AISC Design Guide 13..

AISC Design Guide 13..

AISC Design Guide 13..

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

13<br />

Steel <strong>Design</strong> <strong>Guide</strong> Series<br />

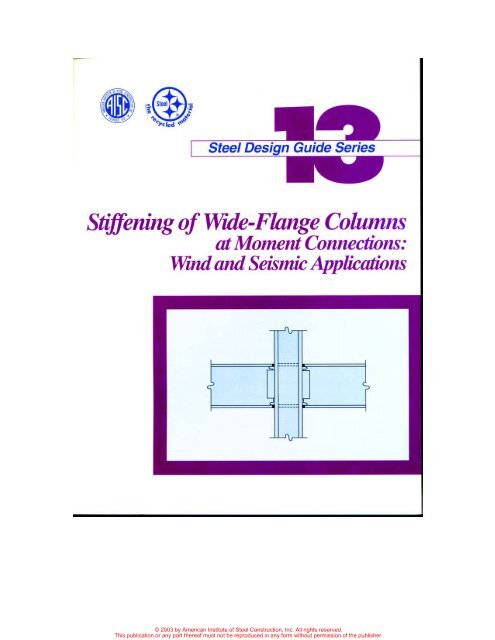

Stiffening of Wide-Flange Columns<br />

at Moment Connections:<br />

Wind and Seismic Applications<br />

Charles J. Carter, PE<br />

American Institute of Steel Construction, Inc.<br />

Chicago, IL<br />

AMERICAN INSTITUTE OF STEEL CONSTRUCTION, INC.

Copyright © 1999<br />

by<br />

American Institute of Steel Construction, Inc.<br />

All rights reserved. This book or any part thereof<br />

must not be reproduced in any form without the<br />

written permission of the publisher.<br />

The information presented in this publication has been prepared in accordance with recognized<br />

engineering principles and is for general information only. While it is believed<br />

to be accurate, this information should not be used or relied upon for any specific application<br />

without competent professional examination and verification of its accuracy,<br />

suitablility, and applicability by a licensed professional engineer, designer, or architect.<br />

The publication of the material contained herein is not intended as a representation<br />

or warranty on the part of the American Institute of Steel Construction or of any other<br />

person named herein, that this information is suitable for any general or particular use<br />

or of freedom from infringement of any patent or patents. Anyone making use of this<br />

information assumes all liability arising from such use.<br />

Caution must be exercised when relying upon other specifications and codes developed<br />

by other bodies and incorporated by reference herein since such material may be modified<br />

or amended from time to time subsequent to the printing of this edition. The<br />

Institute bears no responsibility for such material other than to refer to it and incorporate<br />

it by reference at the time of the initial publication of this edition.<br />

Printed in the United States of America<br />

Second Printing: October 2003<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

TABLE OF CONTENTS<br />

1. Introduction ......................... 1 5.2 Column Stiffening for Weak-Axis Moment<br />

1.1 Scope............................ 1<br />

Connections ...................... 33<br />

1.2 Column Stiffening ................... 2 5.3 Column Stiffening for Concurrent Strong- and<br />

1.3 References Specifications .............. 2<br />

Weak-Axis Moment Connections ....... 34<br />

1.4 Definitions of Wind, Low-Seismic, and<br />

5.4 Web Doubler Plates as Reinforcement for<br />

High-Seismic Applications. ............ 2<br />

Local Web Yielding, Web Crippling, and/ or<br />

1.5 Acknowledgements. .................. 2<br />

Compression Buckling of the Web. ...... 35<br />

5.5 Web Doubler Plates at Locations of Weak-Axis<br />

2. Strong-Axis Moment Connections<br />

to Unreinforced Columns ...............<br />

2.1 Force Transfer in Unreinforced Columns ....<br />

3<br />

3<br />

Connections ......................<br />

5.6 Diagonal Stiffeners ..................<br />

35<br />

36<br />

2.2 Determining the <strong>Design</strong> Strength of an<br />

6. <strong>Design</strong> Examples ..................... 39<br />

Unreinforced Column ................ 5 Example 6-1. ......................... 39<br />

2.3 Column Cross-Sectional Stiffness<br />

Example 6-2. ......................... 40<br />

Considerations .................... 11 Example 6-3. ......................... 41<br />

2.4 <strong>Design</strong> Aids. ...................... 11 Example 6-4. ......................... 45<br />

Example 6-5. ......................... 47<br />

3. Economical Selection of Columns .........<br />

3.1 Achieving Balance Between Increases<br />

13 Example 6-6. .........................<br />

Example 6-7. .........................<br />

47<br />

50<br />

in Material Cost and Reductions in Example 6-8. ......................... 52<br />

LaborCost....................... 13 Example 6-9. ......................... 52<br />

3.2 Eliminating Column Stiffening. ......... 14 Example 6-10. ........................ 54<br />

3.3 Minimizing the Economic Impact of Column Example 6-11. ........................ 55<br />

Stiffening Requirements in Wind and Low- Example 6-12. ........................ 58<br />

Seismic Applications. ............... 15 Example 6-<strong>13.</strong> ........................ 59<br />

3.4 Minimizing the Economic Impact of Column Example 6-14. ........................ 61<br />

Stiffening Requirements in High-Seismic<br />

Applications. ..................... 16 APPENDIX A ......................... 67<br />

4. Strong-Axis Moment Connections APPENDIX B.......................... 75<br />

to Stiffened Columns ................. 17<br />

4.1 Determining the Column Stiffening APPENDIX C ......................... 83<br />

Requirements ..................... 18<br />

4.2 Force Transfer in Stiffened Columns ...... 20 APPENDIX D ......................... 95<br />

4.3 <strong>Design</strong> of Transverse Stiffeners ......... 22 Special Considerations. .................. 95<br />

4.4 <strong>Design</strong> of Web Doubler Plates .......... 27 Moment Connections to Column Webs. ....... 99<br />

5. Special Considerations ................. 33<br />

5.1 Column Stiffening for Beams of Differing<br />

Depth and/ or Top of Steel. ............ 33<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

Chapter 1<br />

INTRODUCTION<br />

1.1 Scope<br />

The design of columns for axial load, concurrent axial load<br />

and flexure, and drift considerations is well established.<br />

However, the consideration of stiffening requirements for<br />

wide-flange columns at moment connections as a routine<br />

criterion in the selection of the components of the struc-<br />

tural frame is not as well established. Thus, the economic<br />

benefit of selecting columns with flange and web thick-<br />

nesses that do not require stiffening is not widely pur-<br />

sued, in spite of the efforts of other authors who<br />

have<br />

addressed this topic previously (Thornton, 1991; Thorn-<br />

ton, 1992; Barger, 1992; Dyker, 1992; and Ricker, 1992).<br />

This <strong>Design</strong> <strong>Guide</strong> is written with the intent of changing<br />

that trend and its contents are focused in two<br />

areas:<br />

1. The determination of design strength and stiffness<br />

for unreinforced wide-flange columns at locations<br />

of strong-axis beam-to-column moment connections;<br />

and,<br />

2. The design of column stiffening elements, such as<br />

transverse stiffeners (alsoknown as continuity plates)<br />

and web doubler plates, when the unreinforced col-<br />

umn strength and/ or stiffness is inadequate.<br />

Recommendations for economy are included in both cases.<br />

Force transfer and design strength of unreinforced<br />

columns with strong-axis moment connections are covered<br />

in Chapter 2. Economical considerations for unreinforced<br />

columns and columns with reinforcement are given in<br />

Chapter 3. Force transfer and design strength of reinforced<br />

columns with strong-axis moment connections, as well as<br />

the design of transverse stiffeners and web doubler plates,<br />

is covered in Chapter 4. Special considerations in column<br />

stiffening, such as stiffening for weak-axis moment con-<br />

nections and framing arrangements with offsets, are cov-<br />

ered in Chapter 5. <strong>Design</strong> examples that illustrate the<br />

application of these provisions are provided in Chapter 6,<br />

with design aids for wind and low-seismic applications in<br />

Appendices A, B, and C.<br />

1.2 Column Stiffening<br />

Transverse stiffeners are used to<br />

increase the strength<br />

and/ or stiffness of the column flange and/ or web at the lo-<br />

cation of a concentrated force, such as the flange force in-<br />

duced by the flange or flange-plate of a moment-connected<br />

beam. Web doubler plates are used to<br />

increase the shear<br />

strength and stiffness of the column panel-zone between<br />

the pair of flange forces from a moment-connected beam.<br />

The panel-zone is the area of the column that is bounded<br />

by the column flanges and the projections<br />

of the beam<br />

flanges as illustrated in Figure 1-1.<br />

If transverse stiffeners and/ or web doubler plates carry<br />

loads from members that frame to the weak-axis of the<br />

Projection of beam flanges, or<br />

transverse stiffeners, if present<br />

Column panel-zone<br />

Figure 1-1 Illustration of column panel-zone.<br />

1<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

column, the recommendations herein must be adjusted as High-seismic applications are those for which inelastic bediscussed<br />

in Sections 5.2, 5.3, and 5.5. As discussed in havior is expected in the beams or panel-zones as a means<br />

