Making Sculpting Loops - Learn Prosthetic Makeup

Making Sculpting Loops - Learn Prosthetic Makeup

Making Sculpting Loops - Learn Prosthetic Makeup

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Learn</strong> <strong>Prosthetic</strong> <strong>Makeup</strong>: <strong>Making</strong> sculpting loops (updated 07 Sept ‘09)<br />

________________________________________________________________<br />

<strong>Making</strong> <strong>Sculpting</strong> <strong>Loops</strong> (updated 07 Sept ‘09) by Stuart Bray<br />

<strong>Sculpting</strong> tools are essential kit for sculpting in clay or plasteline. Usually, there<br />

are two main kinds of sculpting tools-the stick variety which usually are used for<br />

adding material, and loops which are used for taking away. They are not that<br />

expensive to buy, but there are some great tools which are not easily found but<br />

easily made. It’s fun, too.<br />

This article will show you how to make your own loop tools from scratch. <strong>Loops</strong> can be all shapes and<br />

sizes depending on the scale of the job. For blocking out life size figures, you’ll need something bigger,<br />

and for fine lines and wrinkles on prosthetics you’ll need something smaller. The principle remains<br />

the same.<br />

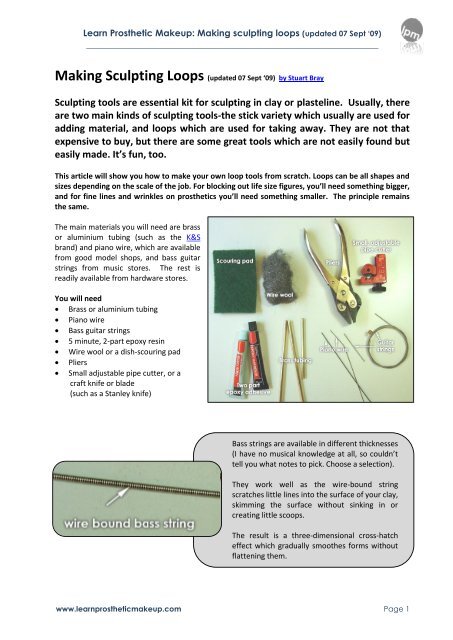

The main materials you will need are brass<br />

or aluminium tubing (such as the K&S<br />

brand) and piano wire, which are available<br />

from good model shops, and bass guitar<br />

strings from music stores. The rest is<br />

readily available from hardware stores.<br />

You will need<br />

Brass or aluminium tubing<br />

Piano wire<br />

Bass guitar strings<br />

5 minute, 2-part epoxy resin<br />

Wire wool or a dish-scouring pad<br />

Pliers<br />

Small adjustable pipe cutter, or a<br />

craft knife or blade<br />

(such as a Stanley knife)<br />

Bass strings are available in different thicknesses<br />

(I have no musical knowledge at all, so couldn’t<br />

tell you what notes to pick. Choose a selection).<br />

They work well as the wire-bound string<br />

scratches little lines into the surface of your clay,<br />

skimming the surface without sinking in or<br />

creating little scoops.<br />

The result is a three-dimensional cross-hatch<br />

effect which gradually smoothes forms without<br />

flattening them.<br />

www.learnprostheticmakeup.com Page 1

<strong>Learn</strong> <strong>Prosthetic</strong> <strong>Makeup</strong>: <strong>Making</strong> sculpting loops (updated 07 Sept ‘09)<br />

________________________________________________________________<br />

Step 1<br />

Use the pipe cutter to cut a length of brass tubing to around 150mm (6”). Cut a two inch (50mm) length<br />

of your piano wire or guitar string.<br />

Incidentally, if you don’t have a pipe cutter,<br />

a sharp craft knife or blade will work. Place<br />

the tube on a hard work surface, and roll<br />

the blade on the tube whilst pressing down.<br />

Eventually, the scored line will cut through<br />

the brass, creating a nice, clean cut.<br />

If you try cutting with a small hacksaw, very often the brass will bend and leave you with a jagged end.<br />

Step 2<br />

Using pliers, slightly flatten the end of the tubing. We want to be able<br />

to freely insert the wire, so make sure it isn’t too closed. If you overdo<br />

it, squeeze the ends gently with the pliers again to open it slightly, or<br />

wiggle a screwdriver in the slot to prise it open.<br />

Step 3<br />

To create a nice curve, bend your wire carefully around the brass<br />

tubing. If you just bend the wire, you can create a point. You can also<br />

use the pliers to bend the wire to any shape you like.<br />

www.learnprostheticmakeup.com Page 2

Step 4<br />

<strong>Learn</strong> <strong>Prosthetic</strong> <strong>Makeup</strong>: <strong>Making</strong> sculpting loops (updated 07 Sept ‘09)<br />

________________________________________________________________<br />

Check your wire fits nicely into the tubing.<br />

Next, squeeze two equal size globs of epoxy<br />

glue onto a mixing surface. Make sure it is well<br />

mixed.<br />

Step 5<br />

Put your mixed glue carefully into the end of your<br />

tubing, making sure it goes down into the tube.<br />

You may need a pin or a little length of wire to get<br />

down far enough. Dip the ends of the loop in the<br />

glue also, then push them into the tube about 5-<br />

6mm. Squeeze the tube gently again with the<br />

pliers, mopping any excess glue with a cotton bud<br />

or piece of tissue.<br />

You may have to hold the tool upside down for a<br />

while, and move it around until the glue thickens<br />

and begins to set. Speed this up with a hairdryer.<br />

That’s pretty much it. Now do the same to the other end, using a different shape loop, or use piano<br />

wire one end, and guitar string on the other.<br />

Experiment with<br />

variations to create<br />

different kinds of tool<br />

marks<br />

www.learnprostheticmakeup.com Page 3

<strong>Learn</strong> <strong>Prosthetic</strong> <strong>Makeup</strong>: <strong>Making</strong> sculpting loops (updated 07 Sept ‘09)<br />

