Plasma Production

Plasma Production

Plasma Production

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Production</strong> capability<br />

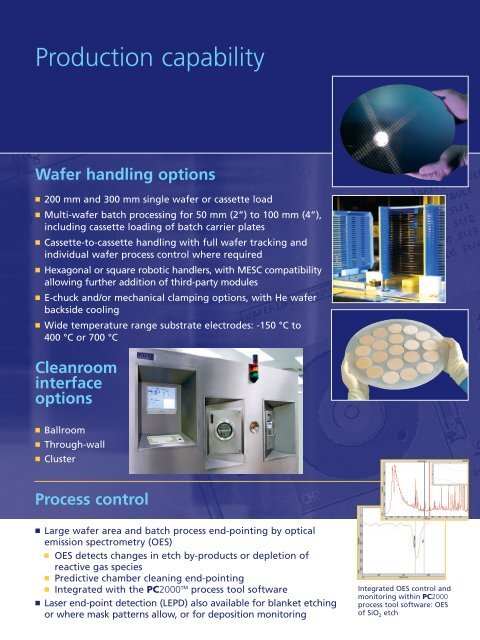

Wafer handling options<br />

■ 200 mm and 300 mm single wafer or cassette load<br />

■ Multi-wafer batch processing for 50 mm (2”) to 100 mm (4”),<br />

including cassette loading of batch carrier plates<br />

■ Cassette-to-cassette handling with full wafer tracking and<br />

individual wafer process control where required<br />

■ Hexagonal or square robotic handlers, with MESC compatibility<br />

allowing further addition of third-party modules<br />

■ E-chuck and/or mechanical clamping options, with He wafer<br />

backside cooling<br />

■ Wide temperature range substrate electrodes: -150 °C to<br />

400 °C or 700 °C<br />

Cleanroom<br />

interface<br />

options<br />

■ Ballroom<br />

■ Through-wall<br />

■ Cluster<br />

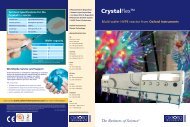

Process control<br />

■ Large wafer area and batch process end-pointing by optical<br />

emission spectrometry (OES)<br />

■ OES detects changes in etch by-products or depletion of<br />

reactive gas species<br />

■ Predictive chamber cleaning end-pointing<br />

■ Integrated with the PC2000 TM process tool software<br />

■ Laser end-point detection (LEPD) also available for blanket etching<br />

or where mask patterns allow, or for deposition monitoring<br />

Integrated OES control and<br />

monitoring within PC2000<br />

process tool software: OES<br />

of SiO 2 etch