Section 5.4, if web doubler plates are required to increase of dissipating the energy induced during strong ground<br />

the panel-zone shear strength, they can also be used to re- motions. Such buildings are designed to<br />

meet the requiresist<br />

local web yielding, web crippling, and/ or compression<br />

ments in both the LRFD Specification and the <strong>AISC</strong> Seisbuckling<br />

of the web per LRFD Specification Section K1. mic Provisions and a response modification factor R that<br />

As discussed in Section 5.6, diagonal stiffening can be is appropriate for the level of detailing required for the<br />

used in lieu of web doubler plates if it does not interfere moment-frame system selected is used in the determinawith<br />

the weak-axis framing. tion of seismic forces. 1<br />

Additionally, the moment con-<br />

nections used in high-seismic applications have special<br />

1.3 References Specifications<br />

This <strong>Design</strong> <strong>Guide</strong> is generally based upon the requirements<br />

seismic detailing that is appropriate for the moment-frame<br />

system selected.<br />

in the <strong>AISC</strong> LRFD Specification for Structural<br />

Steel Buildings (<strong>AISC</strong>, 1993), hereinafter referred to<br />

as 1.5 Acknowledgements<br />

the LRFD Specification, and the <strong>AISC</strong> Seismic Provisions This <strong>Design</strong> <strong>Guide</strong> resulted partially from work that was<br />

for Structural Steel Buildings (<strong>AISC</strong>, 1997a), hereinafter done as part of the <strong>Design</strong> Office Problems activity of<br />

referred to as the <strong>AISC</strong> Seismic Provisions. Although di- the ASCE Committee on <strong>Design</strong> of Steel Building Strucrect<br />

reference to the <strong>AISC</strong> Specification for Structural tures. Chapter 3 is based in large part upon this previous<br />

Steel Buildings—Allowable Stress <strong>Design</strong> and Plastic <strong>Design</strong><br />

(<strong>AISC</strong>, 1989) is not included, the principles herein Textbooks has enhanced this <strong>Design</strong> <strong>Guide</strong> through care-<br />

work. Additionally, the <strong>AISC</strong> Committee on Manuals and<br />

remain generally applicable.<br />

ful scrutiny, discussion, and suggestions for improvement.<br />

The author thanks the members of these <strong>AISC</strong> and ASCE<br />

1.4 Definitions of Wind, Low-Seismic, and High-<br />

Seismic Applications<br />

Committees for their invaluable input and guidance. In<br />

particular, Lawrence A. Kloiber, James O. Malley, and<br />

For the purposes of this <strong>Design</strong> <strong>Guide</strong>, wind, low-seismic<br />

David T. Ricker contributed significantly to the develop-<br />

and high-seismic applications are defined as follows.<br />

ment of Chapters 3 and 4 and William C. Minchin and<br />

Wind and low-seismic applications are those for which Thomas M. Murray provided helpful comments and sugthe<br />

structure is designed to<br />

meet the requirements in the gestions throughout the text of this <strong>Design</strong> <strong>Guide</strong>.<br />

LRFD Specification with no<br />

special seismic detailing.<br />

This includes all applications for which the structural response<br />

is intended toremain in the nominally elastic range 8, 6, and 4 are commonly used for Special Moment Frames (SMF), Inter-<br />

1From <strong>AISC</strong> Seismic Provisions Commentary Table I-C4-1, R-values of<br />

and the response modification factor<br />

R used in the determination<br />

mediate Moment Frames (IMF), and Ordinary Moment Frames (OMF),<br />

of seismic forces, if any, is not taken greater than 3.<br />

respectively.<br />

2<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

Chapter 2<br />

STRONG-AXIS MOMENT CONNECTIONS<br />

TO UNREINFORCED COLUMNS<br />

In wind and low-seismic applications, it is often possible couple in the beam flanges or flange plates. The corre-<br />

to use wide-flange columns without transverse stiffeners sponding flange force Puf<br />

is calculated as:<br />

and web doubler plates at moment-connected beams. To<br />

use an unreinforced column, the following criteria must<br />

Mu<br />

Pu<br />

Puf<br />

<br />

be met:<br />

dm<br />

2<br />

(2.1-1)<br />

1. The required strength (Section 2.1) must be less than where<br />

or equal to the design strength (Section 2.2); and,<br />

Puf<br />

factored beam flange force, tensile or compres-<br />

2. The stiffness of the column cross-section must be adsive,<br />

kips<br />

equate to resist the bending deformations in the col-<br />

Mu<br />

factored beam end moment, kip-in.<br />

umn flange (Section 2.3).<br />

d o<br />

o<br />

2<br />

m m ment arm between the flange f rces, in.<br />

If these criteria cannot be met, column stiffening is required.<br />

Pu<br />

factored beam axial force, kips<br />

The formulation of Equation 2.1-1 is such that the com-<br />

In high-seismic applications, transverse stiffeners are bined effect of the moment and axial force is transmitted<br />

normally required, as discussed in Section 2.3. However, through the flange connections, ignoring any strength con-<br />

it remains possible in many cases to use wide-flange tribution from the web connection, which is usually more<br />

columns in high-seismic applications without web doubler<br />

flexible.<br />

plates at moment-connected beams.<br />

When the moment to be developed is less than the full<br />

flexural strength of the beam, as is commonly the case<br />

2.1 Force Transfer in Unreinforced Columns<br />

when a drift criterion governs the design, and the axial<br />

In an unreinforced column, concentrated forces from the force is relatively small, this calculation is fairly straightbeam<br />

flanges or flange plates are transferred locally into<br />

forward. However, when the full flexural strength of the<br />

the column flanges. These concentrated forces spread beam must be developed, or when the axial force is large,<br />

through the column flange and flange-to-web fillet region<br />

such a model seems toguarantee an overstress in the beam<br />

into<br />

the web as illustrated in Figure 2-1a. Shear is disconnection.<br />

Nonetheless, the above force transfer model<br />

illustrated in Figure 2-1b. Ultimately, axial forces in the remains acceptable because inelastic action intothe range<br />

flange, particularly for a directly welded flange moment<br />

persed between them in the column web (panel-zone) as<br />

column flanges balance this shear as illustrated in Figure of strain hardening allows the development<br />

of the design<br />

2-1c.<br />

flexural strength of the beam in the connection (Huang et<br />

al., 1973). Such self-limiting inelastic action is permitted<br />

2.1.1 Required Strength for Local Flange and Web Limit<br />

in LRFD Specification Section B9. Alternatively, a web<br />

States<br />

connection with a stiffness that is compatible with that of<br />

the connections of the beam flanges can be used toactivate<br />

In wind and low-seismic applications, beam end moments,<br />

the full beam cross-section and reduce the portion carried<br />

shears, and axial forces are determined by analysis for<br />

by the flanges.<br />

the loads and load combinations in LRFD Specification<br />

Note that, if a composite moment connection is used be-<br />

Section A4.1. Note that the total design moment is sel- tween the beam and column, the calculations in Equations<br />

dom equal to the flexural strength of the beam(s). A ra- 2.1-1and2.1-2mustbeadjustedbasedupontheappropriate<br />

tional approach such as that illustrated in Example 6-4 or<br />

similar to<br />

that proposed by Disque (1975) can be used in<br />

conjunction with these loads and load combinations. Different<br />

load combinations may be critical for different The actual moment arm can be readily calculated as the distance be-<br />

