final feb cover - Indian Airforce

final feb cover - Indian Airforce

final feb cover - Indian Airforce

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

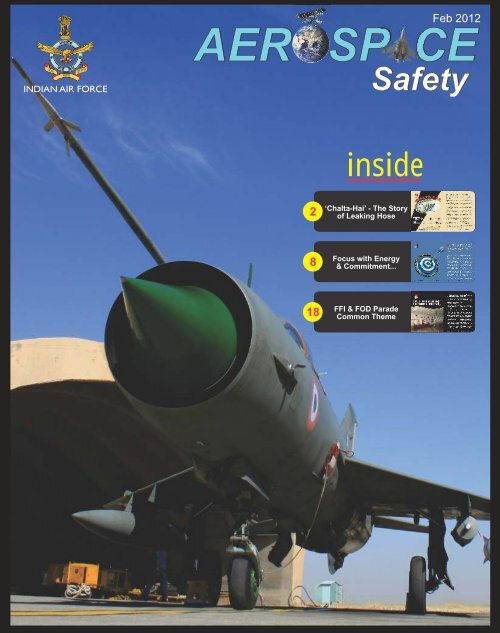

Feb 2012<br />

AEROSP CE<br />

Safety<br />

inside<br />

2<br />

‘Chalta-Hai’ - The Story<br />

of Leaking Hose<br />

8<br />

Focus with Energy<br />

& Commitment...<br />

18<br />

FFI & FOD Parade<br />

Common Theme

Feb 2012<br />

AEROSP CE<br />

Vol.193<br />

Safety<br />

Director General (Inspection & Safety)<br />

Air Mshl AP Garud VM<br />

Principal Director Aerospace Safety<br />

Air Cmde R Marwaha VSM<br />

Chief Editor<br />

Gp Capt DK Singh<br />

Editors<br />

Wg Cdr GS Bishen<br />

Cdr Nikhil Saolapurkar<br />

Sqn Ldr Shashank Sharma<br />

Editorial Assistants<br />

Mr Rakesh Kumar Singh<br />

Mrs S Sangeetha<br />

Cpl RS Thokchom<br />

Graphic Design<br />

JWO G Ramesh<br />

Sgt Chetan Chauhan<br />

Sgt DK Chatterjee<br />

Mr Rajib Paul<br />

Articles/Suggestions may be sent to:<br />

Editor, Aerospace Safety<br />

Institute of Flight Safety<br />

Air Force Palam, New Delhi-110 010<br />

Tele : 011-25672871, 23247789(AFNET)<br />

Fax: 011-25675059<br />

e-mail: editorfsmiaf@yahoo.com<br />

AFNET: flightsafety@dg.iaf.in<br />

Every article must be accompanied<br />

by a brief bio-data and passport size<br />

photograph of the author.<br />

'Aerospace Safety' magazine can be<br />

viewed on the intranet at<br />

http://www.iaf.in/dg/dgissite/fltmagazine.htm<br />

and on the internet at<br />

http://www.indianairforce.nic.in<br />

Suggestions and inputs on Quality<br />

Control issues of the IAF could be sent<br />

to DG(I&S), IAF by e-mail at the<br />

following address: dg_is@yahoo.com<br />

Round-the-clock contact of Principal<br />

Director Aerospace Safety:<br />

Tele:<br />

011-26172738 (Off)<br />

21125130, 21125131 (AFNET)<br />

011-27018241 (Res)<br />

+91-9717095606 (Mob)<br />

e-mail: pdfs_iaf_in@indiatimes.com<br />

AFNET: pdfs@dg.iaf.in<br />

inside<br />

2 Chalta Hai-The Story of Leaking Hose<br />

Gp Capt VVN Srikanth<br />

4 First Air Crash in the History of Aviation<br />

Gp Capt CN Ghosh VM<br />

8 Focus with Energy & Commitment, Execute with Passion<br />

and Precision<br />

AVM Subramanyam<br />

12 MCC - A Bond between Operation and Maintenance<br />

Sgt Aruni Kumar<br />

16 The Over Enthusiastic Comrade<br />

Sqn Ldr MD Sharma<br />

18 FFI and FOD Parade: Common Theme<br />

Gp Capt Narinder Taneja<br />

22 Why this ‘Press-on-Itis’ Ji<br />

Wg Cdr Ashish Kapoor<br />

26 Safe Ground Runs and Safety Norms<br />

WO Kishore Kumar S<br />

28 Accident Brief<br />

32 Good Show<br />

34 Well Done<br />

36 Message<br />

2 12<br />

18<br />

The opinions expressed in the ‘Aerospace Safety’ magazine are<br />

the personal views of the authors, and do not reflect the official<br />

policies of Air HQ. Contributions are welcome, as are comments<br />

and criticism. The Editorial Board reserves the right to make any<br />

improvement/change in the manuscripts.

Editorial<br />

he article on 'First Air Crash in the History of Aviation' takes us down the memory lane and<br />

recounts the initial odds in the history of aviation. We have indeed moved a long way in the<br />

Tform of technological advancements in the field of aviation and the way we in which any<br />

mission is carried out in present day scenario.<br />

The intricacies involved in a successful mission in the present day, especially in military<br />

aviation, pose a comprehensive challenge and necessity of effective and meticulous synergy. Once<br />

this is achieved or close to it, there comes the 'Human Factors' in undertaking the set organizational<br />

goals effectively and still safely. The articles like 'Chalta Hai', 'MCC – A Bond Between Operations<br />

and Maintenance' and 'Safe Grounds Run and Safety Norms' highlight the importance of these<br />

intricacies and the need to undertake the given task meticulously.<br />

The necessity of grooming an Airwarrior with multi tasking capabilities and its inherent<br />

challenges in the form of loss of 'focus' towards undertaking a mission or achieving a target needs<br />

attention. The supervisors at all levels need to be proactive in their approach in ensuring that the<br />

present genre of Air warriors are focused in their tasks and carry no distractions to the aircraft.<br />

