HORIZONTAL DIRECTIONAL DRILLING - nodig-construction.com

HORIZONTAL DIRECTIONAL DRILLING - nodig-construction.com

HORIZONTAL DIRECTIONAL DRILLING - nodig-construction.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>HORIZONTAL</strong> <strong>DIRECTIONAL</strong> <strong>DRILLING</strong><br />

For General Information on Horizontal Directional Drilling click here<br />

TATCO BORING CLAIMS WORLD RECORD CROSSING IN SAUDI<br />

ARABIA<br />

t the end of 2007, Abu Dhabi HDD contractor Tatco Boring and Installation Est., was awarded<br />

A the the contract to <strong>com</strong>plete the drilling works for the Berry Causeway Flank 2 HDD project.<br />

The HDD crossings for this project exceed a length of some 3,150 m which, the <strong>com</strong>pany claims, is<br />

a new world record for this technique.<br />

Tatco Boring operates smaller HDD Rigs but also has four large Herrenknecht HDD drilling rigs<br />

in the range of 100 t to 400 t pullback capacity. Although numerous crossings have previously been<br />

successfully installed the Berry Causeway project was a big challenge for the <strong>com</strong>pany. For the<br />

Berry Causeway project Tatco established a JV partnership with local HDD contractor DCL of<br />

Dammam.<br />

SPONSORS LINKS<br />

Click Name for website access<br />

TT Group<br />

TT-Group: A leading<br />

manufacturer of Trenchless<br />

Technologies: Moles, Pipe<br />

Rammers, HDD, Pipe<br />

Replacement and Auger boring<br />

systems and NoDig-equipment<br />

Herrenknecht<br />

Manufacturer of TBMs,<br />

Pipejacking, Microtunnelling,<br />

HDD and Support Equipment<br />

and Engineering Services.<br />

Perforator Ltd<br />

Sales and Hire of Guided<br />

Auger boring and Pipebursting<br />

systems and tooling.<br />

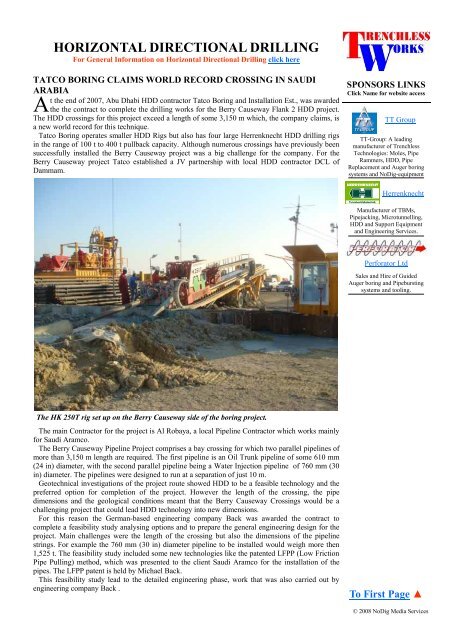

The HK 250T rig set up on the Berry Causeway side of the boring project.<br />

The main Contractor for the project is Al Robaya, a local Pipeline Contractor which works mainly<br />

for Saudi Aramco.<br />

The Berry Causeway Pipeline Project <strong>com</strong>prises a bay crossing for which two parallel pipelines of<br />

more than 3,150 m length are required. The first pipeline is an Oil Trunk pipeline of some 610 mm<br />

(24 in) diameter, with the second parallel pipeline being a Water Injection pipeline of 760 mm (30<br />

in) diameter. The pipelines were designed to run at a separation of just 10 m.<br />

Geotechnical investigations of the project route showed HDD to be a feasible technology and the<br />

preferred option for <strong>com</strong>pletion of the project. However the length of the crossing, the pipe<br />

dimensions and the geological conditions meant that the Berry Causeway Crossings would be a<br />

challenging project that could lead HDD technology into new dimensions.<br />

For this reason the German-based engineering <strong>com</strong>pany Back was awarded the contract to<br />

<strong>com</strong>plete a feasibility study analysing options and to prepare the general engineering design for the<br />

project. Main challenges were the length of the crossing but also the dimensions of the pipeline<br />

strings. For example the 760 mm (30 in) diameter pipeline to be installed would weigh more then<br />

1,525 t. The feasibility study included some new technologies like the patented LFPP (Low Friction<br />

