Using the Soft-Soil tire model

Using the Soft-Soil tire model

Using the Soft-Soil tire model

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

The Adams/Tire <strong>Soft</strong> <strong>Soil</strong> <strong>tire</strong> <strong>model</strong> offers a basic <strong>model</strong> to describe <strong>the</strong> <strong>tire</strong>-soil interaction forces for<br />

any <strong>tire</strong> on elastic/plastic grounds, such as sand, clay, loam and snow.<br />

The <strong>model</strong> requires a <strong>tire</strong> property file with keyword SOFT-SOIL and a road data file (one of <strong>the</strong> existing<br />

formats) with additional soil properties. Two <strong>tire</strong>-soil contact <strong>model</strong>s are offered:<br />

• Elastic-plastic soil deformation <strong>model</strong>, USE_MODE = 1<br />

• Visco-elastic soil deformation <strong>model</strong>, USE_MODE = 2<br />

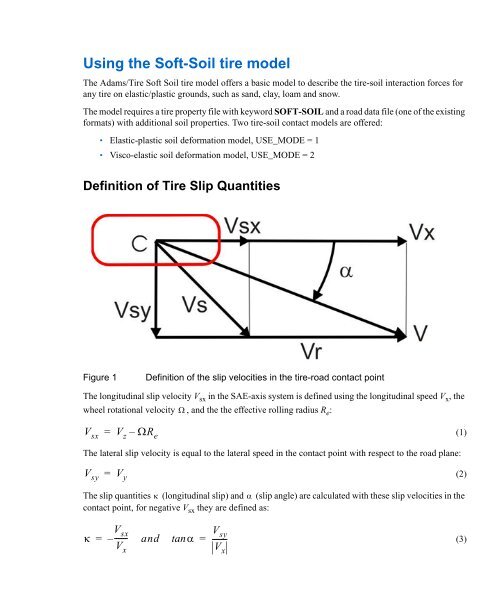

Definition of Tire Slip Quantities<br />

Figure 1<br />

Definition of <strong>the</strong> slip velocities in <strong>the</strong> <strong>tire</strong>-road contact point<br />

The longitudinal slip velocity V sx in <strong>the</strong> SAE-axis system is defined using <strong>the</strong> longitudinal speed V x , <strong>the</strong><br />

wheel rotational velocity and <strong>the</strong> <strong>the</strong> effective rolling radius R e :<br />

V sx = V z – R e<br />

(1)<br />

The lateral slip velocity is equal to <strong>the</strong> lateral speed in <strong>the</strong> contact point with respect to <strong>the</strong> road plane:<br />

V sy<br />

=<br />

V y<br />

(2)<br />

The slip quantities (longitudinal slip) and (slip angle) are calculated with <strong>the</strong>se slip velocities in <strong>the</strong><br />

contact point, for negative V sx <strong>the</strong>y are defined as:<br />

V sx<br />

V x<br />

= –------- and tan<br />

=<br />

V<br />

-------- sy<br />

V x<br />

(3)

2<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

and for positive V sx (driving) as:<br />

<br />

V sx<br />

V r<br />

= –------- and tan<br />

=<br />

V<br />

------- sy<br />

V r<br />

(4)<br />

V r is <strong>the</strong> rolling speed V r is determined using <strong>the</strong> effective rolling radius R e : (5)<br />

Note that for realistic <strong>tire</strong> forces <strong>the</strong> slip angle is limited to degrees and <strong>the</strong> longitudinal slip <br />

1<br />

to .<br />

90<br />

V r R e <br />

Loaded and Effective Tire Rolling Radius<br />

The loaded rolling <strong>tire</strong> radius R l is defined as <strong>the</strong> unloaded <strong>tire</strong> radius R 0 minus <strong>the</strong> <strong>tire</strong> deflection f 0 due<br />

to <strong>the</strong> vertical load:<br />

R l<br />

R 0 f 0<br />

(6)<br />

The effective rolling radius R e (at free rolling of <strong>the</strong> <strong>tire</strong>), which is used to calculate <strong>the</strong> rotational speed<br />

of <strong>the</strong> <strong>tire</strong>, is defined by:<br />

V<br />

Re<br />

<br />

x<br />

<br />

(7)