Happy landings!<br />

(DK (DK Singh) Singh)<br />

Group Group Captain Captain

Gp Capt VVN Srikanth<br />

2 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

When questioned as to when had the leak started,<br />

he replied that it had been there for a long time and<br />

since there was only one refueling cart in the unit,<br />

it could not be repaired<br />

This incident happened in a RPA Sqn. The RPA<br />

refueling is done with the help of a wheel<br />

based refueling cart that is towed by the MM<br />

Jeep. It is a gravity based refueling equipment<br />

which has a long hose pipe. One day while strolling<br />

on a routine walk around the Sqn Hangar, I noticed<br />

a Heron RPA being refueled by the tradesmen on<br />

duty. The senior most technical tradesman present<br />

there was a Sgt with 18 years of service with a team<br />

of two LACs with limited experience on the RPAs. It<br />

was noticed by me that the fuel was leaking from<br />

the metal joint of the refueling hose and there<br />

was a pool of fuel on the ground. It was evident<br />

that the tradesmen were aware of the leaking hose,<br />

but continued with their refueling activity. On<br />

questioning the Sgt as to why he was continuing<br />

in-spite of fuel leakage, he replied that such<br />

leakage is normal and that there was no problem<br />

in continuing with the refueling activity. Once the<br />

refueling was completed the safaiwala would come<br />

and mop up the fuel on ground. When questioned<br />

as to when had the leak started, he replied that it<br />

had been there for a long time and since there was<br />

only one refueling cart in the unit, it could not be<br />

repaired. The refueling activity was stopped by me<br />

and it was directed that the refueling be done only<br />

if the hose was repaired even at the cost of stopping<br />

flying. The hose was repaired locally by changing<br />

the rubber seal in about an hour.<br />

It is evident that the refueling activity with<br />

the leaking hose continued due to the ‘Chalta Hal’<br />

attitude. Even the senior supervisors continued<br />

with the practice. Analysis of the event brought out<br />

following aspects:<br />

The senior Sgt had in the past probably<br />

seen refueling activity being undertaken with a<br />

leaking hose while working on other ac and felt<br />

that it was safe. Having such activities/shortcuts<br />

being adopted as he grew up in service, as a<br />

senior supervisor he permitted similar activity. It<br />

was indirectly being conveyed to those young<br />

tradesmen who would continue in service for<br />

another 15-20 years, that such wrong practices/<br />

shortcuts are acceptable.<br />

There needs to be proper supervision of<br />

all activities, and no shortcuts should be adopted<br />

which could lead to the juniors observing and<br />

learning from each one of us.<br />

In this case the Sgt cannot be blamed<br />

because he grew up in the system fraught with<br />

such examples. I am sure there is no aviator who<br />

has not come across a scenario wherein the aircraft<br />

were refueled with leaking hoses. Those from<br />

the MiG-21 fleet are aware of instances wherein<br />

the engine tradesman sits on the fuselage and<br />

refuels with fuel dripping from the sides a practice<br />

accepted as normal procedure.<br />

All of us agree that a right man for the right<br />

job is very important. But, it works only when the<br />

right man gets the right training at the right time.<br />

Correct lessons should be imparted at all times<br />

and incorrect practices nipped at the budding<br />

level for a safe and bright aerospace power.<br />

It is very true that, “What mind does not<br />

know eyes cannot see” -Therefore, be aware and<br />

be conscious of Safety. ‘It is not my job’ and ‘chalta<br />

hai’ attitude are sure precursors to an accident/<br />

incident.<br />

-Gp Capt VVN Srikanth<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 3

BLAST FROM THE PAST Safety Journal Vol XXIX, 1/90<br />

Gp Capt CN Ghosh VM<br />

Orville Wright was the first of the two<br />

creators of the modern aeroplane, who<br />

also met with an air-crash in the very<br />

beginning of the history of aviation. Luckily,<br />

this disaster did not turn him away from planes,<br />

otherwise what turn the history of aviation may<br />

have taken is anybody’s guess. The courage and<br />

determination, so typical of a flyer, that Orville<br />

displayed then, is being emulated and displayed<br />

even today by thousands of flyers all over the<br />

world.<br />

It was thick of winter. On 23 December 1907<br />

the slumber of the US Army was disturbed by what<br />

is a quirk of history. The US Signal Corps decided<br />

to buy a lighter than air machine and advertisedaccordingly.<br />

The advertisement stated :-<br />

“Lighter than air machine is required. It should<br />

have the capability to carry two men on a sustained<br />

flight of sixty minutes. Its range should be atleast<br />

125 miles and an average speed of 40 miles over a<br />

course of ten miles had to be attained. The ability<br />

should be there to steer it in all directions easily.<br />

Also the plane had to be constructed in such a way<br />

that it could be taken apart for transportation by<br />

truck and easily reassembled.”<br />

The advertisement stirred a hornets’ nest.<br />

The Signal Corps become a centre of journalistic<br />

4 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

abuses, not because it had been slow to recognise<br />

the invention, but because it had done so at all.<br />

The New York Globe wrote in an editorial :-<br />

“One might be inclined to assume from the<br />

following announcement “The US Army is asking for<br />

bids for a military airship” that the era of practical<br />

human flight had arrived or that the government<br />

had seriously taken up the problem of developing<br />

this means of travel. A very brief examination of<br />

the conditions imposed suffices, however to prove<br />

this assumption a delusion. A machine such as is<br />

prescribed on the Signal Corps specifications would<br />

record the solution of all the difficulties in the way<br />

of the heavier than air airships, and, in fact, <strong>final</strong>ly<br />

give mankind almost as complete control of the<br />

air as it now has of the land water. Nothing in any<br />

way approaching such a machine has even been<br />

constructed.”<br />

The Globe brushed aside the claims of Wright<br />

brothers as unconfirmed rumour.<br />

Even the American magazine of Aeronautics<br />

in its January 1908 edition castigated the Signals<br />

Corps for its imaginative scheme. It said “There<br />

is not a single flying machine in the world which<br />

could fulfil these specifications at the present<br />

moment perhaps the Signals Corps has been too<br />

much influenced by the hot air of theorizers in<br />

which aeronautics unfortunately abounds.<br />

The press was more or less correct at that time<br />

because no lighter than air machine could have<br />

satisfied the Army requirement. But press was also<br />

totally unaware that two years earlier in 1905 the<br />

Wright brothers had made more than 40 flights<br />

in an improved model of their original biplane at<br />

Huffman’s pasture on the outskirts of their native<br />

Dayton, Ohio. The journalistic fraternity did not<br />

show any interest about the happenings at Dayton<br />

and did not give any credence to the claim of the<br />

Wrights.<br />

However, in response to the advertisement,<br />

the War Department received 41 applications. The<br />

War Department was shocked by this because they<br />

were more or less sure that only one application<br />

would come, that too from Wright Brothers. On<br />

scrutiny it was found that most applications were<br />

the brainstorm of imaginatives. All but three<br />

applications were rejected because they did not<br />

put up a required 10 per cent of the proposed<br />

cost of the airplane as security deposit. A Chicago<br />

inventor JF Scoot deposited $ 1000 and promised<br />

delivery within 185 days. Another was a well<br />

known experiment. August M. Herring promised<br />

to deliver a plane within 180 days at a cost of<br />

20,000 dollars. The Wrights bid was $ 25,000 with<br />

delivery in 290 days.<br />

The War Department was in a fix. Receipts<br />

of the two unforeseen bids created a problem.<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 5

