about berco - Berco S.p.A

about berco - Berco S.p.A

about berco - Berco S.p.A

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

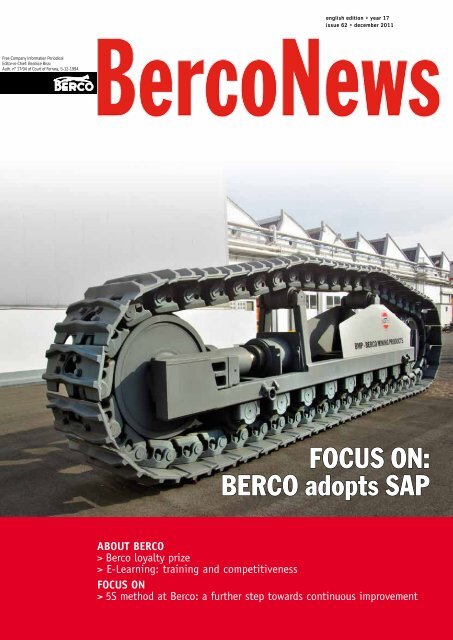

english edition > year 17<br />

issue 62 > december 2011<br />

Free Company Information Periodical<br />

Editor-in-Chief: Beatrice Bissi<br />

Auth. n° 17/94 of Court of Ferrara, 5-12-1994<br />

FOCUS ON:<br />

BERCO adopts SAP<br />

ABOUT BERCO<br />

> <strong>Berco</strong> loyalty prize<br />

> E-Learning: training and competitiveness<br />

FOCUS ON<br />

> 5S method at <strong>Berco</strong>: a further step towards continuous improvement

Editorial<br />

Dear readers,<br />

in this issue:<br />

2-3 EDitorial<br />

3 ABOUT BERCO<br />

<strong>Berco</strong> loyalty prize<br />

4-5-6 FOCUS ON<br />

SAP SPECIAL: <strong>Berco</strong> adopts SAP<br />

6 ABOUT BERCO<br />

E-Learning: training and competitiveness<br />

7 FOCUS ON<br />

5S method at <strong>Berco</strong>: a further step towards<br />

continuous improvement<br />

8 InnovaTION & TecHnologY<br />

<strong>Berco</strong> 2: a new 3000 ton press<br />

9 PRODUCTS & SERVICES<br />

Special undercarriage for ”Nessie 5” cable layer<br />

10 ABOUT BERCO<br />

Remembering Enrico Carbone<br />

Gianni Finessi: a mind made for mechanics<br />

10 NEWS & EVENTS<br />

Thyssenkrupp celebrates 200 years of history<br />

11 DEALERS & CUSTOMERS<br />

ICC Perù and <strong>Berco</strong> at the Extemin 2011 trade show<br />

Verhoeven at Matexpo 2011<br />

<strong>Berco</strong>News is a six-monthly periodical published for <strong>Berco</strong> employees,<br />

