Comil Tooling Select.. - Sawyer/Hanson Innovations

Comil Tooling Select.. - Sawyer/Hanson Innovations

Comil Tooling Select.. - Sawyer/Hanson Innovations

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The information contained within this document is<br />

considered confidential and may not be reproduced<br />

or distributed without the expressed consent of<br />

Quadro Engineering.<br />

S ALES T ECHNICAL B ULLETIN STB008<br />

Quadro ® <strong>Comil</strong> ®<br />

C OMIL ® T OOLING S ELECTION<br />

Q UADRO ® C OMIL ® I MPELLERS<br />

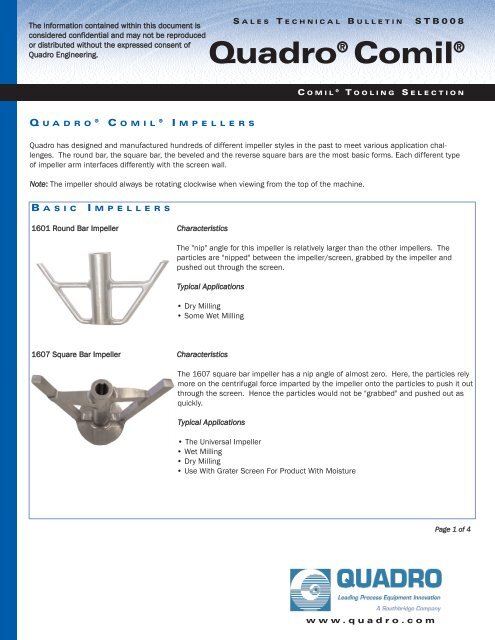

Quadro has designed and manufactured hundreds of different impeller styles in the past to meet various application challenges.<br />

The round bar, the square bar, the beveled and the reverse square bars are the most basic forms. Each different type<br />

of impeller arm interfaces differently with the screen wall.<br />

Note: The impeller should always be rotating clockwise when viewing from the top of the machine.<br />

B ASIC<br />

I MPELLERS<br />

1601 Round Bar Impeller Characteristics<br />

The "nip" angle for this impeller is relatively larger than the other impellers. The<br />

particles are "nipped" between the impeller/screen, grabbed by the impeller and<br />

pushed out through the screen.<br />

Typical Applications<br />

• Dry Milling<br />

• Some Wet Milling<br />

1607 Square Bar Impeller Characteristics<br />

The 1607 square bar impeller has a nip angle of almost zero. Here, the particles rely<br />

more on the centrifugal force imparted by the impeller onto the particles to push it out<br />

through the screen. Hence the particles would not be "grabbed" and pushed out as<br />

quickly.<br />

Typical Applications<br />

• The Universal Impeller<br />

• Wet Milling<br />

• Dry Milling<br />

• Use With Grater Screen For Product With Moisture<br />

Page 1 of 4<br />

www.quadro.com

QUADRO ® COMIL ®<br />

Basic Impellers Cont’d<br />

1609 Beveled Impeller Characteristics<br />

The 1609 beveled impeller is similar to the 1607 however, it has a beveled edge<br />

where the particles can deflect back down into the screen. This "deflection" of<br />

the particles basically keeps them in the screen a little longer than if the<br />

1601 or 1607 impeller were used.<br />

Typical Applications<br />

• For Finer Grind<br />

1612 Impeller Characteristics<br />

The 1612 impeller is opposite that of the 1607. It has the highest "nip" angle and<br />

can "grab" particles and push them out through the screen, even more so than<br />

the 1601 round bar impeller.<br />

Typical Applications<br />

• For Higher Capacities<br />

H OW D O A LL T HESE A FFECT T HE M ILLING P ROCESS<br />

*<br />

*Pr. = Pressure<br />

Page 2 of 4<br />

LOCAL REPRESENTATIVE<br />

Quadro Engineering<br />

613 Colby Drive<br />

Waterloo, ON, CA N2V 1A1<br />

T 519-884-9660<br />

F 519-884-0253<br />

sales@quadro.com<br />

www.quadro.com<br />

Quadro, Inc.<br />

55 Bleeker Street<br />

Millburn, NJ, USA 07041-1414<br />

T 973-376-1266<br />

F 973-376-3363<br />

quadrosales@aol.com<br />

www.quadro.com

QUADRO ® COMIL ®<br />

How Do All These Affect The Milling Process<br />

Cont’d<br />

Capacity: The capacity would be highest for the 1612 because more particles can be "grabbed" and pushed out through the screen.<br />

The 1601 would be ranked second, the 1607 third and the 1609 fourth.<br />

Fine Generation: The 1609 will cause the particles to be retained in the screen longer, hence a higher residence time. When that<br />

happens, there will be more inter-particle attrition creating more fines. This impeller is selected when the user requires fine particles.<br />

The other impellers create less fines, as per the above noted sequence.<br />

Screen Pressure: Highest on the 1612 impeller and lowest on the 1609 impeller.<br />