Chances were that Herring and Scoot had nothing<br />

practical to offer. But as per the regulations, the War<br />

Department was committed to giving the contract<br />

to the lowest bidder. They were also worried because<br />

if Herring and Scoot failed to deliver anything, the<br />

War Department would face severe criticism from<br />

an already skeptical press. Faced with this dilemma<br />

General Alklen accompanied by Captain Chandler<br />

called upon Secretary of State William Howard<br />

Taft. Taft immediately went to President Roosevelt,<br />

who was a staunch supporter of flying and could<br />

possibly guarantee payment to all the successful<br />

bidders. As expected President Roosevelt agreed<br />

to pay for all the three successful machines from<br />

the contingency fund at his disposal. The War<br />

Department thereafter announced that it would<br />

buy three planes from each of the three bidders<br />

if they confirmed to the specified requirements.<br />

On receipt of this communication, Scoot removed<br />

himself from the competition and asked for the<br />

refund of his deposit money. Though it was<br />

supposed to be forfeited, the War Department<br />

repaid the amount in order to save the trouble and<br />

possible disappointment of testing an aeroplane<br />

that may not get off the ground. But Herring did<br />

not give up so easily. He tried his best to get the<br />

contract and sub-contract the same to Wright<br />

brothers. However on 08 February 1908 the Wright<br />

brothers were given contract with a provision that<br />

10 percent of $ 25,000 purchase price would be<br />

deducted for each mile per hour the machine fell<br />

short of the forty mile per hour goal.<br />

For instance, if the machine flew only thirty nine<br />

miles per hour, the Wrights would be penalised<br />

2,500 dollars, if only thirty eight miles then<br />

another 2,500 dollars would be subtracted from<br />

the purchase price and so on. But the contract also<br />

said that a 10 cent bonus for each mile per hour<br />

the plane attained above the stipulated speed,<br />

would be paid.<br />

Having signed this historical contract the<br />

Wright brothers concentrated towards the<br />

development their machine. During all their early<br />

experiments they had continued to fly lying prone,<br />

upto the lower wing, caged in by struts and wires<br />

and directed plane by shifting the hips from side to<br />

side. This was not a practical thing and as a result<br />

the brothers devised a different control system<br />

to enable the pilot to sit and fly. Over the leading<br />

edge of the bottom wing they installed two seats,<br />

one for the pilot and the other for the passenger.<br />

They also invented a new engine capable of<br />

producing thirty five horse power steadily.<br />

The Wright Brothers built two machines as<br />

per the specifications and flew them at Kitty<br />

6 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

Hawk. One them was to be taken by Orville to<br />

Fort Myer, Virginia for the demonstration before<br />

the War Department officials. The other airplane<br />

was to go with Wilber to France where a separate<br />

syndicate had been formed to produce Wright air<br />

planes and to sell them to European Governments.<br />

Before his departure, Wilber decided to try the<br />

plane’s ability to carry two men. He flew with<br />

Charles W Furnas, a Mechanic in their factory, on<br />

14 May 1908. Therefore, Charles Furnas can be<br />

called as ‘History’s First Airplane Passenger’.<br />

Orville arrived at Fort Mayer in the third<br />

week of August, and on 3rd September he<br />

decided to carry out his first flight. But again<br />

there was a general lack of interest which<br />

disheartened Orville. The press refused to give<br />

any credit to the Wright Brothers. However the<br />

second demonstration flight was well attended,<br />

thousands of people thronged the field to watch<br />

this astonishing spectacle. Presumably the press<br />

was informed earlier, as a result, reporters flocked<br />

to the field to see the second flight. Orville took<br />

his friend, Lt. P Lahm, a Signals Corps balloonist,<br />

for a six aerial trip. Gradually Orville increased his<br />

endurance in the air until on 17 November, when<br />

Orville met with the first disaster.<br />

mishap, the newspapers however did not forget to<br />

report the stunning achievements of the Wright<br />

airplane also.<br />

Next year on July 27, Orville fulfilled the<br />

War Department requirement. He exceeded the<br />

requirement for a two man flight with lieutenant<br />

Lahin as passenger. He remained in the air for one<br />

hour, twelve minutes and forty seconds. Three<br />

days later on 30 July he made a speed run with<br />

Lieutenant Benyanin D Foulais aboard, averaging<br />

42.5 miles per hour over a ten miles route. The<br />

Signals Corps took delivery of the machine on 02<br />

Aug 1909 and the Wrights were paid 5000 dollars<br />

as bonus because the speed limit was exceeded<br />

by two miles. The aeroplane was intended purely<br />

for scouting and communication work. Thus the<br />

Wright flyer was the FIRST MILITARY AIRPLANE to<br />

be put into practical service by any government.<br />

It was used that October at the newly established<br />

Army airfield at college park, Maryland, to teach<br />

two Signal Corps officers to fly. Wilbur Wright was<br />

their first instructor.<br />

-Gp Capt CN Ghosh VM<br />

On that date Lieutenant Thomas E Selfridge<br />

wanted to be the passenger with Orville. Orville<br />

acceded to his request and took off with Selfridge<br />

as the passenger. The plane climbed to an altitude<br />

of 125 feet and was in a turn, when suddenly the<br />

starboard propeller cracked.<br />

The aircraft came out of the turn, losing its<br />

thrust. The disparity in pitch between the two air<br />

screws caused a terrific vibration to that flimsy<br />

structure. Orville tried an emergency landing<br />

but the rudder collapsed The plane crashed from<br />

fifty feet off the ground. The First Disaster in<br />

Aviation History took place. Selfridge died<br />

within few hours of the crash. Orville survived<br />

with a fractured left thigh, four broken ribs and<br />

severe shock. The mishap became a front page<br />

news in the newspapers. While writing about this<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 7

