QA and Management Specifications in the ITER Project - Iter Industry

QA and Management Specifications in the ITER Project - Iter Industry

QA and Management Specifications in the ITER Project - Iter Industry

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ITER</strong> for Swiss <strong>Industry</strong><br />

28 th September 2009, Kultur‐Cas<strong>in</strong>o Cas<strong>in</strong>o, Berne<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> <strong>in</strong><br />

<strong>the</strong> <strong>ITER</strong> <strong>Project</strong><br />

Jesus Izquierdo<br />

Eng<strong>in</strong>eer<strong>in</strong>g Support Division – Analysis <strong>and</strong> Codes

Outl<strong>in</strong>e<br />

Issues to address:<br />

1.Why Quality Assurance<br />

2.Why <strong>Management</strong> <strong>Specifications</strong><br />

3.How to satisfy F4E <strong>Management</strong><br />

<strong>Specifications</strong>.<br />

4.Codes <strong>and</strong> St<strong>and</strong>ards.<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 2

Why <strong>QA</strong><br />

Installation Nucléaire de Base<br />

accord<strong>in</strong>g to French Regulation<br />

→ Order of August 10, 1984,<br />

Concern<strong>in</strong>g Quality <strong>in</strong> <strong>the</strong> design,<br />

construction <strong>and</strong> operation of<br />

Basic Nuclear Installations<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 3

Why <strong>QA</strong><br />

French Authority<br />

European <strong>Industry</strong><br />

<strong>and</strong> associations<br />

Quality Order<br />

of August 10,<br />

1984<br />

Nuclear Operator<br />

Domestic Agency<br />

<strong>ITER</strong> <strong>QA</strong><br />

<strong>ITER</strong> <strong>QA</strong><br />

Program<br />

Requirements<br />

<strong>ITER</strong><br />

ORGANIZATION<br />

DA <strong>QA</strong><br />

Program<br />

Requirements<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 4

Why <strong>QA</strong><br />

QUALITY ORDER OF AUGUST 10, 1984 FRENCH REGULATION FOR NUCLEAR SAFETY<br />

The required quality is obta<strong>in</strong>ed <strong>and</strong> ma<strong>in</strong>ta<strong>in</strong>ed on one h<strong>and</strong> by activities performed <strong>and</strong> on <strong>the</strong> o<strong>the</strong>r<br />

h<strong>and</strong> by organized <strong>and</strong> appropriate verification.<br />

Art 1. Graded quality<br />

management system<br />

accord<strong>in</strong>g to safety<br />

importance of<br />

components <strong>and</strong><br />

activities (SIC) - Set up<br />

at t<strong>the</strong> design stage <strong>and</strong><br />

extended throughout all <strong>the</strong><br />

subsequent stages of<br />

existence of <strong>the</strong> Installation.<br />

Art 2. Def<strong>in</strong>ition Art 6. Safety Art 14. Safety<br />

of safety relevant requirement are relevant studies<br />

activities. def<strong>in</strong>ed <strong>and</strong> specificities<br />

Art 7. Approp.<br />

human <strong>and</strong><br />

technical resour.<br />

Art 3. & 4. Ensure<br />

Control of<br />

Suppliers<br />

Art 12. &13.<br />

Manage age NC<br />

<strong>and</strong> <strong>in</strong>cidents<br />

Art 8.<br />

Independent<br />

verification of<br />

safety relevant<br />

activities.<br />

Art 10. & 11. Art 5. Issue of <strong>QA</strong> manual +<br />

Document<strong>in</strong>g data & <strong>QA</strong> compliance report +<br />

manag<strong>in</strong>g records contractors assessment.<br />

At9 Art 9. <strong>QA</strong> management tt team +Evaluation <strong>and</strong> correction monitor<strong>in</strong>g<br />

i<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 5

Why <strong>Management</strong> <strong>Specifications</strong><br />

French<br />

Authority<br />

Regulations<br />

<strong>ITER</strong> <strong>QA</strong> PROGRAM<br />

Compliant with<br />

French Authority Regulations<br />

F4E <strong>QA</strong> PROGRAM<br />

Compliant with<br />

French Authority Regulations<br />

<strong>and</strong> <strong>ITER</strong> <strong>QA</strong> Program<br />

Associate<br />

or<br />

<strong>Industry</strong><br />

QUALITY PLAN<br />

Compliant with<br />

F4E <strong>QA</strong> Program<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 6