customers, suppliers and friends. The articles and photos can be copied<br />

only if expressly authorised by the Editor.<br />

Cover photo: <strong>Berco</strong> – internal yard<br />

Published by: BERCO S.p.A. - Communications Department<br />

Via 1° Maggio, 237 - 44034 Copparo (FE) Italy<br />

Tel. +39 0532 864116 - fax +39 0532 864462,<br />

e-mail: <strong>berco</strong>news@<strong>berco</strong>.com<br />

Editor-in-Chief: Beatrice Bissi<br />

Tel. +39 0532 864431 - fax +39 0532 864462<br />

e-mail: b.bissi@<strong>berco</strong>.com<br />

Editorial Commitee: S. Bottacin, S. Mastellari,<br />

G. Neodo, S. Salatini, S. Salvi, M. Seghieri, D. Musacci<br />

Editorial Secretary: D. Roversi<br />

Tel. +39 0532 864 270 - e-mail: d.roversi@<strong>berco</strong>.com<br />

Graphics and layout: Communications Department<br />

Pictures by: ThyssenKrupp, E. Perelli and others<br />

Printed by: Chinchio Industria Grafica S.p.A. (PD)<br />

Circulation: Italian 2500, English 4.000<br />

as is now customary at the end of the<br />

financial year, I would like to comment<br />

briefly on its main events and<br />

characteristic factors in order to<br />

evaluate and better understand the<br />

final figures.<br />

The year was forecast to be a period of<br />

transition, characterised by further<br />

moderate growth driven mainly by the<br />

so-called emerging countries, accompanied by an overall stability in<br />

the prices of raw materials and basic macroeconomic factors.<br />

It was to be a year in which most of our restructuring plans were to<br />

be brought to completion, with an accompanying rise in production<br />

to an intermediate level between the previous year and the level<br />

forecast for 2011/12 (at the earliest).<br />

The global financial crisis was to draw to a gradual close, restoring<br />

faith in markets and bringing stability to growth and consolidation,<br />

putting the uncertainties, nervousness and volatility that have<br />

wracked the global economy in recent years behind us once and for<br />

all. It is plain for all to see that very little of this actually<br />

happened, as borne out in various ways by our end-of-year figures.<br />

On the growth front, at least for the first 9 months of the year, and<br />

not only in the emerging economies, there was a much bigger than<br />

expected increase in orders, enabling us to increase sales to 45%<br />

higher than the previous year and taking the volume of finished<br />

products to <strong>about</strong> 190,000 tons, at least one year ahead of previous<br />

forecasts.<br />

This major, albeit unexpected and – in some ways – too rapid<br />

increase in volumes, however, had to coexist - not without some<br />

difficulty – with the numerous actions of our current restructuring<br />

plan, which have temporarily limited the production capacity and<br />

efficiency of some of the main process lines at the very time when<br />

we would need to be increasing production to keep pace with<br />

changing market demands.<br />

At the same time, with regard to costs, the sudden rise in volumes<br />

with the consequent greater demand for raw materials and their<br />

derivatives created the illusion, in the first half of the year, that the<br />

world crisis was over, thus generating the ideal conditions for an<br />

immediate, marked, speculative increase in corresponding price<br />

quotes.<br />

Given the composition of our products, it is easy to understand how<br />

such rapid, major variations could have such an immediate impact<br />

on production costs, with inevitable repercussions in terms of<br />

revenue and, unfortunately, without giving us enough time to take<br />

appropriate counter-measures. The scenario was further affected, in<br />

our last trimester - with the Summer break behind us and amidst<br />

expectations for a further increase in demand – by the “cold<br />

shower” of a sudden and worrying redimensioning of orders –<br />

sometimes a total halt – from the main OEMs in the emerging<br />

economies. This was led by China, who had evidently overestimated<br />

their market and had to review and scale down their plans. In a<br />

scenario such as this, even with the significant increase in volumes<br />

and revenue attained, it comes as no surprise that, despite<br />

improving considerably on the previous year, we were able only to<br />

break even, without the satisfaction of a positive result.The<br />

economic and financial events of recent weeks, extensively reported

Editorial<br />

in the daily press, clearly demonstrate how the general<br />

market situation is still highly critical, unstable and<br />

worrying, and the lack of solid growth in industrial<br />

production is further evidence that the global crisis is still<br />

far from over. It is now, therefore, that serious further<br />

efforts have to be made on all levels, with all of us pressing<br />

ahead with conviction, fortitude and determination on the<br />

chosen path of continuous improvement to our business.<br />

Each one of us is called on to draw unreservedly on our<br />

experience, skill and professionalism, in the conviction that<br />

each single contribution is not only useful, but a<br />

determining factor in reaching the necessary goal of<br />

maximum cost containment, which lies at the basis of any<br />

improvement in competitiveness.<br />

Only by so doing can we consolidate our market share and<br />

defend our jobs, achieving the dual goal of making our<br />

company grow and generate the reasonable profit required<br />

as an essential condition for guaranteeing our future. While<br />

being justifiably worried <strong>about</strong> the duration of this critical<br />

and complex economic phase, I am sure that we have the<br />

capacity to take advantage of what has always been our<br />

company's strongest asset, its human resources.<br />

We are a great, well trained and highly motivated team,<br />

spread throughout the Italian factories and our many<br />

foreign branches, and we shall continue to draw on our<br />

renowned professional skill to face up to the trials that still<br />

await us. We will act with courage, honesty, a passion for<br />

our work, team spirit and a proud sense of belonging, with<br />

a constant eye to the interests of the group and the future<br />

of its individual components.<br />

As the festive season approaches, bringing us a brief pause<br />

in our work and a chance to relax for a while with our<br />

nearest and dearest, I wish all of you and your families a<br />

very happy holiday.<br />

Bruno Saturni<br />

Managing Director<br />

About <strong>Berco</strong><br />

<strong>Berco</strong> Loyalty Prize<br />

As has been happening for 25 years, the<br />

<strong>Berco</strong> loyalty prize – the company's way<br />

of acknowledging the dedication of<br />

those who have contributed to its<br />

growth – will be awarded in December.<br />

With this award, <strong>Berco</strong> pays tribute<br />

to the qualities of commitment,<br />

reliability, positive attitude, team<br />

spirit and goal orientation: qualities<br />

that make the workforce a precious<br />

resource, capable of generating real<br />

value added.<br />

The employees, with 30 or 35 years<br />

of “service” to their name, will receive<br />

their awards on Friday December 23<br />

in the Copparo factory conference hall.<br />

BN62 > december 2011<br />

3

Focus On<br />

R<br />

<strong>Berco</strong> adopts SAP<br />

Increased efficiency and the integration of business processes are two of the main goals of an ambitious business<br />

