Tracks and Treads - Finning Canada

Tracks and Treads - Finning Canada

Tracks and Treads - Finning Canada

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

No-risk business: Start with a hazard assessment<br />

He shoots, he scores! <strong>Finning</strong> mechanic saves the tourney<br />

FALL 2008<br />

www.finning.ca<br />

Room to Work<br />

Visit <strong>Finning</strong>’s new<br />

Centre of Excellence<br />

Logging Lift<br />

B.C. forestry company<br />

diversifies for success<br />

Machine<br />

Health Care<br />

Preventive maintenance<br />

keeps your iron tip-top<br />

First<br />

Partnership<br />

An aboriginal joint<br />

venture wins acclaim<br />

A FINNING (CANADA) PUBLICATION Non-deliverable mail should be directed to: 10259 105 Street, Edmonton, AB T5J 1E3 Canadian Publications Mail Product Sales Agreement #40020055

E v E r y B a r n n E E d s a C at<br />

The new Cat ® C-Series Skid Steer offers comfort like the big Cat<br />

machines. Noise <strong>and</strong> dust are reduced thanks to a pressurized <strong>and</strong><br />

sealed cab – an industry first. The optional air ride seat delivers<br />

even more comfort. Plus the wide cab opening makes for easy<br />

entry <strong>and</strong> exit.<br />

Cat Skid Steer loader,<br />

Fully equipped<br />

From as little as $ 18/day<br />

Caterpillar 226B2 Skid Steer loader<br />

*O.A.C. Taxes <strong>and</strong> finance fees extra. Buyout<br />

based on fair market value. Pricing based on 48<br />

payment operating lease.<br />

Count on <strong>Finning</strong> for the best in dealer support.<br />

Be part oF the legaCy.<br />

1-888-finning | finning.ca

18<br />

38<br />

Departments<br />

4 The <strong>Finning</strong> Focus<br />

We’re aiming for zero lost time<br />

incidents<br />

6 Groundbreaker<br />

Re-manufacturing services;<br />

<strong>Finning</strong> International signs a<br />

$360+ million contract;<br />

An update on NAIT’s ThinkBIG<br />

program; B.C.’s new WorkSafe<br />

forestry regulations; A nod to<br />

winners of the 4th annual Wood<br />

WORKS! gala; Good-hearted guy<br />

fixes Zamboni; Old operator opts<br />

for joystick. AND: meet the mega<br />

water truck<br />

12 Yesterday/Today<br />

Affordable <strong>and</strong> versatile, the<br />

backhoe loader remains a vital<br />

construction tool<br />

13 Yellow Iron<br />

New products <strong>and</strong> services<br />

from <strong>Finning</strong><br />

33 Safety First<br />

Learn the difference between a<br />

hazard <strong>and</strong> a risk <strong>and</strong> make your<br />

worksite safer<br />

36 Meeting the Challenge<br />

Lafarge makes the most of the<br />

Preventive Maintenance program<br />

34 Field Test<br />

A blacktop family takes a new<br />

paver for a spin<br />

41 Bill’s Business<br />

Bill discovers <strong>Finning</strong>’s performance<br />

analysis program. Will it<br />

really increase efficiency on site<br />

42 Count On Us<br />

CONTENTS FALL 2008<br />

Features<br />

14 A Rock <strong>and</strong> a Wet Place<br />

A Kelowna construction company<br />

makes a road on a mountainside<br />

18 Three Times Lucky<br />

First Nations joint venture wows<br />

some industry heavyweights<br />

22 Machine Health Care<br />

A little TLC can prevent a world of<br />

pain <strong>and</strong> put the sparkle back in<br />

your scraper<br />

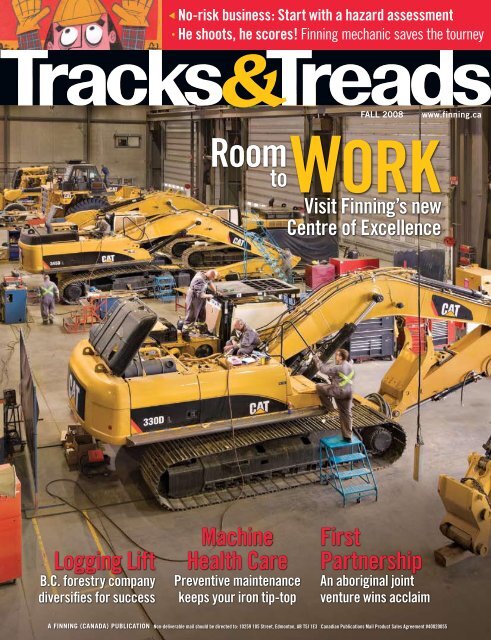

ON THE COvER<br />

<strong>Finning</strong>’s Centre of Excellence<br />

Photograph: DwightArthur/Photek<br />

22<br />

27 SPECIAL REPORT<br />

Centre of Excellence<br />

<strong>Finning</strong>’s huge new workspace in Red Deer<br />

promises to improve workflow <strong>and</strong> free up<br />

techs at branches to serve customers better<br />

38 A Sharke Tale<br />

A central B.C. company proves that there’s<br />

life in the logging industry yet<br />

33<br />

www.finning.ca Fall 2008 • tr acks & treads

The <strong>Finning</strong> Focus<br />

Zero Sum Game<br />

Management at every company<br />

WANTS TO REPORT HIGHER EARNINGS,<br />

BUT WHEN IT COMES TO SAFETY,<br />

null is the greatest number<br />

G<br />

iven its around-the-clock mining operations<br />

<strong>and</strong> high volume of workrelated<br />

travel, Fort McMurray is a place that<br />

sees a lot of people spending a lot of time in<br />

vehicles. Not surprisingly, it’s also a place in<br />

which people spend a lot of time on their<br />

cellphones, two-way radios, PDAs <strong>and</strong><br />

BlackBerrys while on the road.<br />

That’s why the Regional Municipality of<br />

Wood Buffalo, which includes Fort McMurray<br />

<strong>and</strong> 10 other communities, launched a<br />

“Stop Then Talk” safe-driving campaign in<br />

the summer. With the support of <strong>Finning</strong><br />

(<strong>Canada</strong>) <strong>and</strong> the Alberta Motor Association,<br />

the municipality made it m<strong>and</strong>atory<br />

for employees using municipal vehicles to<br />

pull over safely before using a communications<br />

device.<br />

Policies such as this one – <strong>and</strong> a similar<br />

one <strong>Finning</strong> (<strong>Canada</strong>) implemented more<br />

than a year ago – are a sea change in safety<br />

culture. A few years ago, being “unplugged”<br />

on the road meant being inefficient. Today,<br />

it means being smart. With an increasing<br />

number of companies adopting such safety<br />

policies, staying plugged in on the road is<br />

more likely to get you kicked out the door<br />

than patted on the back.<br />

Experts say that the distraction caused by<br />

By Brent Davis<br />

devices such as cellphones slows reaction by<br />

up to 50%. That’s a level comparable to impaired<br />

drivers. How would you feel about a<br />

company that permitted employees to drive<br />

under the influence<br />

It’s difficult to untangle ethics <strong>and</strong> technology.<br />

But leading companies are stepping<br />

up, looking for innovative ways to safeguard<br />

employees as well as the communities in<br />

which they operate. This may be our most<br />

important corporate responsibility. After all,<br />

we don’t work for work’s sake but to enjoy<br />

life – our families, our friends, our hobbies,<br />

our vacations. That’s why we need to choose<br />

safety, at work <strong>and</strong> at home, every day.<br />

Safety is a core value that influences everything<br />

we do at <strong>Finning</strong>. We’re working<br />

hard to develop consistent practices that<br />

encourage our people to put safety first.<br />

<strong>Finning</strong>’s recently improved job hazard<br />

analysis (JHA) is a prime example. JHA is a<br />

process whereby risks are recognized before<br />

starting a task: steps include hazard identification,<br />

assessment <strong>and</strong> control to help<br />

prevent work-related injuries, illnesses,<br />

damage to property <strong>and</strong> environment, <strong>and</strong><br />

near misses. It is a tool proven to prevent<br />

injuries, <strong>and</strong>, as of June 20, it’s a m<strong>and</strong>atory<br />

