Muck pumping systems - Putzmeister Solid Pumps

Muck pumping systems - Putzmeister Solid Pumps

Muck pumping systems - Putzmeister Solid Pumps

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Muck</strong> <strong>pumping</strong> <strong>systems</strong><br />

clean and safe muck transport for modern tunnelling<br />

and mining methods<br />

TS 2616-2 GB

The process –<br />

clean and economical transport by pipeline<br />

<strong>Muck</strong> transport in a closed system<br />

File under: A 1.00, A 4.00, IP 4.05<br />

<strong>Muck</strong> transport to the surface<br />

Tunnelling produces excavated muck<br />

which has to be transported from the<br />

tunnelling machine’s discharge system<br />

through the tunnel to the surface.<br />

Which process is used depends upon the<br />

geological and logistical conditions, and<br />

also upon the space available in the tunnel.<br />

Delivery by pipeline with high-performance<br />

piston pumps is becoming increasingly<br />

popular. The advantages are obvious:<br />

■ Space-saving, e.g. for driving pipelines<br />

in a small tunnel<br />

■ The clean and safe transport of excavated<br />

muck over long distances<br />

■ High output<br />

■ Addition of water rarely or not at all<br />

necessary<br />

■ Simple logistics – no muck cars<br />

needed<br />

■ Operational safety<br />

■ Continuous delivery guaranteed, even<br />

with pressure locks<br />

Double pumps supply a performance of<br />

up to 250 m 3 /h per pump unit. This<br />

means that by using double pumps, tunnel<br />

machines can be equipped with diameters<br />

of up to 14 metres.<br />

Numerous operations in Asia and also in<br />

Europe (e.g. Botlek Tunnel in the<br />

Netherlands) demonstrate the strengths<br />

of this method compared to the transport<br />

of the soil by centrifuged pumps or via<br />

conveyor belts.<br />

Pumping of stiff muck through a pressure lock<br />

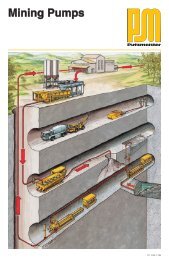

Two muck transport methods<br />

There are two applied methods of delivering<br />

excavated muck using pipelines:<br />

■ <strong>Muck</strong> delivery in a closed system ...<br />

■ ... and in an open system<br />

The closed system<br />

Here the muck pumps are connected<br />

pressure sealed directly behind the outlet<br />

of the screw conveyor of the tunnelling<br />

machine. Care must be taken that the<br />

material to be transported is readily<br />

pumpable.<br />

The pumps transport the soil through the<br />

pipeline to the surface. The muck can be<br />

treated either naturally or with bentonite<br />

and polymers.<br />

In a closed system the existing earth<br />

pressure is maintained throughout the<br />

pump. This prevents water and mud<br />

penetrating the tunnel unchecked.<br />

A system of this type will generally consist<br />

of the following components:<br />

■ A KOS double-piston pump to convey<br />

the material to the surface and maintain<br />

the earth pressure<br />

■ An electronic control unit for pump<br />

and tunnelling machine to ensure the<br />

reliable operation of both units<br />

■ A hydraulic power pack to drive the<br />

KOS<br />

■ A stone trap to detect blockages in the<br />

pipeline and protect the pump<br />

■ Flexible pipeline <strong>systems</strong> comprising<br />

hose lines or pipe scissors<br />

Example – the Størebelt Tunnel in<br />

Denmark<br />

■ The earth and water pressure of up to<br />

0.8 MPa (116 psi) had to be maintained<br />

in order to prevent the inflow of<br />

groundwater<br />

■ The rocks mixed with groundwater<br />

were then conveyed from the screw<br />

conveyor to the muck cars …<br />

■ … and unloaded above ground under<br />

atmospheric pressure<br />

The stone trap<br />

The stone trap has sensors to detect<br />

blockages in the suction line. In such a<br />

case the pump shuts down. Any stones<br />

caught in the pipeline section of the<br />

stone trap can then be easily removed.<br />

The hydraulic power pack<br />

<strong>Putzmeister</strong> high-density pumps are<br />

hydraulically driven. This type of drive<br />

enables the system to respond to virtually<br />

any practical situation with great versatility<br />

and flexibility.<br />

All important data, such as oil temperature<br />

and pressure and the degree of filter<br />

contamination, are displayed for greater<br />

operating precision.<br />

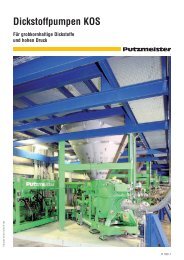

KOS S-tube piston pump<br />