restructuring plan and the use of effective management tools is essential if they are to be achieved<br />

Over a year ago, <strong>Berco</strong> launched an<br />

ambitious business restructuring plan<br />

which, after an initial stage involving<br />

all the areas of the Italian factories,<br />

will then be extended to the foreign<br />

branches.<br />

Increased efficiency and the<br />

integration of business processes<br />

are two of the main goals, and<br />

the use of effective, leading-edge<br />

management tools is essential if<br />

they are to be achieved.<br />

After a series of detailed analyses,<br />

<strong>Berco</strong> has decided to turn its<br />

attention to SAP.<br />

What is SaP<br />

SAP is an IT system created by the<br />

German company of the same name,<br />

SAP AG, one of the leading integrated<br />

management solutions companies in<br />

the world.<br />

SAP integrates all the main business<br />

processes of a company – purchasing,<br />

sales, stock management, production<br />

planning, accounts and finance – in<br />

a single management system.<br />

All the business areas are<br />

interconnected and aligned so that<br />

they can exchange data in reciprocal<br />

data flows.<br />

SAP coordinates, synchronizes and<br />

automates these operations,<br />

drastically reducing the times linked<br />

to information exchanges and<br />

searches and increasing the overall<br />

efficiency of the related processes.<br />

Why SaP<br />

When a company the size of <strong>Berco</strong><br />

decides to update its management<br />

system, it has to enlist the help of<br />

expert, qualified partners and adopt<br />

solutions whose effectiveness has<br />

been amply tested in application<br />

scenarios as similar as possible to<br />

its own. SAP applications and<br />

services are used by more than<br />

176,000 businesses throughout the<br />

world(over 3,500 in Italy), with<br />

measurable results and excellent<br />

satisfaction levels. ThyssenKrupp has<br />

been using SAP for many years in<br />

numerous companies in the group,<br />

and this undoubtedly made the <strong>Berco</strong><br />

management more confident in their<br />

choice of system.<br />

The project team<br />

<strong>Berco</strong> has enlisted the help of top<br />

level partners for the analysis and<br />

planning of its system.<br />

The AtoS team is a pool created from<br />

Atos Origin and Siemens IT Solutions<br />

and Services, which will assist <strong>Berco</strong><br />

in all the development and<br />

implementation stages.<br />

Also, numerous internal resources<br />

have been brought into play: 5<br />

permanent steering committee<br />

members for piloting the project<br />

and coordinating the activities, 21<br />

process owners for implementing the<br />

single business processes in SAP, 39<br />

key users for guaranteeing the<br />

usability of all the new system's vital<br />

functions and 12 IT specialists for<br />

supporting all the data development<br />

and migration activities.<br />

The times<br />

As we go to press, preparations for<br />

4 BN62 > december 2011

SPECIAL<br />

Focus On<br />

the second operational prototype is under way. As you<br />

can see from the diagram on the previous page, the<br />

official go-live of the new system is planned for August<br />

2012. The accounting and finance modules will be<br />

activated at the end of September, to coincide with the<br />

start of the new fiscal year. All customers and suppliers<br />

will be formally asked to organise their delivery schedules<br />

in good time, to reduce the possible problems of the<br />

migration process to a minimum. SAP best practice<br />

actually recommends the early acquisition of all supplies<br />

and the early planning of all deliveries to customers in<br />

relation to the new system's go-live period.<br />

Double interview with Luca Baraldi, director and coordinator of the company restructuring plan, and Giovanni Landi,<br />