part of doing business at <strong>Finning</strong>.<br />

JHA is a key <strong>Finning</strong> initiative to eliminate<br />

workplace injuries in an era that<br />

worships speed <strong>and</strong> technology. In 1994, we<br />

reported 168 lost-time injuries (LTIs). This<br />

statistic caused us to re-evaluate the safety<br />

of our workplace. We implemented company-wide<br />

conference calls, executive health<br />

<strong>and</strong> safety meetings, branch calls, incident<br />

reporting <strong>and</strong> daily learning sessions. Each<br />

brought greater safety awareness, <strong>and</strong>, as a<br />

result, we have seen the number of workplace<br />

injuries reduced. In 2007, our number<br />

of LTIs fell to 11. Ultimately, with the help<br />

of the JHA process, we aim to report zero, a<br />

number that’s the least sought-after when<br />

it comes to earnings, but the most soughtafter<br />

when it comes to safety.<br />

Back in 1985 when I worked in the<br />

Victoria warehouse, I didn’t always put<br />

safety first. But I should have. When I think<br />

about the near-misses I had, I wish I’d had<br />

access to the policies <strong>and</strong> programs <strong>Finning</strong><br />

offers today. More importantly, I wish that<br />

everyone who has safety programs <strong>and</strong> tools<br />

at h<strong>and</strong> takes advantage of them. As much<br />

as rigorous policies <strong>and</strong> controls can mean<br />

more paperwork <strong>and</strong> more time, they’re<br />

a means to make sure that work is just the<br />

beginning of life, not the end.<br />

tracks & treads • Fall 2008 www.finning.ca

fall 2008 Volume 48, No. 3<br />

Publisher<br />

Ruth Kelly<br />

rkelly@venturepublishing.ca<br />

aSSociate Publisher<br />

Daska Davis<br />

ddavis@venturepublishing.ca<br />

Executive Editor<br />

Jeff Howard<br />

jhoward@finning.ca<br />

eDitor<br />

Mifi Purvis<br />

mpurvis@venturepublishing.ca<br />

eDitorial Advisors<br />

Danna Beatty, Crystal Chokshi,<br />

Brad Ledig, Michelle Loewen,<br />

Patrick King<br />

art director<br />

Charles Burke<br />

cburke@venturepublishing.ca<br />

design intern<br />

Rodrigo López Orozco<br />

Production COORDINATOR<br />

Betty-Lou Smith<br />

Production technician<br />

Geoff Cwiklewich<br />

Letters & Feedback<br />

A NOTABLE STORY: Your 75th anniversary issue is a great<br />

read – it’s interesting, informative, fun, as well as being a<br />

microcosm of Western <strong>Canada</strong>’s history for the past 75 years.<br />

Congratulations.<br />

My interest in Caterpillar began in 1973 when I joined Hewitt<br />

Equipment as secretary to Mr. Robert Hewitt. Later, I also wrote<br />

their company magazines. I then moved to Edmonton <strong>and</strong> wrote<br />

the company magazines for R. Angus Alberta Ltd. The Cat years<br />

were the best of my working life.<br />

The only thing I would take issue with is your use of the word<br />

“notorious” to describe the epic Antarctic rescue by Kenn Borek<br />

Air pilots in 2001. That journey <strong>and</strong> rescue in unbelievable cold<br />

<strong>and</strong> total darkness was a tremendous Canadian achievement.<br />

Jane Horsburgh, Salt Spring Isl<strong>and</strong>, British Columbia<br />

Thanks, Jane. You are quite right. “Notorious” means widely<br />

known, but unfavourably so. We should have used the word<br />

“notable,” meaning widely known, but in the favourable sense.<br />

Borek pilot Sean Loutitt’s l<strong>and</strong>ing at the South Pole was<br />

indeed notable or, as you say, tremendous. In a pitch black<br />

Antarctic winter’s night, on a runway lit by burning oil barrels,<br />

Loutitt’s Twin Otter touched down at temperatures of -60˚C to<br />

rescue the Antarctic base’s ailing physician to carry him to<br />

medical treatment. – Editors<br />

circulation coordinator<br />

Am<strong>and</strong>a Damman<br />

circulation@venturepublishing.ca<br />

aDvertising representative<br />

Anita McGillis<br />

amcgillis@venturepublishing.ca<br />

Contributing Writers<br />

Robin Brunet, Dave DiCenzo, Katherine Fawcett,<br />

Keith Haddock, Rick Overwater, Jim Stirling,<br />

Shannon Sutherl<strong>and</strong>, Jim Veenbaas<br />

Contributing PHOTOGRAPHERS<br />

<strong>and</strong> illustrators<br />

Dwight Arthur, Tim Bailey, John McDougall, Chris Pyle,<br />

Kelly Redinger, Rick Tolhurst, Chip Zdarsky<br />

<strong>Tracks</strong> & <strong>Treads</strong> is published to provide its readers<br />

with relevant business, technology, product <strong>and</strong> service<br />

information in a lively <strong>and</strong> engaging manner.<br />

<strong>Tracks</strong> & <strong>Treads</strong> is published for<br />

<strong>Finning</strong> (<strong>Canada</strong>) by<br />

Venture Publishing Inc.<br />

10259-105 Street<br />

Edmonton, Alberta T5J 1E3<br />

Phone: 780-990-0839<br />

Fax: 780-425-4921<br />

Contents © 2008 by <strong>Finning</strong> (<strong>Canada</strong>)<br />

No part of this publication should be<br />

reproduced without written permission.<br />

To the rescue: Borek Air in Antarctica<br />

Tell us what you think<br />

<strong>Tracks</strong> & <strong>Treads</strong> would love to hear from you. Tell us what you think<br />

of the magazine’s stories, columns <strong>and</strong> look, so that we can improve<br />

it <strong>and</strong> make it a more interesting read.<br />

Send your comments to executive editor Jeff Howard by e-mail at<br />

jhoward@finning.ca or the old-fashioned way to: Jeff Howard, <strong>Tracks</strong> & <strong>Treads</strong>,<br />

<strong>Finning</strong> (<strong>Canada</strong>), 16830 – 107 Avenue, Edmonton, Alberta T5P 4C3<br />