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Definition of Tire Slip Quantities<br />

3<br />

For radial <strong>tire</strong>s, <strong>the</strong> effective rolling radius is ra<strong>the</strong>r independent of load in its load range of operation<br />

because of <strong>the</strong> high stiffness of <strong>the</strong> <strong>tire</strong> belt circumference. Only at low loads does <strong>the</strong> effective <strong>tire</strong> radius<br />

decrease with increasing vertical load due to <strong>the</strong> <strong>tire</strong> tread thickness, see <strong>the</strong> Figure 2.<br />

Figure 2<br />

Effective and loaded <strong>tire</strong> radius as a function of <strong>the</strong> vertical load

4<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Effective Rolling Radius and Longitudinal Slip<br />

Figure 3<br />

Side view of a rolling <strong>tire</strong><br />

To represent <strong>the</strong> effective rolling radius R e , a PAC2002 compatible equation is used:<br />

R<br />

d<br />

d<br />

e R f0,F<br />

( Deff<br />

atan( Beff<br />

f ) Feff<br />

f<br />

z 0 0<br />

0 0<br />

)<br />

(8)<br />

f<br />

in which ,F is <strong>the</strong> nominal <strong>tire</strong> deflection at <strong>the</strong> nominal <strong>tire</strong> load F z0 :<br />

0 z0<br />

f<br />

0,F<br />

z0 F<br />

C<br />

z0<br />

z<br />

(9)<br />

and<br />

d<br />

f 0<br />

is called <strong>the</strong> dimensionless radial <strong>tire</strong> deflection, defined by:

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Elastic-plastic <strong>tire</strong>-soil contact<br />

5<br />

f<br />

d<br />

0<br />

f<br />

<br />

f<br />

0<br />

0,F z 0<br />

(10)<br />

Elastic-plastic <strong>tire</strong>-soil contact<br />

The interaction forces for a rigid wheel<br />

The static sinkage of a rigid object into a soft soil depends on <strong>the</strong> load on that object: Bekker [1]<br />

formulated <strong>the</strong> sinkage h of a flat plate with width b as follows:<br />

p(<br />

h )<br />

( k<br />

c<br />

/ b k<br />

<br />

) h<br />

n<br />

(11)<br />

k<br />

k<br />

in which c and are <strong>the</strong> cohesive and frictional moduli respectively, n <strong>the</strong> sinkage exponent. The<br />

static stress p is in equilibrium with <strong>the</strong> vertical force Fz.<br />

Figure 4<br />

Pressure distribution under a flat plate

6<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

When applying this approach to a non-rolling wheel <strong>the</strong> static stress distribution can be estimated as<br />

shown in <strong>the</strong> Figure 5<br />

Figure 5<br />

Static stress distribution under a non-rolling rigid wheel<br />

For <strong>the</strong> dynamic sinkage <strong>the</strong> wheel rotational speed must be taken into account.

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Elastic-plastic <strong>tire</strong>-soil contact<br />

7<br />

Figure 6<br />

Wheel entry and exit angle when rolling on soil<br />

<br />

Assume a wheel soil contact with entry angle f and exit angle r , see also [2], <strong>the</strong>n <strong>the</strong>se angles<br />

can be written as a function of <strong>the</strong> total sinkage h and <strong>the</strong> exit penetration h e as follows:<br />

<br />

<br />

<br />

f<br />

r<br />

acos( 1<br />

h / R )<br />

acos( 1<br />

h<br />

e<br />

/ R )<br />

The exit penetration h e depends on <strong>the</strong> elastic stiffness C s of <strong>the</strong> soil.<br />

(12)

