Final Design Presentation

Final Design Presentation

Final Design Presentation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Final</strong> <strong>Design</strong> <strong>Presentation</strong><br />

Last Wednesday we arranged our second <strong>Design</strong><br />

<strong>Presentation</strong> this season, this time to present<br />

Engine after Dyno, Impact Attenuator and Aerodynamics.<br />

In addition to this, three exciting<br />

projects were presented; the Dynamic Windtunnel<br />

Model and Alternative Powertrain<br />

Bachelor Thesis’, as well as our recently initiated<br />

Active Suspension project. We were happy to see<br />

that the auditorium was �illed and that the questions<br />

and discussions were vibrant like never<br />

before.<br />

Manufacturing<br />

Manufacturing is progressing well, and it is<br />

encouraging for the team to be working on what<br />

now starts to look like a car. With easter right<br />

around the corner and two full weeks of workshop<br />

time ahead of us, we are optimistic towards<br />

our deadline of having a running car in the end of<br />

April - though as with anything in Formula<br />

Student, it will not be easy and will require a lot of<br />

hard work from the entire team.<br />

Driver Selection<br />

What is a big question every year, for every team,<br />

has now also been asked here at Chalmers: Who<br />

will drive the car? Per the rules we will need four<br />

drivers, all students from Chalmers. As we estimate<br />

that 60-70% of the performance is driverdependant,<br />

it is important to pick someone who is<br />

both fast, and who has the right mindset and will<br />

stay calm even in a high-pressure situation. A few<br />

weeks ago we had an initial round of carting<br />

where everyone participated, and last week the<br />

top drivers from that event went out for a test<br />

drive with the CFS11. We are glad to see that we<br />

have several strong and dedicated candidates -<br />

some have been working out for months with the<br />

competition in mind already.<br />

Newsletter March<br />

Days until Rolling Car<br />

21<br />

Days until �irst competition<br />

100<br />

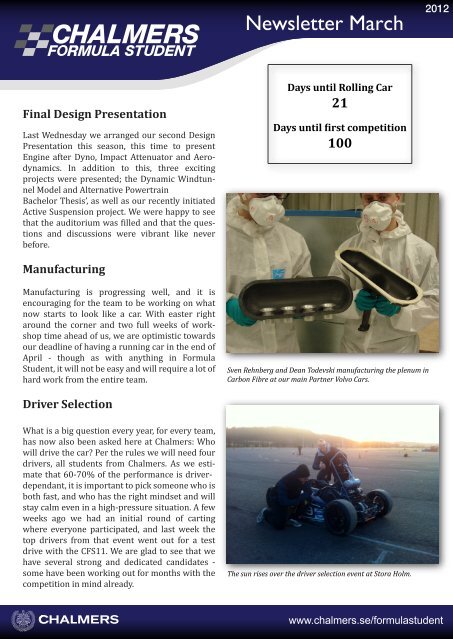

Sven Rehnberg and Dean Todevski manufacturing the plenum in<br />

Carbon Fibre at our main Partner Volvo Cars.<br />

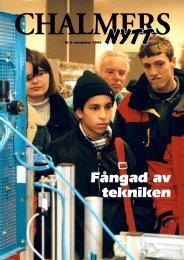

The sun rises over the driver selection event at Stora Holm.<br />

2012<br />

www.chalmers.se/formulastudent

Last day of Dyno testing<br />

With three weeks left to the running car deadline<br />

and 100 days to the �irst competition the dyno crew,<br />

consisting of Sebastion Krause, Blago Minovski,<br />

Tony Persson and Andreas Widroth, completed the<br />

tuning and mapping of the CFS12 Yamaha Fazer<br />

600 cc engine.<br />

Last autumn, the design goal of performance was<br />

set to maximizing the mean torque in the rpmrange<br />

where the majority of the driving time during<br />

a competition is spent. This range is approximately<br />

5 000-10 000 rpm according to logged data from<br />

testing of the CFS11 car. This approach was taken to<br />

get as much drivability and useful power out of the<br />

engine as possible, even if it meant losing some hp<br />

in peak power at 12 000 rpm.<br />

With the goal of delivering a reliable and weight<br />

optimized engine system with suf�icient power and<br />

possibility for low fuel consumption in the back of<br />

our heads, the crew began installation of the engine<br />

and the associated system in one of the engine cells<br />

at the division of combustion at Chalmers. With<br />