AVM Subramanyam<br />

8 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

“<br />

I have three focus areas for you- The first is<br />

that come what may, SU-30s moves in here by<br />

1 st April. The second is that the operating surfaces<br />

need lot of attention, and thirdly, the bird activity<br />

gives me nightmares. I don’t care if paperwork<br />

suffers or if command rings me up ...<br />

When Sachin Tendulkar puts his pads<br />

on in the dressing room and waits for<br />

his turn at the nets or to go into bat<br />

during a match, nobody dares talk to him as he<br />

retreats into his ‘Zone’. One of the most endearing<br />

photographs of the penalty shootout that<br />

decided the 1992 football World Cup <strong>final</strong> was<br />

the one that caught the German goalkeeper, Jens<br />

Lehman, staring into oblivion even as his coach<br />

was desperately trying to shove a piece of paper<br />

into his hands. The paper had all the details of<br />

Argentinian penalty takers. All he did was to look<br />

at two names; the names of the two penalty takers<br />

who had the most predictable directions. Jens<br />

Lehman saved both those penalties by diving the<br />

right way. Talk to any solo mountaineer or read<br />

their memoirs. When they crawl out of their tents<br />

early in the morning for the <strong>final</strong> assault, the first<br />

thing they do is to look up, size up the enemy,<br />

slowly gather their kit to give themselves time<br />

to go over the plan for the last time with go-nogo<br />

and contingency plans, say a prayer, look at<br />

the watch and set off. Closer home, how many<br />

times have you seen a colleague sit quietly for<br />

a moment or two before a sortie, trying to declutter<br />

his mind and focus on the job at hand. At<br />

the same time, how many times have we seen a<br />

Flt Cdr or a CO, break away from a formation as<br />

it is walking to the aircraft saying “I’ll be back in<br />

a minute, AOC is on the line”, So then! I can hear<br />

many of you say; “What’s the big deal” The deal<br />

here honey is all about focus and execution, two<br />

very vital ingredients of Mission Accomplishment<br />

and Flight Safety.<br />

Apart from Mission being the first of the three<br />

IAF Core Values, why I have chosen to concentrate<br />

on Focus and Execution is because these are<br />

areas that need constant attention and have the<br />

greatest impact on Flight Safety. Let me begin<br />

with Focus. I have a serious problem with trying<br />

to understand as to how we can retain focus in<br />

an environment that does its best to distract us.<br />

Then, we are told that we have to multi-task! The<br />

icing on the cake is when we are told to shift focus<br />

without adequate explanation and expected to<br />

cope. What Chaos!! Why did I say-Chaos If you<br />

understand the concept of Chaos in modern day<br />

living and warfare, you will be able to focus with<br />

intensity on the right things at the right time.<br />

The onus of creating an environment wherein<br />

different layers of leadership have different<br />

spans of focus rests with senior leadership. The<br />

mechanics of focus differs at various levels and<br />

defining these areas is the key to focus oriented<br />

leadership. Lest the reader thinks that I am<br />

waffling around with words, let me try and give<br />

you a practical example of what focus means to<br />

different people. An AOC-in-C of an operational<br />

command has numerous focus areas, which he<br />

prioritises and aligns with the tasks assigned to<br />

his command and the overall Mission Statement<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 9

of the IAF. He focuses, delegates, shifts focus,<br />

monitors execution, evaluates results, comes<br />

back to the original point of focus and continues<br />

with this chain. Along the way, he drops issues,<br />

adds on issues and in the process creates a focus<br />

chain that is self-sustaining if there is energy and<br />

commitment in the system. Moving down the<br />

chain, what does focus mean at the station level.<br />

I took over as COO at one of the premier air bases,<br />

which was getting prepared for the new induction<br />

of SU-30s. The AOC there, a man of few words,<br />

spoke in monosyllables and dismissed you from<br />

his office in five minutes by swivelling in his chair<br />

back to a game of Solitaire. In my first meeting<br />

with him sometime in Jan 2004, he told me very<br />

bluntly, “Subbu, I have 3 focus areas for you- The<br />

first is that come what may, SU-30s moves in here<br />

by 1 st April. The second is that the operating<br />

surfaces need lot of attention, and thirdly, the<br />

bird activity gives me nightmares. I don’t care<br />

if paperwork suffers or if command rings me up<br />

about minor snafus from your end, but I want<br />

you on the move, on the airfield, in the towereverywhere<br />

except your office” He asked me to<br />

bring him a plan of action in one week, approved<br />

the plan with minor modifications and followed it<br />

up with full support. To say that we worked hard<br />

would be an understatement and I can say without<br />

hesitation that it was only Focus with loads of<br />

luck and nothing else that facilitated accident<br />

10 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

free flying during the initial months after the SU-<br />

30s inducted at Bareilly. I do not have an issue<br />

with energy, I have seen that our people have no<br />

shortage of energy; it is just that leadership at all<br />

levels need to channelize and focus that energy.<br />

There is no shortage of commitment either, but<br />

a trend that I have seen setting in is that the gap<br />

between the fully committed and the partially<br />

committed is growing wider. To my mind, this is<br />

inevitable in the light of multiple environmental<br />

pressures and opportunities. Today, commitment<br />

is not only a function of your duty& pride for<br />

the uniform, but also about opportunity. While<br />

duty, honour, country, service and unit remain as<br />

important as ever, let us not be overly altruistic.<br />

As a strategy, it may be a good idea to also link<br />

Focus and commitment with opportunities for<br />

personal growth and progress.<br />

Enough about Focus but let me shift focus<br />

onto Execution with Passion and Precision as it<br />

is directly linked to Excellence, the second of the<br />

IAF Core Values. I have no issues with our ability to<br />

execute with precision. It is the passion that I have<br />

seen missing at times. Where is passion actually<br />

needed Certainly not in the cockpit! You need<br />

passion in the preparatory phase before any mission<br />

or project. It is passion that will allow you to dig up<br />

all possible that there is to know about an adversary,<br />

a target, or a system. It is passion that will allow you<br />

to analyse trends and bring that extra bit to the<br />

table, the extra bit that may, in the <strong>final</strong> analysis,<br />

be the difference between success and failure,<br />

or even between life and death During the Kargil<br />

Operations, 17 Sqn could not have maintained 100%<br />

serviceability without passionate commitment from<br />

the STO and his team. Op Geronimo, the mission to<br />

kill Osama-Bin-Laden succeeded without any own<br />

casualties because of Execution with passion and<br />

precision. It also succeeded because of relentless<br />

Focus. So! In your own areas and in your own<br />

humble ways think about<br />

- AVM Subramanyam<br />

Focusing with Energy<br />

& Commitment<br />

Executing with Passion &<br />

Precision<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 11

Sgt Aruni Kumar<br />

12 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

MCC is central repository of information related to<br />

maintenance personnel, equipment and activities<br />

and the successful function of the whole organization<br />

depends upon continuous exchange of information<br />

among them.<br />

Aerospace Power is widely accepted as<br />

the most important factor of future<br />

wars. This is primarily attributable to its<br />

incredible versatility and applicability in any<br />

situation, whether in peace or in conflict. The<br />

exponential increase in Aerospace Power over<br />

the period is attributable to advancements in the<br />

technology. Technology and Aerospace Power<br />

is synergistically linked and these advancements<br />

impinge on the overall maintenance philosophy<br />

of aerospace systems. Only after an affirmation<br />

of optimum level of maintenance on ground<br />

can an operational mission commence. Just like<br />

the maxim “front is do co mo”, maintenance is<br />

do co mo (do co mo is a Japanese word means<br />

“everywhere”). Maintenance in broader sense<br />

involves all activities and actions taken to prepare<br />

man and machine for operations and sustain the<br />

same with required intensity and duration.<br />

In order to achieve the optimum level<br />

of maintenance in the field there is a great<br />

need to develop a philosophy of maintenance<br />

management. In this case, ‘CONTROL’ becomes<br />

one of the key factors of this management<br />

theory. It is on the lines of the same that the<br />

‘Maintenance Control Center’ has evolved in our<br />

esteemed organization.<br />

Maintenance Control Centre was brought<br />

into existence as per AFO 71/71 with a specific<br />

aim to obtain the most effective and efficient use<br />

of all available resources of manpower, aircraft<br />

and other technical resources. It is this setup,<br />

through which close direction and control of the<br />

maintenance activities is done. For the system<br />

to fulfill this aim, all the relevant information in<br />

respect of aircraft, manpower, ground support<br />

equipment, materials, spares and servicing work<br />

load is made available to it, through an efficient<br />

communication system.<br />

Considerable improvement in maintenance<br />

efficiency could be seen after the set up of MCC.<br />

This has become possible due to observance of<br />

the underlined principles :<br />

Clarity of purpose.<br />

Economy of effort.<br />

Maintenance of morale.<br />

Accountability.<br />

MCC : A BOND BETWEEN OPERATION AND<br />

MAINTENANCE<br />

Operational and Maintenance philosophy<br />

in the present scenario has become so<br />

interdependent and overlapping that it is<br />

difficult to talk of any particular one in isolation.<br />

Maintenance Control Centre (MCC) plans all the<br />

maintenance activities in coordination with the<br />

operational commitments. Also, it plays a vital<br />

role in ensuring optimal techno logistic support.<br />

Various maintenance activities need to be<br />

studied in depth and deliberated in order to plan<br />

maintenance activities with an aim to ensure<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 13