8<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Based on <strong>the</strong> terramechanical approach as described in [2] <strong>the</strong> normal and shear stresses can be <strong>model</strong>ed<br />

as shown in <strong>the</strong> Figure 7.<br />

Figure 7<br />

Normal and shear stress <strong>model</strong>ling of a rotating wheel<br />

The wheel normal stress distribution can be defined as function of <strong>the</strong> wheel angle [2,3]:<br />

<br />

<br />

for m f :

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Elastic-plastic <strong>tire</strong>-soil contact<br />

9<br />

n<br />

kc<br />

<br />

( ) R0<br />

k<br />

cos( ) cos( <br />

b <br />

<br />

<br />

for<br />

r m<br />

:<br />

<br />

f<br />

)<br />

n<br />

(13)<br />

(<br />

) R<br />

n<br />

0<br />

kc<br />

<br />

b<br />

k<br />

<br />

<br />

<br />

<br />

cos<br />

<br />

<br />

<br />

f<br />

r<br />

<br />

<br />

m<br />

r<br />

( <br />

f<br />

<br />

m<br />

<br />

)<br />

cos( <br />

<br />

f<br />

<br />

) <br />

<br />

n<br />

with b <strong>the</strong> wheel width and R 0 <strong>the</strong> wheel radius.<br />

<br />

The angle m is <strong>the</strong> angle at which <strong>the</strong> maximum normal stress occurs [4]:<br />

<br />

m a0<br />

a1<br />

)<br />

( <br />

f<br />

(14)<br />

The shear stress [5,6] in longitudinal direction is:<br />

( ) ( c (<br />

)tan( ))( 1<br />

e<br />

x x<br />

x<br />

and in lateral direction yields:<br />

j ( ) / k<br />

)<br />

(15)<br />

( ) ( c (<br />

)tan( ))( 1<br />

e<br />

y<br />

jy(<br />

) / k y<br />

)<br />

(16)<br />

In equations 15 and 16 c represents <strong>the</strong> cohesion stress of <strong>the</strong> soil, <strong>the</strong> friction angle of <strong>the</strong> soil and k x<br />

and k y <strong>the</strong> shear deformation moduli. Assuming that <strong>the</strong> wheel has a longitudinal slip , <strong>the</strong> longitudinal<br />

shear displacement along <strong>the</strong> contact area j x in equation 16 can be estimated [5,6] by using <strong>the</strong><br />

longitudinal slip and wheel radius R 0 :<br />

<br />

j ( ) R [ (<br />

1 )(sin( <br />

x<br />

0<br />

f<br />

f<br />

) sin( ))]<br />

(17)<br />

Similar <strong>the</strong> lateral shear displacement j y will depend on <strong>the</strong> slip angle and <strong>the</strong> wheel radius R 0 :<br />

j ( ) R ( 1 )( <br />

y<br />

0<br />

f<br />

)tan( )<br />

(18)

10<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Figure 8 illustrates <strong>the</strong> shear stress as a function of soil deformation.<br />

Figure 8 Measured shear stress compared to fitted stress (equation 15)<br />

The longitudinal shear deformation modulus k x is defined as:<br />

k<br />

x<br />

k k 1<br />

x0 x<br />

(19)<br />

and <strong>the</strong> lateral shear deformation modulus k y :<br />

k<br />

y<br />

k k 1<br />

y0 y<br />

Having <strong>the</strong> normal and shear stress for <strong>the</strong> rotating wheel, <strong>the</strong> <strong>tire</strong>-soil interaction contact forces and<br />

moments can be calculated:<br />

• Longitudinal force:

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Elastic-plastic <strong>tire</strong>-soil contact<br />