MS – Quality Plan<br />

The control of <strong>the</strong> technical activities of <strong>the</strong> suppliers are carried out<br />

through three contractual documents:<br />

– The technical specification (“what”) to def<strong>in</strong>e <strong>the</strong> object of <strong>the</strong><br />

contract (<strong>the</strong> «as specified» configuration of <strong>the</strong> product).<br />

– The management specification (“how”) to def<strong>in</strong>e <strong>the</strong> quality<br />

requirements to be met by <strong>the</strong> supplier QUALITY PLAN<br />

– The contract/grant agreement to def<strong>in</strong>e <strong>the</strong> commercial <strong>and</strong> legal<br />

requirements <strong>and</strong> provisions that are applicable.<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 7

MS – Quality Plan<br />

The dedicated Quality plan describes <strong>the</strong><br />

operational quality system implemented<br />

by <strong>the</strong> bidder/supplier to ensure that:<br />

• Contract requirements will be met,<br />

• Evidence of such compliance will be<br />

ma<strong>in</strong>ta<strong>in</strong>ed.<br />

The Quality Plan shall have a m<strong>and</strong>atory<br />

structure. This makes it easier for all<br />

<strong>in</strong>volved to:<br />

• Compare Bidders Quality Plans<br />

• Review Quality Plans<br />

• Detect Miss<strong>in</strong>g Items <strong>in</strong> a Plan<br />

•Propose updates<br />

• Use it dur<strong>in</strong>g contract follow-up<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 8

MS – Quality Plan<br />

AT TENDER LEVEL<br />

– The Bidder shall provide, <strong>in</strong> its offer a mean<strong>in</strong>gful outl<strong>in</strong>e of a dedicated QP with <strong>the</strong><br />

plans, schedules <strong>and</strong> explanation of <strong>the</strong> provisions to comply with <strong>the</strong> requirements<br />

– The Bidder will be evaluated on <strong>the</strong> basis of its QP accord<strong>in</strong>g to <strong>the</strong> Tender Specs.<br />

– Certification accord<strong>in</strong>g to <strong>in</strong>ternational st<strong>and</strong>ard is not m<strong>and</strong>atory (but recommended).<br />

Specific requirements can be def<strong>in</strong>ed for each contract through <strong>the</strong> management<br />

specification based on <strong>the</strong> contract complexity.<br />

The Quality Plan shall be referenced as an “outl<strong>in</strong>e’ version where:<br />

– Some sections will be addressed as a description of <strong>the</strong> proposed system<br />

– The rema<strong>in</strong><strong>in</strong>g sections shall have <strong>the</strong> description of <strong>the</strong> Bidder current system.<br />

(To have evidence that all <strong>the</strong> specific requirement are addressed <strong>and</strong> all provision for<br />

ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g <strong>the</strong>se requirements have been foreseen by <strong>the</strong> bidder)<br />

AT CONTRACT LEVEL<br />

1. Kick-off meet<strong>in</strong>g - <strong>the</strong> Supplier shall provide <strong>the</strong> proposed Quality Plan;<br />

2. The Supplier shall not beg<strong>in</strong> any work without <strong>the</strong> QP be<strong>in</strong>g approved <strong>in</strong> writ<strong>in</strong>g<br />

3. Dur<strong>in</strong>g Contract implementation, i <strong>the</strong> Supplier shall update <strong>the</strong> Quality Plan (or parts of<br />

it) as/if required <strong>and</strong> shall submit it for approval to F4E.<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 9