2<br />

tween the centers of the flanges or flange plates as illustrated in Figure<br />

local-strength limit states.<br />

2-1a. Alternatively, as stated in LRFD Specification Commentary Section<br />

K1.7, 0.95 times the beam depth has been conservatively used for<br />

at the column face into an effective tension-compression<br />

d in the<br />

For the general case, the beam end moment is resolved<br />

past.<br />

m<br />

3<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

dm<br />

(a) Beam flange forces<br />

distributed through<br />

column flange and fillet<br />

(b) Free-body diagram<br />

illustrating shear and<br />

axial force transfer<br />

through column panelzone<br />

Note: beam shear and axial force (if any) omitted for clarity.<br />

(c) Free-body diagram<br />

illustrating resulting<br />

column axial forces and<br />

flange forces (moments)<br />

Figure 2-1 Force transfer in unreinforced columns.<br />

detailing and force transfer model. Some possible compos-<br />

Figure C-11.1 can be used. From <strong>AISC</strong> Seismic Provi-<br />

ite connections are illustrated in <strong>AISC</strong> (1997a), Leon et al. sions Section 11.2a, the flange forces in Ordinary Moment<br />

(1996), and Viest et al. (1998). Frames (OMF) need not be taken greater than those that<br />

In high-seismic applications, the moments, shears, and correspond to a moment M u equal to 1. 1RyFyZx<br />

or the<br />

axial forces are determined by analysis for the loads and maximum moment that can be delivered by the system,<br />

load combinations in LRFD Specification Section A4.1 whichever is less.<br />

and <strong>AISC</strong> Seismic Provisions Section 4.1. The resulting For Special Moment Frames (SMF) and Intermediate<br />

flange force Puf<br />

is then determined using Equation 2.1-1. Moment Frames (IMF), a cyclic inelastic rotation capa-<br />

Note that the corresponding connection details have spe- bility of 3 and 2 percent, respectively, is required. Several<br />

cial seismic detailing to provide for controlled inelastic alternative connection details using reinforcement, such as<br />

deformations during strong ground motion as a means of coverplates, ribs, or haunches, or using reduced beam secdissipating<br />

the input energy from an earthquake.<br />

3<br />

For Ordinary Moment Frames (OMF), a cyclic inelastions<br />

(dogbones), have been successfully tested and used.<br />

Such connections shift the location of the plastic hinge<br />

tic rotation capability of 1 percent is required. Moment into the beam by a distance a from the column face as<br />

connections such as those discussed in <strong>AISC</strong> Seismic illustrated in Figure 2-2. From <strong>AISC</strong> Seismic Provisions<br />

Provisions Commentary Section C11.2 and illustrated in Section 9.3a, the flange forces in Special Moment Frames<br />

3<br />

(SMF) and Intermediate Moment Frames (IMF) need not<br />

With strong panel-zones and fully restrained (FR) construction, the primary<br />

source of inelasticity is commonly hinging in the beam itself. If the be taken greater than:<br />

panel-zone is a significant source of inelasticity, or if partially restrained<br />

(PR) construction is used, the flange-force calculation in Equation 2.1-2<br />

Mu<br />

11 . RyFyZ<br />

Vua<br />

Puf<br />

<br />

should be adjusted based upon the actual force transfer model.<br />

d<br />

d<br />

(2.1-2)<br />

4<br />

m<br />

m<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

2.2 Determining the <strong>Design</strong> Strength of an<br />

Unreinforced Column<br />

An unreinforced column must have sufficient strength lo-<br />

cally in the flange(s) and web to<br />

resist the resulting flange-<br />

force couple(s). Moment connections are termed “double<br />

concentrated forces” in LRFD Specification Section K1<br />

because there is one tensile flange force and one compres-<br />

sive flange force acting on the same side of the column<br />

as illustrated in Figure 2-4a. When opposing moment-<br />

where 1.1 is an adjustment factor that nominally accounts<br />

Seismic Provisions Load Combinations 4-1 and 4-2 and<br />

for the effects of strain hardening, and<br />

Equation 2.1-1, the total panel-zone shear force is calculated<br />

with Equation 2.1-3. As a worst case, however, the<br />

Ry<br />

an adjustment factor that nominally accounts for<br />

total panel-zone shear force<br />

Vu<br />

need not be taken greater<br />

material yield overstrength per <strong>AISC</strong> Seismic<br />

than:<br />

Provisions Section 6.2<br />

1.5 for ASTM A36 wide-flange beams V u 0. 8[( Puf) 1( Puf) 2] Vus<br />

(2.1-4)<br />

1.3 for ASTM A572 grade 42 wide-flange beams<br />

1.1 for wide-flange beams in other material The factor 0.8 in Equation 2.1-4 is from <strong>AISC</strong> Seismic<br />

grades (e.g., ASTM A992 or A572 grade 50) Provisions Section 9.3a. It recognizes that the effect of<br />

Fy<br />

beam specified minimum yield strength, ksi the gravity loads will counteract some portion of the effect<br />

Z plastic section modulus of beam cross-section at of the lateral loads on one side of an interior column and<br />

hinge location (distance a from column face), in.<br />

3 thereby inhibit the development of the full plastic moment<br />

Vu<br />

shear in beam at hinge location (distance a from<br />

in the beam on that side.<br />

column face), kips<br />

In wind, low-seismic, and high-seismic applications, for<br />

a distance from face of column flange to<br />

plastic a column with only one moment-connected beam, Equa-<br />

hinge location, in.<br />

tion 2.1-3 can be reduced t o:<br />

The axial force effect is neglected in Equation 2.1-2, since<br />

Vu<br />

Puf<br />

Vus<br />

(2.1-5)<br />

the model is already based conservatively upon the fully<br />

yielded and strain-hardened beam flange at the critical Note that gravity-load reduction, as used for high-seismic<br />