11<br />

F<br />

x<br />

bR<br />

f<br />

<br />

r<br />

{ ( )cos( ) (<br />

)sin( )}d<br />

x<br />

(20)<br />

• Lateral force:<br />

F<br />

y<br />

f<br />

bR ( )d<br />

r<br />

y<br />

(21)<br />

• Vertical load:<br />

F<br />

z<br />

bR<br />

f<br />

<br />

r<br />

{ ( )sin( ) (<br />

)sin( )}d<br />

x<br />

(22)<br />

• Overturning moment:<br />

M x<br />

0<br />

(23)<br />

• Rolling resistance moment:<br />

M<br />

y<br />

<br />

2<br />

bR <br />

<br />

f<br />

r<br />

0<br />

( )sin( )d<br />

<br />

c<br />

rol<br />

F<br />

z<br />

(24)<br />

with c rol <strong>the</strong> <strong>tire</strong> (internal) rolling resistance coefficient.<br />

• Aligning moment:<br />

M<br />

z<br />

f<br />

2<br />

bR ( )sin( )d<br />

r<br />

y<br />

(25)<br />

Tire deformation<br />

In order to take <strong>the</strong> <strong>tire</strong> deflection into account <strong>the</strong> substitution circle approach is taken as was suggested<br />

by Bekker [7]:

12<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Figure 9<br />

Substitution circle to account for <strong>tire</strong> deflection<br />

At a certain penetration of <strong>the</strong> <strong>tire</strong> into <strong>the</strong> soil <strong>the</strong> <strong>tire</strong> deflection and sinkage can be determined by an<br />

iteration process based on <strong>the</strong> fact that <strong>the</strong> vertical <strong>tire</strong> force and <strong>the</strong> force due to <strong>the</strong> sinkage must be<br />

equal.<br />

The <strong>tire</strong> force can be calculated with <strong>the</strong> <strong>tire</strong> stiffness C z and <strong>tire</strong> deflection f 0 by:<br />

F<br />

z,<strong>tire</strong><br />

C<br />

z f 0<br />

(26)<br />

while <strong>the</strong> <strong>tire</strong> sinkage force is defined by equation (22), however, replacing <strong>the</strong> unloaded <strong>tire</strong> radius R 0<br />

by <strong>the</strong> radius of <strong>the</strong> substitution circle R*.<br />

Bekker [7] derived following relation in between <strong>the</strong> <strong>tire</strong> deflection f 0 and <strong>tire</strong> sinkage h:

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Elastic-plastic <strong>tire</strong>-soil contact<br />

13<br />

*<br />

R<br />

f0<br />

1<br />

<br />

h<br />

f<br />

h<br />

R 0<br />

0<br />

<br />

(27)<br />

Elastic and Plastic deformation<br />

Depending on <strong>the</strong> soil properties one part of <strong>the</strong> deformation is elastic and <strong>the</strong> remaining part is nonirreversible<br />

(plastic deformation). The elastic deformation is calculated with by <strong>the</strong> soil stiffness C s at <strong>the</strong><br />

maximum normal stress max :<br />

(<br />

<br />

he<br />

<br />

C<br />

m<br />

s<br />

)<br />

(28)<br />

Multi-pass effect<br />

When a <strong>tire</strong> has passed a certain spot of soil, a second <strong>tire</strong> will experience different soil properties when<br />

rolling over that spot due to <strong>the</strong> plastic deformation of <strong>the</strong> soil by <strong>the</strong> first <strong>tire</strong>.<br />

Therefore this <strong>Soft</strong> <strong>Soil</strong> <strong>tire</strong> <strong>model</strong> stores <strong>the</strong> elastic and plastic deformation of each <strong>tire</strong> as a function of<br />

<strong>the</strong> contact point x,y coordinates. When a <strong>tire</strong> passes a point with plastic deformation caused by a<br />

previous <strong>tire</strong>, <strong>the</strong> normal pressure calculation will account for <strong>the</strong> plastic deformation history.<br />

Figure 10 explains <strong>the</strong> mechanism applied in this <strong>tire</strong> <strong>model</strong> [8]:<br />

Assume two <strong>tire</strong>s rolling after each o<strong>the</strong>r over <strong>the</strong> same spot of soil. The first <strong>tire</strong> will have a total<br />

deformation h 1 existing of a plastic part h p1 and an elastic part h e1 . When a second <strong>tire</strong> passes <strong>the</strong> same<br />

spot, <strong>the</strong> soil will first have an elastic deformation from A to B (= h e1 ) and <strong>the</strong>n continue to follow <strong>the</strong><br />

normal pressure characteristic to point C. The plastic deformation of <strong>the</strong> second <strong>tire</strong> h p2 will be equal to<br />

<strong>the</strong> total deformation h 2 subtracted with <strong>the</strong> elastic deformation h e2 .

