to vaporize metal. Hypertherm cuts mild steel,<br />

stainless steel and aluminum ranging in thickness from 0.048 inches to 2 inches.<br />

POLLUTION CONTROL EQUIPMENT<br />

As discussed in Application FY07-0265, the two plasma arc cutting tables will be ducted in series to a cyclone and a<br />

cartridge filter-type dust collector. The Facility is using the cyclone for large particle removal and is not taking credit for<br />

this in the removal efficiency <strong>of</strong> RTAPs, NOx or PM. Only the cartridge collector will be considered as pollution control<br />

equipment for RTAPs and PM from the Plasma Arc Cutting Tables. The cartridge collector will use the wide-spacing<br />

PolyTech Filter Media in the HemiPleat Filter by Farr Air Pollution Control. Manufacturer’s literature specifies removal<br />

efficiency <strong>of</strong> 99.99% on 0.5 ųm and larger particles by weight.<br />

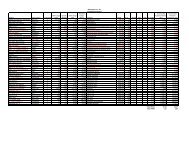

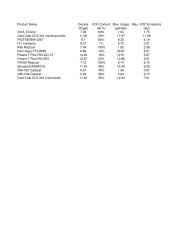

EMISSION CALCULATIONS<br />

Emission testing for plasma arc cutting was conducted on 10/11/2001 at Hypertherm’s Hanover, NH Facility. These<br />

emission rates are summarized in Table 1 Emissions Test Data for Plasma Arc Cutting in Application FY07-0265.<br />

Emission rates for each type <strong>of</strong> metal cut (mild steel, aluminum and stainless steel) were averaged as pounds <strong>of</strong> pollutant<br />

per inch <strong>of</strong> metal cut. The highest <strong>of</strong> the three rates was converted into lbs/day <strong>of</strong> pollutant based on the maximum inches<br />

<strong>of</strong> metal expected to be cut per day (86,400 inches = 72 in/min * 60 min/hr * 20 hr/day). These values are considered the<br />

daily and annual (using 5,616,000 inches) uncontrolled emission rates. Six <strong>of</strong> 17 Regulated Toxic Air Pollutants (RTAPs)<br />

were below the 24-hour DeMinimis values for those pollutants. Ten <strong>of</strong> 17 RTAPs were below the Annual DeMinimis<br />

values for those pollutants.<br />

Post control emission rates in <strong>application</strong> FY07-0265 consider a filter efficiency rating <strong>of</strong> 99.99%. All 17 RTAPs passed<br />

both the 24-hour Adjusted In-Stack Concentration and Annual Adjusted In-Stack Concentration at this filter efficiency.<br />

Emissions testing conducted in Hanover showed that the efficiency <strong>of</strong> the collector cartridges used in that <strong>application</strong> did<br />

not meet the 99% efficiency rating stated in Temporary Permit FP-T-0064. However, though included in the <strong>permit</strong>, the<br />

99% efficiency value was not necessary to maintain compliance with Env-A 1400. “…DES also agrees with Hypertherm’s<br />

conclustion that, although the dust collectors do not meet the 99% control efficiency required in Condition VI <strong>of</strong> the<br />

Permit, emissions from the cutting tables have not caused exceedances <strong>of</strong> the AALs”. 2<br />

In the case <strong>of</strong> the West Lebanon Hypertherm, Inc./Centricut Facility, compliance with the 24-hour and Annual AAL is<br />

dependent upon a minimum performance <strong>of</strong> the cartridge filters. Adjusted In-Stack Concentrations for both the 24-hour<br />

and Annual AAL for all 17 RTAPs can be met with a filter efficiency <strong>of</strong> 97%. Essentially the cartridge collector with the<br />

PolyTech Filter Media is 300 times more effective than it needs to be to assure compliance with the AALs.<br />

The criteria pollutants particulate matter (PM) and Oxides <strong>of</strong> Nitrogen (NOx) were evaluated to be below the major source<br />

thresholds or 50 and 100 tons per year (tpy), respectively for these pollutants. Particulate matter was evaluated at the 97%<br />

removal efficiency <strong>of</strong> the filter. NOx emitted was considered as 100% <strong>of</strong> the daily and annual uncontrolled emission rate as<br />

the cartridge filter is not considered a pollution control device for NOx. The Facility is a True Minor source for these<br />

pollutants.<br />

See the emissions calculations <strong>summary</strong> at: Hyper_Review_<strong>of</strong>_GZACalcs.xls.<br />

2 Pamela G. Monroe to Mr. John Blair, June 11, 2002.

PERMIT APPLICATION<br />

REVIEW SUMMARY<br />

<strong>New</strong> <strong>Hampshire</strong> <strong>Department</strong> <strong>of</strong> Environmental Services<br />

Air Resources Division<br />

P.O. Box 95, 29 Hazen Drive<br />

Concord, NH 03302-0095<br />

Phone: 603-271-1370 Fax: 603-271-7053<br />

Facility: Hypertherm, Inc./Centricut Engineer: Muriel Lajoie<br />

Location: Two Technology Drive, West Lebanon, NH 03784<br />

AFS #: 3300990304 Application #: FY07-0265 Date: DRAFT<br />

STACK INFORMATION<br />

The following table details the stack parameters for the <strong>permit</strong>ted devices:<br />

