You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

09-09-05<br />

<strong>Boloc</strong><br />

Cold rolled annealed Boron steel<br />

for hardening in water or oil<br />

Definition<br />

The <strong>Boloc</strong> Steel Grades are a group of hardenable, fine grained<br />

weldable steel. The <strong>Boloc</strong> Steel Grades are precision rolled<br />

and Open Coil Annealed giving fine tolerances and extra even<br />

properties throughout the band. It may well replace grades<br />

with medium high and high carbon content for applications<br />

where high strength, hardness, toughness and wear resistance<br />

are required.<br />

Welding<br />

Boron Steel Grades are usually welded in the same way as conventional<br />

high strength steels. Welding methods and filler metals<br />

producing low hydrogen contents should be used. The welds<br />

should, if possible, be placed in those areas of the construction,<br />

where the load is the lowest. The transition between weld and<br />

base material should be made as mooth as possible, e.g. by TIGtreatment.<br />

Hardening/Cutting/Punching<br />

See Technical Report MAS 5:1 respectively MAS 5:2<br />

Delivery condition<br />

Unannealed or annealed.<br />

Other information<br />

The Boron Steel Grades are characterized by good formability.<br />

They can be bent to a small radius in the annealed condition.<br />

They also show good toughness and tempering after hardening<br />

can be omitted in most cases. Additional information can be obtained<br />

from <strong>Duroc</strong> Special Steel <strong>AB</strong>, Technical customer service.<br />

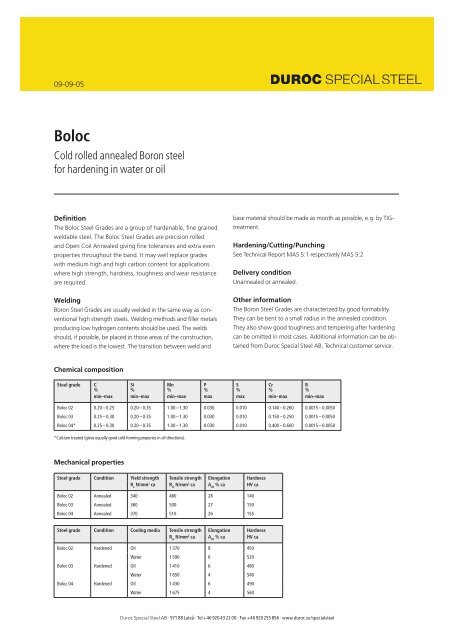

Chemical composition<br />

Steel grade C Si Mn P S Cr B<br />

% % % % % % %<br />

min–max min–max min–max max max min–max min–max<br />

<strong>Boloc</strong> 02 0.20 – 0.25 0.20 – 0.35 1.00 – 1.30 0.030 0.010 0.140 – 0.260 0.0015 – 0.0050<br />

<strong>Boloc</strong> 03 0.25 – 0.30 0.20 – 0.35 1.00 – 1.30 0.030 0.010 0.150 – 0.250 0.0015 – 0.0050<br />

<strong>Boloc</strong> 04* 0.25 – 0.30 0.20 – 0.35 1.00 – 1.30 0.030 0.010 0.400 – 0.600 0.0015 – 0.0050<br />

*Calcium treated (gives equally good cold forming properies in all directions).<br />

Mechanical properties<br />

Steel grade Condition Yield strength Tensile strength Elongation Hardness<br />

R e<br />

N/mm 2 ca R m<br />

N/mm 2 ca A 80<br />

% ca HV ca<br />

<strong>Boloc</strong> 02 Annealed 340 480 28 140<br />

<strong>Boloc</strong> 03 Annealed 360 500 27 150<br />

<strong>Boloc</strong> 04 Annealed 370 510 26 155<br />

Steel grade Condition Cooling media Tensile strength Elongation Hardness<br />

R m<br />

N/mm 2 ca A 80<br />

% ca HV ca<br />

<strong>Boloc</strong> 02 Hardened Oil 1 370 8 450<br />

Water 1 590 6 520<br />

<strong>Boloc</strong> 03 Hardened Oil 1 410 6 480<br />

Water 1 650 4 540<br />

<strong>Boloc</strong> 04 Hardened Oil 1 430 6 490<br />

Water 1 675 4 560<br />

<strong>Duroc</strong> Special Steel <strong>AB</strong> · 971 88 Luleå · Tel +46 920 43 22 00 · Fax +46 920 255 856 · www.duroc.se/specialsteel

September 2009<br />

The particulars in this data sheet are correct at the time of going<br />

to print and are intended to give general guidance for the use of<br />

the product. Subject to changes arising from continual product<br />

development. The information and data must not be regarded as<br />

guaranteed values, unless specially confirmed in writing.