14<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Figure 10<br />

Normal pressure characteristic for multi-pass approach<br />

Note:<br />

The <strong>tire</strong> <strong>model</strong> stores <strong>the</strong> x, y coordinates, <strong>the</strong> elastic and plastic deformation and <strong>tire</strong> width<br />

of each <strong>tire</strong>. Because of <strong>the</strong> one-point of contact approach used in this <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong>,<br />

<strong>the</strong> total stored plastic deformation will be applied for a next <strong>tire</strong> when its contact point<br />

comes into <strong>the</strong> rut of a previous <strong>tire</strong>.<br />

Visco-elastic <strong>tire</strong>-soil contact<br />

Next to elastic-plastic deformation <strong>model</strong>s for soft soil, also visco-elastic <strong>model</strong>ing approaches exist.<br />

Wanjii e.o. [9] derived a visco-elastic <strong>model</strong> for <strong>the</strong> normal stress along <strong>the</strong> contact line in between <strong>the</strong><br />

<strong>tire</strong> and <strong>the</strong> soil. A three element Maxwell approach is used for a rigid wheel, see Figure 11.

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Visco-elastic <strong>tire</strong>-soil contact<br />

15<br />

Figure 11<br />

Three element Maxwell <strong>model</strong> for a rigid wheel on visco-elastic soil<br />

For this <strong>model</strong> <strong>the</strong> normal stress in <strong>the</strong> contact in between <strong>tire</strong> and ground is:<br />

x <br />

<br />

A x <br />

G1<br />

2 2 G2VxTr<br />

V T <br />

( x ) ( xA<br />

x ) (<br />

xA<br />

VxTr<br />

) 1<br />

e<br />

x r<br />

xA<br />

2R0<br />

R0<br />

<br />

<br />

<br />

x<br />

<br />

(29)<br />

With<br />

x<br />

a<br />

R<br />

0<br />

)<br />

sin( <br />

f<br />

)<br />

x<br />

R<br />

sin( <br />

0<br />

2<br />

T r /<br />

G<br />

In which<br />

T r is <strong>the</strong> relaxation time<br />

<br />

is <strong>the</strong> viscosity of <strong>the</strong> soil

16<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

V x is <strong>the</strong> forward velocity of <strong>the</strong> <strong>tire</strong><br />

G 1 is <strong>the</strong> first elastic modulus<br />

G 2 is <strong>the</strong> second elastic modulus<br />

The longitudinal and lateral shear stresses are calculated using <strong>the</strong> equations 15 until and including 19 as<br />

used for <strong>the</strong> elastic-plastic <strong>tire</strong>-soil <strong>model</strong>. Similar for <strong>the</strong> <strong>tire</strong>-ground interaction forces equation (20 -<br />

24) are used.<br />

For <strong>the</strong> multi-pass effect, <strong>the</strong> road deformation at <strong>the</strong> exit of <strong>the</strong> <strong>tire</strong>-soil contact (point B) and <strong>the</strong> time<br />

of deformation occurrence is stored. When a second <strong>tire</strong> passes <strong>the</strong> same spot, <strong>the</strong> road deformation<br />

corrected with <strong>the</strong> relaxation effect is taken to correct <strong>the</strong> road height input.<br />

References:<br />

1. Bekker, M.G., Off-<strong>the</strong>-road-locomotion, Ann Arbor, The University of Michigan Press, 1960.<br />

2. G. Ishigami, A. Miwa, K. Nagatani, K. Yoshida, Terramechanics - Based Model for Steering<br />

Maneuver of Planetary Exploration Rovers on Loose <strong>Soil</strong>, Journal of Field robotics 24(3), 233-<br />

