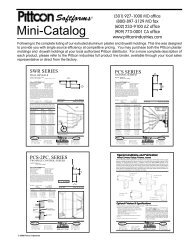

Column Covers - DCS® Metal Column Covers - Light Coves

Column Covers - DCS® Metal Column Covers - Light Coves

Column Covers - DCS® Metal Column Covers - Light Coves

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mouse Click on any page during the specific product<br />

display view will return to that Product Index<br />

All Products are American Made<br />

Fabricated, Manufactured, and Finished<br />

in the United States of America<br />

LEED® Architectural Green Building commitment

DIVISION OF PITTCON CUSTOM CORPORATION<br />

Series 8500<br />

Plastic Laminate or Veneer<br />

clad <strong>Column</strong> <strong>Covers</strong><br />

CC-7

12345678901234567890123<br />

12345678901234567890123<br />

12345678901234567890123<br />

12345678901234567890123<br />

12345678901234567890123<br />

12345678901234567890123<br />

Series 8500-Details<br />

Quarter Round<br />

<strong>Column</strong> Cover<br />

(Wall Mount)<br />

Half Round<br />

<strong>Column</strong> Cover<br />

(Wall Mount)<br />

Three-Quarter &<br />

Partial <strong>Column</strong><br />

<strong>Covers</strong><br />

Post Location<br />

Config. 'B'<br />

Minimum 7" R<br />

Maximum 36" R<br />

Full <strong>Column</strong><br />

Cover with<br />

2 Joints<br />

Maximum 18"<br />

(36" Dia )<br />

Config. 'A'<br />

Maximum 48" Dia-'A'<br />

Maximum 36" Dia-'B'<br />

Full <strong>Column</strong><br />

Cover with<br />

3 Joints<br />

Available 14" to 36" Dia<br />

36" Dia. and Above<br />

(Max 55" Dia.)<br />

Race-Track Oval<br />

<strong>Column</strong> Cover<br />

Extended Half<br />

<strong>Column</strong> Cover<br />

Aluminum Edge<br />

Protector<br />

Interlocking<br />

Tape<br />

12345678901234567890123<br />

2<br />

Maximum 36" Dia x 90" Width<br />

(Available Wider with Addition of Flat Panels)<br />

Maximum 36" Dia x 72" Width<br />

(Available Wider with Addition<br />

of Flat Panels)<br />

Screws Through Bracket<br />

Must Engage Substructure<br />

Behind

Series 8500-Details<br />

1/4" 1/2" Insert, Factory<br />

Painted.<br />

1/2"<br />

2 1/2"<br />

2-5/8"<br />

Post Mounting<br />

Brackets as Required<br />

by Pittcon<br />

Reveal Joint with Insert<br />

Tight Joint with Insert<br />

<strong>Column</strong> <strong>Covers</strong> Clad with Plastic Laminate or Veneer:<br />

Aluminum in .090 Standard Thickness (2.3mm)<br />

• Clad with matte or high gloss plastic laminate finishes<br />

by the following manufacturers:<br />

Wilsonart<br />

Nevamar<br />

Formica<br />

Pionite<br />

• Clad with wood veneers (unfunished)<br />

• Clad with Belbien® vinyl laminate finishes<br />

The SERIES 8500 column cover system offers a durable plastic laminate or wood<br />

veneer finish. The column covers come with a choice of two joint configurations. The<br />

SIDE-LOCK TM version provides a vertical reveal snap-in insert for those conditions<br />

where a vertical reveal is desired (above left). The exposed edges at the joint are<br />

protected by a high strength aluminum extrusion. The SNAP-FORM ® version provides<br />

a tight joint with an overlapping aluminum T-Spline protector, (above right),<br />

applicable for other column cover conditions. The column cover halves are<br />

roll-formed and supplied in two identical halves, with a factory supplied aluminum post<br />

post system. They are easily demountable for access to enclosed elements.<br />

The SERIES 8500 is available with a wide variety of options, including recessed top,<br />

mid-level and base reveals, stacking columns covers, racetrack oval and other designs,<br />

all of which are described elsewhere in this brochure. Please contact the factory<br />

or your local Pittcon sales representative for further details.<br />

3

Series 8500-Options<br />

Special Interlock Assembly Locks<br />

<strong>Column</strong> Cover to Grill Track<br />

The SERIES 8500 <strong>Column</strong> <strong>Covers</strong> can be Provided<br />

