Sheet Metal Testing Machine Model 102 - Erichsen

Sheet Metal Testing Machine Model 102 - Erichsen

Sheet Metal Testing Machine Model 102 - Erichsen

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

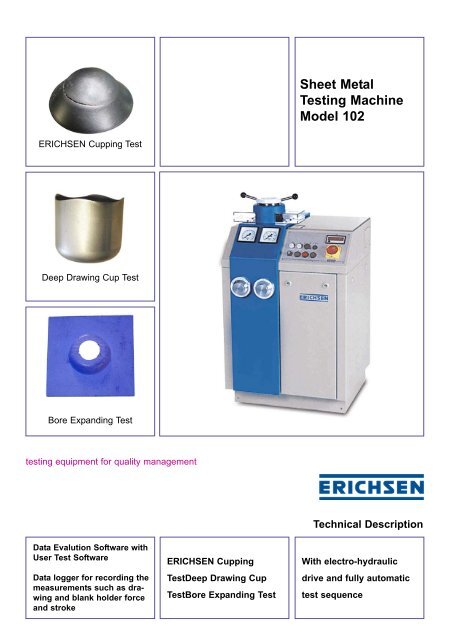

<strong>Sheet</strong> <strong>Metal</strong><strong>Testing</strong> <strong>Machine</strong><strong>Model</strong> <strong>102</strong>ERICHSEN Cupping TestDeep Drawing Cup TestBore Expanding Testtesting equipment for quality managementData Evalution Software withUser Test SoftwareData logger for recording themeasurements such as drawingand blank holder forceand strokeERICHSEN CuppingTestDeep Drawing CupTestBore Expanding TestTechnical DescriptionWith electro-hydraulicdrive and fully automatictest sequence

Product<strong>Sheet</strong> <strong>Metal</strong> <strong>Testing</strong> <strong>Machine</strong>, <strong>Model</strong> <strong>102</strong>, withelectro-hydraulic drive, max. drawing force of 60 kNand automatic switch off at specimen failure.ApplicationThis <strong>Sheet</strong> <strong>Metal</strong> <strong>Testing</strong> <strong>Machine</strong> is intended fortesting materials in the medium thickness range(0.1 to approx. 3.5 mm). It provides rapid an reliablequality monitoring for sheet metal producers andusers.<strong>Model</strong> <strong>102</strong> is suitable for• the ERICHSEN Cupping Test on all ferrous andnon-ferrous metals in accordance withISO 8490 JIS Z-7729EN 14-58 UNI 3037EN 14-67 UNE 7080EN ISO 20482 GOST 10 510BS 38 55 ICONTEC 21NF A 03-602 SIS 11 26 35NF A 03-652 SABS 0132-197ASTM 643-84 GB 4156-84In addition, the Olsen Test as used in the USAcan be performed on the testing machine whenappropriate tools are set up.• the Deep Drawing Cup Test for thedetermination of the ear forming tendency andmaximum drawing ratio according toDIN EN 1669 MSZ 5731-68DIN 50 155 GB/T 15825UNI 6124-67 ISO 11531There are important reasons for using the <strong>Sheet</strong><strong>Metal</strong> <strong>Testing</strong> <strong>Machine</strong>, <strong>Model</strong> <strong>102</strong>, for qualityassurance:♦ Lowering of manufacturing costs by making spotchecks on the drawing quality of cold rolled sheetduring production or in the process department.♦ Sorting out of material of lower quality arriving atthe Goods Inwards Department. Without specialtest preparation it is immediately possible toestablish if the material supplied has theprescribed drawing quality.♦ Determining the most appropriate sheet thicknessfor a particular drawn workpiece to optimise theratio of price to suitability for the manufacturingprocess.Quantitative measurement of sheet quality by meansof the ERICHSEN Cupping Test provides a basis ofcommunication between sheet metal producers andusers.The form of the crack and the surface roughness(= grain size) also provide information on the qualityof the sheet metal and is suitability for drawing,giving valuable information especially to the sheetmetal producer.The good functional layout of <strong>Model</strong> <strong>102</strong> makes thismachine particularly user friendly. Operators withoutprevious knowledge or experience can be quicklytrained to operate the machine continuously. Allrelevant test tools can be set up in the test cylinderquickly and without difficulty.The sturdy design and the hydraulic systememployed ensure that minimum wear is experiencedso that accurate test results are assured over a longperiod of time.• the Bore Expanding Testin accordance with Siebel and Pomp (KWI)ISO 16630Depending of the testing method the following sheetmetal thicknesses can be tested:<strong>Erichsen</strong> Cupping TestDeep Drawing Cup TestBore Expanding Test0.1 - 3.5 mm0.2 - 1.5 mm0.2 - 2.0 mmThe above mentioned maximum sheet thicknessesare based on material with a tensile strength of400 N/mm².DescriptionThe machine consists of a sturdy sheet metalhousing into which the test aggregate (test cylinderwith work piston, sheet holder piston) and the testtools as well as the hydraulic system are integrated.The operator's controls are arranged conveniently ona control panel. As an option, an electro-hydraulicblanking press for the manufacture of blanks for theDeep Drawing Cup Test can be fitted into themachine housing.When carrying out the ERICHSEN Cupping Test,the sheet metal specimen in the form of strip isinserted into the test cylinder and centralised bylocating diagonally. The sheet holder force of 10 kN(in accordance with the standard) is adjusted using aspecial regulating valve, and the actual cuppingprocess is initiated by selecting the standardiseddrawing speed on the speed regulator.