Stack<br />

Inside<br />

Diameter<br />

(ft)<br />

Exhaust Flow<br />

(acfm)<br />

Exhaust<br />

Temp.<br />

( o F)<br />

Plasma Arc Cutting<br />

Tables 1& 2<br />

Height Above<br />

Ground (ft)<br />

Stack<br />

Configuration<br />

1.08 2,000 70 22.83 Vertical and<br />

Unobstructed<br />

MODELING<br />

Modeling is not necessary as the source has demonstrated compliance with Env-A 1405.05 Adjusted In-Stack<br />

Concentration Method and the air flow exiting the stack is unobstructed.<br />

EMISSION TESTING<br />

No emissions testing will be required at this time.<br />

SITE VISITS/INSPECTIONS<br />

As <strong>of</strong> the date <strong>of</strong> this engineering <strong>summary</strong>, there have been no site visits or inspections <strong>of</strong> the Hypertherm, Inc./Centricut<br />

Facility in West Lebanon.<br />

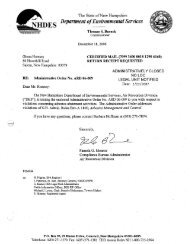

REPORTS/FEES<br />

Annual Emission Reports/Fees<br />

This is a new <strong>permit</strong> subject to <strong>permit</strong> fees under Env-A 702.02(a) and (b). The Facility submitted the fee required under<br />

Env-A 702.02(a) with the <strong>permit</strong> <strong>application</strong>. An invoice was sent to the Facility for the fee due under Env-A 702.02(b) on<br />

1/23/2008 in accordance with Env-A 702.02(c).<br />

CHANGES FROM PREVIOUS PERMIT<br />

Not applicable.<br />

REVIEW OF REGULATIONS<br />

State Regulations<br />

Env-A 600 – Permitting<br />

• 607.01(g) – Not Applicable – The Facility does not have any volatile organic compound (VOC) emissions.<br />

607.01(n) – Not Applicable - The Facility is a true minor source <strong>of</strong> all criteria pollutants (PM & NOx).<br />

• 607.01 (v) – Applicable – The source has a control device to reduce pollutants subject to Env-A 1400 and requires<br />

a <strong>permit</strong>.<br />

Env-A 1200 – Prevention, Abatement and Control <strong>of</strong> Stationary Source Air Pollution<br />

• 1204 – There is no source at the Facility subject to any VOC RACT requirements.<br />

• 1211.01(m) – Not Applicable – The Facility TPE for NOx is < 50 tpy.

PERMIT APPLICATION<br />

REVIEW SUMMARY<br />

<strong>New</strong> <strong>Hampshire</strong> <strong>Department</strong> <strong>of</strong> Environmental Services<br />

Air Resources Division<br />

P.O. Box 95, 29 Hazen Drive<br />

Concord, NH 03302-0095<br />

Phone: 603-271-1370 Fax: 603-271-7053<br />

Facility: Hypertherm, Inc./Centricut Engineer: Muriel Lajoie<br />

Location: Two Technology Drive, West Lebanon, NH 03784<br />

AFS #: 3300990304 Application #: FY07-0265 Date: DRAFT<br />

Env-A 1400 – Regulated Toxic Air Pollutants<br />

• 1402.01(c) – Applicable/Not Applicable – The exemption applies to only six <strong>of</strong> 17 Regulated Toxic Air Pollutants<br />

(RTAPs) which are below the 24-hour deminimis values for those pollutants and ten <strong>of</strong> 17 RTAPs which are below<br />

the annual deminimis values for those pollutants.<br />

• 1403.01(a) – Applicable – The Facility emits eleven <strong>of</strong> 17 RTAPs above the 24-hour de-mimimis values for those<br />

pollutants and seven <strong>of</strong> 17 RTAPs above the annual de-minimis values for those pollutants.<br />

• 1405.05 – Applicable – The Facility has chosen to demonstrate compliance with Env-A 1400 by using the<br />

Adjusted In-Stack Concentration.<br />

Env-A 2100 – Particulate Matter and Visible Emissions Standards<br />

• 2103.01 – Applicable – The Plasma Arc Cutting Tables are a source <strong>of</strong> visible emissions.<br />

• 2103.02 – Applicable – Average opacity from all stationary devices shall not exceed 20% opacity for any<br />

continuous 6-minute period in any 60 minute period during startup, shutdown or malfunction.<br />

Federal Regulations<br />

• No federal regulations are applicable to the Facility.<br />

SUMMARY AND CONCLUSIONS<br />

The operations, as applied for, will be capable <strong>of</strong> meeting all regulations and standards for air quality. A Temporary Permit<br />

shall be drafted.<br />

H:\Permitting\Source Files\Hypertherm\07-0265_TP\Hyper_Summary.doc