with a Factory Installed Grill Track Opening Such as<br />

Shown Here (grill track by others) or with an Optional<br />

Expansion Joint as Detailed Below.<br />

Pl. Lam. or Veneer on .090"<br />

Aluminum Substrate<br />

Special Mounting Plates<br />

Attach to Floor on Either<br />

side of Expansion<br />

Joint<br />

Overlapping Plates Allow<br />

<strong>Column</strong> Cover Reveal to<br />

Expand and Contract<br />

with Floor<br />

Joint Plate is Attached<br />

via Locking Insert<br />

Available 14" to 36" Dia<br />

Joint Plates can be the<br />

Same Material as <strong>Column</strong><br />

Cover or Supplied<br />

in a Complimentary<br />

Color or Finish<br />

4

Series 8500-Options<br />

Optional Telescoping<br />

Top Reveal Allows for<br />

Height Adjustment at<br />

Ceiling<br />

Optional Acoustical or<br />

Drywall Ceiling Trims are<br />

Available for Trimming<br />

<strong>Column</strong> Cover at Ceiling<br />

Although <strong>Column</strong> <strong>Covers</strong><br />

are Available up to 16' in<br />

Height, the Introduction<br />

of Stacking Joints Al-<br />

lows for Almost any<br />

Height Desired.<br />

The Joint Between Each<br />

Stacked Section is Controlled<br />

by a Factory Installed<br />

Alignment Insert<br />

The SERIES 8500 <strong>Column</strong> Cover Comes with a Reveal<br />

Joint for Those Applications Where a Vertical<br />

Reveal is Desired. It is also Available with a Tight Joint<br />

Protected by an Aluminum Insert. <strong>Column</strong> <strong>Covers</strong> are<br />

Available up to 16' in Height in Single Lengths.<br />

Stacking Joints Allow for Almost Unlimited Height.<br />

Aluminum Inserts Protect Edges of <strong>Column</strong><br />

from Damage. Consult Factory for Colors.<br />

5

Series 8500-Installation<br />

Installation Details<br />

No Scale<br />

Use Plumb Bob or<br />

Level to Ensure<br />

Posts are Installed<br />

Correctly<br />

Telescoping Post<br />

Mounting Bracket<br />

Aluminum Post<br />

Note:<br />

Post Height Should be 1"<br />

Less than <strong>Column</strong> Height<br />

to Allow for Adjustment<br />

Wooden Post Installation<br />

Template<br />

Secure Mounting<br />

Bracket to Floor<br />

Using Proper<br />

Fasteners<br />

(Not Provided)<br />

SAMPLESPECIFICATION<br />

Section 05-58-13 Architectural <strong>Metal</strong> <strong>Column</strong> <strong>Covers</strong><br />

Part 1 - General<br />

1.01 Description of work<br />

A. Furnish all material necessary for a complete installation of the<br />

SERIES 8500 column covers. <strong>Column</strong> covers to be self-aligning,<br />