MS – Graded Quality Level<br />

Quality Implementation with<strong>in</strong> Fusion for Energy projects uses a “Graded Approach” to<br />

def<strong>in</strong>e <strong>and</strong> perform quality requirements.<br />

The Quality Classes are def<strong>in</strong>ed <strong>in</strong>: FE-<strong>QA</strong>-010 - Quality Classification (where specific<br />

requirements for each quality class are provided)<br />

They are def<strong>in</strong>ed on <strong>the</strong> basis of:<br />

– Safety Importance Class assigned to <strong>the</strong> item,<br />

– Anticipated impact of item failure or malfunction on plant availability,<br />

– Maturity <strong>and</strong> complexity related to a risk of failure or malfunction.<br />

Items may belong to one of four (4) quality classes, def<strong>in</strong>ed as follows:<br />

Class 1<br />

Class 2<br />

Any Safety Related class Item OR any item whose failure/malfunction could result <strong>in</strong> extensive<br />

mach<strong>in</strong>e downtime<br />

Any Non-Safety Related Class Item whose failure could result <strong>in</strong> major downtime <strong>and</strong><br />

cost/schedule impacts.<br />

Class 3<br />

Any Non-Safety Related Class Item whose failure could result <strong>in</strong> limited it downtime, cost/schedule<br />

impact<br />

Class 4<br />

Commercial Grade Items that are off <strong>the</strong> commercial shelf purchased item us<strong>in</strong>g manufacturers<br />

catalogues without <strong>the</strong> need to provide an eng<strong>in</strong>eer<strong>in</strong>g g specification. No <strong>QA</strong> Program applicability.<br />

A m<strong>in</strong>imum of a Certificate of Conformity (CoC) is required on delivery.<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 10

MS – Control Plan<br />

Matrix with <strong>the</strong> WBS <strong>and</strong> <strong>the</strong><br />

milestones, criteria, key po<strong>in</strong>ts (hold,<br />

acceptance, review, notification, etc).<br />

The Control plan is a sequence of<br />

critical operations, <strong>in</strong>structions <strong>and</strong><br />

requirements, activities that F4E or its<br />

representative <strong>in</strong>tends to observe<br />

Includes <strong>the</strong> requirements <strong>and</strong> actors of<br />

activities <strong>and</strong> <strong>the</strong> status of <strong>the</strong> operation<br />

listed.<br />

Will be used as a Review Matrix by:<br />

- supplier<br />

-F4E<br />

Annex to <strong>the</strong> Quality Plan<br />

(Up-to-date status is essential)<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 11

MS - Documentation Schedule<br />

Contract Implementation <strong>and</strong> Follow-up<br />

Documentation.<br />

Up-to-date list of:<br />

– records<br />

– plans/ schedules/ manuals<br />

– draw<strong>in</strong>gs/ models<br />

– documents <strong>and</strong> data expected dur<strong>in</strong>g<br />

<strong>the</strong> contract <strong>and</strong>/or essential to<br />

perform <strong>the</strong> task <strong>and</strong>/or part of <strong>the</strong><br />

ADP<br />

– Progress Meet<strong>in</strong>gs Documentation<br />

(decision records)<br />

– Progress Report (usually monthly)<br />

– F<strong>in</strong>al <strong>and</strong> Intermediate Report<br />

Annex to <strong>the</strong> Quality Plan<br />

Up-to-date status is essential<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 12

MS - Subcontract<strong>in</strong>g<br />

Subcontractor must be accepted by F4E<br />

Quality Assurance Requirement:<br />

– Quality System, or<br />

– Assessment Report<br />

All major or critical items <strong>and</strong> activities<br />

subcontracted by <strong>the</strong> Supplier<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 13

