MaquetaciÅ n 1 - Promatec Food Ventures

MaquetaciÅ n 1 - Promatec Food Ventures

MaquetaciÅ n 1 - Promatec Food Ventures

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

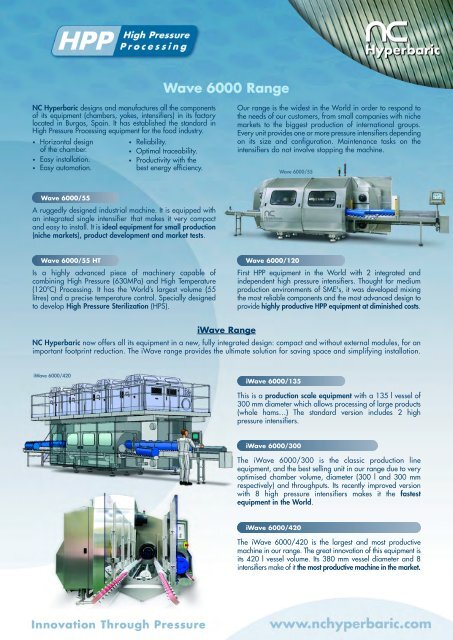

NC Hyperbaric designs and manufactures all the components<br />

of its equipment (chambers, yokes, intensifiers) in its factory<br />

located in Burgos, Spain. It has established the standard in<br />

High Pressure Processing equipment for the food industry.<br />

• Horizontal design<br />

of the chamber.<br />

• Easy installation.<br />

• Easy automation.<br />

• Reliability.<br />

• Optimal traceability.<br />

• Productivity with the<br />

best energy efficiency.<br />

Our range is the widest in the World in order to respond to<br />

the needs of our customers, from small companies with niche<br />

markets to the biggest production of international groups.<br />

Every unit provides one or more pressure intensifiers depending<br />

on its size and configuration. Maintenance tasks on the<br />

intensifiers do not involve stopping the machine.<br />

Wave 6000/55<br />

Wave 6000/55<br />

A ruggedly designed industrial machine. It is equipped with<br />

an integrated single intensifier that makes it very compact<br />

and easy to install. It is ideal equipment for small production<br />

(niche markets), product development and market tests.<br />

Wave 6000/55 HT<br />

Is a highly advanced piece of machinery capable of<br />

combining High Pressure (630MPa) and High Temperature<br />

(120ºC) Processing. It has the World’s largest volume (55<br />

litres) and a precise temperature control. Specially designed<br />

to develop High Pressure Sterilization (HPS).<br />

Wave 6000/120<br />

First HPP equipment in the World with 2 integrated and<br />

independent high pressure intensifiers. Thought for medium<br />

production environments of SME's, it was developed mixing<br />

the most reliable components and the most advanced design to<br />

provide highly productive HPP equipment at diminished costs.<br />

iWave Range<br />

NC Hyperbaric now offers all its equipment in a new, fully integrated design: compact and without external modules, for an<br />

important footprint reduction. The iWave range provides the ultimate solution for saving space and simplifying installation.<br />

iWave 6000/420<br />

iWave 6000/135<br />

This is a production scale equipment with a 135 l vessel of<br />

300 mm diameter which allows processing of large products<br />

(whole hams…) The standard version includes 2 high<br />

pressure intensifiers.<br />

iWave 6000/300<br />

The iWave 6000/300 is the classic production line<br />

equipment, and the best selling unit in our range due to very<br />

optimised chamber volume, diameter (300 l and 300 mm<br />

respectively) and throughputs. Its recently improved version<br />

with 8 high pressure intensifiers makes it the fastest<br />

equipment in the World.<br />

iWave 6000/420<br />

The iWave 6000/420 is the largest and most productive<br />

machine in our range. The great innovation of this equipment is<br />

its 420 l vessel volume. Its 380 mm vessel diameter and 8<br />

intensifiers make of it the most productive machine in the market.

The Wave 6000 range allows High Pressure Processing of<br />

food up to a maximum pressure of 6000 bar / 600 MPa /<br />

87.000 psi. in a range of temperature from +5ºC up to +30ºC<br />

(+41ºF up to +86ºC). Every equipment provides:<br />

• Automated loading & unloading conveyor.<br />

• Automated Empty Basket return conveyor.<br />

• SCADA system.<br />

• Internet connection for remote maintenance.<br />

• 2 pressure transducers with auto checking system.<br />

NC Hyperbaric complies with the<br />

97/23/CE Directive, relating to<br />

EU member state legislation<br />

regarding pressure equipment,<br />

and the ASME code (U3<br />

stamp) which allows installation<br />

of its equipment in the USA and<br />

other countries in the World<br />

under the ASME code.<br />

Tandem Configuration<br />

For higher volume production, NC Hyperbaric has developed the Tandem configuration. Two machines will share their intensifiers,<br />

achieving a productivity improvement of 15-20% due to the decreased pressure come up time.<br />

DIMENSIONS<br />

Equipment<br />

CYCLE TIMES AND OUTPUTS<br />

Total cycle time Number of<br />

Equipment Nº of intensifiers Power kW Vessel filling ratio<br />

in minutes* cycles/hour<br />

Output**<br />

Kg/hour (Pounds/hour)<br />

Wave 6000/55 1 55<br />

6.7 9<br />

50%<br />

246 (543)<br />

Wave 6000/120 2 100<br />

7.3 8.3<br />

50%<br />

497 (1,095)<br />

iWave 6000/135 2<br />

4<br />

100<br />

190<br />

7.3<br />

7.4<br />

8.3<br />

8.1<br />

55%<br />

55%<br />

614 (1,355)<br />

1,338 (2,950)<br />

iWave 6000/300<br />

iWave 6000/420<br />

Ø inside<br />

mm. (inch)<br />

Vessel Capacity litres<br />

(US liq. gallons)<br />

Vessel length<br />

mm. (inch)<br />

Footprint area*<br />

m 2 (sq ft)<br />

Wave 6000/55 200 (7.9”) 55 (14.5) 2,000 (78.7) 22 (237)<br />

Wave 6000/120 200 (7.9”) 120 (31.7) 4,050 (159.4) 37 (398)<br />

iWave 6000/135 300 (11.8”) 135 (36.7) 2,200 (86.6) 39 (420)<br />

iWave 6000/300 300 (11.8”) 300 (79.3) 4,500 (177.2) 61 (657)<br />

iWave 6000/420 380 (15”) 420 (111) 4,000 (157.5) 56 (603)<br />

* Including working and maintenance space requirements.<br />

6<br />

280<br />

6.5 9.1<br />

55%<br />

1,523 (3,358)<br />

8 370<br />

6.1 9.8<br />

55%<br />

1,623 (3,579)<br />

6<br />

280<br />

8.1 7.4<br />

60%<br />

1,867 (4,117)<br />

8<br />

370<br />

7.4 8.1<br />

60%<br />

2,043 (4,505)<br />

The rights are reserved to modify the characteristics indicated in this catalogue without previous advice.<br />

* Total cycle time: cycle time for vacuum-packed products including loading and unloading, raising of pressure, 3 minutes holding time at 600 MPa, release of<br />

pressure and the necessary time for machine movements and operations.<br />

** Output: for vacuum-packed products processed at 600 MPa / 6,000 bar / 87,000 psi during 3 minutes.<br />

Mayo 2010