positive interlock, without exposed fasteners or supports.<br />

1.02 Submittals<br />

A. Submit complete shop drawings detailing quantities, sizes, finish,<br />

configurations, and column attachment methods.<br />

B. Submit product literature, specifications, information, and installation<br />

instructions.<br />

1.03 Quality Assurance<br />

A. Manufacturer to have a minimum of ten years experience in the<br />

manufacturing of column covers.<br />

B. Manufacturer to inspect all aspects of the product to ensure that<br />

specifications have been met, and that they comply with approved<br />

shop drawings.<br />

C. Manufacturer shall issue a one year limited warranty ensuring<br />

product against defects in workmanship and materials.<br />

Part 2 - Products<br />

2.01 Acceptable Manufacturers<br />

Pittcon Industries Pittcon Industries<br />

6409 Rhode Island Ave. 3330 W. Flower Street<br />

Riverdale, MD 20737 Phoenix, Arizona 85017<br />

2.02 Materials<br />

A. <strong>Column</strong> covers shall be roll-formed from .090" aluminum and clad<br />

with specified plastic laminate or veneer.<br />

B. All fasteners are to be concealed.<br />

C. All support structures to be supplied by column cover manufacturer.<br />

D. All column covers are to be shipped with protective material on<br />

all exposed surfaces.<br />

2.03 Fabrication<br />

The SERIES 8500 column cover system consists of the following<br />

parts:<br />

1) Two custom rolled column cover half sections<br />

2) Four post mounting brackets with mounting screws<br />

3) Two extruded aluminum posts (with reveal inserts if SIDE-<br />

LOCK TM )<br />

4) Mid-level post reinforcement brackets<br />

5) Self tapping flat head screws for bracket attachment<br />

6) Post installation template for aligning posts<br />

7 ) One set of drawings / instructions / suction cup per order<br />

The following customer supplied items are also recommended :<br />

1) Plumb bob & carpenters level<br />

2) Ramset or lag type masonry fasteners for mounting brackets<br />

Typical Installation Procedure<br />

1 ) Determine the position of the column cover around structural<br />

member. Install one stud in place, using a level to ensure<br />

plumb-ness. Position the opposite stud in place using the<br />

supplied post installation template. Make sure that studs are<br />

securely fastened to the ceiling and floor utilizing proper<br />

fasteners. Install any base reveals at this time fastening to<br />

both post and floor.<br />

2 ) Seat one side of first column half into the opening of the metal<br />

post. Using the suction cup, spring column half gently around<br />

outside of opposite post and seat in opening. Repeat this<br />

procedure for the other column half, taking care not to unduly<br />

stretch halves.<br />

3 ) If column cover is a SNAP-FORM ® model, use a heavily padded<br />

2x4 and rubber mallet to engage the two sides. Starting at the<br />

bottom of the column cover and working your way up, firmly<br />

strike the padded block with the rubber hammer on both<br />

column halves along joint. This will positively engage the<br />

interlock assembly. If your column is a SIDE-LOCK TM model,<br />

insert the vertical locking reveal between the two column<br />

halves and engage it in the post.<br />

A. <strong>Column</strong> covers shall be roll-formed to specific dimensions and tolerances,<br />

and accurately formed to radii shown on drawings.<br />

B. <strong>Column</strong> covers shall be fabricated in two vertically divided sections<br />

attached with a demountable interlock joint.<br />

C. <strong>Column</strong> covers shall be fabricated in single length heights of 16' where<br />

required, with the addition of stacking joints to allow for heights above 16'.<br />

Part 3 - Execution<br />

3.01 Inspection & Installation<br />

A. Contractor to inspect column covers upon receipt to ensure that no<br />

damage has occurred during shipment.<br />

B. <strong>Column</strong> cover to be correctly oriented and installed in accordance with<br />

manufacturer's shop drawings and installation instructions to ensure<br />

proper installation.<br />

C. <strong>Column</strong> cover to be erected plumb and level.<br />

3.02 Cleaning & Protection<br />

A. Contractor to remove protective material supplied by column cover<br />

manufacturer.<br />

B. Contractor to clean all visible surfaces after installation.<br />

C. Contractor to protect column covers from damage by other trades<br />

Pittcon Industries Division Pittcon Architectural <strong>Metal</strong>s, LLC<br />

6409 Rhode Island Avenue 3330 W. Flower Street<br />

Riverdale, Maryland 20737 Phoenix, Arizona 85017<br />

(800) 637-7638 , (301) 927-1000 (800) 637-7638 , (602) 233-9100<br />

Fax: (301) 699-8690 Fax: (602) 233-9400<br />

c 2008 Pittcon Industries<br />

6<br />

Fabricated with Pride in<br />

Riverdale, Maryland-U.S.A.

Columbia Architectural Products<br />

Phone: (301)937-4383<br />

Fax: (301)937-6850<br />

10722 Tucker Street<br />

Beltsville, MD 20705<br />

SECTION 05 58 13<br />

COMPOSITE ALUMINUM COLUMN COVERS<br />

PART 1 GENERAL<br />

1.1 SECTION INCLUDES<br />

A. Composite aluminum column covers and beam wraps.<br />

1.2 RELATED SECTIONS<br />

A. Section 05 12 00 - Structural Steel.<br />

B. Section 05 50 00 - <strong>Metal</strong> Fabrications.<br />

C. Section 06 10 00 - Rough Carpentry.<br />

D. Section 07 42 43 - Composite Wall Panels.<br />

1.3 SUBMITTALS<br />

A. Submit under provisions of Section 01 33 00.<br />

B. Product Data: Manufacturer's data sheets on each product to be used, including:<br />

1. Preparation instructions and recommendations.<br />

2. Storage and handling requirements and recommendations.<br />

3. Installation methods.<br />

C. Shop Drawings: Shop drawings shall show material type, overall thickness,<br />

dimensions, sizes, joints, finishes, attachments and relationship of adjoining work.<br />

D. Selection Samples: For each finish product specified, two complete sets of color<br />

chips representing manufacturer's full range of available colors and patterns.<br />

1. Samples shall include a color card of standard colors, or a color standard for<br />

special colors.<br />

05 58 13 - 1

2. Samples shall include samples of all support materials to be used.<br />

E. Verification Samples: For each finish product specified, two samples, minimum size<br />

3.5 inches (88.9 mm) square, representing actual product, color, and patterns.<br />

1. Samples shall include a color card of standard colors, or a color standard for<br />

special colors.<br />

2. Samples shall include samples of all support materials to be used.<br />

1.4 QUALITY ASSURANCE<br />

A. Manufacturer Qualifications: Manufacturer shall use an attachment system that has<br />

been used successfully in at least ten projects utilizing systems, materials and<br />

techniques as specified.<br />

B. Installer Qualifications: Installer shall have a minimum of two years experience in<br />

the installation of column covers similar to those required for this Project.<br />