minimum down time for an aircraft, besides<br />

monitoring the life of component.<br />

MCC is a maintenance organization which is<br />

seamless, adaptive and knowledge and capability<br />

centric. It has its appropriate place in the overall<br />

decision making process at higher levels of<br />

the organization. It is the central repository of<br />

information related to maintenance personnel,<br />

equipment and activities. The successful<br />

function of the whole organization depends<br />

upon continuous exchange of information<br />

among them. Today, in the era of information<br />

technology, rapid dissemination of information is<br />

imperative for the modern armed forces. Correct<br />

documentation along with fastest means of<br />

communication is an inevitable factor in effective<br />

maintenance administration which in turn has<br />

significant impact on the operational activities.<br />

All efforts need to be made to ensure<br />

effectiveness of MCC that enhance maintenance<br />

activities and in turn operational capabilities.<br />

Following are the suggested measures which<br />

must be taken into consideration to strengthen<br />

this bond :<br />

99 Proper planning before under taking any<br />

maintenance activities.<br />

99 Proper direction of the planned work.<br />

14 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

99<br />

Proper controlling of the planned work.<br />

99 Proper analysis of the activities and<br />

maintenance of technical records.<br />

99 Any Concessions need to be revalidated<br />

and action initiated for the same.<br />

99 Regular review of Tech Orders needs to<br />

be carried out.<br />

99 We must ensure that No aircraft passing<br />

out after servicing/major snag rectification is<br />

cleared till documents, including cannibalization<br />

are complete and vetted.<br />

99 In order to ensure that only capable<br />

person is working on the flying machine a<br />

proper record of proficiency book 1081 of<br />

every individual is to be maintained.<br />

99 Proper manning plan of the human<br />

resource.<br />

99 Finally, for all of the above, all necessary<br />

aids must be provided by the Technical<br />

administration.<br />

- Sgt Aruni Kumar<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 15

Sqn Ldr MD Sharma<br />

Ejections are associated with a significant<br />

possibility of spinal injuries. Therefore<br />

it is essential that an ejected pilot be<br />

immobilised at the landing site itself and<br />

transferred to a hospital with minimal handling<br />

so as to prevent any deterioration in his condition<br />

and to prevent any subsequent complications.<br />

However, to expedite the rescue proceedings,<br />

many a times, these pilots are brought to the<br />

SMC/hospitals in a friend’s car or motorbike.<br />

This well-intentioned action can have disastrous<br />

consequences for the injured pilot. It happened<br />

at our station once.<br />

The Institute of Flight Safety team was<br />

carrying out a practice inspection of our station<br />

and I was chosen to attend to any emergency<br />

that might require medical attendance.<br />

16 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

Surely enough, an on-base crash was<br />

simulated and the knight in shining armour<br />

with a stethoscope around his neck was called<br />

upon to attend to two aircrew who had ejected.<br />

Answering the call of duty, I reached the ‘crash’<br />

site and found two ‘pilots’ lying face down and a<br />

horde of people watching every action of mine.<br />

Not one given to stage fright, I turned the ‘ejected<br />

pilot over, applied the cervical collars, scooped<br />

them up in scoop stretchers and strapped them<br />

down on spinal board stretchers.<br />

Just as I started feeling good about a job<br />

well done, lo! Horror of horrors! An officer from<br />

our station drove up to the ambulance and<br />

opened the rear door of his car. What happened<br />

next was nothing short of a comedy of errors. He<br />

pointed to the rear seat and told me, “ I have an<br />

ejected pilot on the back seat. Evacuate him to<br />

the hospital!”<br />

Without batting an eyelid, I grabbed an<br />

innocent bystander airman; put him in the car’s<br />

rear seat, promptly put him on the stretcher with<br />

a cervical collar and loaded the stretcher on to<br />

the ambulance. Job done; story over! Or is it<br />

If one analyses the sequence of events, it was<br />

apparent that the ‘friend’ had no clue about what<br />

he was doing. The golden rule of evacuating an<br />

ejected aircrew is - Suspect spinal injury until<br />

proved otherwise and act accordingly. In such<br />

a situation, the last thing a doctor wants to see<br />

is the aircrew being brought to the hospital or<br />

SMC in a car, or even worse, a motorbike by an<br />

over-enthusiastic comrade rather than in an<br />

ambulance. However, in this particular case, this<br />

was precisely what had happened.<br />

Countless articles have been written in<br />

this regard and the issue has been discussed<br />

‘ad nauseam’ in various forums. However, such<br />

episodes still occur with alarming regularity.<br />

Why is it that despite considerable effort, ejected<br />

aircrew still arrive at the SMC/hospitals in cars or<br />

motorbikes<br />

There is an emergent need to sensitize our<br />

flying men and the medical men about the<br />

potentially catastrophic ramifications of such<br />

actions.<br />

In case of an ejection, the human spine is<br />

subjected to a considerable amount of force with<br />

a very high onset rate within a very short span<br />

of time. This, combined with the fact that the<br />

aircrew’s posture at the time of ejection might<br />

have been less than perfect, raises the distinct<br />

possibility of him having sustained a spinal<br />