250 (2007), Wiley Periodicals, Inc.<br />

3. Yoshida, K., Watanabe, T., Mizuna, N., Ishigami, G., Terramechanics - based analysis and<br />

traction control of a lunar/planetary rover. In Proceedings of <strong>the</strong> Int. Conf. Of Field and Service<br />

Robotics (FSR '03), Yamanashi, Japan.<br />

4. Wong, J.Y., Reece, A., Prediction of rigid wheel performance based on <strong>the</strong> analysis of soil-wheel<br />

stresses part I, performance driving rigid wheels, Journal of Terramechanics, 4, 81-98.<br />

5. Janosi, Z. Hanamoto, B., The analytical determination of drawbar pull as a function of slip for<br />

tracked vehicle in deformable soils, In proceedings of <strong>the</strong> 1 st Int. conf. on Terrain-Vehicle<br />

systems, Torino, Italy.<br />

6. Wong, J.Y., Theory of Ground Vehicles, John Wiley & Sons, Inc., second edition, 1993.<br />

7. Bekker, M.G., Introduction to terrain-vehicle systems, Ann Arbor, The University of Michigan<br />

Press, 1969.<br />

8. AS 2 TM User's Guide, version 1.12, AESCO GbR, Hamburg.<br />

9. S. Wanjii, T. Hiroma, Y. Ota, T. Kataoka, Predicition of Wheel Performance by Analysis of<br />

Normal and Tangential Stress Distributions under <strong>the</strong> Wheel-<strong>Soil</strong> Interface, Journal of<br />

Terramechanics, Vol. 34, No. 3, pp. 165-186, 1997.<br />

10. Schmid, I.C., Interaction of Vehicle and Terrain Results from 10 Years Research at IKK, Journal<br />

of Terramechanics, Vol. 32, No. 1, pp. 3-26, 1995.<br />

11. Schmid, I.C., Aubel, Th., Der elastische Reifen auf nachgiebiger Fahrbahn - Rechen<strong>model</strong>l im<br />

Hinblick auf Reifendruckregelung, VDI Berichte nr. 916, 1991.<br />

12. Faßbender, F., Simulation der Vertikaldynamik von Fahrzeugen auf Geländeböden mit STINA -<br />

SOIL TIRE INTERFACE TO ADAMS einem Zusatzmodul für das Mehrkörperprogramm<br />

ADAMS. Number 521 in Fortschritt-Berichte VDI Reihe 12. VDI Verlag, Düsseldorf, 2002.<br />

Dissertation Universität der Bundeswehr Hamburg.

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Feature and property overview of <strong>the</strong> Adams/Tire <strong>Soft</strong> <strong>Soil</strong> Tire <strong>model</strong><br />

17<br />

Feature and property overview of <strong>the</strong> Adams/Tire <strong>Soft</strong> <strong>Soil</strong> Tire<br />

<strong>model</strong><br />

• Two <strong>tire</strong>-road contact <strong>model</strong>s:<br />

• Elastic-plastic contact <strong>model</strong><br />

elastic <strong>tire</strong>: <strong>tire</strong> deflection is taken into account<br />

multi-pass effect: road plastic deformation history is stored and taken into account when<br />

ano<strong>the</strong>r <strong>tire</strong> passes <strong>the</strong> same spot<br />

• Visco-elastic contact <strong>model</strong><br />

rigid <strong>tire</strong>: no <strong>tire</strong> deflection<br />

multi-pass effect: road viscous deformation is stored. The stored deformation reduced by <strong>the</strong><br />

relaxation effect is taken into account when ano<strong>the</strong>r <strong>tire</strong> passes <strong>the</strong> same spot<br />

• Tire effective rolling radius is defined similar to pac2002 <strong>tire</strong> <strong>model</strong><br />