section.<br />

applications in Equation 2.1-4, is not appropriate in Equa-<br />

tion 2.1-5 for a column with only one moment-connected<br />

2.1.2 Required Strength for Panel-Zone Shear<br />

beam.<br />

As illustrated in Figure 2-3, the total panel-zone shear<br />

force<br />

Vu<br />

at an interior column results from the combined<br />

effects of two moment-connected beams and the story<br />

shear Vus. In wind and low-seismic applications, the to-<br />

tal panel-zone shear force<br />

V is calculated as:<br />

V ( P ) ( P ) V (2.1-3)<br />

u<br />

u<br />

uf 1 uf 2<br />

In high-seismic applications, when the flange forces have<br />

been calculated using the moment resulting from <strong>AISC</strong><br />

us<br />

Reinforced zone or zone between<br />

beam end connection and reduced<br />

beam section (RBS)<br />

a<br />

Plastic hinge location<br />

Figure 2-2 Schematic illustration of moment connection<br />

for high-seismic applications.<br />

5<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

connected beams coincide, a pair of double concentrated<br />

Pu<br />

Fr o P u 04 . Py, R v 09 . 06 . Fydct w 14 . <br />

forces results as illustrated in Figures 2-4b (the gravity<br />

Py<br />

load case) and 2-4c (the lateral load case).<br />

The design strength of the panel-zone in shear must be<br />

(2.2-2)<br />

checked for all columns with moment connected beams.<br />

In the second assumption, it is recognized that signif-<br />

For a tensile flange force, the design strength of the flange<br />

icant post-yield panel-zone strength is ignored by limitin<br />

local flange bending and the design strength of the web<br />

ing the calculated panel-zone shear strength to<br />

that in the<br />

in local yielding must also be checked. For a compres-<br />

nominally elastic range. At the same time, it must be realsive<br />

flange force, the design strength of the web in lo-<br />

ized that inelastic deformations of the panel-zone can sigcal<br />

yielding, crippling, and compression buckling must be<br />

nificantly impact the strength and stability of the frame.<br />

checked. Note that the compression buckling limit state<br />

Accordingly, a higher strength can generally be utilized<br />

is applicable only when the compressive components of a<br />

as long as the effect of inelastic panel-zone deformation<br />

pair of double concentrated forces coincide as illustrated in<br />

on frame stability is considered in the analysis. When this<br />

Figure 2-4b (i.e., at the bottom flanges). If the magnitudes<br />

option is selected, the resulting design strength given in<br />

of these opposing flange forces are not equal, the compres-<br />

Equations 2.2-3 and 2.2-4 is determined from LRFD Specsion<br />

buckling limit state is checked for the smaller flange<br />

ification Equations K1-11 and K1-12 with consideration of<br />

force, since only this portion of the larger flange force must<br />

the magnitude of the axial load<br />

Pu<br />

in the column:<br />

be resisted. Each of these limit states is discussed below.<br />

Fr o P u 075 . Py,<br />

2.2.1 Panel-Zone Shear Strength<br />

3b t2<br />

f f<br />

In wind and low-seismic applications and high-seismic R v 0. 9 0. 6Fydctw<br />

1 <br />

ddt<br />

applications involving Ordinary Moment Frames (OMF),<br />

b cw<br />

(2.2-3)<br />

(P uf ) 1 (P uf ) 1<br />

the design shear strength of the panel-zone Rv<br />

is determined<br />

with the provisions of LRFD Specification Section<br />

Fr o P u 075 . Py,<br />

K1.7, which allows two alternative assumptions.<br />

b t<br />

2<br />

The first assumption is that, for calculation purposes,<br />

3 f f 12 . Pu<br />

R v 09 . 06 . Fydct w 1<br />

19 . <br />

the behavior<br />

of the panel-zone remains nominally within<br />

ddt b cw Py<br />

<br />

the elastic range. The resulting design strength given in<br />

Equations 2.2-1 and 2.2-2 is then determined from LRFD (2.2-4)<br />

Specification Equations K1-9 or K1-10 with consideration<br />

of the magnitude of the axial load<br />

Pu<br />

in the column:<br />

For Fy<br />

equal to or less than 50 ksi, all W-shapes listed<br />

in ASTM A6 except a W30 90 and a W16 31 have<br />

For P u 0. 4 Py, R v 0. 9 0. 6 Fydctw<br />

(2.2-1) a web thickness that is adequate to<br />

prevent buckling<br />

(M u ) 2 (M u ) 1<br />

V us<br />

(P uf ) 1<br />

(P uf ) 1<br />

V u<br />

<br />

<br />

V us<br />

Note: shear forces in beams and moments and axial forces in column omitted for clarity.<br />

Figure 2-3 Panel-zone web shear at an interior column (with<br />

moment-connected beams bending in reverse curvature).<br />

6<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

±Puf<br />

±(Puf)2<br />

±(Puf)1 ±(Puf)2<br />

±(Puf)1<br />

±Puf<br />

±(Puf)2<br />

±(Puf)1 ±(Puf)2<br />

±(Puf)1<br />

(a) Double concentrated forces (b) A pair of double concentrated forces,<br />

gravity load case<br />

(c) A pair of double concentrated forces,<br />

lateral load case<br />

Figure 2-4 Moment connection flange force terminology.<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.<br />

7

under panel-zone web shear per LRFD Specification Sec- Note that Equation 2.2-7 is in a form that has been adapted<br />

tion F2. For Fy<br />

50 ksi, these two shapes exceed the from that which appears in the <strong>AISC</strong> Seismic Provisions.<br />

limit on ht / w by 1.9 and 1.5 percent, respectively. Thus,<br />

for all practical purposes, in wind and low-seismic applications,<br />

shear buckling of the column web need not be<br />

2.2.2 Local Flange Bending<br />

F<br />

4 When a directly welded flange or flange-plated moment<br />

checked for columns with y equal to or less than 50 ksi.<br />

connection is used, differential stiffness across the width<br />

In high-seismic applications involving Special Moment<br />

of an unstiffened column flange results in a stress concen-<br />

Frames (SMF) or Intermediate Moment Frames (IMF), the<br />

tration in the weld adjacent to the column web as illuseffect<br />

of inelastic panel-zone deformation on frame stabiltrated<br />

in Figure 2-5 that must be limited for tensile flange<br />

ity must be considered in the analysis. The design shear<br />

forces. The design local flange bending strength Rn<br />

strength of the panel-zone Rv<br />

given in Equations 2.2-5<br />

given in Equation 2.2-8 is determined from LRFD Speciand<br />

2.2-6 is determined from <strong>AISC</strong> Seismic Provisions<br />

fication Equation K1.1 with consideration of the proximity<br />

Section 9.3a:<br />

of the concentrated flange force to the end of the column:<br />

Fr o P u 075 . Py,<br />

2<br />

R n 0. 9 6. 25 tf<br />

Fy Ct<br />

(2.2-8)<br />

3b t2<br />

f f<br />

R v 0. 75 0. 6Fydctw<br />

1 (2.2-5) When an extended end-plate moment connection is used,<br />

ddt b cw<br />

flange bending must be limited to<br />

prevent yielding of the<br />

column flange under tensile flange forces. The design local<br />

Fr o P u 075 . Py,<br />

flange bending strength Rn<br />

given in Equation 2.2-9 is<br />

b t<br />

2<br />

determined from Murray (1990) with consideration of the<br />

3 f f 12 . Pu<br />

R v 075 . 06 . Fydct w 1<br />

19 . <br />

proximity of the concentrated flange force tothe end of the<br />

ddt b cw Py<br />

column as:<br />

(2.2-6)<br />

bs<br />

2<br />

R n 0. 9 <br />

t F C<br />

p f y t (2.2-9)<br />

These provisions are identical to those in LRFD Specification<br />

Equations K1-11 and K1-12, except that a lower re-<br />

m e<br />

sistance factor is used to provide an added margin against<br />

where<br />

excessive panel-zone yielding. Additionally, to prevent t f column flange thickness, in.<br />

shear buckling under the higher inelastic demand associ-<br />

Fy<br />

column specified minimum yield strength, ksi.<br />

ated with high-seismic loading, the minimum thickness of<br />

Note that Equation 2.2-9 was developed from rethe<br />

unreinforced column web given in Equation 2.2-7 is<br />

search that considered only ASTM A36 material<br />

determined from <strong>AISC</strong> Seismic Provisions Section 9.3b:<br />

(Curtis and Murray, 1989). If column material<br />

d d t<br />

with higher yield strength is used, it is recom-<br />

m c 2 f<br />

tw<br />

min <br />

(2.2-7)<br />

mended that Fy<br />

be taken conservatively as 36 ksi<br />

90<br />

in Equation 2.2-9.<br />

where<br />

tw<br />

column web thickness, in.<br />

b f column flange width, in.<br />

t f column flange thickness, in.<br />

db<br />

beam depth, in.<br />

dc<br />

column depth, in.<br />

Fy<br />

column minimum specified yield strength, ksi<br />

Pu<br />

column required axial strength, in.<br />

Py<br />

FyA, column axial yield strength, in.<br />

A column cross-sectional area, in.<br />

2<br />

dm<br />

moment arm between concentrated flange forces,<br />

in.<br />

4If using allowable stress design, the shear buckling limit is slightly<br />

more conservative and the following W-shapes must be checked<br />

for shear buckling: W44230, W40215, W40199, W40183,<br />

W40174, W40167, W40149, W36150, W36135, W33130,<br />

W33118, W3099, W3090, W2784, W2468, W2455,<br />

W2144, W1835, W1631, W1626, W1422, and W1214.<br />

Figure 2-5 Concentration<br />

of stress in flange or<br />

flange-plate weld for a<br />

column with thin flanges<br />

and no transverse<br />

stiffeners.<br />

8<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

Ct<br />

0.5 if the distance from the column end to the<br />

closer face of the beam tension flange is less than<br />

When an extended end-plate moment connection is used,<br />

the concentrated force is distributed to the column web as<br />

10t<br />

f<br />

illustrated in Figure 2-7b. The design local web yielding<br />

1 otherwise<br />

strength Rn<br />

given in Equation 2.2-11 is determined from<br />

b s 2. 5(2 pftfb), in., for a four-bolt unstiffened exconcentrated<br />

Murray (1990) with consideration of the proximity of the<br />

tended end plate; see Figure 2-6a<br />

flange force to the end of the column:<br />

2pft fb3. 5 pb, in., for an eight-bolt stiffened<br />

extended end plate; see Figure 2-6b<br />

R n 1. 0 [ Ct(6k2 tp) N] Fytw<br />

(2.2-11)<br />

p f distance from centerline of bolt tonearer surface<br />

o o<br />

d 1<br />

where<br />

f the tensi n flange, in; b plus / 2 in. is genercolumn<br />

web thickness, in.<br />

ally enough toprovide wrench clearance; 2 in. is tw<br />

<br />

a common fabricator standard<br />

Fy<br />

column specified minimum yield strength, ksi<br />

t fb beam flange thickness, in.<br />

k distance from outside face of column flange tothe<br />

pb<br />

vertical pitch of bolt group above and bolt group<br />

web toe of the flange-to-web fillet, in.<br />

below tension flange, in.<br />

N beam flange or flange plate thickness plus 2 w, in.<br />

1/4<br />

pe<br />

Ct<br />

0.5 if the distance from the column end to<br />

the<br />

m 1. 36d<br />

<br />

for a four-bolt unstiffened extended closer face of the beam flange is less than dc<br />