injury. In such a situation, it is imperative that the<br />

spine be stabilised and movement restricted to<br />

a minimum before evacuating the pilot to the<br />

SMC/hospital. This not only stabilises the spine<br />

in case of a fracture, but also prevents further<br />

deterioration of the pilot’s condition which<br />

may result from unnecessary and completely<br />

avoidable movement.<br />

Carrying an ejected aircrew in a car or<br />

motorbike might sound like a good idea, especially<br />

if the pilot seems to be apparently alright and is<br />

walking and talking. However, nothing could be<br />

further from the truth. Given the fact that the guy<br />

just got his spine hammered along the long axis,<br />

allowance should always be made for an outside<br />

chance of a spinal injury. Even if he claims to<br />

be fine and is in high spirits, there might be an<br />

overt injury lurking underneath, which might<br />

be diagnosed later on MRI. At that moment, he<br />

needs to lie down, be immobilised so as to restrict<br />

spinal movement to a minimum and evacuated<br />

to the hospital. Sitting in a car or on a motorbike<br />

may aggravate the damage which might have far<br />

reaching consequences on the ejected aircrew’s<br />

flying career.<br />

The car might be air conditioned and very<br />

comfortable; but by giving a lift to the ejected<br />

aircrew, the well intentioned, over-enthusiastic<br />

comrade may end up doing more damage than<br />

good.<br />

-Sqn Ldr MD Sharma<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 17

Gp Capt Narinder Taneja<br />

18 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

Have you heard of the acronym FFI The<br />

most possible answer from across the<br />

readers would be yes. The acronym FFI<br />

stands for ‘free from infection’. As an Air warrior<br />

in charge of a small cafeteria serving tea to an<br />

individual section or a large Tech Flt cafeteria<br />

in the technical area of a base to the different<br />

messes, the word FFI is obviously familiar.<br />

Because, month after month and year after year,<br />

you will encounter the Medical officer coming<br />

on the monthly sanitary round or inspection<br />

(whichever way you may look at it) and asking<br />

for the FFI chart. The FFI is supposed to have the<br />

nominal roll of all food handlers working in an<br />

eating establishment. And the monthly record<br />

of their inspection by the SHO staff at the SMC.<br />

And yet, at least in a sizeable proportion of the<br />

eating establishments, the MO / SMO routinely /<br />

regularly observes in the sanitary diary that FFI<br />

chart not up-to-date.<br />

FFI is just one small component of the<br />

checklist that the MO is looking at during the<br />

sanitary inspection. You go through the sanitary<br />

diary of any station across the Armed Forces and<br />

you will find common threads across all of them.<br />

Pest-o-flash U/S, not installed, Aqua guard and<br />

coolers (leaking, U/S, not clean), food containers in<br />

the kitchen stores without lids/ kept on the floor/<br />

untidy/ inadequate, meat chopping block not<br />

maintained clean with salt on top, food samples<br />

inadequate in quantity/ not up to date/ not<br />

labeled etc. These are very common yet recurrent<br />

and almost ubiquitous observations.<br />

The question is : Why do we need a policing<br />

authority, so to say, to come every month and ask<br />

for the FFI chart when the implications of healthy<br />

food handlers are so obvious and known to<br />

everyone Why should food containers in a mess<br />

be inadequate or why should aqua guards not be<br />

repaired urgently/ immediately.<br />

Do the answers to these questions have<br />

relation with flight safety Though not obvious as<br />

a direct relation, the ensuing discussion will make<br />

it amply clear how we approach a preventive<br />

activity, be it preventive health and preventive<br />

medicine or preventive safety on ground or<br />

preventive flight safety.<br />

Besides the lack of importance given to any<br />

preventive activity, there are possibly more yet<br />

subtle and complex explanations that can also<br />

be put forward and placed in the context of flight<br />

safety.<br />

Ignorance<br />

It is possible that there is a general ignorance<br />

about the importance of public health measures<br />

among personnel at various levels of the<br />

organisation, starting from the Cdr at the base<br />

down to the last worker in the chain of individuals<br />

practicing public health measures.<br />

Inadequate interest in the job<br />

It is important that each and every person<br />

takes pride in his/ her job, be it the Safaiwala,<br />

the cook or the catering clerk in the mess. If we<br />

all decided that we would do the job to a high<br />

standard of excellence, we will automatically<br />

ensure that we are knowledgeable about the job<br />

and will play our role in either ensuring public<br />

health or in promoting positive health. If the food<br />

handling staff are aware that they have a skin<br />

infection and how it can cause a bout of food<br />

poisoning, they will themselves remain off from<br />

food handling duty and not wait for someone<br />

else to point that out. Good knowledge, the will<br />

to make a change and little extra effort will make<br />

a huge impact on public health. This is what<br />

preventive health is all about.<br />

Similar logic applies to FFI. Rather than taking<br />

it only as a medical inspection requirement, if<br />

the significance of FFI, of each element of the<br />

examination and hygiene of the food handlers<br />

is understood by the staff, then the staff will and<br />

should take pride in declaring themselves. ‘I am<br />

free from infection ‘are you’ (Something on the<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 19