• Tire properties are very basic (<strong>tire</strong> vertical stiffness and damping, unloaded radius, width and<br />

effective rolling radius parameters)<br />

• The existing Adams/Tire roads can be used, just an additional section with <strong>the</strong> soil properties is<br />

required. These soil properties are valid for <strong>the</strong> whole road.<br />

<br />

• Linearization of - F x characteristic during q-statics to ensure robust q-statics<br />

• Linear vertical <strong>tire</strong> stiffness can be replaced by a (non-linear) deflection-load curve<br />

• Scaling factors of road friction, <strong>tire</strong> cornering and longitudinal stiffness' are supported<br />

• SMP (multi-thread, C++ solver) is supported<br />

• Tire-road contact is a one-point contact<br />

• Camber effects are not taken into account<br />

• Overturning moment is not calculated<br />

• No bulldozing effects<br />

Example of <strong>the</strong> <strong>tire</strong> property file for <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> Tire <strong>model</strong>:<br />

$----------------------------------------------------------MDI_HEADER<br />

[MDI_HEADER]<br />

FILE_TYPE = 'tir'<br />

FILE_VERSION = 2.0<br />

FILE_FORMAT = 'ASCII'<br />

(COMMENTS)<br />

{comment_string}<br />

'Tire - XXXXXX'<br />

'Pressure - XXXXXX'<br />

'Test Date - XXXXXX'<br />

'Test <strong>tire</strong>'<br />

'New File Format v2.1'<br />

$---------------------------------------------------------------units

18<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

[UNITS]<br />

LENGTH<br />

= 'mm'<br />

FORCE<br />

= 'newton'<br />

ANGLE<br />

= 'degree'<br />

MASS<br />

= 'kg'<br />

TIME<br />

= 'sec'<br />

$---------------------------------------------------------------<strong>model</strong><br />

! use mode 1 2<br />

! --------------------------------------------------------------<br />

! flexible wheel/<strong>tire</strong> with elastic-plastic road X<br />

! rigid wheel/<strong>tire</strong> with visco-elastic road X<br />

!<br />

PROPERTY_FILE_FORMAT = 'SOFT-SOIL'<br />

USE_MODE = 1.0<br />

$-----------------------------------------------------------dimension<br />

[DIMENSION]<br />

UNLOADED_RADIUS = 309.9<br />

WIDTH = 235.0<br />

ASPECT_RATIO = 0.45<br />

$-----------------------------------------------------------parameter<br />

[PARAMETER]<br />

NOMINAL_TIRE_LOAD = 4000<br />

VERTICAL_STIFFNESS = 310.0<br />

VERTICAL_DAMPING = 0.5<br />

ROLLING_RESISTANCE = 0.01<br />

BREFF = 8.4<br />

DREFF = 0.27<br />

FREFF = 0.07<br />

$---------------------------------------------------------------shape<br />

[SHAPE]<br />

{radial width}<br />

1.0 0.0<br />

1.0 0.2<br />

1.0 0.4<br />

1.0 0.5<br />

1.0 0.6<br />

1.0 0.7<br />

1.0 0.8<br />

1.0 0.85<br />

1.0 0.9<br />

0.9 1.0<br />

$----------------------------------------------------------load_curve<br />

$ For a non-linear <strong>tire</strong> vertical stiffness<br />

$ Maximum of 100 points<br />

[DEFLECTION_LOAD_CURVE]<br />

{pen fz}<br />

0 0.0<br />

1.0 212.0<br />

2.0 428.0<br />

3.0 648.0<br />

5.0 1100.0<br />

10.0 2300.0<br />

20.0 5000.0<br />

30.0 8100.0

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Example of <strong>the</strong> required <strong>Soil</strong> properties in <strong>the</strong> Road Data File:<br />

19<br />

Example of <strong>the</strong> required <strong>Soil</strong> properties in <strong>the</strong> Road Data File:<br />

Existing road data files can be used, but a 'SOIL_PROPERTIES' section has to be added:<br />