MS – Change <strong>Management</strong><br />

Divergences are addressed with <strong>the</strong><br />

follow<strong>in</strong>g processes:<br />

Change – a previously proposed <strong>and</strong><br />

approved modification to a specified<br />

requirement (current approved<br />

configuration basel<strong>in</strong>es).<br />

Deviation - a previously planned<br />

alternative to a specified requirement<br />

def<strong>in</strong>ed for a specific scope (a limited<br />

quantity of product or period of time, <strong>and</strong><br />

for a specific use).<br />

Nonconformity – any condition which<br />

does not comply with a specified<br />

requirement.<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 14

Codes <strong>and</strong> St<strong>and</strong>ards<br />

Multi-code approach is applied for <strong>the</strong> selection of <strong>the</strong> Codes for<br />

various <strong>ITER</strong> components:<br />

• <strong>the</strong> wide variety of <strong>the</strong> <strong>ITER</strong> components <strong>and</strong> loads which does not allow to<br />

use one exist<strong>in</strong>g <strong>in</strong>dustrial Code;<br />

• <strong>the</strong> needs to use some advantages of specific exist<strong>in</strong>g Codes to cover <strong>the</strong><br />

particular <strong>ITER</strong> operational requirements;<br />

• <strong>the</strong> unique feature of some <strong>ITER</strong> components (magnet, <strong>in</strong>-vessels) for which<br />

<strong>the</strong>re are no exist<strong>in</strong>g Codes <strong>and</strong> special Codes shall be developed;<br />

• <strong>the</strong> reduction of cost of equipment due to <strong>the</strong> procurement shar<strong>in</strong>g with <strong>the</strong><br />

<strong>ITER</strong> Members.<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 15

Codes <strong>and</strong> St<strong>and</strong>ards - Mechanics<br />

In France, <strong>the</strong> basic regulatory documents do not require specific<br />

design <strong>and</strong> manufactur<strong>in</strong>g Codes, but are documents formulat<strong>in</strong>g<br />

general Essential Safety Requirements (ESR) <strong>and</strong> <strong>the</strong> ways how to<br />

fulfil <strong>the</strong>se requirements from technical <strong>and</strong> legal po<strong>in</strong>t of view.<br />

• Pressure Equipment Directive, 97/23/EC (PED), Directive <strong>the</strong><br />

French order No 1046, 13th December 1999 concern<strong>in</strong>g pressure<br />

equipment (<strong>and</strong> ammenndmends)<br />

• French Order dated 12th December 2005 concern<strong>in</strong>g nuclear<br />

pressure equipment<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 16

Codes <strong>and</strong> St<strong>and</strong>ards - Mechanics<br />

•<strong>ITER</strong> components are designed <strong>and</strong> manufactured follow<strong>in</strong>g, when<br />

possible, exist<strong>in</strong>g <strong>in</strong>dustrial codes.<br />

• Special additional requirements have been prepared as addendum or<br />

technical specifications to <strong>the</strong> basic selected codes for specific systems<br />

• Follow<strong>in</strong>g <strong>the</strong> procurement based on <strong>in</strong>ternational contributions <strong>the</strong><br />

reference codes are selected from <strong>the</strong> ASME codes. ASME has also<br />

published documents that provide guides to demonstrate conformity to<br />

European requirements<br />

• In some cases European Codes have been or could be selected for<br />

special application where <strong>the</strong> rules better address specific applications.<br />

• Dur<strong>in</strong>g <strong>the</strong> <strong>ITER</strong> design phase a large effort has been devoted to <strong>the</strong><br />

preparation of design criteria for <strong>the</strong> magnets <strong>and</strong> <strong>the</strong> <strong>in</strong>-vessel<br />

components.<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 17

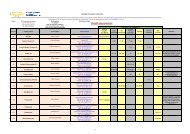

Codes <strong>and</strong> St<strong>and</strong>ards - Mechanics<br />

Component<br />

Magnets<br />

PED Category<br />

or ESPN category & level<br />

Magnet structure no PED<br />

Manifolds <strong>and</strong> pip<strong>in</strong>g PED<br />

Selected Codes<br />

Design – Structural Design Criteria - Magnet<br />

Manufactur<strong>in</strong>g – Technical specification<br />

Acceptance criteria – SDC-MC, based on ASME<br />

XI<br />

Comments<br />

Notified Body is not <strong>in</strong>volved.<br />

Vacuum<br />

ESPN:<br />

Metallic parts<br />

Agreed Notified Body shall<br />

Vessel Category IV for pressure <strong>and</strong><br />

Nuclear Level N2/N3<br />

Design <strong>and</strong> Manufactur<strong>in</strong>g: RCC-MR 2007<br />

Non-metallic w<strong>in</strong>dows<br />

Technical specifications<br />

check design, manufactur<strong>in</strong>g<br />

<strong>and</strong> conformity.<br />

Blanket<br />

Blanket Modules – Cat. IV<br />

Design – Structural t Design Criteria i – IVC<br />

Agreed Notified Body shall<br />

Pip<strong>in</strong>g <strong>and</strong> manifold – Cat. I, Manufactur<strong>in</strong>g, <strong>in</strong>spection: ASME or EN<br />