lines of the slogan of Census of India 2011. I have<br />

been counted, have you)<br />

Inadequate Pride<br />

As was the case with inadequate interest<br />

so is inadequate pride in one’s job, sometimes<br />

presuming that it is a small job. The various<br />

categories of food handlers may be made to<br />

believe that there’s is a small time work, preparing<br />

and serving food day in and day out. Yet we can<br />

assist these people in developing sense of pride<br />

by recognizing their role in our health. .<br />

Recognition<br />

Pride also comes from recognition. My three<br />

best working hands in the SMC at my previous<br />

unit were the gardener, an ayah and a lascar. All<br />

these three individuals, performing seemingly<br />

ordinary work were duly acknowledged by the<br />

station with award of best civilian awards. They<br />

were our partners in success.<br />

FFI vs FOR<br />

Does the above explanation sort of ring<br />

common bells as far as flight safety is concerned.<br />

Let’s discuss one example of flight safety activity:<br />

FOR parade and see how it matches with FFI.<br />

Every morning in the briefing you will hear the<br />

ATC rep telling you that 40 people including two<br />

Safaiwallas reported for the FOR parade. Even if<br />

one is absent, the Group Cdr has an apologetic<br />

tone and tells the Cdr that he will find out about<br />

the defaulter and come back to him. Possibly 24<br />

or 30 people, who were doing the parade earlier,<br />

were missing foreign objects lying on the runway<br />

and the number had been increased to 40. Then<br />

one morning, an angry AOC got up and after<br />

a sarcastic smile, he suddenly shouted at the<br />

audience. FOR parade was a parade, gentlemen<br />

and not a stroll in the garden or a morning walk.<br />

FOR parade is serious business and if required,<br />

he will increase the number of people on the<br />

parade till he got an absolutely foreign object<br />

clear runway for flying ops. He meant business<br />

and he was absolutely right. But the question is<br />

what about those 40 people and 2 safaiwallas<br />

and the duty officer Are they ignorant Largely,<br />

No. Every Air Warrior in the IAF knows (or ought<br />

to know) the damage to man and machine even<br />

a small foreign object can do. It is just that some<br />

proportion of these people chose to decide that<br />

FOR is not my responsibility or there is no pride<br />

in the chore (which is a secondary duty to be<br />

logged).<br />

Inadequate knowledge understanding of the<br />

problem: A safety perspective.<br />

To be fair to a certain proportion of personnel<br />

who have spent their initial years in non-flying<br />

establishments, their awareness of flight safety<br />

20 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

activity and hazards to FS could be low. It is the<br />

organization’s responsibility that flight safety is<br />

taught right from the initial days of exposure to<br />

Air force. It should not be left to be an on the job<br />

exposure. It should also not be left to an individual’s<br />

motivation and interest to understand his role in<br />

flight safety And the flight safety people should<br />

best do this.<br />

Inadequate interest in job<br />

You detail an individual for a duty, which he<br />

does once in 2-3 months. Chances are that he will<br />

go, do the ‘duty’ without his heart in it. Does he<br />

put his full mind and body in the parade Very<br />

likely he may be proceeding on leave that dayor<br />

he is thinking that soon after the parade he<br />

has to take his pregnant wife to the hospital for<br />

a check up, or he has been put for this parade as<br />

a punishment. Can we expect any genuine work<br />

from him He may see and yet not see. You may<br />

want to say that all these are beyond the control<br />

of the organisation. The question is, we have<br />

heard time and again that aviators should leave<br />

all their worries when they enter the cockpit (Not<br />

that it may be humanly possible) but I have never<br />

heard in any FS talk that gentlemen, for that 40-<br />

45 mins of the FOR parade shut out your mind<br />

from all diversions. Your 100% focus should be on<br />

the runway and the foreign objects lying there.<br />

Pride and recognition<br />

I do not recall a FS award in the station to<br />

someone for doing a great FOR parade. Why don’t<br />

we announce that so and so people have picked up<br />

so many foreign objects in the month Announce<br />

the names of the members of the FOR parade of that<br />

day. Let there be a sense of pride and achievement<br />

that FOR is also acknowledged. Every foreign object<br />

that an individual picks up is eventually his significant<br />

contribution to FS by preventing an incident/<br />

accident. May be a slogan like: “each one, pick one,<br />

prevent one” to show as his contribution to FS will go<br />

a long way in enhancing safety.<br />

Where does the above discussion lead us to Any<br />

activity, whose results are not immediate, tends to<br />

get less of importance and attention. However, with<br />

dissemination of the importance of the activity, the<br />

critical role that each individual in the chain of that<br />

activity plays, it is expected that everyone involved<br />

will take pride in his role in preventing illnesses or<br />

incidents on the ground /air. Recognition should also<br />

be given to successful preventive activities that may<br />

not lead to immediate positive objective outcomes<br />

such as ensuring high hygiene and sanitation in<br />

the station of doing a marvelous job during an FOR<br />

parade.<br />

-Gp Capt Narinder Taneja<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 21

Wg Cdr Ashish Kapoor<br />

The radio jockey on the car stereo said that<br />

Kolaveri di means murderous rage and the<br />

song… well it has a catchy tune. I walked<br />

into the office with the freshness of the tune<br />

lingering in the mind. Later in the day, as I picked<br />

up yet another file on aircraft accident caused by<br />

press-on-itis or get-home-itis the phrase ‘Kolaveri<br />

di’ was replaced by ‘Why this press-on-itis ji’ A<br />

large number of accidents/incidents flashed<br />

across in my thoughts.<br />

Press-on-itis or Get-home-itis simply means<br />

the condition when a pilot undertakes a flight as<br />

per a fixed plan despite deteriorating conditions<br />

when common sense would have a dictated<br />

a more safer alternative say to divert or for a<br />

helicopter simply to carry out a precautionary<br />

landing.<br />

In Nov 2010, a Friday, a Mi-17 was to return<br />

back from a high altitude helipad detachment to<br />

a base in the plains on completion of detachment.<br />

The captain a Flt Lt, an experienced pilot in the<br />

area, was planned to go on leave the same evening.<br />

The co-pilot was another Flt Lt, a course junior to<br />

the captain, who was on his first commitment<br />

to the area. The CoI findings bring out that the<br />

reported weather was marginal at the helipad,<br />

Visibility 1500m in Rain and Mist and at the pass,<br />

Visibility 1000m partially clear, when the aircraft<br />

took off from the helipad at 1204h. At 1205h the<br />

weather at the helipad reportedly deteriorated to<br />

22 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

800m in Rain Fog! The aircraft crashed after a few<br />

minutes of Take Off. In the absence of flight data<br />

and cockpit voice recorder, both having been<br />

destroyed in the post accident fire, the exact<br />

cause of the crash has not yet been ascertained.<br />

Circumstantial evidence suggests that ‘Press-onitis’<br />

as a factor would have contributed to the<br />

accident.<br />

In Sep 10, a Saturday, a Chetak was to return<br />

on completion of detachment from one airfield<br />

to another. The ferry back had been planned the<br />

day before but could not be accomplished due<br />

to bad weather. The ferry was planned at 1030h<br />

but the ferry out had to be delayed till arrival and<br />

handing over of detachment to the new crew<br />

who just ferried in at about 1100h. The ferry back<br />

had been planned with two refueling halts. The<br />

aircraft took off at 1213h, two minutes before a<br />

weather warning came into effect at departure<br />

airfield. The captain communicated his change<br />

of destination to a helipad not in the flight plan<br />

but which offered refueling and saved him one<br />

refueling halt back to base minutes after take off to<br />

the departure airfield. The radar at hill top helipad<br />

location informed the captain of deterioration of<br />

visibility and drifting in of ground level clouds at<br />

their site to the captain well in time. The captain,<br />

probably hoping that the clouds will drift away,<br />

continued towards his revised en-route refueling<br />

halt. The captain was a Sqn Ldr with Cat/IR B/Green<br />

and the copilot was a Flt Lt with Cat/IR C/White.<br />

Subsequently, an attempt was made to land in nil<br />

visibility leading to a fatal Controlled Flight Into<br />

Terrain (CFIT) accident. Another unfortunate case<br />

of press-on-itis when the option to select a field<br />

and land was so much feasible.<br />

In Feb 2001 a Mi-8 took off from an ALG for an<br />

air maintenance sortie. The weather was marginal<br />

but within limits. By the time the aircraft returned<br />

from the drop the weather around the ALG had<br />

packed up. Apparently, the crew decided to<br />

make an attempt to press on despite the weather<br />

resulting in a fatal CFIT accident. The crew were<br />

planned to return back to base on completion of<br />

the sortie. Another unfortunate case of press-onitis.<br />

Why others Way back in 1991, I was ferrying<br />

a Mi-8 from base to a ALG in Arunachal for a<br />

detachment. On reaching the valley mouth I<br />

found the visibility reducing to about 1.5 Kms and<br />

less and the cloud ceiling had dropped forcing<br />

me to descend to 100 m AGL. I gave blind R/T<br />

call declaring my intention to divert to alternate<br />

and turned away. But within minutes of my call I<br />

heard the captain of a Mi-17 give a call that he was<br />

crossing the ridge for the ALG and was changing<br />

over to its frequency. I allowed the call to hurt<br />

my ego and re-revised my plan to proceed once<br />

again to the original destination. We were lucky to<br />

have reached the ALG safely that day. But I guess<br />

I learned my lesson. Years later on completion<br />

of a long detachment at an airfield two Mi-25s<br />

were to be ferried back to base. I was leading<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 23