b<br />

end plate<br />

1 otherwise<br />

1/4<br />

w leg size of fillet weld or groove weld reinforce-<br />

ment, if used, in.<br />

pe<br />

1.<br />

13d<br />

<br />

for an eight-bolt stiffened extended<br />

b<br />

tp<br />

end-plate thickness, in.<br />

end plate<br />

dc<br />

column depth, in.<br />

g db<br />

pe<br />

k1<br />

2 4<br />

g bolt gage, in.<br />

2.2.4 Web Crippling<br />

db<br />

bolt diameter, in. The design local web crippling strength Rn<br />

given in<br />

k1<br />

distance from beam web centerline to flange toe<br />

Equation 2.2-12 is determined from LRFD Specification<br />

of flange-to-web fillet, in. Equations K1-4, K1-5, or K1-6 with consideration of the<br />

proximity of the concentrated flange force tothe end of the<br />

2.2.3 Local Web Yielding<br />

column:<br />

When a directly welded flange or flange-plated moment<br />

15 .<br />

connection is used, the concentrated force is distributed 2 tw<br />

Ft y f<br />

R n 0. 75 135Cttw<br />

1 Nd<br />

to<br />

the column web as illustrated in Figure 2-7a. The design<br />

t <br />

f t w<br />

local web yielding strength Rn<br />

given in Equation<br />

2.2-10 is determined from LRFD Specification Equations<br />

(2.2-12)<br />

K1-2 or K1-3 with consideration of the proximity of the<br />

concentrated flange force to the end of the column:<br />

where<br />

Ct<br />

0.5 if the distance from the column end to<br />

the<br />

R n 1. 0 [ Ct(5 k) N] Fytw<br />

(2.2-10)<br />

closer face of the beam compression flange is less<br />

than dc/2<br />

1 otherwise<br />

tw<br />

column web thickness, in.<br />

Nd<br />

3 N/ dc<br />

if the distance from the column end to<br />

the<br />

closer face of the beam tension flange is either:<br />

(1) greater than or equal t o dc/2; or, (2) less than<br />

dc/2 and N/ dc<br />

is less than or equal to<br />

0.2.<br />

4N<br />

<br />

<br />

0.<br />

2<br />

d otherwise<br />

c<br />

t f<br />

Fy<br />

column flange thickness, in.<br />

column specified minimum yield strength, ksi<br />

(a) Four-bolt unstiffened (b) Eight-bolt stiffened<br />

N beam flange or flange plate thickness plus 2wfor<br />

directly welded flange or flange-plated moment<br />

connection, in.<br />

Figure 2-6 Configuration of extended end-plate moment<br />

beam flange thickness plus (2w2 tp) for extended<br />

connections.<br />

end-plate moment connections, in.<br />

9<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

w leg size of fillet weld or groove weld reinforce- web compression buckling strength Rn<br />

given in Equament,<br />

if used, in.<br />

tion 2.2-13 is determined from LRFD Specification Equations<br />

K1-8 with consideration of the proximity of the<br />

tp<br />

end-plate thickness, in.<br />

d column depth, in.<br />

concentrated flange force to the end of the column:<br />

c<br />

Note that, from LRFD Specification Commentary Sec-<br />

4, 100C t Fy<br />

R . <br />

tion K1.4, for the rolled shapes listed in ASTM A6, the<br />

n 0 90 (2.2-13)<br />

h<br />

limit state of web crippling will not govern the design of<br />

where<br />

transverse stiffening for a moment connection, except toa<br />

W1250 or W1033 column. That is, if transverse stiffcloser<br />

face of the compression flanges is less than<br />

Ct<br />

0.5 if the distance from the column end to<br />

the<br />

ening is required, another limit state, such as local web<br />

yielding or local flange bending, will be more critical in<br />

dc/2<br />

all except the aforementioned two<br />

cases.<br />

1 otherwise<br />

tw<br />

column web thickness, in.<br />

Fy<br />

column specified minimum yield strength, ksi<br />

2.2.5 Compression Buckling of the Web<br />

h dc<br />

2 k, in.<br />

When a pair of compressive flange forces coincide as il- dc<br />

column depth, in.<br />

lustrated in Figure 2-4b, the column web is subject to out- k distance from outside face of column flange tothe<br />

of-plane buckling as illustrated in Figure 2-8. The design<br />

web toe of the flange-to-web fillet, in.<br />

3<br />

t w<br />

k<br />

k<br />

t p<br />

1:1 slope<br />

5k + N<br />

N<br />

±P uf<br />

6k + N + 2tp<br />

N<br />

±P uf<br />

±F y<br />

2.5<br />

1<br />

3<br />

±F y<br />

1<br />

(a) Directly welded flange or flangeplated<br />

moment connection<br />

(b) Extended end-plate moment<br />

connection<br />

Figure 2-7 Local force transfer for local web yielding limit state.<br />

Zone of column web subject to<br />

compression buckling (out-of-plane)<br />

(P uf ) 2<br />

h k(P uf ) 1<br />

k<br />

Figure 2-8 Compression buckling of the column web.<br />

10<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

2.3 Column Cross-Sectional Stiffness Considerations<br />

In addition to<br />

satisfying the strength requirements given<br />

if testing demonstrates that the intended inelastic rotation<br />

can be achieved without their use.<br />

in Section 2.2, the supporting column must also<br />

have sufficient<br />

stiffness to resist local deformations of the cross-<br />

2.4 <strong>Design</strong> Aids<br />

section under the tensile and compressive flange forces. In For wind and low-seismic applications, the determination<br />

wind and low-seismic applications, design for the strength of the design strength of unreinforced wide-flange shapes<br />

criteria in Section 2.2 has historically resulted in columns<br />

used as columns is simplified with the tables in Appenwith<br />

suitable stiffness as well as strength. In high-seismic dices A, B, and C. In Appendix A, the design column<br />

applications, however, the associated higher inelastic de- panel-zone shear strength is tabulated. In Appendix B, the<br />

mand necessitates a more explicit consideration of flange design local column strength at locations of concentrated<br />

stiffness to limit the variation in stress distribution across<br />

flange forces is tabulated assuming that the concentrated<br />

the width of the connected flange or flange plate. <strong>AISC</strong> force is not at a column-end location. In Appendix C, the<br />

Seismic Provisions Sections 9.5 and 11.3 indicate that design local column strength at locations of concentrated<br />

transverse stiffeners that match the configuration of those<br />

flange forces is tabulated assuming that the concentrated<br />

used in the qualifying cyclic tests (see <strong>AISC</strong> Seismic Pro-<br />

force is at a column-end location. The use of these tables<br />

visions Appendix S) for the moment connection tobe used is illustrated in several of the example problems in Chapare<br />

required. Note that transverse stiffeners are not required ter 6.<br />

11<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

Chapter 3<br />

ECONOMICAL SELECTION OF COLUMNS<br />

Transverse stiffeners and web doubler plates are ex- welding transverse stiffeners and web doubler plates that<br />

tremely labor-intensive detail materials due primarily to is predominant in their cost.<br />

the fit-up and welding that is associated with their use. An equivalent column weight change is tabulated from<br />