check design, manufactur<strong>in</strong>g<br />

System<br />

Level N3<br />

st<strong>and</strong>ards (conventional parts) <strong>and</strong> TechSPecs <strong>and</strong> conformity.<br />

+ TBD<br />

fror o<strong>the</strong>r<br />

Divertor case to be considered<br />

Titi Tritium<br />

Categories I-IV, IV Level N2,<br />

Design <strong>and</strong> Manufactur<strong>in</strong>g:<br />

Conformity with PED/ESPN<br />

Plant <strong>and</strong> N3 or non-nuclear<br />

- Vessels ASME Section VIII, Div. 2<br />

required, Agrreed notifyed<br />

Detritiation<br />

- Pip<strong>in</strong>g ASME B 31.3, Category M<br />

Body required.<br />

- Valves ASME B16.34<br />

Use of EN st<strong>and</strong>ards under<br />

-…<br />

consideration.<br />

And Technical <strong>Specifications</strong><br />

…<br />

Complete table <strong>in</strong> “Codes <strong>and</strong> St<strong>and</strong>ards for <strong>ITER</strong> Mechanical Components”<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 18

Codes <strong>and</strong> St<strong>and</strong>ards - Mechanics<br />

RCC-MR 2002<br />

Generic - Integrated <strong>in</strong> <strong>the</strong> base<br />

Code<br />

- Rules for bolts (RB 3280 +A6)<br />

- Materials<br />

- Electron Beam <strong>and</strong> Laser<br />

weld<strong>in</strong>g<br />

- Pressure test<br />

- Rules for box structures<br />

(RC3800+RC4000)<br />

Specific - Appendix A19<br />

- Categorization of welded jo<strong>in</strong>ts<br />

- Special rules for permanent<br />

attachments seal<strong>in</strong>g welds <strong>and</strong><br />

Cu coat<strong>in</strong>g<br />

- Use of alternative NDE methods<br />

(Ultrasonic Test<strong>in</strong>g <strong>and</strong> Photo<br />

Thermal Camera)<br />

- Low Co materials<br />

<strong>ITER</strong> needs - box type structure -<br />

Requirements of ESP <strong>and</strong> ESPN<br />

Introduction of European (Harmonized) St<strong>and</strong>ards<br />

RCC-MR 2007<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 19

Codes <strong>and</strong> St<strong>and</strong>ards - Electrical<br />

To refer as much as possible <strong>the</strong> <strong>in</strong>ternational electrical st<strong>and</strong>ards<br />

issued by <strong>the</strong> International Electro-technical Commission (IEC).<br />

To facilitate <strong>the</strong> licens<strong>in</strong>g process by adopt<strong>in</strong>g French St<strong>and</strong>ards <strong>and</strong><br />

European Directives cover<strong>in</strong>g <strong>the</strong> follow<strong>in</strong>g items:<br />

– <strong>in</strong>stallation <strong>and</strong> operation rules;<br />

– design, manufactur<strong>in</strong>g <strong>and</strong> test<strong>in</strong>g of components affect<strong>in</strong>g<br />

safety (nuclear <strong>and</strong> personnel) <strong>and</strong> fire protection.<br />

<strong>ITER</strong> Electrical Design H<strong>and</strong>book, Part 3: Codes <strong>and</strong> St<strong>and</strong>ards<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 20