www.finning.ca<br />

www.finning.ca Fall 2008 • tracks & treads

News & Reviews<br />

by david dicenzo<br />

Grading the Grader<br />

John Lindroos isn’t exactly a member of<br />

the video game generation. At 73, the<br />

Wetaskiwin native doesn’t wear out<br />

his wrists with endless hours on a Wii<br />

or an Xbox. So when Lindroos, a longtime<br />

grader operator for the County of<br />

Wetaskiwin, needed to get up to speed on a<br />

new M-series Cat grader that features a variety<br />

of joysticks, he turned to a more youthful<br />

teacher – his 25-year-old son Phillip.<br />

Father <strong>and</strong> son had trained on a simulator<br />

at the same time, but Phillip got a head start,<br />

logging 120 hours on the real thing, which<br />

was delivered while his dad was off recovering<br />

from knee surgery. And it was up to Phillip<br />

to teach dad when he returned to work.<br />

“He was teacher for a day,” John says with a<br />

laugh. “It went good.”<br />

“It was basically just to get him familiarized<br />

with the controls,” Phillip adds. “When<br />

my dad came back, I spent half a day with<br />

him showing him all the controls, what does<br />

what. He did really good.”<br />

The M-series Cat grader is a radical departure<br />

from the older H-series models that<br />

John knows so well. Cat invested about four<br />

years of research <strong>and</strong> ultimately came up<br />

with a motor grader that replaces a complicated<br />

set of levers with a joystick that looks a<br />

bit like a fighter jet’s h<strong>and</strong> control.<br />

That didn’t matter to John, who,<br />

despite having 37 years under his belt with<br />

the county (30 of which he spent operating<br />

graders), wanted to learn all about the new<br />

machine. He says that after running the<br />

grader for the past few months, it’s a piece<br />

of cake.<br />

“I like the machine,” says John. “The visibility’s<br />

good <strong>and</strong> it seems to be a real nice<br />

machine. It’s quiet.”<br />

John figures he has a few years left<br />

working at the county before he packs it in,<br />

suggesting that he would love to get his 40-<br />

year pin before retiring.<br />

“I’m playing it by ear,” says the veteran<br />

operator. “I’m getting old but if I didn’t<br />

enjoy the work, I wouldn’t have done it for<br />

this long.”<br />

Perhaps a second career as a video gamer<br />

is in the cards.<br />

Is There a Mechanic in the House<br />

What’s the worst-case scenario for a kid’s<br />

hockey tournament A couple of teams<br />

are no shows They’re out of pucks No<br />

hot coffee for the parents in the st<strong>and</strong>s<br />

How about a Zamboni zoning out on<br />

the middle of the ice between games<br />

That’s what happened at a tourney<br />

for seven- <strong>and</strong> eight-year-olds at Cardel<br />

Place in Calgary last winter. Luckily,<br />

<strong>Finning</strong> field technician Shawn Wallz<br />

was around when the Zamboni went on<br />

the fritz. Wallz’s son Ryan was playing in<br />

the tournament <strong>and</strong>, like an off-duty doctor<br />

jumping out of the crowd to treat an injured<br />

player, Wallz had no trouble offering his<br />

skills to help out.<br />

“We were going to find our seats <strong>and</strong><br />

we noticed that the piece at the back of<br />

the Zamboni where it actually scrapes the<br />

ice had broken off,” recalls Wallz. “It was<br />

putting huge scrapes into the ice.”<br />

The off-duty mechanic saw the looks of<br />

disappointment on the players’ faces. “The<br />

kids were getting pretty upset because they<br />

knew that was going to be it for the tournament.<br />

I thought I’d go have a look at it.”<br />

Wallz’s expertise is diagnosing <strong>and</strong> repairing<br />

generator engines <strong>and</strong> natural gas engines<br />

out in the field. He saw that the chain<br />

on the machine had snapped <strong>and</strong> the snow<br />

guard was caught up in the wheel. Wallz<br />

drove to a nearby store, grabbed some parts<br />

<strong>and</strong>, within about four hours, had the Zamboni<br />

back up <strong>and</strong> running. Once the thing<br />

fired up, the players <strong>and</strong> the crowd were<br />

beaming. “Everybody was pretty happy,”<br />

tracks & treads • Fall 2008 www.finning.ca

groundbreaker<br />

dampening dust devils<br />

tw<br />

enty-thous<strong>and</strong> gallons is a whole lot of<br />

water. It’s as much as a person will drink<br />

in an entire lifetime. It’s enough to fill a<br />

backyard swimming pool. <strong>and</strong> it’s also the<br />

amount that can be corralled into cat’s massive<br />

777F mega water truck.<br />

ten<br />

of these giants were scheduled to<br />

be shipped to three different customers<br />

in the Fort McMurray area late in the summer.<br />

though water trucks themselves have<br />

been around for ages, ken shultis, <strong>Finning</strong>’s<br />

industry marketing manager for mining<br />

trucks, says their presence in Fort Mac will<br />

be a first.<br />

“We’ve got way more trucks being deliv-<br />

ered up there now than we have had in the<br />

past,” says shultis. “there’s so much activity<br />

going on in the oils<strong>and</strong>s.”<br />

the water trucks are crucial for safety<br />

<strong>and</strong> visibility on haul roads. a spray bar is<br />

positioned on the back end of each truck,<br />

wetting down the road for the other vehicles<br />

following behind. “they water the road to<br />

keep the dust down,” shultis explains. “It’s<br />

environmentally friendly <strong>and</strong> safer on the<br />

haul roads.” Otherwise, dust clouds kicked<br />

up by passing vehicles would obscure the<br />

road ahead.<br />

Water trucks, he says, aren’t anything<br />

new. In fact, contractors used to take old<br />

trucks <strong>and</strong> fashion their own water trucks<br />

out of them. But with Fort Mac buzzing,<br />

<strong>Finning</strong> decided to make 10 new units<br />

available<br />

to customers in the area. according<br />

to shultis, the trucks are worth $1.5<br />

million each.<br />

Water trucks aren’t<br />

anything new.<br />

Contractors used to<br />

take old trucks <strong>and</strong><br />

fashion their own water<br />

trucks out of them. but<br />

with Fort Mac buzzing,<br />

<strong>Finning</strong> decided to make<br />

10 new units available.<br />

says Wallz. “They came up to me <strong>and</strong> shook<br />

my h<strong>and</strong>.”<br />

Though a few tournament games were<br />

cancelled because of the delay, Wallz’s<br />

h<strong>and</strong>iwork enabled play to continue into the<br />

championship game. That was particularly<br />

important to the Wallz family because young<br />

Ryan’s team had made it that far.<br />

“He was one of the happiest people,”<br />

Wallz says of his son, whose team won the<br />

tourney. “No doubt about that.”<br />

www.finning.ca Fall 2008 • tracks & treads

A Retiring Guy<br />

The qualities Jack Klemke’s father instilled in<br />

him – a strong work ethic <strong>and</strong> integrity – have<br />

been driving Klemke <strong>and</strong> his company, now<br />

called KMC Mining, since he <strong>and</strong> his dad Ted<br />

first started up in Moosejaw, Saskatchewan<br />

in 1949.<br />

“He <strong>and</strong> I were 50/50 in business until<br />

1966, when he retired,” 77-year-old Jack says<br />

of his father. After almost six full decades of<br />

business, the “younger” Klemke felt retirement<br />

calling. On March 3, he walked into<br />

the Alberta-based offices for his last official<br />

day of work, closing a chapter in the history<br />

of the oils<strong>and</strong>s. “It was time to pass the<br />

torch,” says Klemke. “With a good team, the<br />

time was right.”<br />

The native of Swift Current, Saskatchewan,<br />

started work on a single Caterpillar<br />

RD7 tractor with “a six-yard scraper behind<br />

it.” Klemke was confident that both business<br />

<strong>and</strong> his fleet would grow, but admits that<br />

he had no idea of how the mining industry<br />

would change. And he couldn’t predict the<br />

influence he’d have in the field.<br />

In its infancy, KMC was active building irrigation<br />

canals in the Prairies. In the 1960s,<br />

the company built Alberta’s highways,<br />

including the final leg of Highway 63,<br />

which enabled year-round access to<br />

Fort McMurray.<br />

But by the early 1970s, mining was the<br />

company’s focus <strong>and</strong> KMC was getting into<br />

heavy equipment. Klemke says that they<br />

were the second contractor onsite at Syncrude,<br />

a hotbed of mining innovation. “On<br />

that first job, we brought in a frontend hydraulic<br />

shovel,” he says. “It was fairly basic<br />

but we helped the suppliers of those shovels<br />

transition into what we have today, larger<br />

equipment, suited to the oils<strong>and</strong>s.<br />

“And I think we had the first three 789<br />

trucks in North America in 1986. We took<br />

them to the oils<strong>and</strong>s <strong>and</strong> worked through<br />

all the teething problems there,” he says.<br />

“That’s a long ways from a six-yard scraper.”<br />

Klemke says that working with Cat <strong>and</strong><br />

<strong>Finning</strong> over the years, tailoring equipment<br />

for the oils<strong>and</strong>s, was a rewarding experience.<br />

But as a gr<strong>and</strong>father of 10 children<br />

<strong>and</strong> the great gr<strong>and</strong>father of one, work is no<br />

longer top priority. Klemke’s son Dan is now<br />

CEO, making KMC a third-generation family<br />

show.<br />

Klemke has channeled his energy into<br />

some important personal causes. He <strong>and</strong> his<br />

wife have been actively involved in spreading<br />

the message of Christianity across the globe,<br />

working in places like North Africa, the Middle<br />

East <strong>and</strong> Central Asia.<br />

That work ethic <strong>and</strong> integrity he learned<br />

from his father Ted so many years ago still<br />

exists in retirement.<br />

<strong>Tracks</strong> & <strong>Treads</strong> Puzzle<br />

Sharpen your pencil, take a seat <strong>and</strong> have a go at our firstever<br />

word search puzzle.<br />

Find these 12 hidden words based on the stories in the<br />

pages of this issue of <strong>Tracks</strong> & <strong>Treads</strong> <strong>and</strong> bask in your own<br />

cleverness. Plus, keep your eyes peeled in future issues for<br />

more crosswords <strong>and</strong> word search puzzles.<br />

mining<br />

paver<br />

zamboni<br />

forestry<br />

mechanic<br />

Caterpillar<br />

technician<br />

preventive<br />

maintenance<br />

excellence<br />

construction<br />

service<br />

tracks & treads • Fall 2008 www.finning.ca

groundbreaker<br />

A Historic<br />

Sale<br />

A major deal was recently inked between<br />

<strong>Finning</strong> International <strong>and</strong> Suncor Energy<br />

Inc., ensuring that there will be plenty of<br />

yellow iron visible in the rich Alberta oils<strong>and</strong>s.<br />

At the company’s annual general<br />

meeting back in May, <strong>Finning</strong> announced<br />

that it had agreed to a $360-million contract<br />

to supply heavy equipment to Suncor<br />

for work in the oils<strong>and</strong>s.<br />

Suncor will receive 22 Cat 797b mining<br />

trucks, 19 D11T tractors <strong>and</strong> five D8T<br />

bulldozers over the course of this year <strong>and</strong><br />

2009, bringing the company’s fleet of massive<br />

mining trucks to 67 units, 51 of which<br />

will be 797s (the largest mining trucks in<br />

the world) along with 16 model 793 units.<br />

“Growth in mining activity in the oils<strong>and</strong>s<br />

continues to be very strong, <strong>and</strong> <strong>Finning</strong>’s<br />

position as the major supplier of large mobile<br />

mining equipment <strong>and</strong> as the key<br />

service partner to the oils<strong>and</strong>s producers<br />

continues to exp<strong>and</strong>,” Mike Waites, <strong>Finning</strong><br />