constantly new challenges and a lot of practice in<br />

problem solving for engines and electronics, testing<br />

of last year’s intake and exhaust system begun. We<br />

can attest that this made us take a leap towards the<br />

CFS project goal of delivering the Engineers of<br />

Tomorrow! These early tests with the CFS11<br />

systems were great for calibration and reference,<br />

but also an instructive way to learn how to operate<br />

the dyno.<br />

The mapping of the engine was performed by the<br />

following procedure:<br />

• Setting the injected fuel/air-ratio by the volumetric<br />

ef�iciency and lambda tables for all combinations<br />

of rpm and loads, to match the installed intake<br />

and exhaust system.<br />

• Mapping the ignition timing for maximum brake<br />

torque in every load case.<br />

• Adjusting the lambda table for the best combination<br />

of power and fuel consumption.<br />

Newsletter March<br />

The comparison between the �inal dyno results and<br />

the simulations run in GT-Power during the design<br />

phase, showed better conformance than we could<br />

ever have expected. The rpm for which we got<br />

peaks in power and torque matched almost<br />

perfectly. In comparison to CFS11, our engine<br />

system has a 3 % higher mean torque in the rpmrange<br />

it was designed for, as well as higher power<br />

all the way from 5 500 to 11 500 rpm.<br />

Despite the limited time and the need for a quick<br />

rebuild of an engine, the CFS12 engine group managed<br />

to perform all necessary tests and are very<br />

satis�ied with the results that will help us reach our<br />

goals. However, the �inal tuning of the settings will<br />

be done on the track and/or in a rolling dyno with<br />

the possibility of transient rpm sweeps.<br />

Tony Persson<br />

Engine<br />

2012<br />

The Engine installed in one of the the engine cells at Chalmers<br />

www.chalmers.se/formulastudent

Manager’s Corner:<br />

This is Engineering<br />

I had the pleasure this month to introduce <strong>Design</strong><br />

<strong>Presentation</strong> #2, which gave the members of<br />

CFS12 and CFS13 the opportunity to demonstrate<br />

initial results of current and future projects.<br />

These presentations gave me the con�idence that<br />

the future of CFS is bright, and I look forward to<br />

following their development together with you<br />

over the coming years. For 2012, the running car<br />

deadline is fast approaching and it is excellent to<br />

see a constant throughput of parts from the work-<br />

Motorsport- Motorsport-<br />

sensors<br />

VIP<br />

Gold<br />

Produktion & Modell AB<br />

Silver<br />

Bronze<br />

Newsletter March<br />

shop. We all are looking forward to<br />

the completion of the car so that an<br />

extensive testing phase can be undertaken, the<br />

“Operate” phase of the CDIO concept which the<br />

project is built around, and this is the time when<br />

we �ind out if what we designed & simulated is the<br />

same in reality. It should be kept in mind that CFS<br />

is �irst and foremost an educational project and<br />

that an excellent �inal competition result is as a<br />

result of the excellent education we provide. We<br />

don’t just “build cool stuff” at Chalmers Formula<br />

Student – we Deliver the Engineers of Tomorrow!<br />

Jonathan Rice<br />

tandemhopp.se<br />

We are always open to new partners who wish to help us<br />

in our goal of Delivering the Engineers of Tomorrow.<br />

Contact us at formulastudent@lists.chalmers.se<br />

2012<br />

Department of Automotive Engineering<br />

www.chalmers.se/formulastudent