________________________________________________________________<br />

Coarse and fine<br />

Another couple of variations are to use acupuncture needles and fret saw blades as loop material.<br />

Acupuncture needles are available from online acupuncture suppliers and<br />

health stores, and are quite inexpensive. They have both a thin wire and a<br />

wire bound section, so both ends can be used. This is great wire for fine, detail work.<br />

Fret saw blades are available from hardware stores, and are good for more coarse work, when blocking<br />

out shapes and smoothing larger forms.<br />

You need to use a blowtorch to heat the blade white-hot in order to successfully bend it, otherwise the<br />

brittle metal snaps.<br />

Twist & Shout<br />

Another variation is to twist some wire to create another kind of rough texture which is excellent for<br />

raking. Use piano/music wire or something a little less hard if you find it too tough to work.<br />

Cut a 300mm (12”) length, and fold it in half.<br />

Put the ends into the jaws of a pair of pliers,<br />

molegrips or metalworking vice. Insert a tool or<br />

strong rod such as a screwdriver in the loop. Now<br />

you can grasp both ends of the wire<br />

www.learnprostheticmakeup.com Page 4

<strong>Learn</strong> <strong>Prosthetic</strong> <strong>Makeup</strong>: <strong>Making</strong> sculpting loops (updated 07 Sept ‘09)<br />

________________________________________________________________<br />

Twist the ends in opposite directions, working<br />

against the resistance of the wire.<br />

Keep going until the wire starts to buckle and<br />

loops onto itself. When it looks like the picture,<br />

you’re done twisting.<br />

As before, cut the wire to size, being careful to<br />

create the loop by bending it around something<br />

circular in profile, such as a round handle on a<br />

vice, a paintbrush or a battery.<br />

Insert the ends into the slightly flattened tubing,<br />

and apply adhesive. If you want, you can crimp it<br />

in place instead or in addition to the adhesive.<br />

If you don’t have a crimping tool, you can use a pair of pliers with a<br />

crimping device in the jaws, as shown above left.<br />

Make sure that squash the middle area between the two twisted prongs,<br />

as shown in the middle picture. Once you have squeezed the jaws tight,<br />

you should have a nice clean groove in the end holding your wire firmly.<br />

Make thicker versions with extra wire. In the picture on the right, I used<br />

two loops of wire at the same time and repeated the procedure. Do this to<br />

create tougher loops for larger tools or for working with firmer sculpting<br />

material.<br />

www.learnprostheticmakeup.com Page 5

<strong>Learn</strong> <strong>Prosthetic</strong> <strong>Makeup</strong>: <strong>Making</strong> sculpting loops (updated 07 Sept ‘09)<br />

________________________________________________________________<br />

And, finally…<br />

Here is a variation using the same techniques using brass square section rod. I have chosen to use 1/16<br />

and 1/32 gauge from K&S. The shot on the right just shows you a comparison of sizes.<br />

1/32” 1/16”<br />

Cut yourself a decent amount of brass rod to work with-here I used about 65mm (2½”) to make this one.<br />

Using molegrips, pliers or a vice, slowly twist the brass rod in opposite directions.<br />

Make sure they there is plenty of the rod in the jaws to be able to grip the brass while twisting, and<br />

maintain a firm grip whilst you do it. Molegrips or a vice are best, as this grip is held in place<br />

mechanically rather than by the strength of your hands.<br />

Keep twisting slowly until you end up with something that looks like this…<br />

www.learnprostheticmakeup.com Page 6

<strong>Learn</strong> <strong>Prosthetic</strong> <strong>Makeup</strong>: <strong>Making</strong> sculpting loops (updated 07 Sept ‘09)<br />

________________________________________________________________<br />

…and then bend your twisted brass into shape before<br />

inserting into your tube and fix as before, using an<br />

epoxy resin glue, crimping or both.<br />

Voila- the finished twisted brass loop tool. These<br />

work really well with plasteline and clay, and should<br />

give you years of excellent service. You may as well<br />

make a few once you have all the bits you need. That<br />

way, if you lose or break any, you can just grab<br />

another to keep sculpting.<br />

Have fun experimenting with different shapes and<br />

sizes, and create your own customised sculpting tool<br />

kit. If you ever break or lose any of your tools, you’ll<br />

be able to replace them with ease.<br />

Happy tool-making!<br />

Stuart<br />

Having trouble finding materials<br />

Maybe it has a different name or supplier in your country<br />

Is there an alternative<br />

Drop me a line at mail@learnprostheticmakeup.com, and I’ll<br />

do my very best to help you.<br />

Questions or comments about this article<br />

Get in touch at www.learnprostheticmakeup.com<br />

Take care whenever working with makeup materials.<br />

Familiarise yourself with the products and take appropriate<br />

health and safety measures. We suggest you obtain and<br />

consult the relevant MSDS (Material Safety Data Sheets) from<br />

your supplier whenever possible. This article is for your<br />

information only. We cannot accept any responsibility for<br />

your actions.<br />

©Copyright Stuart Bray 2009<br />

Photographs © Jane Hobson<br />

www.learnprostheticmakeup.com Page 7