International president <strong>and</strong> chief executive<br />

officer said at the time of the announcement.<br />

“There are currently 120 of the 797 haul<br />

trucks operating in the Alberta oils<strong>and</strong>s, <strong>and</strong><br />

in 2008 we are scheduled to deliver more<br />

than 65 additional 797s.”<br />

“You have to be honest<br />

with everybody. We have<br />

a pretty good reputation<br />

in gr<strong>and</strong>e Prairie.”<br />

Building a Reputation<br />

ken Wilson was looking for a new challenge<br />

when the contractor he worked<br />

for in Gr<strong>and</strong>e Prairie closed up shop in<br />

the late 1970s. With one machine, the<br />

Gr<strong>and</strong> Prairie native decided to start<br />

his own company, focusing on roadwork.<br />

“I only planned on running one or two<br />

pieces,” Wilson says. “But the work was<br />

there <strong>and</strong> we grew.”<br />

thirty years later, ken Wilson<br />

contracting Ltd. is one of the most<br />

respected<br />

operations in the area. Wilson’s<br />

company does work on highways <strong>and</strong><br />

roads, oilfields <strong>and</strong> subdivisions in the<br />

Gr<strong>and</strong>e Prairie <strong>and</strong> Gr<strong>and</strong>e cache areas.<br />

It runs about 40 predominantly<br />

cat pieces<br />

now, which is a far cry away from the single<br />

machine Wilson had going in ’78.<br />

the 58-year-old says one of the company’s<br />

biggest jobs in the early days was<br />

building a retaining pond at nearby<br />

IvyLake. But whatever the job, the common<br />

thread for<br />

ken Wilson contracting Ltd.<br />

has always been to do things well <strong>and</strong><br />

be honest.<br />

“You have to be honest with everybody,<br />

telling them if you can or can’t do it or<br />

what it’s going to cost up front,” Wilson says.<br />

“We have a pretty good reputation in<br />

Gr<strong>and</strong>e Prairie.”<br />

www.finning.ca Fall 2008 • tracks & treads

Aaron Settle had no idea what he was in for<br />

when he applied to ThinkbIG in 2005. The<br />

joint program between <strong>Finning</strong>, Caterpillar<br />

<strong>and</strong> the Northern Alberta Institute of Technology<br />

is designed to arm students with the<br />

educational requirements needed to obtain<br />

a heavy equipment technician ticket.<br />

And in Settle’s case, he went a long<br />

way to get them. The 21-year-old from<br />

Kaslo, b.C. made the epic 1,200-kilometre<br />

trek to Fairview, Alberta. on 10<br />

occasions in his trusty Gr<strong>and</strong> Am.“<br />

I found out about the program reading<br />

<strong>Tracks</strong> & <strong>Treads</strong> magazine,” says Settle, whose<br />

father owns a logging company in british<br />

Columbia, Settle would spend two months<br />

at a time in the classroom in Alberta <strong>and</strong><br />

then two months at the <strong>Finning</strong> branch in<br />

Castlegar, b.C. doing his practicum where<br />

in. July of 2007, he was hired as a secondyear<br />

apprentice mechanic. Now a third-year<br />

apprentice, he’s running his own service<br />

truck – <strong>and</strong> loving it. “It could be anything,”<br />

he says of the varied assignments his job<br />

entails. “That’s part of the fun <strong>and</strong> I like<br />

the service truck for that reason. you never<br />

know what you’re going to be doing the<br />

next day.”<br />

The lack of skilled tradespeople in<br />

Alberta is well-documented. but for the past<br />

five years, <strong>Finning</strong>, in partnership with Cat<br />

<strong>and</strong> NAIT, has been trying to do something<br />

to combat that shortfall with ThinkbIG.<br />

“We saw it as a good opportunity to build<br />

heavy equipment technicians for the future,”<br />

says Amy Eleniak, <strong>Finning</strong>’s team lead,<br />

apprenticeship. “We’ve had a really good<br />

success rate.”<br />

ThinkbIG was launched in March 2003.<br />

The program accepts first- <strong>and</strong> second-year<br />

students, no more than 24 per group. Eleniak<br />

says that the 20-month program runs<br />

through five continuous semesters, with no<br />

summer break. Each semester is 16 weeks<br />

long <strong>and</strong> students spend half that time in<br />

the classroom, the other half working in a<br />

<strong>Finning</strong> branch. Not only do they get the<br />

Caterpillar education, but they also have to<br />

satisfy other requirements to be eligible to<br />

become a heavy equipment technician in<br />

Alberta. “They don’t get their ticket at the<br />

end of this program,” Eleniak says. “They<br />

still have to get hired on as an apprentice<br />

<strong>and</strong> finish off their hours.”<br />

Settle says that one of the biggest<br />

bonuses of the program for him was<br />

learning about the most up-to-date technology,<br />

especially as it pertained to Cats.<br />

“It was very Cat-specific,” he says.<br />

“The technological part of the program was<br />

really good.”<br />

Graduates of ThinkbIG have pursued a<br />

variety of different jobs upon completion of<br />

the program. Many are hired immediately<br />

by <strong>Finning</strong>. One former student is now an<br />

instructor at NAIT.<br />

PHOTOGRAPH COuTyESy NAIT<br />

10 tracks & treads • Fall 2008 www.finning.ca

By the Numbers<br />

Number of millionaires<br />

worldwide in 2007,<br />

a new high:<br />

10,100,000<br />

Number of Yukon athletes<br />

who participated in this<br />

summer’s olympic games:<br />

2<br />

The number<br />

of Canadian<br />

athletes who<br />

have been<br />

medalists in both<br />

the summer <strong>and</strong><br />

winter games:<br />

1<br />

Ranking of labour shortages,<br />

the state of the economy,<br />

consumer spending <strong>and</strong> rising<br />

energy costs, in terms of their<br />

impact on hiring decisions<br />

made by Canadian employers:<br />

1, 2, 3, 4<br />

Estimated monthly cost<br />

of operating the new<br />

3G Apple iPhone:<br />

Number of years a Quebec<br />

law, which was revoked in<br />

June of this year, required<br />

that margarine be white<br />

in colour:<br />

21<br />

Size in carats of a<br />

diamond recovered<br />

at the Gahcho Kué<br />

project 300 kilometres<br />

northeast of yellowknife:<br />

25.13<br />

Number of cases of<br />

Neilson salted butter<br />

stolen from a B.c.<br />

Superstore, July 7:<br />

1,008<br />

Percentage of Suncor<br />

employees who are<br />

aboriginal:<br />

9<br />

Rank of Suncor among<br />

industrial employers<br />

of aboriginal people in<br />

<strong>Canada</strong>:<br />

www.finning.ca Fall 2008 • tracks & treads 11

Yesterday/Today<br />

Story by keith haddock<br />

Affordable <strong>and</strong> versatile, the backhoe loader has evolved over<br />

the years <strong>and</strong> remains a vital tool on construction sites<br />

Still Digging<br />

For the past four decades, backhoe loaders<br />

have been the mainstay of mechanized<br />

utility work. Even with the advent of miniexcavators,<br />

the increasive popularity of<br />

skid steer loaders <strong>and</strong> number of companies<br />

making compact-sized machines, the<br />

backhoe loader has held its ground. It has<br />

become more versatile <strong>and</strong> has adapted to<br />

modern construction practices. It wins out<br />

over most other small digging machines because<br />

of its superior mobility: it can travel<br />

at highway speeds over short to medium<br />

distances.<br />

Towards the end of the 1970s, Caterpillar<br />

recognized the importance of the loader<br />

backhoe <strong>and</strong> the potential for even wider<br />

markets for this type of machine. Noting the<br />

success of pioneer builders, especially those<br />

in the United Kingdom, Caterpillar decided<br />

to add backhoe loaders to its product line. It<br />

started up an intensive development program<br />

to design <strong>and</strong> build its own machines. With<br />

production of loader backhoes assigned to<br />

Caterpillar’s plant at Leicester, Engl<strong>and</strong>, the<br />

wraps were taken off the first model, the 416,<br />

in 1985. In the 14-foot digging depth class,<br />

the 416 carried a 62-flywheel horsepower<br />

engine. Special features included a back-ofcentre<br />

carry position for the backhoe, which<br />

provided superior stability when travelling, as<br />

well as single cylinder bucket roll-back.<br />

By 1989, Caterpillar had exp<strong>and</strong>ed its<br />

backhoe loader line to six models ranging<br />

in size up to the 95-flywheel horsepower<br />

446, which offered a st<strong>and</strong>ard digging depth<br />

of 17 feet <strong>and</strong> up to 21 feet with its extended<br />

arm. Included in the line were two side-shift<br />

models, the 428 <strong>and</strong> 438. On side-shift models,<br />

the backhoe boom assembly is carried<br />

on a sliding frame so the boom pivot can be<br />

positioned at any point from the left to the<br />

DIG IN: Caterpillar’s first loader backhoe, the 416, proved that power was in the eye of the beholder<br />