Pipe Pulling) method, which was presented to the client Saudi Aramco for the installation of the<br />

pipes. The LFPP patent is held by Michael Back.<br />

This feasibility study lead to the detailed engineering phase, work that was also carried out by<br />

engineering <strong>com</strong>pany Back .<br />

To First Page ▲<br />

© 2008 NoDig Media Services

<strong>HORIZONTAL</strong> <strong>DIRECTIONAL</strong> <strong>DRILLING</strong><br />

For General Information on Horizontal Directional Drilling click here<br />

One of the drilling mud units<br />

operating in support of the HK250T<br />

drilling rig (right). Below, a view<br />

across the water over the boring<br />

route.<br />

SPONSORS LINKS<br />

Click Name for website access<br />

TT Group<br />

TT-Group: A leading<br />

manufacturer of Trenchless<br />

Technologies: Moles, Pipe<br />

Rammers, HDD, Pipe<br />

Replacement and Auger boring<br />

systems and NoDig-equipment<br />

Herrenknecht<br />

Some main features of the project plan included:<br />

• Pilot hole drilling using the intersect (‘meet in the middle’) technology, the guidance<br />

system for whic was provided by Prime Horizontal<br />

• Engineering of the drilling methodology to reduce friction, torque and buckling<br />

• Minimise the required pulling forces for the final installation of the pipeline<br />

Al Robaya prepared the pipeline string and the required equipment for the LFPP method. For the<br />

drilling works Tatco Boring started from both sides of the crossing using a Herrenknecht HK400M<br />

rig on the Abu Ali side and a Herrenknecht HK 250T rig on Berry Causeway side. To ensure bore<br />

conditions remained at their best, altogether 4 mud pumps, 4 drilling mud mixing units and 4<br />

recycling units were established on site.<br />

After installation of a 406 mm (16 in) diameter casing at the entry points on both sides of the bore<br />

to stabilise the entry areas, the pilot hole drilling was <strong>com</strong>pleted using a mud motor and 170 mm<br />

(6⅝ in) diameter drill pipe. The ‘meeting point’ of the two pilot holes was planned for the ⅓ - ⅔<br />

Manufacturer of TBMs,<br />

Pipejacking, Microtunnelling,<br />

HDD and Support Equipment<br />

and Engineering Services.<br />

Perforator Ltd<br />

Sales and Hire of Guided<br />

Auger boring and Pipebursting<br />

systems and tooling.<br />

To First Page ▲<br />

© 2008 NoDig Media Services

<strong>HORIZONTAL</strong> <strong>DIRECTIONAL</strong> <strong>DRILLING</strong><br />

For General Information on Horizontal Directional Drilling click here<br />

position along the bore path. After finishing pilot hole operation, a number of different reaming<br />

steps were undertaken followed by a cleaning run to prepare the bore for the pipe installation.<br />

The first pipeline string, the 610 mm (24 in) diameter crude oil pipeline was the first to be pulled<br />

in. and was <strong>com</strong>pleted at the time of writing. The pulling forces required for the pull-in operation<br />

remained within the calculated range during the whole process. It was here especially that the LFPP<br />

technique helped to reduce the required pulling forces. The actual pulling force used was less then<br />

40 t.<br />

After the successful <strong>com</strong>pletion of the first pipeline installation in June 2008 preparation works for<br />

the second parallel larger diameter pipeline crossing are now underway. Given the learning<br />

experiences gained from the first crossing, <strong>com</strong>pletion of the second crossing is planned within the<br />

next 3 months. Website: www.herrenknecht.<strong>com</strong><br />

SPONSORS LINKS<br />

Click Name for website access<br />

TT Group<br />

TT-Group: A leading<br />

manufacturer of Trenchless<br />

Technologies: Moles, Pipe<br />

Rammers, HDD, Pipe<br />

Replacement and Auger boring<br />

systems and NoDig-equipment<br />

Herrenknecht<br />

Manufacturer of TBMs,<br />

Pipejacking, Microtunnelling,<br />

HDD and Support Equipment<br />

and Engineering Services.<br />

Perforator Ltd<br />

Sales and Hire of Guided<br />

Auger boring and Pipebursting<br />

systems and tooling.<br />

To submit editorial for Trenchless Works Issue 26<br />

please email copy and pictures to:<br />

ian@<strong>nodig</strong>media.co.uk by 10 October, 2008<br />

For TW Sponsorship and advertising rates click here<br />

To First Page ▲<br />

© 2008 NoDig Media Services