SAP implementation Project Manager<br />

Giovanni Landi,<br />

Information Service &<br />

Data Security Manager<br />

Giovanni Landi, you are the<br />

Project Manager for the<br />

implementation of SAP. What has<br />

driven <strong>Berco</strong> to take up this<br />

challenge<br />

”The <strong>Berco</strong> group has grown<br />

greatly in recent years, and in it<br />

there are heterogeneous elements<br />

that have objective interfacing<br />

difficulties. We are fully aware of the need to integrate<br />

the management systems of all the company structures,<br />

and we've decided to do it using the same system that<br />

our stockholder has been using for years in the main<br />

companies in the ThyssenKrupp group.”<br />

Luca Baraldi, you have been given the important task<br />

of directing and coordinating the company restructuring<br />

plan. Is the decision to adopt SAP an integral part of<br />

this plan<br />

”If <strong>Berco</strong> is to continue growing and improving its<br />

performance, it needs to have a high level of integration<br />

between the different stages of the supply chain.<br />

The structural model for the <strong>Berco</strong> of tomorrow must<br />

be based on instruments of proven effectiveness.<br />

SAP is universally acknowledged to be the system that<br />

best responds to these needs.”<br />

What benefits will the adoption of SAP bring to <strong>Berco</strong><br />

Baraldi: ”SAP regulates the ways that information is<br />

recorded and exchanged within a business, and<br />

guarantees that all the data required for any operation<br />

are available at the time the operation has to be<br />

performed.<br />

As well as increasing efficiency, this also increases<br />

management's knowledge. If each phase of a process<br />

is monitored, the people in charge of that processes<br />

performance will be able to identify the bottlenecks<br />

and act in time to remove them.”<br />

Landi: ”The key word is knowledge. An integrated system<br />

encourages the adoption of c ommon working methods,<br />

more oriented to mutual cooperation.<br />

Each user is made to see his or her work in a wider<br />

context, and to realise that the consequences of his or<br />

her actions must necessarily affect the next stage of<br />

the process flow.”<br />

At the ends of the supply chain there<br />

are the customers and the suppliers.<br />

What impact will SAP have on them<br />

Baraldi: ”Actually, SAP is already<br />

standard practice in our industry.<br />

Many customers of primary<br />

importance have turned to SAP for<br />

the renewal of their IT systems.<br />

Potentially, the integration between<br />

Luca Baraldi,<br />

Operations Director<br />

<strong>Berco</strong> and these partners will be perfect. For all the others,<br />