C. Mock-Up: Provide a mock-up for evaluation of surface preparation techniques and<br />

application workmanship.<br />

1. Finish areas designated by Architect.<br />

2. Do not proceed with remaining work until workmanship and color are<br />

approved by Architect.<br />

1.5 DELIVERY, STORAGE, AND HANDLING<br />

A. All materials shall be protected during fabrication, shipment, site storage and<br />

erection to prevent damage to the finished work form other trades. Materials to be<br />

stored in fully enclosed space where they will be protected against damage from<br />

moisture, direct sunlight, surface contamination and other harmful affects.<br />

B. Store and dispose of solvent-based materials, and materials used with solventbased<br />

materials, in accordance with requirements of local authorities having<br />

jurisdiction.<br />

1.6 WARRANTY<br />

A. Finish Warranty: Provide manufacturer's standard finish warranty.<br />

PART 2 PRODUCTS<br />

2.1 MANUFACTURERS<br />

A. Acceptable Manufacturer: CAP; Columbia Arcitectural Products, which is located at:<br />

10722 Tucker Street, Beltsville, MD 20705; Tel: 301-937-4383; Email:<br />

tec.pan@verizon.net Web: www.tecpan.com<br />

B. Substitutions: Not permitted.<br />

C. Requests for substitutions will be considered in accordance with provisions of<br />

Section 01 60 00.<br />

1. Other systems may be submitted for approval as provided for in the<br />

specification at least ten working days prior to submission of bids. Companies<br />

desiring to submit a proposal shall submit all descriptive information of the<br />

system proposed including photographs and shop drawings of at least three<br />

projects similar in detail and scope.<br />

2.2 ALUMINUM COMPOSITE SYSTEM<br />

05 58 13 - 2

A. <strong>Column</strong> Cover System: CAP Aluminum Composite <strong>Column</strong> Cover with reveals.<br />

1. Material: ALPOLIC or Reynobond composite panels, aluminum sheet facing.<br />

a. Core: PE (Standard core).<br />

b. Core: FR (Fire-rated core).<br />

2. Material Thickness: 4 mm (0.157 inch).<br />

3. Material Thickness: As required based on application and core composition.<br />

4. Finish: Factory baked-on PVDF finish, applied per AAMA standards, free of<br />

scratches and blemishes. Color to be selected from manufacturer's standard<br />

colors.<br />

5. Fabrication:<br />

a. Height up to 16 feet (4876.8 mm) without concealed horizontal joints.<br />

b. Vertical reveal as indicated and slight vertical construction joint.<br />

c. Recessed horizontal reveals at the top and bottom as indicated on the<br />

Drawings.<br />

d. Concealed fasteners only.<br />

e. Recessed horizontal reveals at the top and bottom as indicated on the<br />

Drawings.<br />

f. Recessed horizontal reveals at all construction joints at locations<br />

indicated on the Drawings.<br />

g. Horizontal butt joints.<br />

h. Height up to twelve feet without concealed horizontal joints.<br />

i. Vertical reveal as indicated and slight vertical construction joint.<br />

j. Concealed fasteners only.<br />

k. Recessed horizontal reveals at the top and bottom as indicated on the<br />

Drawings.<br />

l. Recessed horizontal reveals at all construction joints at locations<br />

indicated on the Drawings.<br />

m. Horizontal butt joints.<br />

PART 3 EXECUTION<br />

3.1 EXAMINATION<br />

A. Do not begin installation until substrates have been properly prepared.<br />

B. If substrate preparation is the responsibility of another installer, notify Architect of<br />

unsatisfactory preparation before proceeding.<br />

3.2 PREPARATION<br />

A. Clean surfaces thoroughly prior to installation. Inspect column covers prior to<br />

installation for dents, scratches or other defects.<br />

3.3 INSTALLATION<br />

A. Install column covers in accordance with manufacturer's written instructions and<br />

shop drawings.<br />

B. Erect column covers plumb, level, square, true to line, securely anchored and in<br />

proper alignment and relationship to work of other trades.<br />

3.4 PROTECTION<br />

A. Protect installed products until completion of project.<br />

B. Remove protective covering immediately after installation to prevent adhesive<br />

transfer.<br />

05 58 13 - 3

C. Clean all surfaces following installation.<br />

D. Touch-up, repair or replace damaged products before Substantial Completion.<br />

END OF SECTION<br />

05 58 13 - 4

Florida<br />

Thomas SchreiberMiami, Iw<br />

Sales Representative<br />

tom@dcs-sales.com<br />

(407) 648-5348 Phone<br />

(407) 505-4336 Fax<br />

www.dcs-sales.com<br />

8805 Tamiami Trail North, Suite 107<br />

Naples, FL 34108<br />

Puerto Rico, US Virgin Islands - Caribbean<br />

Island groups-Lucayan Archipelago<br />

Greater Antilles, Lesser Antilles, Bahamas