right of the machine. This simple feature,<br />

more popular in Europe than in North America,<br />

allows the operator to dig flush to walls<br />

<strong>and</strong> footings <strong>and</strong> offers more flexibility when<br />

excavating around obstructions. The 428 <strong>and</strong><br />

438 could dig to 15 feet 9 inches <strong>and</strong> came<br />

with power units of 70 <strong>and</strong> 84-flywheel horsepower,<br />

respectively.<br />

Caterpillar refined its loader backhoe<br />

models with the introduction of the Series II<br />

models in 1990, then followed in 1992 with<br />

the announcement of the upgraded B-series.<br />

The B models sported a curved excavator-style<br />

backhoe boom, which first appeared on the<br />

original 446 in 1989. This design provided<br />

more clearance when digging over obstacles<br />

<strong>and</strong> a greater overall digging depth. The<br />

B models were also endowed with increased<br />

power to 74 flywheel horsepower for the 416B<br />

to 84 flywheel horsepower for the 436B.<br />

Keeping pace with the latest technology,<br />

in 1993 Caterpillar introduced its first<br />

loader backhoe with optional four-wheel<br />

drive <strong>and</strong> four-wheel steer on its side-shift<br />

438B model <strong>and</strong>, in 1996 made this feature<br />

available on certain models in its newly designed-series.<br />

Never allowing its designs<br />

to stagnate, in 2001 Caterpillar introduced<br />

the first of its D-series backhoe loaders: the<br />

420D <strong>and</strong> 430D. The entire D-series line,<br />

completed in 2004, with the introduction of<br />

the 446D at 102 horsepower, boasted pilotoperated<br />

joystick controls for ease of operation<br />

<strong>and</strong> increased backhoe bucket rotation<br />

to 205 degrees.<br />

Today, Caterpillar serves the loader backhoe<br />

market with its latest E-series, which<br />

comprises 10 sizes of machines available<br />

in different options, including tool carrier<br />

<strong>and</strong> side-shift models. They range from the<br />

78-horsepower 416E to the 137-horsepower<br />

450E. Affordable for even the smallest<br />

contractor <strong>and</strong> capable of performing a<br />

wide variety of jobs, the backhoe loader will<br />

continue to perform a vital role on construction<br />

sites for the foreseeable future.<br />

photograph courtesy keith haddock<br />

12 tracks & treads • Fall 2008 www.finning.ca

yellowiron<br />

New Products <strong>and</strong> Ser vices from <strong>Finning</strong><br />

PM service - Scheduled. Professional. Peace of mind<br />

Keep your machines in top form with <strong>Finning</strong>’s Preventive<br />

Maintenance service. All PM services are scheduled at<br />

your convenience <strong>and</strong> delivered by qualified heavy equipment<br />

technicians who quickly identify potential problems<br />

<strong>and</strong> ensure serious issues are noted for effective follow<br />

up. PM service is delivered using state-of-the-art PM<br />

trucks designed to ensure optimum, environmentallyfriendly<br />

service. We’ve doubled the size of our capacity<br />

<strong>and</strong> we’re now in Kamloops. Call today.<br />

Order Cat parts online<br />

With <strong>Finning</strong>’s PartStore, you can order parts quickly<br />

<strong>and</strong> efficiently – online. Once your PartStore account is<br />

set up, you’ll be able to check parts availability <strong>and</strong> prices<br />

<strong>and</strong> see Caterpillar’s Service Information System, which<br />

provides access to more than 17,000 publications on all<br />

1977- present Caterpillar machine <strong>and</strong> engine product<br />

lines. To register for this free service, visit www.finning.ca<br />

or contact <strong>Finning</strong> (<strong>Canada</strong>) eBusiness at 1-888-FINNING<br />

(346-6464).<br />

Numbers you can count on: 1-888-FINNING & 24/7<br />

Working in the wee hours Need to order parts at 3 a.m.<br />

No problem. At the <strong>Finning</strong> Customer Support Centre,<br />

we’re here for you with the advice you need 24 hours<br />

a day, seven days a week. Call 1-888-FINNING from<br />

anywhere, day or night, to reach skilled, knowlegeable<br />

<strong>Finning</strong> equipment professionals.<br />

Caterpillar machines are built to be rebuilt<br />

The extensive Caterpillar Certified Rebuild program<br />

incorporates the very latest Cat technology <strong>and</strong> critical<br />

engineering updates into your machine at a fraction of the<br />

cost of buying new. After a thorough evaluation, including<br />

more than 350 tests <strong>and</strong> inspections <strong>and</strong> the automatic<br />