Amperage Draw: Highest on the 1612 and lowest on the 1609 impeller.<br />

S CREEN<br />

S ELECTION<br />

Quadro has designed and manufactured hundreds of different types of screens but this Bulletin illustrates the few basic types.<br />

“R” Round Holed Screens: Used primarily for dry sizing or powder into liquid dispersion.<br />

Applications incude dry granulation sizing in tablet manufacturing, bakery mix fat dispersion,<br />

deagglomeration of soil, sizing and bulk density tuning of spray dried powders. Sizes range from<br />

0.006” (0.15mm) - 0.250” (6.35mm) hole diameters.<br />

“Q” Square Holed Screens: Used for wet (moist) product sizing and when larger particle sizes<br />

are required. Applications include wet granulation sizing/dispersion in tablet manufacturing, sizing<br />

moist chicken or seafood coating for reclaim, de-wrapping candy, cheese chunks and sizing<br />

centrifuge solids. Sizes range from 0.156”H X 0.156”L (3.96mmH X 3.96mmL) to 1.00”H X<br />

1.00”L (25.4mmH X 25.4mmL) hole dimensions; where “H” and “L” are the Height and Length,<br />

respectively.<br />

“S” Slotted Holed Screens: Used for breaking capsules before the “G” screen was introduced.<br />

Applications include wet granulation sizing/dispersion in tablet manufacturing, separating dried<br />

fruits such as raisins, cranberries, apricots, apples and pineapples (note, please consult Quadro<br />

for a specially designed “S” screen for these applications), breaking glass bottles/syringes for<br />

drug reclaim, sizing wet detergent lumps from cyclone wall build-up. Sizes range from 0.156”H X<br />

0.380”L (3.96mmH X 9.65mmL) to 1.00”H X 2.18”L (25.4mmH X 55.37mmL) hole dimensions;<br />

where “H” and “L” are Height and Length, respectively.<br />

Page 3 of 4<br />

LOCAL REPRESENTATIVE<br />

Quadro Engineering<br />

613 Colby Drive<br />

Waterloo, ON, CA N2V 1A1<br />

T 519-884-9660<br />

F 519-884-0253<br />

sales@quadro.com<br />

www.quadro.com<br />

Quadro, Inc.<br />

55 Bleeker Street<br />

Millburn, NJ, USA 07041-1414<br />

T 973-376-1266<br />

F 973-376-3363<br />

quadrosales@aol.com<br />

www.quadro.com

QUADRO ® COMIL ® Page 4 of 4<br />

S CREEN S ELECTION C ONT’ D<br />

“G” Grater Holed Screens: They have a cutting edge on the holes. Used for sizing products<br />

that are harder or more ductile (with some elasticity). Applications include sizing tablets in the<br />

Pharmaceutical and Nutraceutical industries, powderizing cream-filled cookies for reclaim,<br />

grating cheese, chopping nuts, sizing compacted “ribbons” from roller compactors in dry tablet<br />

manufacturing, sizing pre-compressed slugs in tablet manufacturing, sizing cereal flakes, sizing<br />

bread loaves for crumbs. This screen is often used when a tighter particle size distribution<br />

curve is desired. Sizes range rom 0.040” (1.00mm) to 1.25” (31.75mm) hole diameters.<br />

A PPARENT H OLE S IZE<br />

When selecting the proper screen hole size, the apparent<br />

hole size must be considered. What is the apparent<br />

hole size It is the size of the screen hole that is<br />

"perceived" by a particle traveling by the screen hole.<br />

At zero velocity, when a particle "looks" at a hole, it<br />

sees the actual diameter of the hole. In this slide it is<br />

labeled as D1.<br />

However, if the particle was traveling at a certain velocity,<br />

let's say "v", it will "see" the diameter of the hole as<br />

D2.<br />

“C” Condidur Holed Screens: They also have a cutting edge on the holes. It is available in<br />

smaller holed sizes when compared to the “G” screen. This allows for finer milling with less<br />

chance of screen blinding. Sizes range from 0.006” (0.15mm) to 0.039” (0.99mm) hole diameters.<br />

Other specialty screens have not been covered here. Please consult Quadro for further details and also, the Application<br />

Bulletins for more information.<br />

D1 is always greater than D2. As the velocity goes up, the apparent hole size goes down.<br />

For example, if you require a particle to be sized to 30 US Std mesh (or 0.0234"), then the screen selected should have a<br />

hole diameter of approximately 18 or 20 US Std Mesh (0.0394" or 0.0331") or larger; of course, this depends on the impeller<br />

rpm. Testing is generally recommended for proper tooling selection.<br />

LOCAL REPRESENTATIVE<br />

Quadro Engineering<br />

613 Colby Drive<br />

Waterloo, ON, CA N2V 1A1<br />

T 519-884-9660<br />

F 519-884-0253<br />

sales@quadro.com<br />

www.quadro.com<br />

Quadro, Inc.<br />

55 Bleeker Street<br />

Millburn, NJ, USA 07041-1414<br />

T 973-376-1266<br />

F 973-376-3363<br />

quadrosales@aol.com<br />

www.quadro.com