Additionally, issues such as restraint, lamellar tearing and these estimated costs based upon a mill price of $425 per<br />

welding sequence must be addressed when transverse ton, which is a median value in the common range of<br />

stiffeners and/ or web doubler plates are used. As such, from $400 t o $450 per ton FOB,<br />

67 ,<br />

and a 14-ft floor-to-<br />

they add considerable cost in spite of their disproportion- floor height. The tabulated values are calculated as the esately<br />

low material cost. If transverse stiffeners and web timated cost times 2000 lb per ton divided by $425 per ton<br />

doubler plates can be eliminated and an unreinforced col-<br />

divided by the 14-ft length. The resulting value is the esumn<br />

can be used, significant cost savings can often be re- timated maximum per-foot column-weight increase that<br />

alized. Additionally, the elimination of column stiffening could be made to eliminate that element of the column<br />

will simplify (and thereby economize) connections that stiffening without increasing cost. In fact, because the tabare<br />

made to the weak axis of the column. ulated values do not consider other intangible economic<br />

In wind and low-seismic applications, the specification<br />

benefits, such as the simplification of connections that are<br />

of column sizes that eliminate transverse stiffeners is en- made to the weak axis of the column, the tabulated value<br />

couraged. In high-seismic applications, however, trans- should be considered conservative.<br />

verse stiffeners will normally be required, as discussed As an example, consider a W1490 column with fullpreviously<br />

in Section 2.3.<br />

depth transverse stiffeners (Case 5, Table 3.1) at each<br />

In wind, low-seismic, and high-seismic applications, beam flange (2 pairs total) and one web doubler plate<br />

the specification of column sizes that eliminate web dou- (Case 8, Table 3.1). The total of the tabulated column-<br />

bler plates is encouraged. Web doubler plates require weight-change values for this column stiffening arrangesignificant<br />

welding intothe column flange-to-web fillet region<br />

(k-area), which is an area of potentially lower notch ment is 40 lb/ft 82 lb/ft 122 lb/ft. Thus, if any<br />

heavier W14 up to and including a W14211 column<br />

toughness (<strong>AISC</strong>, 1997b). The shrinkage that accompa- could be used without transverse stiffeners and a web dou-<br />

nies the cooling of these welds typically can distort the bler plate, it would likely be more economical than the<br />

cross-section and overwelding in this region carries the W1490. In most cases, the actual increase in column<br />

potential for cracking. Additionally, the weld joint may re- weight required to eliminate column stiffening will be<br />

quire the use of a non-prequalified detail as discussed in much less than the maximum calculated and a significant<br />

Section 4.4.3.<br />

economic benefit can be realized.<br />

When the required column-weight change exceeds the<br />

3.1 Achieving Balance Between Increases in Material<br />

Cost and Reductions in Labor Cost<br />

sum of the tabulated values, some engineering judgment<br />

must be used. If the comparison is unfavorable, but still<br />

In Table 3.1, estimated costs are given for some arbitrarily close, the use of a heavier column might still be justiselected<br />

transverse stiffener and web doubler plate details fied by the aforementioned intangibles. Alternatively, the<br />

as illustrated in Figure 3-1. These estimated costs were designer may still find it advantageous to<br />

investigate the<br />

determined by averaging the cost estimates5<br />

provided by possibility of eliminating the web doubler plate only ( or<br />

several fabricators and rounding the result to<br />

the near- transverse stiffeners only in some cases).<br />

est five-dollar increment. When comparing these typical As an example, consider again the W1490 column<br />

details toactual details, it should be noted that the compar-<br />

at each beam flange (two pairs total) and one web dou-<br />

than the thicknesses or overall dimensions of the plate ma-<br />

bler plate (Case 8, Table 3.1). If any heavier W14 up to<br />

with full-depth transverse stiffeners (Case 5, Table 3.1)<br />

ative weld types and sizes are of much greater significance<br />

terials. It is the labor involved in cutting, profiling, and<br />

6FOB stands for “free on board,” which indicates that the quoted price<br />

5<br />

assumes delivery to the indicated location. In the above case, the indi-<br />

The estimated costs are predicated upon the material and labor costs<br />

cated location is the mill itself; subsequent shipping would incur addithat<br />

existed at the time this <strong>Design</strong> <strong>Guide</strong> was written (circa early 1999).<br />

tional cost.<br />

Because it is anticipated that labor costs will continue to<br />

rise at a faster<br />

rate than material costs, the user may find it advantageous toperiodically<br />

7Because mill prices fluctuate, the designer may find it advantageous to<br />

inquire with local fabricators to determine a more current estimate of periodically inquire with fabricators, steel mills, or other shape suppliers<br />

these costs.<br />

to determine the current range of mill prices.<br />

13<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

and including a W14159 column could be used with- the design strength of the column, yet there will be<br />

out a web doubler plate, but with the transverse stiff- little or no impact on the material cost. Mill grade<br />

eners, it would be more economical than the W1490. extras for 50-ksi wide-flange material are largely<br />

Similarly, if any heavier W14 up to<br />

and including a nonexistent in shapes that weigh as much as 150 lb<br />

W14120 column could be used without transverse stiff- per ft of length.<br />

8<br />

Even for W-shapes in weight ranges<br />

eners, but with a web doubler plate, it would be more eco-<br />

that have grade extras, these nominal cost differences<br />

nomical than the W1490. of twoor three pennies per pound are negligible when<br />

compared to<br />

the advantage gained in detail material<br />

savings. Column material with even higher yield<br />

3.2 Eliminating Column Stiffening<br />

strength, such as ASTM A913 grade 65 material, is<br />

From Section 3.1, it is clear that there is significant poten-<br />

also available; however, the associated material cost<br />

tial for economic benefit when transverse stiffeners and<br />

differential is greater.<br />

web doubler plates can be eliminated. Therefore, the de-<br />

2. Consider a different column section that has a<br />

signer should consider alternatives that eliminate the need<br />

thicker flange and/ or web, as appropriate. This infor<br />

column stiffening, when possible. The design aids in<br />

crease in material cost, given today’s typical FOB<br />

Appendices A, B, and C provide for the rapid identifimill<br />

price for common grades9<br />

of steel of approx-<br />

cation<br />

of column strength and stiffening requirements in<br />

imately $400 t o $450 per ton, is in most cases<br />

wind and low-seismic applications. Some additional suggestions<br />

follow.<br />

8Inquire with steel mills to determine the current range of shapes for<br />

1. Specify column material with yield strength of 50 which a grade extra applies.<br />

ksi, such as ASTM A992 or A572 grade 50 steel.<br />

9Common grades include ASTM A992, ASTM A572 grade 50, and<br />

The increased minimum yield strength will increase A36.<br />

Table 3.1<br />

Estimated Cost of Various Column Stiffening Details (as illustrated in Figure 3-1)<br />

Equivalent<br />

Column Weight<br />

(lb/ft) if Wide-<br />

Flange Steel Costs<br />

Attachment to Attachment to Estimated $425 per Ton from<br />

Case Thickness Column Flange Column Web Cost<br />

3<br />

Rolling Mill<br />

Partial-Depth Transverse Stiffeners (Two Pairs)<br />

1 3 3<br />

4 PL 4 / 0’-10 (ASTM A36) with one / / corner clip each<br />

2 4 4<br />

1<br />

1/ 2 in. fitted to bear<br />

3/ 16-in. fillet welds $80 27<br />

2 1 in. fitted to bear<br />

5/ 16 -in. fillet welds $120 40<br />

3<br />

1/ 2 in.<br />

1/ 4-in. fillet welds<br />

3/ 16-in. fillet welds $90 30<br />

4 1 in.<br />

1 1<br />

/ -in. fillet welds<br />

5/ -in. fillet welds $140 47<br />

2 16<br />

Full-Depth Transverse Stiffeners (Two Pairs)<br />

1 9 3 3<br />

4 PL 4 / 1’-0 / (ASTM A36) with two / / corner clips each<br />

2 16 4 4<br />

5<br />

1/ 2 in.<br />

1/ 4-in. fillet welds<br />

3/ 16-in. fillet welds $120 40<br />

6 1 in.<br />

1/ 2-in. fillet welds<br />

5/ 16-in. fillet welds $210 71<br />

7<br />

1<br />

1 / in. CJP groove weld<br />

1<br />

1<br />

/ -in. fillet welds $470 158<br />

2 2<br />

Web Doubler Plate (One)<br />

1 PL 12 / 2’-0 (ASTM A36)<br />

5 8<br />

8<br />

1/ 2 in. CJP groove weld<br />

3/ 16-in. fillet welds $245 82<br />

9<br />

3/ 4 in. CJP groove weld<br />

5/ 16-in. fillet welds $370 124<br />

10<br />

3/ 4 in.<br />

5 2<br />

/ 8-in. fillet weld<br />

5/ 16-in. fillet welds $215 72<br />

11 1 in.<br />

7 2<br />

/ -in. fillet weld<br />

5/ -in. fillet welds $305 103<br />

8 16<br />

1The consulted fabricators were asked if they would instead prefer a CJP-groove-welded detail in place of this<br />

