SwRI engineers design, build and test a prototype wind turbine array

SwRI engineers design, build and test a prototype wind turbine array

SwRI engineers design, build and test a prototype wind turbine array

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

D017011<br />

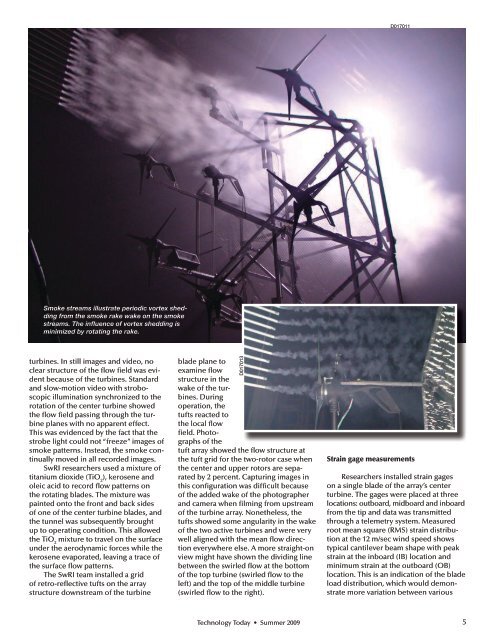

Smoke streams illustrate periodic vortex shedding<br />

from the smoke rake wake on the smoke<br />

streams. The influence of vortex shedding is<br />

minimized by rotating the rake.<br />

<strong>turbine</strong>s. In still images <strong>and</strong> video, no<br />

clear structure of the flow field was evident<br />

because of the <strong>turbine</strong>s. St<strong>and</strong>ard<br />

<strong>and</strong> slow-motion video with stroboscopic<br />

illumination synchronized to the<br />

rotation of the center <strong>turbine</strong> showed<br />

the flow field passing through the <strong>turbine</strong><br />

planes with no apparent effect.<br />

This was evidenced by the fact that the<br />

strobe light could not “freeze” images of<br />

smoke patterns. Instead, the smoke continually<br />

moved in all recorded images.<br />

<strong>SwRI</strong> researchers used a mixture of<br />

titanium dioxide (TiO 2<br />

), kerosene <strong>and</strong><br />

oleic acid to record flow patterns on<br />

the rotating blades. The mixture was<br />

painted onto the front <strong>and</strong> back sides<br />

of one of the center <strong>turbine</strong> blades, <strong>and</strong><br />

the tunnel was subsequently brought<br />

up to operating condition. This allowed<br />

the TiO 2<br />

mixture to travel on the surface<br />

under the aerodynamic forces while the<br />

kerosene evaporated, leaving a trace of<br />

the surface flow patterns.<br />

The <strong>SwRI</strong> team installed a grid<br />

of retro-reflective tufts on the <strong>array</strong><br />

structure downstream of the <strong>turbine</strong><br />

blade plane to<br />

examine flow<br />

structure in the<br />

wake of the <strong>turbine</strong>s.<br />

During<br />

operation, the<br />

tufts reacted to<br />

the local flow<br />

field. Photographs<br />

of the<br />

tuft <strong>array</strong> showed the flow structure at<br />

the tuft grid for the two-rotor case when<br />

the center <strong>and</strong> upper rotors are separated<br />

by 2 percent. Capturing images in<br />

this configuration was difficult because<br />

of the added wake of the photographer<br />

<strong>and</strong> camera when filming from upstream<br />

of the <strong>turbine</strong> <strong>array</strong>. Nonetheless, the<br />

tufts showed some angularity in the wake<br />

of the two active <strong>turbine</strong>s <strong>and</strong> were very<br />

well aligned with the mean flow direction<br />

everywhere else. A more straight-on<br />

view might have shown the dividing line<br />

between the swirled flow at the bottom<br />

of the top <strong>turbine</strong> (swirled flow to the<br />

left) <strong>and</strong> the top of the middle <strong>turbine</strong><br />

(swirled flow to the right).<br />

D017013<br />

Strain gage measurements<br />

Researchers installed strain gages<br />

on a single blade of the <strong>array</strong>’s center<br />

<strong>turbine</strong>. The gages were placed at three<br />

locations: outboard, midboard <strong>and</strong> inboard<br />

from the tip <strong>and</strong> data was transmitted<br />

through a telemetry system. Measured<br />

root mean square (RMS) strain distribution<br />

at the 12 m/sec <strong>wind</strong> speed shows<br />

typical cantilever beam shape with peak<br />

strain at the inboard (IB) location <strong>and</strong><br />

minimum strain at the outboard (OB)<br />

location. This is an indication of the blade<br />

load distribution, which would demonstrate<br />

more variation between various<br />

Technology Today • Summer 2009 5