Electropac_06-0037_Eng Sum(excel)

Electropac_06-0037_Eng Sum(excel)

Electropac_06-0037_Eng Sum(excel)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

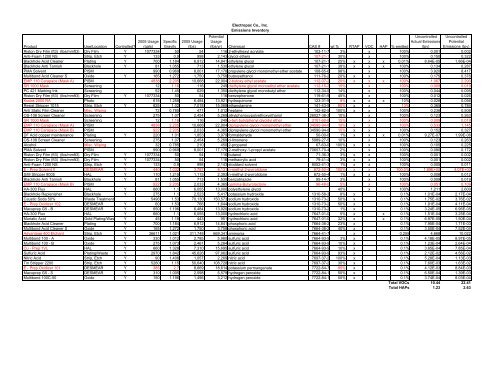

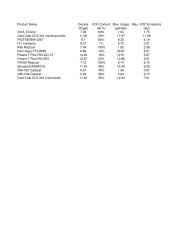

<strong>Electropac</strong> Co., Inc.<br />

Emissions Inventory<br />

Potential<br />

Usage<br />

(lbs/yr) Chemical CAS # wt % RTAP VOC HAP % emitted<br />

Uncontrolled<br />

Actual Emissions<br />

(tpy)<br />

Uncontrolled<br />

Potential<br />

Emissions (tpy)<br />

Product Use/Location Controlled<br />

2005 Usage<br />

(gals)<br />

Specific<br />

Gravity<br />

2005 Usage<br />

(lbs)<br />

Riston Dry Film (ft3) (lbs/mmft3) Dry Film Y 1077334 50 54 116 2-ethylhexyl acrylate 103-11-7 3% x 100% 0.001 0.002<br />

Anti-Foam 1200 NS Strip, Etch Y 133 0.9 998 2,143 glycol ethers 107-21-1 30% x 100% 0.150 0.322<br />

Blackhole Acid Cleaner Plating Y 700 1.184 6,912 14,841 ethylene glycol 107-21-1 25% x x x 0.01% 8.64E-05 1.86E-04<br />

Blackhole Anti Tarnish Blackhole Y 81 1.055 713 1,530 ethylene glycol 107-21-1 38% x x x 100% 0.134 0.287<br />

PMA Solvent PISM 990 0.969 8,001 17,178 propylene glycol monomethyl ether acetate 108-65-6 98% x 100% 3.920 8.417<br />

Multibond Acid Cleaner S Oxide Y 165 1.272 1,750 3,758 butoxyethanol 111-76-2 20% x x 100% 0.175 0.376<br />

EMP 110 Carapace (Mask A) PISM 4838 2.205 10,668 22,904 2-butoxy ethyl acetate 112-07-2 20% x x x 100% 1.<strong>06</strong>7 2.290<br />

SR 1000 Mask Screening 12 1.16 116 249 diethylene glycol monoethyl ether acetate 112-15-2 15% x 100% 0.009 0.019<br />

PC 421 Marking Ink Screening 52 1.45 629 1,350 diethylene glycol monobutyl ether 112-34-5 14% x 100% 0.044 0.095<br />

Riston Dry Film (ft3) (lbs/mmft3) Dry Film Y 1077334 50 54 116 benzophenone 119-61-9 45% x 100% 0.012 0.026<br />

Kodak 2000 RA Photo 618 1.258 6,484 13,921 hydroquinone 123-31-9 8% x x x 10% 0.026 0.056<br />

Resist Stripper 1015 Strip, Etch Y 825 1.02 7,018 15,<strong>06</strong>8 ethanolamine 141-43-5 80% x x 13% 0.365 0.784<br />

Anti Static Film Cleaner Misc. Wiping 72 0.785 471 1,012 heptane 142-82-5 100% x x 100% 0.236 0.5<strong>06</strong><br />

OS-108 Screen Cleaner Screening 275 1.07 2,454 5,269 alkylphenoxypolyethoxyethanol 26027-38-3 10% x 100% 0.123 0.263<br />

SR 1000 Mask Screening 12 1.16 116 249 p-tert-butylphenyl glycidyl ether 3101-60-8 15% x 100% 0.009 0.019<br />

EMP 110 Carapace (Mask A) PISM 4838 2.205 10,668 22,904 dipropylene glycol monomethyl ether 34590-94-8 10% x x 100% 0.533 1.145<br />

EMP 110 Carapace (Mask B) PISM 922 2.205 2,033 4,365 dipropylene glycol monomethyl ether 34590-94-8 15% x x 100% 0.152 0.327<br />

DF Acid copper maintenance Plating Y 220 1.01 1,853 3,979 formaldehyde 50-00-0 1% x x x 0.01% 9.27E-07 1.99E-<strong>06</strong><br />

OS-108 Screen Cleaner Screening 275 1.07 2,454 5,269 d-limonene 5989-27-5 10% x 100% 0.123 0.263<br />

Alcohol Misc. Wiping 32 0.785 210 450 2-propanol 67-63-0 100% x x 100% 0.105 0.225<br />

