Laboratory-dissolvers-mixers-mills

Laboratory-dissolvers-mixers-mills

Laboratory-dissolvers-mixers-mills

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Laboratory</strong>-<strong>dissolvers</strong>-<strong>mixers</strong>-<strong>mills</strong><br />

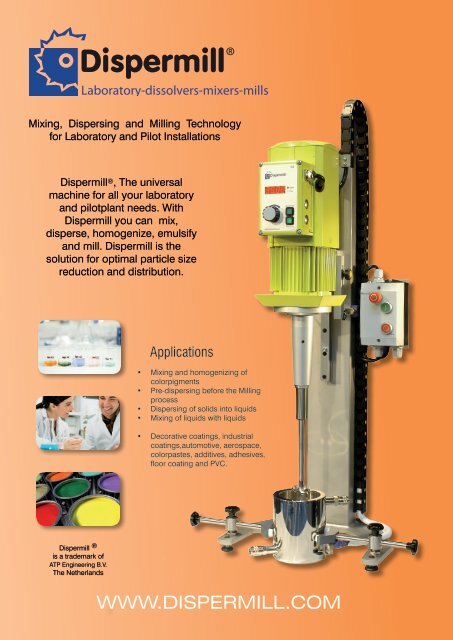

Mixing, Dispersing and Milling Technology<br />

for <strong>Laboratory</strong> and Pilot Installations<br />

Dispermill ® , The universal<br />

machine for all your laboratory<br />

and pilotplant needs. With<br />

Dispermill you can mix,<br />

disperse, homogenize, emulsify<br />

and mill. Dispermill is the<br />

solution for optimal particle size<br />

reduction and distribution.<br />

Applications<br />

• Mixing and homogenizing of<br />

colorpigments<br />

• Pre-dispersing before the Milling<br />

process<br />

• Dispersing of solids into liquids<br />

• Mixing of liquids with liquids<br />

• Decorative coatings, industrial<br />

coatings,automotive, aerospace,<br />

colorpastes, additives, adhesives,<br />

floor coating and PVC.<br />

Dispermill ®<br />

is a trademark of<br />

ATP Engineering B.V.<br />

The Netherlands<br />

WWW.DISPERMILL.COM

Dispersing technology<br />

with vacuum in a one-step process<br />

DISPERMILL ® laboratory-<strong>dissolvers</strong>, will perform almost any mixing task in the modern laboratory, whether<br />

gentle stirring or where high shearing is required.<br />

The DISPERMILL® can produce outstanding<br />

results on most applications. Low noise drive<br />

system with continuous adjustable speed. Hightech<br />

PID electronics ensures constant speed<br />

even when viscosity changes.<br />

All DISPERMILL® <strong>dissolvers</strong> are complete with<br />

safety protection according to CE. Adjustable<br />

quick fit clamping device, integrated timer 0-100<br />

min. Automatic stop. Emergency Mainswitch.<br />

Continuous readout of speed and time on<br />

digital display.<br />

<strong>Laboratory</strong> dissolver 250ml till 2 Litre<br />

model Orange-line<br />

Stainless steel stand, with Smooth action lifting<br />

device. Immersable parts made from stainless<br />

steel, several mixing tools available such as<br />

propeller and rotor/stator.<br />

Vacuum system for Dispermill<br />

Several products require processing under vacuum For this purpose<br />

we supply an additional vacuum kit which is easy to fit on all<br />

Dispermill® laboratory <strong>dissolvers</strong>. Available in 1, 3, 5, 8 and 12 Litre.<br />