from the very outset <strong>Berco</strong> will be able to give faster<br />

feedback and greater reliability in purchasing schedules(for<br />

suppliers)and delivery schedules(for customers).”<br />

Landi: ”We aim to automate as many external data<br />

exchanges as possible, especially with raw materials<br />

suppliers.<br />

At the same time, we'll be able to acquire orders from<br />

very big OEM customers by means of EDI transfer<br />

procedures, reducing manual intervention to a minimum.<br />

Greater end-to-end integration of supply chain processes<br />

and rapid and precise information availability will facilitate<br />

the accurate scheduling and performance of operations<br />

in all areas.”<br />

So far so good. Is there a negative side<br />

Baraldi: ”A project on this scale involves a certain amount<br />

of risk. In particular, in the data migration stage from<br />

the old process to the new one and in the initial periods<br />

of using SAP, there can be inefficiencies and slow-ups.<br />

Preparations need to be made well in advance, working<br />

together with customers and suppliers and creating special<br />

safety stocks.<br />

Shrewd, pragmatic risk management will help us to<br />

minimise the transitory negative impact.<br />

Even more important is the careful assessment of possible<br />

interference and frictions between the SAP project and<br />

all the other restructuring projects, especially those<br />

initiated in recent years.<br />

Often, these projects have the same goals as SAP, but<br />

with very different methods.”<br />

Landi: ”We're making big efforts to bridge the organisational<br />

gaps that came to light in the project analysis stages.<br />

Introducing SAP doesn't mean just updating our IT systems.<br />

It means changing our way of working, transforming our<br />

BN62 > december 2011 5

Focus On<br />

way of envisaging the company – and adapting its<br />

business structures accordingly.”<br />

Have you planned future developments of the initial<br />

project Is there a ”phase two”<br />

Landi: ”There's more than a phase two. SAP's modular<br />

structure has made it possible for us to define a starting<br />

model that guarantees the vital functions of the<br />

organisation.<br />

Improvements can then be introduced gradually in the<br />

subsequent stages, to avoid overloading the users and<br />

the company in general.<br />

The first step will definitely be the roll-out to the foreign<br />

branches, and this alone calls for a high level of<br />

commitment and elasticity from all the personnel<br />

involved.<br />

The “Italy implementation”, which is what we have<br />

called the current project, will be extended to cover the<br />

complete physical management of stock, the integration<br />

of the related automatic local subsystems, the gradual<br />

inclusion of systems for acquiring data from the main<br />

production units and lines, the drawing up and<br />

implementation of group-level planning and control<br />

systems, the centralisation of orders, data analysis, and<br />

so on.”<br />

Baraldi: ”We have already laid the basis for the creation<br />

of a simulation environment for the development of<br />

complex “what-if” scenarios, above all with regard to<br />

factory load optimisation and the dynamic management<br />

of production capacity according to variations in demand.<br />

It's an ambitious project, but now is the time to give it<br />

everything we've got.<br />

We have to gain ground rapidly, if we want to keep our<br />

leading position in an ever more competitive industry.”<br />

Stefano Salatini<br />

About <strong>Berco</strong><br />

E-LEARNING: TRAINING AND COMPETITIVENESS<br />

Throughout the world, there is a rapid evolution towards a knowledge-based society and economy. Access to<br />

up-to-date information and knowledge is a crucial factor in the strengthening of business competitiveness<br />

E-learning has now come to represent a concrete response to the<br />

demand for continuous training from an adult public already<br />

active in the world of work. This learning and training process<br />

has been made possible by new web technologies that give users<br />

access to various kinds of information in digital form at any time<br />

and from any place with an on-line connection.<br />

The combined use of different channels of communication<br />

(reading, viewing and listening) helps students to memorise<br />

things more easily.<br />

Recent studies have shown that students learn more easily with<br />

these tools than in traditional classroom situations. Training by<br />

”e-learning” also has other advantages over traditional training<br />

methods:<br />

▶ COST REDUCTION<br />

▶ FLEXIBILITY<br />

▶ EFFECTIVENESS<br />

▶ EASILY UPDATABLE<br />

▶ A SINGLE SYSTEM FOR THE COLLECTION AND DISSEMINATION OF COMPANY<br />

KNOWLEDGE; REPRODUCIBLE<br />

▶ EASILY MONITORABLE AND ASSESSABLE<br />

▶ A MINIMUM OF TECHNICAL REQUIREMENTS<br />

▶ E-LEARNING CAN ALSO BE USED BY BRANCHES, VISITORS,<br />

CUSTOMERS, CONTRACTORS...<br />

▶ FREEDOM TO MAKE MISTAKES<br />

▶ LOWER CONSUMPTION OF RESOURCES(ENVIRONMENTALLY FRIENDLY)<br />

WHAT IS BERCO DOING<br />

<strong>Berco</strong> management has decided that the first<br />

area where e-learning is to be used must<br />

necessarily be Health and Safety at work.<br />

Consequently, working with external experts,<br />

we are developing teaching material that<br />

reflects the situation in our company as much<br />

as possible, using images and videos filmed<br />

directly in the workplace. Currently, the <strong>Berco</strong><br />

working group is made up of people from the<br />

Prevention and Protection Service and<br />

Personnel Management, and the courses for<br />

employees will begin by the end of the year.<br />

For technical/organisational reasons, the initial<br />

courses will use a mixture of traditional and<br />

electronic training methods, grouping a certain<br />

number of people together with PCs in a<br />

designated classroom.<br />

The potential of these systems in the near<br />

future is immense:<br />

• home-based training<br />

• contractor training<br />

• training in different languages in different<br />

parts of the world<br />

• transmission via mobile phone, for personnel<br />

on location or on worksites.<br />

Saverio Salvi<br />

Head of Prevention and Protection Services<br />

6<br />

BN62 > december 2011

Focus On<br />

5S method at BERCO:<br />

a further STEP towards<br />

continuous improvement<br />

A methodological approach that aims to eliminate waste, focusing on concepts such as order, cleaning, standardisation<br />

and visual management<br />

”Moving your business ahead”, <strong>Berco</strong>'s<br />

now famous catchphrase, conveys the<br />

idea of development and movement<br />

with an eye to the future.<br />

But the continuous and frenetic<br />

changes affecting the world and<br />

markets are already here in the<br />

present for all to see.<br />

This continuous evolution makes<br />

absolute references impossible:<br />

something seen as excellent one day<br />

can turn out to be mediocre the day<br />

after and can even lead to market<br />

exclusion.<br />

For this reason, <strong>Berco</strong> has decided to<br />

work towards improvement, with the<br />

aim of achieving the ever more<br />

ambitious goals needed to win the<br />

increasingly fierce battle against<br />

competitors.<br />

A battle in which concern for quality<br />

alone is no longer enough; what is<br />

required is a focus on continuously<br />

improving efficiency, leading to a<br />

gradual reduction in internal costs.<br />

WHY BERCO HAS DECIDED TO START FROM THE 5Ss<br />

A methodological approach that aims to start a process for the elimination<br />

of waste, focusing on concepts such as order, cleaning, standardisation and<br />

visual management.<br />

These are notions which, while seemingly banal – at least in the first two<br />

cases – conceal unexpected potential and imply an important change in the<br />

mentality of people in a working environment.<br />

In a company with such deeply entrenched habits like <strong>Berco</strong>, therefore, the<br />