Since the testing machine is equipped with thefunction "automatic stop at specimen failure" theforward speed is automatically stopped when thecrack occurs, so that in any case an objective testresult is achieved. The ERICHSEN cupping value isdisplayed with an accuracy of 0.1 mm on the digitalcounter.When carrying out the Deep Drawing Cup Test, theround blank manufactured by the electro-hydraulicblanking press, is placed into an infinitely variablecentring device located in the test cylinder. Afterpreselection of the sheet holder pressure the blank isdrawn by a drawing punch (normally 33 mm dia.) to acylindrical hollow part, the socalled cup. The innerdiameter of the drawing die used, corresponds to thesheet thickness to be tested. After return of thedrawing piston to the starting position, the cup canbe removed from the test head without any difficulty.When carrying out the Bore Expanding Test (KWI)the initial bore (in accordance with the dimensions ofthe tools, i. e. normally 7.5 mm or 12 mm) is appliedto the sheet metal specimen by drilling and reaming.Afterwards this initial bore is expanded until a crackappears.♦ Ear Measuring Instrument, <strong>Model</strong> 126, for rapidmeasurement of ears formed on cylindrical cupsof diameters from 15 to 50♦ Ear Measuring Instrument, <strong>Model</strong> 126 C, forrapid measurement of ears formed on cylindricalcups of diameters from 20 to 100 mm.Test Tools for the Deep Draw Bore ExpandingTest acc. to Siebel and Pomp (KWI)♦ Bore expanding test tool D (initial bore 12 mm)♦ Bore expanding test tool E (initial bore 7.5 mm)♦ Boring jig for drilling the initial bores♦ Drills, drilling bushes and reamersAdditional Facilities for Tests on lacquered sheetmetal specimens according to DIN ISO 1520♦ Special microscope with holder and illuminationfor optical observation of the test procedureAccessoriesThe various accessories make this sheet metaltesting machine particularly versatile. For furtherdetailed specifications please see our Price ListNo. <strong>102</strong>.Data Evalution System with user test software, PC,monitor and printer for data evalution (under WIN2000/XP) for the ERICHSEN Cupping Test and DeepDrawing Cup Test.Details see back page.Data logger for recording the measurements such asdrawing and blank holder force and stroke by time;the connection is made by a USB connection to anexternal PC (to be supplied by the user). Thesoftware included in the scope of supply runs underWIN 2000/XP. The system consisting of measuringtransducer for drawing force and analogue output forthe stroke as well as the corresponding interfaces,A/D converter module.Test Tools for the ERICHSEN Cupping Test♦ Test tools for the ERICHSEN Cupping Test inaccordance with EN ISO 20482.Test Tools for the Deep Drawing Cup Test♦ Electro-hydraulic Blanking Press (blankingforce 200 kN)♦ Deep Drawing Cup Test Tool B1 (drawingpunch 33 mm dia.)♦ Test Tools for Earing Test on non-ferrousmetals in accordance with DIN 50 155Technical DataDimensions Width 650 mmHeight 1100 mmDepth 620 mmWeight, netapprox. 150 kgMain supply230 or 400 V, 3~, 50 HzMotor performance1 kWDrawing forcemax. 60 kNBlank holder forcemax. 12 kNDrawing speedmax. 220 mm/minPunch strokemax. approx. 40 mmIndication of punch strokeDrawing punch diameterBlank diameterOrd.-No.Order InformationsProduct-Descriptiondigital(accuracy 0.,1 mm)max. 33 mmmax. 75 mm0012.01.31 <strong>Sheet</strong> <strong>Metal</strong> <strong>Testing</strong> <strong>Machine</strong>,<strong>Model</strong> <strong>102</strong>Supplied with:♦ Test Tool No. 27♦ One Filling of Hydraulic Oil♦ Operating ManualFurther details and accessories please see our Price ListNo. <strong>102</strong>.

Modified ERICHSEN Cupping TestThe ERICHSEN Cupping Test (in accordance with EN ISO 20482, and corresponding to national and internationalstandards) is a test providing simple and quick means of assessing the multi-axis ductility of sheet and strip using aprocedure that relates closely to practical processes. The depth range reached at failure is, however, only an initialguide to the evaluation of the forming properties of the sheet metal.Data Evalution System with User Test SoftwareThe software enables the continuous acquisition ofmeasured values with simultaneous display of theforce/displacement diagram throughout the formingprocess. Once the maximum force has been reached,the movement of the drawing punch is stoppedautomatically and the diagram is evaluated by the PC.Simultaneously, the measurements taken areprocessed further using a theoretical model for theplastic deformation of the material based on work donein association with the University of Siegen/Germany.On this basis, the equipment not only provides valuesfor the normal ERICHSEN Cupping Test result -ERICHSEN Index I E - but also for elongation at failureA E , tensile strength Rm E , and the n-value n E . (Thesuffix E indicates that the parameter has beenmeasured using the ERICHSEN process.)This data is presented immediately on the VDU oncompletion of the test alongside the graph of theforce against displacement. Either a printout can thenbe obtained and the data saved or the data can beeasily transfered to other evaluation programmes(e.g. Microsoft Excel). Practical experience hasshown that these new ERICHSEN parameters havea good correlation with corresponding valuesobtained conventionally, with the significantadvantage that the considerable effort required toprepare conventional test specimens is eliminated.The scope of supply includes PC, VDU and printer.The right of technical modifications is reserved.TBE <strong>102</strong> - VIII/2007