1D-2D<br />

D<br />

2D-3D<br />

0,5D-1D<br />

Correct use of the<br />

dissolver<br />

Best results will be achieved<br />

by following the guide<br />

dimensions as shown in the<br />

illustration. The peripheral<br />

speed of the disc should<br />

reach 20m/sec.<br />

Insert adapter for smaller vessels<br />

1 into 5 Litre<br />

<strong>Laboratory</strong> vacuum dissolver 5 Litre<br />

model Yellow-line<br />

Model Speed Power Torque Voltage<br />

Orangeline<br />

Yellowline<br />

Ivoryline<br />

Ivory HT<br />

2027<br />

2075<br />

2110<br />

2200<br />

0-10.000 RPM<br />

0-9000 RPM<br />

0-4500 RPM<br />

0-2200 RPM<br />

0,27kW / 0.4HP<br />

0.75kW/ 1HP<br />

1.1kW/ 1,5HP<br />

1.1kW/ 1,5HP<br />

0.5 Nm<br />

1.3 Nm<br />

3.6 Nm<br />

7.6 Nm<br />

230VAC +/-10%<br />

230VAC +/-10%<br />

230VAC +/-10%<br />

230VAC +/-10%<br />

Redline 2150 0-9000 RPM 1.5kW/ 2HP 2.7 Nm 400VAC +/-10%<br />

Capacity<br />

250ml - 2L<br />

500ml - 8L<br />

1L - 25L<br />

1L - 25L<br />

1L - 25L<br />

Blueline<br />

2220<br />

0-4500 RPM<br />

2.2kW/ 3HP<br />

7.3 Nm<br />

400VAC +/-10%<br />

10L - 50L<br />

ATEX<br />

8400<br />

930-8400 RPM<br />

0.75kW/ 1HP<br />

1.3 Nm<br />

400VAC +/-10%<br />

500ml - 8L<br />

ATEX<br />

5800<br />

930-4500 RPM<br />

1.1kW/ 1.5HP<br />

3.6 Nm<br />

400VAC +/-10%<br />

1L - 15L<br />

Dispermill ® , other Power and speed configurations on request.

Milling technology<br />

Mixing and milling in a one-step process<br />

• No waste during milling<br />

• Direct product control<br />

• Fast and easy cleaning<br />

• High efficiency due to optimal<br />

product flow. (no dead areas)<br />

• Many available accessories<br />

• Mirror polished dome<br />

• Patented system<br />

Millhead<br />

This patented basket guarantees an optimal flow and<br />

eliminates any possible “dead-zones” To accommodate the<br />

diversity of product range, different baskets are available.<br />

Standard upon delivery are 1 basket with 1 screen with a slot<br />

size of 0,5 mm. Other sizes can be delivered upon request.<br />

Media selection<br />

All kinds of milling media are applicable from 0,5 up to 1,8<br />

mm in diameter but should be taken seriously. Inform yourself<br />

about the possibilities. The selection and matching of the<br />

media is still very critical. Our recommended beads are good<br />

for 10000 milling hours.<br />

Milling kit<br />

All parts in contact with the product are made from high quality hardened and<br />

stainless steel. The Millingkit comes with a jacketed vessel. The inlet and outlet water<br />

connections for the vessel are provided.<br />

Capacity Micromill<br />

Capacity Quartermill<br />

: 750 mL up to 2 Litre (1HP)<br />

: 5L up to 8 Litre (2HP)<br />

Marine propeller<br />

For low viscosity<br />

1 - 3000 cps<br />

Turbo propeller<br />

Average viscosity<br />

3000-6000 cps<br />

Pumperblade<br />

High viscosity<br />

> 6000 cps<br />

Micromill®

Mixing and Dispersing Accessories<br />

the right tools for process optimization<br />

DISPERMILL ® laboratory-<strong>dissolvers</strong>, will perform almost any mixing task in the<br />

modern laboratory, whether gentle stirring or where high shearing is required.<br />

Stainless Steel Dispersing Vessels<br />

available in 0.5 -1 -2 -3 -5 -8<br />

-15 -20 -50 Litre<br />

Stainless Steel Jacketed Dispersing<br />

Vessels<br />

available in 1 -2 -3 -5 -8 -15<br />

-20 -50 Litre<br />

Ask for the possibilities of specials and customization of your machine<br />

Dispersing Disc Butterfly Mixer Marine propeller Single PP Millingdisc Double PP Millingdisc<br />

Mixing Elements<br />

type function 20 30 40 50 60 70 80 90 100 120 125 140<br />

Dispersing<br />

Disc<br />

Single PP<br />

Millingdisc<br />

Double PP<br />

Millingdisc<br />

Marine<br />

Propeller<br />

Butterfly<br />

Mixer<br />

Other sizes on request<br />

To disperse or dissolve pigments<br />

and other solids into a liquid.<br />

for grinding pigments with glass<br />

beads<br />

for grinding pigments with glass<br />

beads<br />

To mix low to medium viscosity<br />

liquids<br />

To mix medium to high viscosity<br />

liquids<br />

ATP Engineering B.V.<br />

Palmpolstraat 56, 1327 CH Almere<br />

P.O. Box 50261, 1305 AG Almere<br />

The Netherlands<br />

T. +31 (0)36 - 53 16 165<br />

F. +31 (0)36 - 53 13 794<br />

E. info@Dispermill.com