The pump system<br />

A KOS double-piston pump is generally<br />

used for muck delivery. This type of<br />

pump is particularly suitable for coarsegrain<br />

material with a high solids content.<br />

It produces pressures of up to 20 MPa<br />

(2900 psi) and outputs of up to<br />

500 m 3 /h.<br />

London Heathrow tunnel<br />

Two <strong>Putzmeister</strong> single-piston decompression<br />

pumps removed 200 m 3 /h of<br />

untreated loamy soil from the shield area<br />

supported by compressed air. This prevented<br />

the ground from subsiding and<br />

the loamy soil was not contaminated by<br />

auxiliary fluids, such as bentonite or<br />

polymers.<br />

Flanged-on muck decompression pump<br />

■ Servicing is infrequent and wear is<br />

minimal since the KOS has few<br />

moving parts<br />

■ Because of the generous and free<br />

material flow the suction resistance is<br />

particularly low<br />

■ The hydraulic circuit is kept well separated<br />

from the conveyed material<br />

Screw conveyor with two muck pumps<br />

type KOS 1480<br />

TS 2616-2 GB<br />

TS 2616-2 GB

<strong>Muck</strong> transport in an open system<br />

MPT muck pump<br />

for the open system<br />

The open system<br />

The open system is used where the muck<br />

is moved by excavators or where the<br />

material has to be crushed or mixed<br />

before being pumped.<br />

The muck has to be made pumpable.<br />

Crushers or mixers are attached to the<br />

system for this purpose.<br />

The “processed” muck is then conveyed<br />

openly to the pump, which delivers the<br />

material above ground.<br />

Such an installation generally consists of:<br />

■ a double-piston pump<br />

■ a hydraulic aggregate<br />

■ a mixing trough<br />

Alternatively complete muck pump<br />

<strong>systems</strong> are used. Examples of this are<br />

the MPT 16 and MPT 40 “muck pump<br />

tunnel” installations.<br />

The extremely compact MPT 16, for<br />

example, is eminently suitable for use in<br />

small pipes from ND 1400 upwards.<br />

Very good pumpable material from a EPB tunnel<br />

boring machine<br />

TS 2616-2 GB

The accessories – pipelines,<br />

sluices, damping <strong>systems</strong> ...<br />

Boundary layer lubricant injection<br />

nozzle<br />

This reduces the pressure significantly<br />

and thus protects the pump. This means<br />

less costs, since both pipeline and pump<br />

can be reduced in size. In addition there<br />

is an approximately 50 % reduction in<br />

the energy requirement. Stiff materials<br />

are conveyed over large distances at low<br />

pressure.<br />

Control <strong>systems</strong><br />

The <strong>Putzmeister</strong> POS operating system<br />

enables the user to control and monitor<br />

all parameters automatically. It functions<br />

independently or as an integral component<br />

of the tunnelling machine’s central<br />

control system.<br />

Hydraulically controlled pressure<br />

valves (HMC-S)<br />

When <strong>pumping</strong> at high pressure material<br />

sometimes flows back during switchover.<br />

This is prevented by a valve fitted<br />

downstream.<br />

HMC-S valves are used for fine-grain or<br />

pasty material. The valve seats are particularly<br />

resistant, guaranteeing a hermetically<br />

sealed system. In addition they<br />

prevent nozzle wear.<br />

The boundary layer lubricant injection nozzle<br />

reduces wear in the pump and pipeline<br />

The POS controls and monitors the complete<br />

muck-removal installation<br />

The “power damper” ensures that delivery is<br />

even and continuous<br />

ZX delivery lines are eminently suitable for conveying<br />

muck over long distances<br />

The HMC-S valve effectively prevents the back-flow of muck into the pump<br />

<strong>Putzmeister</strong> Products and Services<br />

Concrete <strong>Pumps</strong> · Industrial Technology PIT ·<br />

Telebelt · Mörtelmaschinen GmbH · Dynajet<br />

High Pressure Cleaners · Services · Concrete<br />

Project Division CPD · Consulting and Data<br />

Technology · Academy<br />

<strong>Putzmeister</strong> AG<br />

Max-Eyth-Str. 10 · D-72631 Aichtal<br />

P.O.Box 2152 · D-72629 Aichtal<br />

Tel. +49 (7127) 599-0<br />

Fax +49 (7127) 599-520<br />

www.putzmeister.com<br />

E-mail: pmw@pmw.de<br />

TS 2616-2 GB<br />

Right to make technical amendments reserved · © by <strong>Putzmeister</strong> AG 2007 · All rights reserved · Printed in Germany (10704RR)