larger-size fillet-welded detail. In all cases, the answer was no.<br />

2A 3/ -in. by 3<br />

4 / 4-in. bevel on the column-flange edges of the web doubler plate is used to clear the column<br />

flange-to-web fillet. It should be noted that the fillet-welded web doubler plate detail in Case 10 is not suitable<br />

for high seismic applications because the weld size does not develop the strength of the full thickness of the<br />

web doubler plate.<br />

3A floor-to-floor height of 14 ft has been used in this tabulation.<br />

14<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

easily offset by the savings in labor costs, as illus- in wind and low-seismic applications:<br />

trated previously in Section 3.1.<br />

1. Where allowed by governing building codes, de-<br />

3. Consider a deeper cross-section for the beam that<br />

sign column stiffening in response to<br />

the actual<br />

is connected to the column. Increasing the depth of<br />

moments and resulting flange forces rather than<br />

the beam decreases the flange force delivered due to<br />

the full flexural strength of the cross-section; the<br />

the increase in moment arm between the flange-force<br />

latter simply wastes money in the majority<br />

of<br />

couple. If it were possible toreplace a W1650 with<br />

cases. When the Engineer of Record (EOR) dela<br />

W1850, the material cost would not be increased;<br />

egates the determination<br />

of the column stiffenif<br />

a lighter, deeper shape were suitable, the material<br />

ing requirements, the design forces and moments<br />

cost would in fact be decreased. Even if there were<br />

should alsobe provided.<br />

an increase in material cost, it would in most cases be<br />

2. If designing in allowable stress design, take adeasily<br />

offset by the savings in labor costs. Note that<br />

vantage of the allowable stress increase in windthis<br />

suggestion may instead be punitive when the mo-<br />

load applications (load combinations in LRFD<br />

ment connection is designed to develop the strength<br />

inherently account for such concurrent occurrence<br />

of the beam.<br />

of transient loads).<br />

4. Increase the number of moment-resisting connec-<br />

3. Properly address reduced design strength at col-<br />

tions and/ or frames to reduce the magnitude of the<br />

umn-end applications. The typical beam depth<br />

moment delivered to a given connection to<br />

a level<br />

is usually such that the reduced design strength<br />

that is within the local design strength of the column<br />

provisions for column-end applications apply<br />

section.<br />

only at the nearer flange force.<br />

4. Increase the number of moment-resisting connec-<br />

tions and/ or frames toreduce the magnitude of the<br />

3.3 Minimizing the Economic Impact of Column<br />

Stiffening Requirements in Wind and Low-<br />

moment delivered toa given connection toa level<br />

Seismic Applications<br />

that allows a more economical stiffening detail.<br />

In some cases, the need for column stiffening may not be<br />

5. Give preference to<br />

the use of fillet welds instead<br />

avoidable. When this is the case, the following suggestions<br />

of groove welds when their strength is adequate<br />

may help minimize the cost impact for building structures<br />

and the application is appropriate (see Chapter 4).<br />

(a) Partial-depth transverse<br />

stiffeners (Cases 1, 2, 3<br />

and 4)<br />

(b) Full-depth transverse<br />

stiffeners (Cases 5, 6<br />

and 7)<br />

(c) Web doubler plate<br />

(Cases 8, 9, 10 and 11)<br />

Note: dimensions and edge connections for the above column stiffening<br />

elements are as given in Table 3.1, based upon a W14 column.<br />

Figure 3-1 Column stiffening arrangements for cost estimates in Table 3.1.<br />

15<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

This is particularly true for the welds connecting<br />

11. Recognize that, in the concentrated-flange-force<br />

transverse stiffeners to the column.<br />

design provisions in LRFD Specification Section<br />

6. When possible, use a partial-depth transverse<br />

K1, it is assumed that the connection is a directly<br />

stiffener, which is more economical than a fulltion,<br />

welded flange or flange-plated moment connec-<br />

depth transverse stiffener because it need not<br />

not an extended end-plate moment connec-<br />

be fitted between the column flanges. Select<br />

tion. Appropriate design strength equations are<br />

the partial-depth transverse stiffener length to<br />

given in Chapter 2 based upon the recommenda-<br />

minimize the required fillet-weld size for the<br />

tions in Murray (1990).<br />

transverse-stiffener-to-column-web weld. 12. Limit the number of different thicknesses that<br />

7. While transverse stiffeners are required in pairs<br />

are used throughout a given project for transwhen<br />

the limit states of local flange bending<br />

verse stiffeners and web doubler plates. Produc-<br />

or local web yielding are less than the required<br />

tion economy is achieved when many repetitive<br />

strength, a single transverse stiffener is permitted<br />

elements can be used.<br />

and should be considered when the limit states of<br />

web crippling and/ or compression buckling of the 3.4 Minimizing the Economic Impact of Column<br />

web only are/is less than the required strength.<br />

Stiffening Requirements in High-Seismic<br />

8. In cases when the flange force is only compres-<br />

sive, allow the option to<br />

weld the transverse stiff-<br />

Applications<br />

In high-seismic applications, economy suggestions 4, 5,<br />

ener end or tofinish it tobear on the inside flange.<br />

6,<br />

10<br />

9, 10,<br />

11<br />

11, and 12 in Section 3.3 remain applica-<br />

In most lateral load resisting frames, however,<br />

ble. Additionally, economy suggestion 1 remains applicamoments<br />

are reversible and the design flange<br />

ble for web doubler plates, when the flange force(s) are<br />

force may be either tensile or compressive.<br />

determined from LRFD Specification Section A4.1, <strong>AISC</strong><br />

9. Use a single web doubler plate up to<br />

a required<br />

1<br />

Seismic Provisions Section 4.1, and Equation 2.1-1.<br />

thickness of / 2 in. If thicker web reinforcement<br />

is required, consider the use of two plates, one on<br />

each side of the column web. This practice may<br />

be more economical and is likely to<br />

reduce heat<br />

input, weld shrinkage, and member distortion.<br />

10Applicable when a moment connection is made to one flange only.<br />

10. Select the web doubler plate thickness sothat plug<br />

11Note that this may not be possible in high-seismic applications if the<br />

welding between the column web and web dou-<br />

column web thickness itself does not meet the seismic shear buckling<br />

bler plate is not required.<br />

criteria given in Equation 4.4-6.<br />

16<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

Chapter 4<br />

STRONG-AXIS MOMENT CONNECTIONS TO<br />

STIFFENED COLUMNS<br />

When the required strength (Section 2.1) exceeds the de- extend past the partial-depth and full-depth transverse<br />

sign strength of the column for the concentrated forces stiffeners, respectively. In Figure 4-6, the web doubler<br />

(Section 2.2), or when the stiffness of the column cross- plate(s) extend to but not past the full-depth transverse<br />

section is inadequate to resist the bending deformations stiffeners.<br />

in the column flange (Section 2.3), column stiffening is As illustrated in Figures 4-4, 4-5 and 4-6 the web dou-<br />

required. Several common stiffening arrangements are il- bler plates that are fillet welded to the column flanges are<br />

lustrated in Figures 4-1 through 4-6 with common weld- shown thicker than those that are groove welded tothe col-<br />

ing options for the attachments of the stiffening elements umn flanges are. This is intended to<br />

visually highlight the<br />

to the column. increased thickness that is often required to<br />

facilitate the<br />

In Figures 4-1 and 4-2, a column with partial-depth use of a fillet-welded edge detail (see Section 4.4.2).<br />

transverse stiffeners only and a column with full-depth Fillet-welded and groove-welded details are illustransverse<br />

stiffeners only are illustrated, respectively. In trated generally in all cases. Fillet-welded details will be<br />