Codes <strong>and</strong> St<strong>and</strong>ards - Electrical<br />

SSEN EQUIPMENT<br />

MV / LV DISTRIBUTION<br />

TRANSFORMERS<br />

Manufactur<strong>in</strong>g<br />

St<strong>and</strong>ard<br />

Indoor /<br />

Outdoor<br />

Facilities<br />

Site<br />

Installation<br />

St<strong>and</strong>ard<br />

Nuclear Safety<br />

Personal<br />

Safety<br />

Tokamak<br />

Complex<br />

Test<br />

IEC 60076-1 IEC 60068-3-3<br />

IEC 60076-2<br />

IEC 60076-1<br />

IEC 60076-…<br />

IEC 60076-2<br />

IEC 60076-7<br />

IEC 60296<br />

IEC 60068-3-3<br />

IEC 60076-…<br />

IEC 60364<br />

IEC 60364-4<br />

IEC 60664-1<br />

IEC 60780<br />

IEC 60754<br />

IEC 60076-11<br />

IEC 60068-1<br />

IEC 60905<br />

IEC 60479<br />

IEC 61000-5<br />

(SR)<br />

IEC 61249-2-<br />

IEC 60664-1<br />

IEC 60364<br />

IEC 61000-5<br />

IEC 61140<br />

IEC 61000-6-2<br />

IEC 60980<br />

21<br />

IEC 60754<br />

IEC 61140<br />

NF C15-100<br />

100<br />

IEC 61000-6-4<br />

(SR)<br />

IEC 61000-6-2<br />

NF C15-100<br />

HD 538-2 S1<br />

IEC 61000-6-4<br />

NF C 52-112 /<br />

IEC 61249-2-<br />

NF EN 50464<br />

21<br />

CIRCUIT BREAKER<br />

IEC 60664-1<br />

IEC 60947-1<br />

IEC 60947-2<br />

IEC 61000-5<br />

IEC 61000-6-2<br />

IEC 61000-6-4<br />

IEC 60364<br />

IEC 60947-1<br />

IEC 60068-1<br />

IEC 60947-2<br />

IEC 60364 IEC 61000-5<br />

IEC 61140<br />

NF C15-100<br />

IEC 60068-3-3<br />

IEC 60364-4<br />

IEC 60479<br />

IEC 61140<br />

NF C15-100<br />

IEC 60754<br />

IEC 61249-2-<br />

21<br />

IEC 60068-3-3<br />

IEC 60439-1<br />

IEC 60664-1<br />

IEC 60947-1<br />

IEC 60947-2<br />

IEC 61000-4-2<br />

IEC 61000-4-4<br />

…<br />

…<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 21

Codes <strong>and</strong> St<strong>and</strong>ards – Build<strong>in</strong>gs,<br />

Civil Works<br />

Safety Related Build<strong>in</strong>gs - <strong>ITER</strong> Structural Design Code for Build<strong>in</strong>gs<br />

– Adaptation of state-of-<strong>the</strong>-art structural design criteria for civil works<br />

– Specificities of <strong>the</strong> configurations <strong>and</strong> loads of a fusion nuclear plant<br />

– Based on <strong>the</strong> concept of <strong>the</strong> limit state design used jo<strong>in</strong>tly with <strong>the</strong><br />

method of <strong>the</strong> partial factors, as stipulated <strong>in</strong> Eurocode EN 1990<br />

– First part devoted to <strong>the</strong> design specifications of <strong>the</strong> safety important<br />

build<strong>in</strong>gs of <strong>ITER</strong><br />

– Construction rules def<strong>in</strong>ed <strong>in</strong> second part (topography, tolerances,<br />

earthworks, concrete works, formwork, re<strong>in</strong>forcement, base isolation<br />

<strong>and</strong> elastomeric bear<strong>in</strong>gs, leak-tight metal parts on conta<strong>in</strong>ment, etc.).<br />

No safety related build<strong>in</strong>gs - Application of Eurocode (ma<strong>in</strong>ly)<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 22

THANKS FOR YOUR ATTENTION<br />

<strong>QA</strong> <strong>and</strong> <strong>Management</strong> <strong>Specifications</strong> - J. Izquierdo - September 2009 23