replacement of approximately 7,000 parts, you get a likenew<br />

machine <strong>and</strong> warranty.<br />

www.finning.ca Fall 2008 • tracks & treads 13

MAKE THE HIGH ROAD: Arthon’s 740s haul loads of<br />

blasted rock on a blistering Okanagan day. Higher up,<br />

the mountain goats are watching<br />

14 tracks & treads • Fall 2008 www.finning.ca

ARock<br />

<strong>and</strong> a<br />

Wet<br />

Place<br />

Story by Jim Stirling<br />

photography by john Mcdougall<br />

In the dusty confines of a busy<br />

Okanagan Lake highway project,<br />

a B.C. construction company<br />

is making it work<br />

Imagine for a moment you’re a hawk,<br />

wings motionless as you ride the thermals.<br />

Beneath you winds a busy two-lane ribbon<br />

of highway, dotted with cars, RVs <strong>and</strong><br />

trucks, some of them towing speedboats.<br />

Framing the highway on one side is a wall of rock.<br />

On the other, the l<strong>and</strong> drops abruptly to the sparkling<br />

waters of Okanagan Lake below.<br />

The raptor’s eye view of this section of Okanagan<br />

Valley shows some of the physical challenges facing<br />

a construction project underway on Highway<br />

97, north of Summerl<strong>and</strong> in the scenic valley of<br />

southern British Columbia.<br />

Arthon Contractors Inc., based in the Okanagan<br />

Mission area of Kelowna, has a $38.5-million,<br />

two-year contract from the provincial Ministry of<br />

Transportation <strong>and</strong> Highways to twin an approximately<br />

seven-kilometre section of the highway. It’s<br />

a major construction job, one that’s stuck between<br />

a rock <strong>and</strong> a wet place.<br />

www.finning.ca Fall 2008 • tracks & treads 15

COMPANY PROFILE: Arthon Contractors Inc.<br />

Arthon has assembled the people <strong>and</strong><br />

equipment it needs to get the job done, including<br />

eight new Caterpillar high-capacity<br />

rock trucks. Twinning the busy highway<br />

through the peak of tourist season is problematic<br />

enough. But an additional <strong>and</strong><br />

unexpected challenge to construction<br />

scheduling was presented by a small group<br />

of local residents.<br />

A herd of about 20 mountain goats using<br />

the bluffs above the highway alignment usually<br />

move on up to higher ground in<br />

the spring. But not this year. Instead,<br />

they opted to stay put, have their kids<br />

<strong>and</strong> keep an eye on all the action below<br />

them. At last count, there were six new<br />

baby goats in the extended family. Arthon<br />

had to be equally quick on its corporate<br />

feet to accommodate the continuing presence<br />

of the unexpected sidewalk superintendents.<br />

“We had stop-work orders <strong>and</strong> extended<br />

no-blasting areas around the goat bluffs,”<br />

summarizes Steve Dimond. “We had to go<br />

to other areas of the project as best we could.<br />

It was something that couldn’t be foreseen.”<br />

Dimond is a partner in Arthon Contractors,<br />

along with Kerry Leong <strong>and</strong> Guy Ferrari. Arthon<br />

was incorporated in 1991 <strong>and</strong> bought its<br />

first rock-crushing equipment to use in a Kelowna<br />

development. Today, Arthon has grown<br />

to become a prominent general contracting<br />

company <strong>and</strong> a specialist in moving massive<br />

amounts of rock <strong>and</strong> earth.<br />

The company calls on all its expertise on<br />

the Highway 97 project, with some 1.8 million<br />

cubic metres of rock <strong>and</strong> other material<br />

to move. Dimond explains that the limited<br />

capacity of the soils that support the existing<br />

highway means that more than half of the new<br />

alignment has to be created above the present<br />

two-lane road. And that, in turn, necessitates<br />

extensive rock-blasting <strong>and</strong> material removal.<br />

The company’s newly acquired Caterpillar<br />

equipment is designed to assist with that sizable<br />

task. On site, Arthon Construction has<br />

four new Cat 740 articulated trucks <strong>and</strong> four<br />

Cat 775 rigid frame units on a lease-to-own<br />

basis, reports Dimond. The 40 <strong>and</strong> 75 designations<br />

reflect the machines’ approximate<br />

carrying capacity in tonnes, so these units<br />

are no babies.<br />

Arthon’s equipment management<br />

<strong>and</strong> logistical approach to the<br />

project looks pretty favourable.<br />

“The Cat trucks have performed quite<br />

well,” says Dimond. “There have been a few<br />

warranty issues, but the wheels have been<br />

turning daily.”<br />

That’s doubly important given the impact<br />

of the goat delays on the project. “When you<br />

purchase each piece of equipment, you try<br />

<strong>and</strong> get the best deal you can,” he points out.<br />

“The key question we asked ourselves was ‘did<br />

this job by itself justify the Cat machines’<br />

And there’s always a value for them at the end<br />

of the job to consider.”<br />

Arthon is also using Cat dozers on the<br />

road-twinning project in D6 to D10 sizes <strong>and</strong><br />

a Cat 235 excavator. Dimond says May was<br />

a productive month, with the company taking<br />

advantage of short hauls to deposit some<br />

30,000 equivalent t<strong>and</strong>em loads of material<br />

to a designated stockpile site.<br />

Traffic management is a significant issue<br />

on the project. Highway 97 is a major artery<br />

year-round in an area that’s growing rapidly.<br />

Additional pressure comes from the sum-<br />

mer tourist traffic. Arthon <strong>and</strong> the Ministry<br />

of Transportation <strong>and</strong> Highways have tried<br />

to establish realistic trade-offs with regular,<br />

scheduled road closures to expedite the job.<br />

The parties developed a pattern of occasional<br />

morning <strong>and</strong> afternoon closures, restricted to<br />

30 minutes or less when traffic volumes are<br />

highest, with the possibility to close the road<br />

for an hour at other times during the day. The<br />

relative quiet of darkness allows Arthon to<br />

close the road for up to two hours at a go in<br />

the middle of the night. Dimond says<br />

that extensive use of e-mails <strong>and</strong> good<br />

co-operation from local radio stations<br />

serve to maximize information <strong>and</strong><br />

minimize inconvenience to the travelling<br />

public.<br />

“If we can do it faster, the pain will be over<br />

faster,” he says of the overall approach. But,<br />

that said, company reps have to mind that it<br />

can get difficult trying to accelerate construction<br />

activity if they try to commit too much<br />

equipment to a confined area. Establishing<br />

a balance is the goal: one that makes some<br />

sense for the time-pressured contractor <strong>and</strong><br />

keeps the traffic flowing.<br />

Equipment working on the job was consuming<br />

between 10,000 <strong>and</strong> 11,000 litres of<br />

fuel a day. In early summer, Dimond says the<br />

fuel consumption was translating to 1.2 litres<br />

of fuel per cubic metre of material moved.<br />

What it means is that Arthon’s equipment<br />

management <strong>and</strong> logistical approach to the<br />

project looks pretty favourable. “All in all,<br />

things have gone quite well so far,” summarizes<br />

Dimond.<br />

Arthon’s peak summer construction involved<br />

about 60 to 80 employees, including<br />

contractors. The summer surge of traffic will<br />

dissipate <strong>and</strong> crews will remain on the job<br />

16 tracks & treads • Fall 2008 www.finning.ca

BOTTOMS uP: The company is calling on all its<br />

expertise <strong>and</strong> cat equipment to move 1.8 million<br />

cubic metres of rock from the hillside<br />

through the winter of 2008-2009. arthon<br />

remains<br />

hopeful it will be able to catch up on<br />

at least some of the unforeseen goat-induced<br />

delays. Heavy winter snows might curtail<br />

work on occasion. But<br />

dimond anticipates<br />

that next spring <strong>and</strong> summer will see the anticipated<br />

paving of the new highway, clawed<br />

from the rock walls.<br />

that assumes, of course, the mountain<br />

goats are not planning any further intervention<br />

into arthon construction’s project.<br />

Hopefully, they will be content to look down<br />

from their rocky perch with bemusement, as<br />

four lanes of traffic zip along at 100 kilome-<br />

tres<br />

an hour through their beautiful section of<br />

the Okanagan Valley.<br />

Sea to Sky Pioneer<br />

there’s much behind-the-scenes activity that<br />

takes place before a customer puts a new<br />

piece of Caterpillar equipment to work. <strong>and</strong><br />

that’s just after the initial decision to go Cat<br />

has been made.<br />

Consider some of the preparatory work<br />

required before arthon Construction could<br />

assign its new Caterpillar trucks to the job<br />

site on a road-twinning project in b.C.’s<br />

okanagan Valley.<br />

the four new Cat 740 articulated trucks<br />

that arthon ordered were built in Engl<strong>and</strong>,<br />

shipped to <strong>Canada</strong>’s west coast <strong>and</strong> prepped<br />

by <strong>Finning</strong> (<strong>Canada</strong>) staffers in Langley, b.C.,<br />

recalls Norm roine, a customer account<br />

manager for heavy construction, based in<br />

Vernon, b.C. all the new equipment goes<br />

through a rigorous <strong>and</strong> complete check<br />

before it’s h<strong>and</strong>ed over. Customers such as<br />

arthon want to put the piece to work as soon<br />

as they take possession. an idle machine<br />

doesn’t make money.<br />

the four Cat 775 rigid frame trucks that<br />

arthon also ordered for use on the highway<br />

97 improvement project presented a different<br />

set of challenges. they are substantially<br />

larger machines – with a carrying capacity<br />

of about 75 tonnes – <strong>and</strong> they arrived at the<br />

jobsite in pieces. For example, the frame<br />

<strong>and</strong> body system were transported in separate<br />

loads. the challenge was to assemble<br />

them on site.<br />

Just to make life more interesting, unexpected<br />

delivery delays put pressure on<br />

arthon’s already tight timelines. “We allowed<br />

about 100 hours per truck to put the 775s<br />

together,” reports roine, who, as a 30-year<br />

veteran with <strong>Finning</strong>, knows all about meeting<br />

such pressures. “our guys were in that<br />

range or improved on that timeline. they did<br />

a fabulous job; they really did,” roine says.<br />

the project has seen its share of collaborative<br />

solutions, roine says. “back in January,<br />

we sat down with arthon <strong>and</strong> its mechanical<br />

contractor <strong>and</strong> asked what else <strong>Finning</strong> could<br />

do to help the project,” he says. “<strong>and</strong> everyone<br />

put their heads together.”<br />

as a result of those discussions, both<br />

parties decided to squeeze in some trailer<br />

storage on site, to maintain a small parts<br />

inventory that would speed common repairs.<br />

the inventory included filters <strong>and</strong> other items<br />

that are needed frequently on a large-scale<br />

heavy construction project. the on-site storage<br />

capability augments the three-timesweekly<br />

scheduled parts <strong>and</strong> service runs<br />

that <strong>Finning</strong> operates through the okanagan<br />

Valley. regular service runs, coupled with the<br />

on-site storage, allow more inventory as the<br />

customer requires it <strong>and</strong> increases uptime.<br />

www.finning.ca Fall 2008 • tracks & treads 17

COMPANY PROFILE: Three Nations Ventures<br />

TOP JOBS: Prior to being elected chief of the<br />

Salteau First Nation, Harley Davis was a proud<br />

full-time employee of Three Nations Ventures<br />

18 tracks & treads • Fall 2008 www.finning.ca

Three Times<br />

a First Nations joint venture wows a<br />

B.c. logging industry heavyweight,<br />

sending critics running for cover<br />

STory by ROBIN BRuNET<br />

phoTography by DIGITAL B PHOTOGRAPHICS<br />

FIVE FROM 3NV: Three Nations Ventures President Darrell Garbitt<br />

(left) with four 3NV team leaders. From left to right: Mike Koosis,<br />

Warren Garbitt, Art Walker <strong>and</strong> David Gentry. They proudly hold the<br />