Figure 4-3, a column with web doubler plate(s) only is il- preferable in the majority of cases although partial-joint-<br />

lustrated. In Figures 4-4, 4-5, and 4-6, columns with both penetration or complete-joint-penetration groove welds<br />

transverse stiffeners and web doubler plates(s) are illus- may be the best choice in some cases. Ultimately, prefertrated.<br />

In Figures 4-4 and 4-5, the web doubler plate(s) ence should be given to the use of details that require the<br />

Section A-A<br />

B<br />

transverse<br />

stiffeners fillet<br />

welded to column<br />

flanges<br />

transverse<br />

stiffeners fillet<br />

welded to column<br />

web<br />

A<br />

transverse<br />

stiffeners groove<br />

welded to column<br />

flanges<br />

A<br />

transverse<br />

stiffeners groove<br />

welded to column<br />

web<br />

B<br />

Section B-B<br />

Figure 4-1 Column with partial-depth transverse stiffeners.<br />

17<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

least amount of weld metal with due consideration of the 4.1.2 Local Flange Bending<br />

material preparation requirements.<br />

When the column flange thickness is inadequate to<br />

resist<br />

the tensile flange force, a pair of transverse stiffeners extending<br />

at least one-half the depth of the column web is re-<br />

4.1 Determining the Column Stiffening<br />

Requirements<br />

quired. They must be welded to the loaded column flange<br />

In wind and low-seismic applications, various alternative to develop the strength of the welded portion of the transstiffening<br />

details utilizing transverse stiffeners, web dou-<br />

verse stiffener. The weld tothe column web must be sized<br />

bler plates, or a combination thereof, are permitted in todevelop the unbalanced force in the transverse stiffener<br />

LRFD Specification Section K1, depending upon the limit to<br />

the web.<br />

state(s) for which column stiffening is required. The welding<br />

requirements are also<br />

specified for each case therein. 4.1.3 Local Web Yielding<br />

In high-seismic applications, the required placement and<br />

When the column web thickness is inadequate toresist the<br />

welding of transverse stiffeners and web doubler plates is<br />

tensile or compressive flange force, either a pair of transgiven<br />

in LRFD Specification Section K1 and <strong>AISC</strong> Seisverse<br />

stiffeners or a web doubler plate,<br />

13<br />

extending at least<br />

mic Provisions Sections 9.3c, 9.5 and 11.3. These column-<br />

the depth of the column web is required.<br />

one-half<br />

stiffening requirements and alternatives are summarized<br />

In wind and low-seismic applications, when required<br />

in Sections 4.1.1 through 4.1.6.<br />

for a tensile flange force, and in high-seismic applications,<br />

4.1.1 Panel-Zone Web Shear<br />

the transverse stiffener must be welded tothe loaded<br />

When the column web thickness is inadequate toresist the<br />

required panel-zone shear strength, a web doubler plate<br />

is required.<br />

12<br />

The welding requirements for web doubler<br />

12Alternatively, diagonal stiffening can be used if it does not interfere<br />

with the weak-axis framing; see Section 5.6.<br />

plates are as summarized in Section 4.4.3 and 4.4.4.<br />

13See Section 5.4.<br />

Section A-A<br />

B<br />

transverse<br />

stiffeners fillet<br />

welded to column<br />

flanges<br />

transverse<br />

stiffeners fillet<br />

welded to column<br />

web<br />

A<br />

transverse<br />

stiffeners groove<br />

welded to column<br />

flanges<br />

A<br />

transverse<br />

stiffeners groove<br />

welded to column<br />

web<br />

B<br />

Section B-B<br />

Figure 4-2 Column with full-depth transverse stiffeners.<br />

18<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

column flange to develop the strength of the welded por- flange to develop the force transmitted to<br />

the transverse<br />

tion of the transverse stiffener. In wind and low-seismic stiffener. In high-seismic applications, the transverse stiffapplications<br />

when required for a compressive flange force, ener must be welded to the loaded flange to develop the<br />

the transverse stiffener must either bear on or be welded strength of the welded portion of the transverse stiffener.<br />

tothe loaded flange todevelop the force transmitted tothe The weld to the column web must be sized to develop<br />

transverse stiffener. the unbalanced force in the transverse stiffener into<br />

the<br />

The weld to the column web must be sized to develop column panel-zone.<br />

the unbalanced force in the transverse stiffener into<br />

the<br />

column panel-zone.<br />

4.1.5 Compression Buckling of the Web<br />

4.1.4 Web Crippling<br />

When the column web thickness is inadequate toresist the<br />

opposing compressive flange forces, either a transverse<br />

When the column web thickness is inadequate toresist the stiffener, a pair of transverse stiffeners or a web doubler<br />

compressive flange force, either a transverse stiffener, a plate,<br />

15<br />

extending the full depth of the column web, is repair<br />

of transverse stiffeners or a web doubler plate,<br />

14<br />

ex- quired.<br />

tending at least one-half the depth of the column web, is In wind and low-seismic applications, the transverse<br />

required. stiffener must either bear on or be welded to the loaded<br />

In wind and low-seismic applications, the transverse flange to develop the force transmitted to<br />

the transverse<br />

stiffener must either bear on or be welded to the loaded<br />

See Section 5.4. See Section 5.4.<br />

14 15<br />

web doubler plate beveled and fillet<br />

welded to column flanges<br />

Section A-A<br />

web doubler plate groove welded to<br />

column flanges<br />

B<br />

See note below<br />

web doubler<br />

plates fillet welded<br />

to column web<br />

(top and bottom)<br />

A<br />

A<br />

B<br />

Section B-B<br />

Note: 2.5k minimum for directly welded flange and flange-plated moment<br />

connections, 3k + t p minimum for extended end-plate moment<br />

connections (top and bottom)<br />

Figure 4-3 Column with web doubler plate(s).<br />

19<br />

© 2003 by American Institute of Steel Construction, Inc. All rights reserved.<br />

This publication or any part thereof must not be reproduced in any form without permission of the publisher.

stiffener. In high-seismic applications, the transverse stiff- transferred locally intothe column flanges. These concen-<br />

ener must be welded to the loaded flange to develop the trated forces spread through the column flange and flangestrength<br />

of the welded portion of the transverse stiffener. to-web fillet region intothe web, transverse stiffener(s), if<br />

The weld to the column web must be sized to develop used, and web doubler plate(s), if used. Shear is dispersed<br />

the unbalanced force in the transverse stiffener into the between them in the column panel-zone. Ultimately, axial<br />

column panel-zone.<br />

forces in the column flanges balance this shear.<br />

4.1.6 Flange Stiffness 4.2.1 Required Strength for Transverse Stiffeners<br />

In wind and low-seismic applications, flange stiffness is<br />

The following discussion is applicable to<br />

the required<br />

addressed by the local flange bending limit state (Section<br />

strength of the ends of the transverse stiffener in tension<br />

4.1.2). In high-seismic applications, transverse stiffeners<br />

and/ or compression. The required strength of the transwill<br />

normally be required (see Section 2.3) in pairs with<br />

verse stiffener in shear to transmit an unbalanced load to<br />

welding as described in Sections 4.3.4 and 4.3.5.<br />

the column panel-zone is covered in Section 4.3.2.<br />

4.2 Force Transfer in Stiffened Columns<br />

In wind and low-seismic applications, transverse stiffeners<br />

are required only when the concentrated flange force<br />

In a stiffened column, the load path is similar to<br />

that deumn<br />

(Section 2.1.1) exceeds the design strength of the col-<br />

scribed in Section 2.1, except that the added stiffening<br />

flange or web (Sections 2.2.2 through 2.2.5). In an<br />

elements share in a portion of the force transfer. Concen-<br />

exact solution, this force would be apportioned between<br />

trated forces from the beam flanges or flange plates are<br />

the web and transverse stiffeners on the basis of relative<br />

web doubler plate beveled and fillet<br />

welded to column flanges<br />

Section A-A<br />