PMA Solvent PISM 990 0.969 8,001 17,178 2-methoxy-1-propyl acetate 7<strong>06</strong>57-70-4 2% x 100% 0.080 0.172<br />

Riston Dry Film (ft3) (lbs/mmft3) Dry Film Y 1077334 50 54 116 butanol 71-36-3 3% x x 100% 0.001 0.002<br />

Riston Dry Film (ft3) (lbs/mmft3) Dry Film Y 1077334 50 54 116 methacrylic acid 79-41-4 3% x x 100% 0.001 0.002<br />

Anti-Foam 1200 NS Strip, Etch Y 133 0.9 998 2,143 stoddard solvent 8052-41-3 1% x x 100% 0.005 0.011<br />

E - Prep Solvent II DESMEAR Y 440 1.032 3,787 8,131 n-methyl-2-pyrrolidone 872-50-4 100% x x 100.0% 1.89E+00 4.07E+00<br />

S/M Stripper 8005 HAL Y 110 1.215 1,115 2,393 n-methyl-2-pyrrolidone 872-50-4 1% x x 100% 0.0<strong>06</strong> 0.012<br />

Blackhole Anti Tarnish Blackhole Y 81 1.055 713 1,530 benzotriazole 95-14-7 3% x 100% 0.009 0.019<br />

EMP 110 Carapace (Mask B) PISM 922 2.205 2,033 4,365 gamma-Butyrolactone 96-48-0 5% x 100% 0.051 0.109<br />

HA-300 Flux HAL Y 660 1.1 6,055 13,000 polyethylene glycol 40% x 100% 1.211 2.600<br />

Blackhole Replenisher Blackhole Y 275 1.1 2,523 5,417 potassium hydroxide 1310-58-3 8% x 0.1% 1.01E-04 2.17E-04<br />

Caustic Soda 50% Waste Treatment 5496 1.53 70,130 150,573 sodium hydroxide 1310-73-2 50% x 0.1% 1.75E-02 3.76E-02<br />

E - Prep Oxidizer 102 DESMEAR Y 60 1.53 766 1,644 sodium hydroxide 1310-73-2 50% x 0.1% 1.91E-04 4.11E-04<br />

Macuprep G5 - B DESMEAR Y 650 1.196 6,484 13,920 sodium hydroxide 1310-73-2 1% x 0.1% 3.24E-05 6.96E-05<br />

HA-300 Flux HAL Y 660 1.1 6,055 13,000 hydrochloric acid 7647-01-0 5% x x 0.1% 1.51E-04 3.25E-04<br />

Muriatic Acid Gold Plating/Was Y 45 1.18 443 951 hydrochloric acid 7647-01-0 32% x x 0.1% 6.97E-05 1.50E-04<br />

Blackhole Acid Cleaner Plating Y 700 1.184 6,912 14,841 phosphoric acid 7664-38-2 23% x 0.1% 7.95E-04 1.71E-03<br />

Multibond Acid Cleaner S Oxide Y 165 1.272 1,750 3,758 phosphoric acid 7664-38-2 40% x 0.1% 3.50E-04 7.52E-04<br />

Advantage 400 Etchant Strip, Etch Y 36611 1.021 311,748 669,341 ammonia 7664-41-7 x 0.255 4.668 10.022<br />

Multibond 100 - A Oxide Y 330 1.012 2,785 5,980 sulfuric acid 7664-93-9 3% x 0.1% 4.18E-05 8.97E-05<br />

Multibond 100 - B Oxide Y 275 1.073 2,461 5,284 sulfuric acid 7664-93-9 10% x 0.1% 1.23E-04 2.64E-04<br />

Cu - Prep 1VL HAL Y 660 1.328 7,310 15,695 sulfuric acid 7664-93-9 10% x 0.1% 3.65E-04 7.85E-04<br />

Sulfuric Acid Plating/Waste Y 2970 1.842 45,626 97,962 sulfuric acid 7664-93-9 93% x 0.1% 2.12E-02 4.56E-02<br />

Nitric Acid Strip, Etch Y 90 1.408 1,057 2,269 nitric acid 7697-37-2 100% x 0.1% 5.28E-04 1.13E-03<br />

Tin Stripper 2200 Strip, Etch Y 5280 1.15 50,640 108,728 nitric acid 7697-37-2 30% x 0.1% 7.60E-03 1.63E-02<br />

E - Prep Oxidizer 101 DESMEAR Y 385 2.7 8,669 18,614 potassium permanganate 7722-64-7 95% x 0.1% 4.12E-03 8.84E-03<br />

Macuprep G5 - S DESMEAR Y 310 1.005 2,598 5,579 hydrogen peroxide 7722-84-1 50% x 0.1% 6.50E-04 1.39E-03<br />

Multibond 100C-50 Oxide Y 150 1.196 1,496 3,212 hydrogen peroxide 7722-84-1 50% x 0.1% 3.74E-04 8.03E-04<br />