250,000 no time loss award<br />

I<br />

t’s June, three days before Three<br />

Nations Ventures will receive<br />

plaques from tembec,<br />

a leader<br />

in integrated forest products, <strong>and</strong><br />

<strong>Finning</strong> (canada) commemorating 250,000<br />

consecutive person hours worked at the tem<br />

-<br />

bec Log Yard in chetwynd, British columbia,<br />

with no time lost to on-the-job incidents.<br />

tembec<br />

mill manager Wayne<br />

clement is enjoying<br />

the moment. “I knew from the beginning<br />

that three<br />

Nations would be a success,”<br />

he says. “But frankly, I didn’t think they would<br />

achieve so much, so quickly.”<br />

Operating consistently in a dem<strong>and</strong>ing<br />

work environment with no major mishap is<br />

indeed remarkable. But it’s just one facet of<br />

the amazing progress made by a small group<br />

of people who started with nothing five years<br />

ago, <strong>and</strong> today preside over six contracts inte-<br />

gral<br />

to the tembec<br />

Pulp Mill, which produces<br />

500 air-dried metric tonnes of pulp daily. add<br />

to this the fact that<br />

three Nations Ventures<br />

(more commonly known as 3NV) is comprised<br />

mainly of saulteau, West Moberly <strong>and</strong><br />

Blueberry<br />

river<br />

First Nations b<strong>and</strong> members,<br />

<strong>and</strong> you have a genuine made-in-B.c. success<br />

story that demonstrates the business capabilities<br />

of the community as a whole.<br />

tom<br />

aird, a saulteau member who is<br />

3NV’s accountant <strong>and</strong> human resources specialist,<br />

echoes the sentiments of his colleagues<br />

when he says: “I’m very proud of 3NV. It adheres<br />

to old-fashioned values, <strong>and</strong> it succeeds<br />

because of the mutual respect we have for each<br />

other <strong>and</strong> for tembec<br />

personnel. there<br />

are no<br />

prejudices here, just a collective desire to be<br />

the best possible contractor.”<br />

“to<br />

repeat the quote of a b<strong>and</strong> chief prior<br />

to 3NV being formed,” Lyle Mortenson says,<br />

“‘all we wanted was a h<strong>and</strong> up, not a h<strong>and</strong><br />

out.’” Mortenson is a non-native forestry consultant<br />

for 3NV with lifelong experience as a<br />

liaison between industry <strong>and</strong> First Nations.<br />

“today,<br />

our debt-to-equity ratio is one to five,<br />

we always show a profit at year end. <strong>and</strong><br />

in addition<br />

to our incident-free status, we’ve won<br />

tembec<br />

several awards [from cN rail]<br />

for the<br />

safe h<strong>and</strong>ling of smelt ash.”<br />

at<br />

any given time of the day, the tembec<br />

log yard is a hive of activity, with as many as<br />

100 trucks arriving daily on the property. three<br />

Nations Ventures employs 33 people (twothirds<br />

of whom are First Nations members) to<br />

perform everything from scaling <strong>and</strong> unloading<br />

to shunting <strong>and</strong> mill maintenance. every<br />

year, the yard processes 450,000 cubic metres<br />

of wood. cat 924 wheel loaders load smelt<br />

into rail cars, while<br />

325MHs stack logs in tall,<br />

neat piles. the<br />

feeding of the mill, which employs<br />

160 people, is non-stop, <strong>and</strong> the yard<br />

work far surpasses its predecessor, run by Louisiana-Pacific,<br />

in terms of productivity.<br />

the<br />

venture’s success has roots not just in<br />

the people of the region, but also in tembec’s<br />

confidence in them. residents<br />

of the area who<br />

are involved in the project credit tembec<br />

for<br />

giving 3NV the “h<strong>and</strong> up” it was seeking. “to<br />

call tembec<br />

a model of a modern business<br />

would be an understatement,” says aird. “In<br />

fact, I’ve never come across another compa-<br />

ny<br />

like it, not just because it fosters First Nations<br />

business involvement, but because it<br />

genuinely treats us as equals.”<br />

tembec’s<br />

presence in<br />

chetwynd dates back<br />

to 2002, when delegates from Quebec arrived<br />

to finalize purchase of the old Louisiana-Pacific<br />

pulp mill <strong>and</strong> re-open the facility, which had<br />

been closed for two years. tembec<br />

arrived with<br />

a long history of working with First Nations<br />

across<br />

canada, most notably in its sawmills in<br />

northern Ontario <strong>and</strong> New Brunswick. so the<br />

regional b<strong>and</strong>s were excited by the prospect<br />

of the Quebec-based forestry giant transforming<br />

the Louisiana-Pacific mill, which was an<br />

www.finning.ca Fall 2008 • tracks & treads 19

COMPANY PROFILE: Three Nations Ventures<br />

oriented str<strong>and</strong> board specialist, into a mill.<br />

“Here we were setting up a pulp mill,” says<br />

Tembec mill manager Wayne Clement. “And<br />

we were committed to partnering with any<br />

b<strong>and</strong>s if an opportunity for outside operations<br />

arose that was integral to our main facility.”<br />

That opportunity arose almost immediately<br />

when Tembec decided to focus exclusively<br />

on pulp mill management <strong>and</strong> contract<br />

out auxiliary operations, such as the log yard.<br />

“There are seven b<strong>and</strong>s in the Chetwynd region<br />

<strong>and</strong> we met with all of them,” recalls<br />

Clement. “Four had no<br />

interest in partnering with<br />

us, but the Saulteau, West<br />

Moberley <strong>and</strong> Blueberry<br />

River b<strong>and</strong>s were keen on<br />

the idea. They became 3NV,<br />

I liaised with their business<br />

leaders, <strong>and</strong> we hammered<br />

out a deal whereby they<br />

agreed to perform to our high st<strong>and</strong>ards <strong>and</strong><br />

we gave them the scaling contract.”<br />

“Even at this early stage, I was impressed<br />

by everyone’s determination to prove themselves,<br />

<strong>and</strong> I figured the scaling operations<br />

would be in good h<strong>and</strong>s,” Clement adds.<br />

“I didn’t think anything beyond that.<br />

I assumed this would be enough work for any<br />

one group to h<strong>and</strong>le.”<br />

From a regional perspective, there was<br />

considerable skepticism as to the ability of<br />

this small group (at that time, there were only<br />

four 3NV yard people) to fulfill their contract.<br />

Mortenson recalls the negative attitude some<br />

people held. “Many locals thought Clement<br />

was crazy to give Three Nations the scaling<br />

contract,” he recalls. Mortensen heard<br />

the usual ugly bigotry <strong>and</strong> stereotypes. “It’s to<br />

Clement’s considerable credit that he ignored<br />

the detractors,” Mortensen says. It took less<br />

than a year for the critics to eat their words.<br />

Even though Three Nations had little or<br />

no experience in the work they were about to<br />

undertake, they followed the cardinal rule of<br />

business: hire people who do <strong>and</strong> learn from<br />

them. So 3NV hired Mortenson to help hammer<br />

out its business plan; he subsequently<br />

became Three Nations’ general manager.<br />

The joint venture also hired Cyril Brewster,<br />

Louisiana-Pacific’s previous log yard supervisor,<br />

<strong>and</strong> retained other professionals to find<br />

ways of improving operations. And 3NV rearranged<br />

the decking to accommodate more<br />

wood, developed better work schedules, <strong>and</strong><br />

undertook cross-training – teaching some employees<br />

to perform more than one duty.<br />

Cross-training continues today <strong>and</strong> has<br />

proven to be a major factor in productivity.<br />

“It significantly benefits Tembec if someone<br />

can unload <strong>and</strong> then drive a vehicle without<br />

blinking an eye,” Brewster says. It’s common<br />

for 3NV members to be versed in the skills to<br />

perform as many as four jobs. “It’s great for<br />

sick leave situations, or at times when certain<br />

assignments take precedence over others. And<br />

Many locals thought Clement<br />

was crazy to give Three Nations<br />

the scaling contract. It took less<br />

than a year for the critics<br />

to eat their words.<br />

it gives 3NV members the ability to apply for<br />

a variety of jobs if they choose to move on<br />

from Tembec.”<br />

Critics also suspected that it would be<br />

tough to train a group of<br />

log-yard newbies. “It’s not<br />

difficult at all,” Brewster<br />

replies. “It’s never difficult<br />

when you have folks who<br />

are eager to learn <strong>and</strong> deliver<br />

the goods.”<br />

From the outset, 3NV<br />

became adept at maintaining<br />

strict on-site safety<br />

st<strong>and</strong>ards. Brewster gives<br />

an example of the culture<br />

of safety that dictates the<br />

behaviour of his crew. “In<br />

many work environments,<br />

the norm is to have safety<br />

meetings monthly, but we<br />

have them weekly. Our<br />

motto is, if you think it’s<br />

unsafe or if you’re even slightly unsure of<br />

something, then don’t act. Call attention to<br />

your concerns.”<br />

It quickly became obvious to Clement<br />

that 3NV could run operations from scales<br />

to decks, so he was more than receptive when<br />

the organization expressed an interest in picking<br />

up other contracts. “We gave them the<br />

contract to load smelt onto rail cars, <strong>and</strong> they<br />

also picked up shunting, de-activation <strong>and</strong><br />

TOWN COUNCIL: Councilor Clarence Willson <strong>and</strong> Betty Brown<br />

with Chief Rol<strong>and</strong> Willson, of West Moberly First Nation, holding<br />