5S method represents not only the first step towards a new change, but also<br />

a “casting out nines” check.<br />

Hiroyuki Hirano, inventor of the 5S method, says that ”good organisations<br />

develop beginning with the 5Ss; bad organisations fall apart beginning with<br />

the 5Ss”.<br />

What we are expecting from this new approach, which is being extended to<br />

the whole factory, is the creation of a different working environment, where<br />

new standards of behaviour help the company to measure up to global markets<br />

in an ever more competitive way.<br />

As Niccolo Machiavelli wrote, ”there is nothing more difficult to take in hand,<br />

more perilous to conduct, or more uncertain in its success, than to take the<br />

lead in the introduction of a new order of things”.<br />

The application of the 5S method thus represents a tangible change which<br />

implies – above all – a mental change, and lays the basis for the continuous<br />

improvement of our company.<br />

Marco Munerato<br />

Workshop Engineering Department – Continuous Improvement<br />

BEFORE<br />

after<br />

5S<br />

5. Shitsuke - sustaining: ensure that this way of thinking<br />

1. Seiri - sorting: sort out the things you need from everything<br />

not essential to the work that upsets order and leads to a<br />

waste of time or resources<br />

2. Seiton - straightening: put everything in its proper place,<br />

as in the old saying ”a place for everything and everything in<br />

its place”<br />

3. Seiso - systematic cleaning: keep everything clean and in<br />

order at all times; a clean, orderly workspace is one that<br />

doesn't “hide” inefficiencies<br />

4. Seiketsu - standardise: define identical, standard procedures<br />

for the continuous rationalisation of resources and workspaces<br />

and acting is sustained in company activities...<br />

BN62 > december 2011 7

Innovation & Technology<br />

BERCO 2: a new 3000 ton PRESS<br />

After 35 years of loyal service, the historic forging hammer in the Castelfranco Veneto factory makes way for<br />