Total VOCs 10.44 22.41<br />

Total HAPs 1.23 2.63

<strong>Electropac</strong> Co., Inc.<br />

RTAP <strong>Sum</strong>mary<br />

Potential<br />

Emissions<br />

(lbs/day)<br />

Potential<br />

Emissions<br />

(lbs/yr)<br />

Annual<br />

Demin<br />

(lbs/yr)<br />

Annual<br />

AAL<br />

(ug/m3)<br />

stack flow<br />

rate<br />

(acfm)<br />

emission<br />

rate<br />

(ug/sec)<br />

In-Stack<br />

Concentration<br />

(ug/m3)<br />

24-hr Demin<br />

24-hr AAL<br />

flow rate<br />

Adjusted<br />

Chemical CAS #<br />

(lbs/day)<br />

(ug/m3)<br />

(m3/sec)<br />

In-Stack<br />

formaldehyde 50-00-0 0.00001 0.004 0.01 3.8<br />

2-propanol (isopropyl alcohol) 67-63-0 1.2324 449.81 14 5,044<br />

n-butyl alcohol 71-36-3 0.0095 3.47 2.4 875<br />

methacrylic acid 79-41-4 0.0095 3.47 2.8 1,010<br />

ethylene glycol 107-21-1 1.7627 643.39 4 1,444<br />

butoxyethanol 111-76-2 2.0593 751.64 102 37,318<br />

2-butoxyethyl acetate 112-07-2 12.5503 4,580.87 5.2 1,892 659 439 6900 3.256253 65860.31 20225.80 50.56<br />

hydroquinone 123-31-9 0.3051 111.37 0.079 29 10 6.7 28000 13.21378 1601.196 121.18 0.30<br />

ethanolamine 141-43-5 4.2934 1,567.10 0.21 77 27 18 28000 13.21378 22530.6 1705.08 4.26<br />

heptane 142-82-5 2.7728 1,012.07 65 23,681<br />

n-methyl-2-pyrrolidone 872-50-4 22.3422 8,154.90 11 4,102 1429 952 5000 2.359604 117245 49688.41 124.22<br />

potassium hydroxide 1310-58-3 0.0012 0.43 0.089 32<br />

sodium hydroxide 1310-73-2 0.2089 76.25 0.26 96<br />

hydrochloric acid 7647-01-0 0.0026 0.95 0.084 31<br />

phosphoric acid 7664-38-2 0.0135 4.92 0.12 43<br />

ammonia 7664-41-7 54.9165 20,044.52 0.79 287 100 100 28000 13.21378 288184.8 21809.42 54.52<br />

sulfuric acid 7664-93-9 0.2558 93.38 0.0056 2 0.71 0.48 33000 15.57338 1342.569 86.209 0.216<br />

nitric acid 7697-37-2 0.0956 34.89 0.15 53<br />

potassium permanganate 7722-64-7 0.0484 17.68 0.0079 2.9 1 0.67 28000 13.21378 254.2339 19.24 0.05<br />

hydrogen peroxide 7722-84-1 0.0120 4.40 0.078 28<br />

stoddard solvent 8052-41-3 0.0587 21.43 21 7,581<br />

dipropylene glycol monomethyl ether 34590-94-8 8.<strong>06</strong>90 2,945.19 24 8,750

Calculation of Emissions from Resist Stripper 1015<br />

givens:<br />

per manufacturer solution contains 80% by wt ethanolamine<br />

solution used uses 3% of the solution mixed with water<br />

molecular weight of ethanolamine = 61.1<br />

exhaust flow rate = 200 acfm<br />

process is operated at 130 F = 625 R = 55 C<br />

Antoine Coefficients for ethanolamine (from Perry's Chemical <strong>Eng</strong>ineering Handbook, 6th edition)<br />

a = 7.456<br />

b= 1577.67<br />

c= 173.370<br />

Calculations:<br />

the vapor pressure of pure ethanolamine at 55 C is calculated using Antoine's Equation<br />

log p = a - [b/(T+c)] = 7.456 - [1577.67/(55+173.370)] 0.5476<strong>06</strong><br />

p = 3.528627 mm Hg<br />

p = 0.004643 atm<br />

Raoult's Law states that the partial vapor pressure of each component is equal to the product of its pure vapor<br />

pressure and its liquid mole fraction.<br />

moles of ethanolamine = wt. Fraction/mol. wt. = 0.0003928<br />

moles of remaining solution (assumed water) = 0.05422222<br />

mole fraction of ethanolamine = moles ethanolamine/moles solution = 0.007192<br />

partial vapor pressure = 0.00719 * 0.004643 =<br />

3.3391E-05 atm<br />

vapor concentration is calculated using the Ideal Gas Law, PV = nRT<br />

n/V = 7.31664E-08 moles/cf<br />

vapor concen. = n/V * mol. wt. = 4.47046E-<strong>06</strong> lb/cf<br />

emissions = (vapor concen.) * (flow rate * 60 min/hr) =<br />

0.054 lbs/hr<br />

resist stripper usage rate is approximately 0.52 lb/hr<br />

% of solvent emitted = 0.054/(0.52*0.8) = 13%