a copy of their safety award<br />

other contracts. In short, the business venture<br />

of 3NV became a sustainable business in its<br />

own right.”<br />

Three Nations Ventures decided early on to<br />

use <strong>Finning</strong> as its exclusive equipment dealer,<br />

a decision made partly because the equipment<br />

previously used by Louisiana-Pacific<br />

could only deck logs up to 24 feet compared<br />

to Caterpillar’s 325MHs, which could deck<br />

up to 30 feet, increasing log yard capacity by<br />

20 tracks & treads • Fall 2008 www.finning.ca

20 percent. “These logs are only eight feet<br />

wide, but not once have we had a deck fall,”<br />

Mortenson says. “We inherited some pieces<br />

of L-P equipment, but everything has been replaced<br />

by Cat. We prefer the way the machines<br />

run <strong>and</strong> they have been an integral part of our<br />

efficiency.”<br />

<strong>Finning</strong>’s Fort St. John forestry customer account<br />

manager Damien Bennett ranks Three<br />

Nations Ventures as “one of our best customers.<br />

They have their own mechanics for general<br />

repairs <strong>and</strong> maintenance but rely on us for the<br />

more complicated work <strong>and</strong> are very proactive<br />

in preventive maintenance. In fact, I would say<br />

they are meticulous. Plus, they’re good communicators,<br />

which is essential in any dealercustomer<br />

relationship.”<br />

Typical of a good communicator is office<br />

PASS THE SAULTEAU: Saulteau First Nations<br />

b<strong>and</strong> member Tom Aird, barbecuing for the<br />

crew, jokes with Warren Garbitt (in the hard<br />

hat) <strong>and</strong> company president, Darrell Garbitt<br />

(left). West Moberly First Nations elder Max<br />

Desjarlais is looking things over<br />

manager <strong>and</strong> Saulteau member Niki Courtorielle,<br />

a four-year veteran of 3NV, who never<br />

seems phased by her hectic work environment,<br />

no matter how busy things get. “Everyone<br />

encourages each other around here,”<br />

she says. “And consequently I look forward to<br />

coming to work every morning, no matter the<br />

problems we might face.”<br />

Any group has its whiz kid, <strong>and</strong> at 3NV<br />

that person would be Tom Aird, whose computer<br />

skills frequently amaze Brewster. “Tom<br />

has set up computer systems for the oil <strong>and</strong><br />

gas industry <strong>and</strong> government, <strong>and</strong> he does<br />

everything at 3NV from h<strong>and</strong>ling human resources<br />

to accounting,” Brewster says. “He’s<br />

also one of these guys who, if you complain<br />

to about some sort of computer problem,<br />

takes a look at what’s wrong <strong>and</strong> says something<br />

like `It‘s not a big deal,’ then fixes it in a<br />

flash,” Brewster adds.<br />

Aird, who also owns his own logging company<br />

in Fort St. John <strong>and</strong> is a father of five,<br />

prefers to deflect such praise towards his colleagues.<br />

“Binding us together is a strong sense<br />

of community,” he says. “We support community<br />

events, we’re very active in local sports <strong>and</strong><br />

charities, <strong>and</strong> we nurture a sense of looking<br />

out for one another. Beyond our commitment<br />

to Tembec <strong>and</strong> beyond advancing First Nations<br />

causes, we’re investing in our children’s<br />

welfare. This is all about opening the door of<br />

opportunity for them.”<br />

As 3NV celebrates its fifth year of success, its<br />

members weigh in about how influential the<br />

business may be in the gr<strong>and</strong> scheme of things.<br />

“On a regional scale, at least, the word is out<br />

that this is a great breakthrough,” says Brewster.<br />

Mortenson agrees, even though he concedes<br />

that cultural prejudice is still alive <strong>and</strong><br />

well in some sectors. “But change is slowly<br />

coming,” he says, “just as society’s attitude<br />

towards women slowly evolved for the better.<br />

Until the day comes when everyone is<br />

treated equal, we’ll just keep working hard<br />

<strong>and</strong> breaking records.”<br />

To which Clement replies, “3NV is a real<br />

asset to Tembec. They’ve done everyone<br />

proud.”<br />

www.finning.ca Fall 2008 • tracks & treads 21

EQUIPMENT PROFILE: Mixcor Aggregates Inc.<br />

22 tracks & treads • Fall 2008 www.finning.ca

a little tLc today could help put<br />

the sparkle back in your scraper<br />

<strong>and</strong> avoid a world of pain<br />

Story by KaThERINE FawcETT<br />

photogrAphy by KELLy REdINGER<br />

MIX IT UP: Terry Mix, left, <strong>and</strong> Robert Knoll<br />

check out Mixcor’s 980G before they get the<br />

day’s work underway<br />

E<br />

veryone at work knows that if you drive Robert<br />

knoll’s 980G loader, or his new 980H, you’d better<br />

use the boot-cleaning brush mounted to the steps of the<br />

ladder before you get in. <strong>and</strong> don’t forget to sweep it out<br />

when you’re done. You could almost eat off the floor of his<br />

machines. “Not that I’d want to,” jokes the veteran operator.<br />

“But you could.”<br />

Meticulous about the care <strong>and</strong> maintenance of all the equipment<br />

he uses, the cat 980G has been knoll’s baby since the winter<br />

of 1996. “Baby” recently celebrated 25,000 hours of use, loading<br />

pit run <strong>and</strong> crushed gravel into trucks. that’s almost three full years<br />

worth of hours – a mighty feat, even for a cat.<br />

knoll has been a loader-operator with Leduc-based Mixcor aggregates<br />

Inc., a second-generation aggregate s<strong>and</strong> <strong>and</strong> gravel company,<br />

for 17 years. Mixcor supplies materials for roads <strong>and</strong> commercial developments<br />

in edmonton <strong>and</strong> throughout central alberta. the family-run<br />

company recently wrapped up a large project that involved<br />

providing half a million tons of gravel for the expansion of the edmonton<br />

International airport.<br />

Mixcor president terry Mix says that guys like knoll – conscientious<br />

<strong>and</strong> detail-oriented – allow the company to get the most out of<br />

its machines <strong>and</strong> finish its jobs on time <strong>and</strong> without incident.<br />

“He’s very observant,” says Mix. “He’ll notice if you touch a tire.<br />

robert has the reputation of being the fussiest, keeping the cleanest<br />

loader <strong>and</strong> accurately loading the most material in a day.”<br />

www.finning.ca Fall 2008 • tracks & treads 23

EQUIPMENT PROFILE: Mixcor Aggregates Inc.<br />

A LONG LOOK: Part of preventive maintenance<br />

involves knowing a machine <strong>and</strong> inspecting it<br />

carefully, like operator Kevin Unger is doing here<br />

The daily dem<strong>and</strong> on Knoll <strong>and</strong> his machines<br />

is gruelling. “It’s not just working eight<br />

hours a day in some cushy job loading wash<br />

rock,” says Mix. “He’s loading s<strong>and</strong> <strong>and</strong> gravel<br />

from pit run. Vehicles are lined up every day.<br />

Ten to 12-hour shifts, loading up to 10,000<br />

tons per day of gravel into trucks.”<br />

Mix admits he’s pleasantly surprised at<br />

how reliable <strong>and</strong> productive the older machine<br />

has been. “The paint is a little faded, but<br />

other than that it’s in mint condition.”<br />

<strong>Finning</strong> representative Len Bushell<br />

recently sold Mixcor the 980H. When he<br />

saw the G with 25,000 hours, he too was surprised.<br />

“I went ‘What You’ve got to be kidding<br />

me.’ It looked as good as the br<strong>and</strong> new<br />

one. It just goes to show what you can do with<br />

a good reliable machine, good preventive<br />

maintenance <strong>and</strong> a good operator.”<br />

Preventive maintenance is something<br />

Knoll swears by. It starts with the daily walkaround.<br />

“I throw my lunch kit in the cab <strong>and</strong> do<br />

the walk-around,” says Knoll. “Every morning.<br />

Same thing at night,” says Knoll. “I’m<br />

picky. I’ve mellowed out a bit now, but you’ve<br />

got to be on top of things.”<br />

He checks for leaks, checks wheel nuts<br />

by running his h<strong>and</strong> around them, checks<br />

bucket pins <strong>and</strong> makes sure the windshield<br />

is clean. He says that even making sure the<br />

mirrors are adjusted right is part of preventive<br />

maintenance. It also means being diligent<br />

with the 200-hour <strong>and</strong> 500-hour servicing.<br />

Some of this work is done in-house, some requires<br />

<strong>Finning</strong>-certified technicians, but all is<br />

carefully recorded.<br />

“We’ve probably touched every major<br />

component in that machine but we’ve never<br />

had a major component cause any downtime.<br />

It’s always been a planned replacement<br />

or rebuild, from hydraulics to engine,” says<br />

Mix proudly.<br />