$-----------------------------------------------------SOIL_PROPERTIES<br />

[SOIL_PROPERTIES]<br />

FRICTION_ANGLE = 37.2 $units: degree<br />

COHESION_STRESS = 8.0E-4 $units: N/mm**2<br />

SOIL_DEFORM_MOD_KX0 = 43.0 $units: mm<br />

SOIL_DEFORM_MOD_KX1 = 0.6283 $units: mm/deg<br />

SOIL_DEFORM_MOD_KY0 = 20.0 $units: mm<br />

SOIL_DEFORM_MOD_KY1 = 0.2269 $units: mm/deg<br />

!visco-elastic <strong>tire</strong>:<br />

ELASTIC_MODULUS_G1 = 0.071E-3 $units: N/mm**3<br />

ELASTIC_MODULUS_G2 = 1.072E-3 $units: N/mm**3<br />

SOIL_VISCOSITY = 7.14E-3 $units: Ns/mm**3<br />

!plastic-elastic <strong>tire</strong>:<br />

PRESSURE_SINKAGE_KC = 1.37E-3 $units: N/mm**(n+1)<br />

PRESSURE_SINKAGE_KFI = 8.14E-4 $units: N/mm**(n+2)<br />

SINKAGE_EXPONENT = 1 $units: = n<br />

SOIL_INTERACTION_A0 = 0.4 $units: -<br />

SOIL_INTERACTION_A1 = 0.15 $units: -<br />

SOIL_STIFFNESS = 8.14E-3 $units: N/mm**3<br />

Symbols<br />

B eff<br />

b<br />

c<br />

c rol<br />

D eff<br />

C z<br />

C s<br />

f 0<br />

effective rolling radius factor<br />

<strong>tire</strong>/wheel width<br />

cohesion<br />

<strong>tire</strong> rolling resistance coefficient<br />

effective rolling radius factor<br />

<strong>tire</strong> vertical stiffness<br />

soil stiffness<br />

<strong>tire</strong> deflection<br />

d<br />

dimensionless <strong>tire</strong> deflection<br />

f 0<br />

f0,F<br />

z 0<br />

G 1<br />

G 2<br />

F eff<br />

F x<br />

nominal <strong>tire</strong> deflection<br />

elastic modulus<br />

elastic modulus<br />

effective rolling radius factor<br />

longitudinal force

20<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

F y<br />

F z<br />

F z0<br />

h<br />

h e<br />

h p<br />

k c<br />

k <br />

lateral force<br />

vertical load<br />

nominal <strong>tire</strong> load<br />

sinkage<br />

elastic deformation<br />

plastic deformation<br />

cohesive modulus<br />

frictional modulus<br />

k x soil deformation modulus<br />

k y soil deformation modulus<br />

M x overturning moment<br />

M y rolling resistance moment<br />

M z aligning moment<br />

n sinkage component<br />

p static stress<br />

R e effective rolling radius<br />

R 0 unloaded (free) <strong>tire</strong>/wheel radius<br />

R l <strong>tire</strong> loaded radius<br />

R* radius of substitution circle<br />

T r relaxation time<br />

V total <strong>tire</strong>/wheel speed<br />

V r <strong>tire</strong> rolling velocity<br />

V x <strong>tire</strong>/wheel forward speed (parallel to wheel plane)<br />

V sx longitudinal slip speed<br />

V sy lateral slip speed<br />

<br />

<br />

<br />

<br />

<br />

slip angle<br />

longitudinal slip<br />

friction angle<br />

normal stress<br />

<strong>tire</strong>/wheel rotational speed

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong><br />

Symbols<br />

21<br />

x<br />

y<br />

<br />

f<br />

r<br />

<br />

longitudinal shear stress<br />

lateral shear stress<br />

wheel angle<br />

wheel soil entry angle<br />

wheel soil entry angle<br />

viscosity of <strong>the</strong> soil

22<br />

Adams/Tire<br />

<strong>Using</strong> <strong>the</strong> <strong>Soft</strong>-<strong>Soil</strong> <strong>tire</strong> <strong>model</strong>