an Eumuco 3000 ton press<br />

After 35 years of loyal service, the<br />

historic forging hammer in the<br />

Castelfranco Veneto factory makes way<br />

for an Eumuco 3000 ton press.<br />

This year, after 35 years of loyal service,<br />

the historic Lasco forging hammer line<br />

has gone into retirement; the<br />

hammering of ”Berta” (as it was known<br />

not just in the factory but all over the<br />

village of Castelfranco Veneto) bore<br />

witness to the fervent activity within<br />

the factory.<br />

The fully automatic, rapid-changeover<br />

line was definitely futuristic in its time<br />

and up to the beginning of 2010 was<br />

allowing us to forge roller halves and<br />

wheel hubs of up to 60 kg.<br />

After so many excellent years of service,<br />

however, the line was due for a major<br />

electronic retrofit which, in any event,<br />

could not have guaranteed the high<br />

performance levels now required.<br />

As the task of the forging line in<br />

the Castelfranco factory is to supply<br />

the roller and hub processing lines, at<br />

the end of 2010, as part of the<br />

restructuring plan, it was decided to<br />

start transferring the Eumuco 3000 unit<br />

from the Busano Canavese factory and<br />

complete the line.<br />

The salient aspects of the line are many<br />

and regard all the components: the Saet<br />

heating furnace (the first ever on a<br />

<strong>Berco</strong> line), the robotized cell<br />

(manufactured by a completely new<br />

external supplier) serving the trimming<br />

press and the main Eumuco 3000 press<br />

itself, fully overhauled with state-ofthe-art<br />

electrical retrofitting. The result<br />

is a technologically evolved, extremely<br />

high-performance production line,<br />

conforming to the latest workplace<br />

safety regulations and capable of<br />

producing large-size items already<br />

hardened in-line.<br />

The Saet heating furnace,<br />

equipped with the latest IGBTbased<br />

1500 KW static converter<br />

model, also has a filtration/<br />

rephasing system to upgrade the<br />

power factor.<br />

The robotized cell is structured<br />

around two Kuka KR 150/2000<br />

heavy-duty handling robots,<br />

which, thanks to the lay-out,<br />

is able to supply the trimming<br />

press in very competitive times;<br />

in future, it will be possible to<br />

add a further<br />

upset forging<br />

press, as the cell<br />

for this is already<br />

designed.<br />

The main item in<br />

the line is obviously<br />

the extremely powerful<br />

and newly retrofitted<br />

Eumuco 3000 ton press,<br />

which, despite its many<br />

years of active service,<br />

still has much to offer.<br />

The electrical control<br />

panel has one of the most modern PLC<br />

control devices available, with a builtin<br />

safety system that guarantees<br />

complete operator safety in forging<br />

operations.<br />

Retooling is fast and safe thanks to a<br />

totally new rapid forging tool change<br />

device, installed on one of our lift<br />

trucks.<br />

When the performance of the new line<br />

is analysed and matched to that of the<br />

old forging hammer, the advantages are<br />

clear to see: an approximately 15%<br />

saving in forging time for 30-ton class<br />

rollers, which increases with the<br />

increase in size up to 25% for 40 tons;<br />

as the forging of net-shaped rollers is<br />

possible, there is also a saving in steel<br />

consumption and roughing time.<br />

We can safely say that, with the<br />

implementation of this new hot forging<br />

line, the factory's potential in this<br />

strategically important process has been<br />

considerably increased and improved.<br />

Marco Balducci<br />

Operations and Maintenance<br />

<strong>Berco</strong> Castelfranco Veneto<br />

8<br />

BN62 > december 2011

Products & Services<br />

SPECIAL UNDERCARRIAGE for<br />

”NESSIE 5” cable layer<br />

<strong>Berco</strong> Deutschland working together with its customer Petry Maschinenbau GmbH on<br />

the production of a special model<br />

<strong>Berco</strong>, as global market leader, not only supplies<br />

individual undercarriage components to OEMs<br />

(e.g. Liebherr, Atlas Copco, Volvo/ABG) and to<br />

aftermarket customers, but is also constantly involved<br />

in special projects.<br />

A particularly spectacular example of a special project<br />

is the undercarriage that our customer Petry<br />

Maschinenbau GmbH, Edewecht, designed and<br />

manufactured in only three and a half months in<br />

cooperation with <strong>Berco</strong> Deutschland.<br />

Christoffers Onshore and Subsea GmbH use this<br />

undercarriage in the tidal flats off the British coast for<br />

laying cables.<br />

The machine has an overall weight of 120 tons without<br />

cables and is powered by a 1000 HP - 12 cylinder diesel<br />

engine via 4 travel gears.<br />

The base plate width is 2750 mm, a total overall length<br />

of 10000 mm for each track frame.<br />

The base plates are mounted on three chains, each<br />

with 155 links. A total of 260 track rollers are used.<br />

The cable drum too is driven by a track chain.<br />

The uniqueness of this special model and the technical<br />

challenges in this field of use can be seen particularly<br />

well in the photos.<br />

Due to the excellent performance of “Nessie 5”, intensive<br />

work is already going on for the project “Nessie 6”.<br />

Rainer Schumburg<br />

Aftermarket Sales Director <strong>Berco</strong> Deutschland<br />

BN62 > december 2011<br />

9

About <strong>Berco</strong><br />

Remembering Enrico Carbone<br />

Sadly, Enrico Carbone died in July<br />

of this year. He worked at <strong>Berco</strong>,<br />

first of all as a metallurgist and head<br />

of heat treatments, and then as a<br />

consultant, from<br />

the 1950s until<br />

after the new<br />

millenium.<br />

Even though he left<br />

<strong>Berco</strong> almost<br />

10 years ago,<br />

the signs of his<br />

presence remain in<br />

many key areas<br />

of the company:<br />

the heat treatment lines, the<br />

metallurgical laboratory and the<br />

steels used for the products were<br />

instigated by him and developed<br />

thanks to his undisputed technical<br />

skill, backed up by an insatiable<br />

curiosity and innovative drive.<br />

I joined <strong>Berco</strong> as a metallurgist<br />

in 1998 and was one of the last<br />

people to<br />

work in<br />

close<br />

contact<br />

with Luca<br />

Carbone.<br />

I still<br />

remember<br />

him as a<br />

man of<br />

extraordinary energy, mental lucidity<br />

and precision in the analysis of<br />

technical problems, with a rigorous<br />

work ethic, always wanting to be up<br />

to date on the latest innovations<br />

and always berating everybody, from<br />

the Managing Director to the<br />

youngest of his colleagues, <strong>about</strong><br />

critical questions emerging in the<br />

company.<br />

He was a constant stimulus and a<br />

point of reference on metallurgical<br />

subjects, not only for his colleagues<br />

in the company but for anybody who<br />

approached him respectfully and<br />

sincerely to discuss a technical<br />

point; these highly fruitful<br />

discussions often developed into<br />

lively exchanges, with his Ligurian<br />

soul expressing itself in shrill tones.<br />

Stefania Bottacin<br />

Quality and Reliability<br />

Division Manager<br />

Gianni Finessi: a mind made for mechanics<br />

I am one of the few people, not yet retired,<br />

who had the opportunity to work with Gianni<br />

Finessi, who died this summer.<br />

I believe that he, more than anybody else, has<br />

left an indelible mark on the company.<br />

He was more than just a responsible engineer.<br />

He had a mind made for mechanics. In his long<br />

career he designed an enormous number of<br />

machines and devices, both for the machine<br />

tools produced and sold by <strong>Berco</strong> and for the<br />

machines and production lines in our workshops.<br />

Despite his apparently gruff manner, he was<br />

always ready to help anybody encountering<br />

difficulties in their work and to find solutions<br />

together. He was a man of few words, sometimes<br />

hard to understand, but we all new that at the<br />

start of every project he had clear ideas on<br />

what to aim for and how to<br />

get there. I am very grateful<br />

for the things I learnt from<br />

him, and consider myself<br />

fortunate to have worked<br />

with a person of his calibre<br />

for <strong>about</strong> 25 years.<br />

And I think I'm speaking on<br />

behalf of many other people<br />

who worked with him when<br />

I express a heartfelt: THANK<br />

YOU MAESTRO!<br />

Andrea Cornetti<br />

Special Devices Designer<br />

10<br />

News & Events<br />

BN62 > december 2011<br />

THYSSENKRUPP CELEBRATES<br />

200 YEARS OF HISTORY<br />

This important anniversary<br />

was marked by a ceremony in<br />

Villa Hügel on the 20th of<br />

November, to commemorate<br />

and celebrate the first<br />

foundation stone laid by Friedrich Krupp in<br />

1811. The event was attended by <strong>about</strong><br />

200 guests, including representatives of<br />

the German government and numerous<br />

managers.

Dealers & Customers<br />

ICC Perù and <strong>Berco</strong> at the<br />

Extemin 2011 trade show<br />

Extemin 2011, the most important<br />

mining industry trade fair in South<br />

America and one of the most important<br />

in the world, was held last September<br />

in Arequipa, Perù. The presence at<br />

Extemin 2011 of the<br />

biggest mining<br />

companies in the<br />

world reflects the<br />

growth trend in the<br />

Peruvian mining<br />

industry.<br />

Currently, Perù is the<br />

biggest producer<br />

of metals in South<br />

America, apart from<br />

copper, and the third<br />

biggest attractor of<br />

investment funds.<br />

ICC Perù, a leading<br />

supplier of top<br />

quality components<br />

at competitive prices, has been <strong>Berco</strong>'s<br />

dealer in Perù since 1996. It has<br />

branches in all the main cities and<br />

offers its customers a wide range of<br />

quality products, together with<br />

supporting services and technical<br />

training.<br />

ICC Perù was at the Extemin 2011<br />

trade fair with an important stand,<br />

where high quality components<br />

from Copparo were on show<br />

together with the other products<br />

it distributes.<br />

Thanks to the precious support<br />

given by <strong>Berco</strong> during the fair,<br />

we were able to demonstrate to<br />

our customers the highly<br />

productive teamwork and<br />

excellent relationship that bonds<br />

<strong>Berco</strong> to ICC Perù, which<br />

contributes to strengthening the<br />

quality guarantee of our products<br />

and the pledge to our customers<br />

to strive for excellence and<br />

continuous improvement.<br />

And so, our presence this year at<br />

Extemin has helped to strengthen<br />

the bonds that ICC Perù has not<br />

only with its customers and<br />

suppliers, but also with the<br />

biggest mining and construction<br />

companies on the market.<br />

Verhoeven at Matexpo 2011<br />

On 8 – 11 September, Benelux distributor Verhoeven<br />

Grondverzetmachines BV attended the Matexpo Fair in Belgium,<br />

which takes place every 2 years. This is the most important fair<br />

in the Belgian construction industry, but with an increasing<br />

number of Dutch visitors every year.<br />

Verhoeven, the Benelux specialist in undercarriage parts solutions,<br />

together with its partner <strong>Berco</strong> exhibited all its product groups<br />

to more than 38000 visitors.<br />

For more info visit: www.verhoevenbv.com<br />

BN62 > december 2011<br />

11