the formation when we encountered bad weather<br />

enroute. I diverted and the formation landed at an<br />

abandoned runway despite R/T calls from other<br />

aircraft in the air in the vicinity at that time that<br />

they were proceeding to destination. The sortie<br />

to base was resumed on improvement in weather.<br />

A case of Press-on-itis corrected by crew resource<br />

management, wherein the inputs from the co-pilot<br />

and flight engineer on their comfort level, dictated<br />

a safer decision.<br />

So, what are the causal factors They are a<br />

‘page lot’ and the aircrew must always be aware<br />

so that they can recognize the symptoms and take<br />

preventive measures:-<br />

P- Poor Crew Resource Management is a<br />

key factor towards Press-on-itis accidents. No one<br />

in the multi crew cabin puts his view point strongly<br />

and even the support services personnel leave it<br />

to the captain thinking ‘he knows best’.<br />

A- Almost there, and we can hack it<br />

feeling.<br />

G- Get the job done. A captain may try<br />

to prove to oneself, a junior and impressionable<br />

crew or a colleague in the peer group that ‘Ek bar<br />

commitment kar di to kar di’.<br />

E- Ego is certainly one of the major factors<br />

in Press-on-itis. How foolish would it appear to<br />

back track one’s own well considered decisions<br />

and the desire to demonstrate superior skills are<br />

one of the causal factors.<br />

L- Loss of Situational Awareness. This<br />

is something totally avoidable in a multi crew<br />

environment and even for single pilot aircraft alert<br />

support service personnel can chip in with correct<br />

professional advice but they don.<br />

O- Overconfidence leading to incorrect<br />

24 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

Press-on-itis or Get-home-itis simply means the<br />

condition when a pilot undertakes a flight as per a fixed<br />

plan despite deteriorating conditions when common sense<br />

would have dictated a more safer alternative to divert or<br />

simply to carry out a precautionary landing.<br />

planning and consideration of what if scenarios<br />

will ultimately lead to faulty aeronautical decision<br />

making.<br />

T- Task saturation, especially when<br />

fatigued can lead to being trapped into the<br />

press-on -itis syndrome. Target fixation due<br />

too competitive an environment within the<br />

squadron can lead to overlooking of the golden<br />

rule of aviation that the first thing one must do<br />

is fly your machine safely. I know of many a crew<br />

on a check sortie who in the excessive effort to<br />

impress as regards TOTs have been lax on the<br />

other parameters be it height maintenance or<br />

laid down speed restrictions so that in the debrief<br />

they can say we were within +/- 5 seconds at the<br />

waypoints.<br />

The preventive methods which flow out<br />

of an understanding of the causal factors are<br />

‘Why FACE B’:-<br />

W- Crew need to be taught to ask ‘Why’<br />

‘What if’ scenarios are <strong>cover</strong>ed during general<br />

and exercise briefings as emergencies during<br />

training and combat missions. But a look at a large<br />

number of accidents suggests that there is a need<br />

for the supervisors to ensure that such elements<br />

are adequately discussed and briefed even for<br />

seemingly routine sorties and ferry flights.<br />

F- Fuel planning for adverse weather<br />

and clear fuel markings on the map at critical<br />

waypoints to ensure correct Go/ No Go decisions<br />

will lead to avoiding press-on-itis scenarios.<br />

A- Crew need to be trained to select<br />

suitable and safer ‘Alternatives’. Risk assessment<br />

training must factor fatigue at the end of a long<br />

flight<br />

C- The service must have a demonstrated<br />

‘Commitment’ to safety. No undue pressure<br />

must be put to undertake missions especially for<br />

VIP flights as it sends the conflicting message of<br />

different rules for different people.<br />

E- There must be adequate ‘Emphasis’ on<br />

observing laid down minima and adherence to<br />

SOPs.<br />

B- During ‘Briefings’ bring out Go/ No Go<br />

criteria. Be aware of your/ crew desire for presson-itis.<br />

During debrief analyze decision making<br />

during the sortie. Just because you made it does<br />

not mean that the decision making was flawless.<br />

Bring out the errors made and draw appropriate<br />

lessons.<br />

Press-on-itis is a dangerous mental state. Many<br />

accidents are caused or are suspected to have<br />

been caused by it. Awareness of unreasonable<br />

pressure to get to destination, either self generated<br />

or due company policy, would lead to steps to<br />

avoid the same. Good training that stresses<br />

awareness, setting of boundaries or tramlines,<br />

sound knowledge of SOPs, planning ahead for<br />

contingencies and disciplined adherence to<br />

minima are the key to avoiding press-on-itis. Have<br />

a safe flight and happy landings!<br />

-Wg Cdr Ashish Kapoor<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 25

SAFE GROUND RUNS AND SAFETY NORMS<br />

WO Kishore Kumar S<br />

It was a hot summer of north and in the scorching<br />

heat we left the safety bay to attend the ground<br />

run in tech flight. Usually, as per the policy, three<br />

safety operators and one SVO attends the ground<br />

run in CFT. One crew takes position near the aircraft<br />

during start ups with the BCF hose and applicator<br />

laid out to react in case of any eventuality.<br />

On reaching, we found the aircraft ready;<br />

however, the crew was clearing the ground<br />

equipment which were not required at the site.<br />

One Appa (start up vehicle) was parked near the<br />

aircraft and the gang leader asked the MTD to<br />

remove the vehicle from the ground run site to<br />

start the ground run. The moment MTD switched<br />

on the ignition of the vehicle, a big ball of fire came<br />

out of the vehicle engine and the vehicle was on<br />

fire with close proximity to the aircraft. Alarm<br />

bells rang and panic buttons were pressed. We<br />

were just positioning the CFT near the aircraft for<br />

ground run. Suddenly, one crew took out the BCF<br />

hose reel and the other crew on top of the CFT<br />

operated the cylinder to extinguish the fire.<br />

However, in panic, nobody knew which lever<br />

was to be opened, whether applicator valve by the<br />

operator or the pipe line valve near the cylinder<br />

junction by the IC. With a bang, the Halon gas<br />

compressed by nitrogen in the cylinder came<br />

out blasting the hose and emptying the costly<br />

gas from the BCF cylinders just by wasting in the<br />

air. Thank God, the vehicle fire was extinguished<br />

with the help of CO2 trolley parked nearby thus<br />

ensuring the safety of aircraft.<br />

Ground run environment in any tech flight<br />

is quite demanding and stress full. Most of the<br />

time with resource crunches and other ops<br />

26 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

and admin limitations, often a compromise on<br />

safety tends to happen. With the present policy<br />

of multi-skilling the tech crew to assist the CFT<br />

crew during ground run, a need to create safety<br />

awareness among the technicians involved in<br />

the ground run is vital. Most of the time, non<br />

availability of adequate designated properly<br />

paved parking bays for CFTs with adequate run<br />

out distance near the ground run point pose a<br />

problem in providing a conducive atmosphere<br />

near the AB point. With everybody sticking on to<br />

their own constraints and SOPs, the safety takes<br />

a back seat. Often CFTv vehicles are compelled<br />

to reverse near the parked aircraft which is highly<br />

irregular. The positioning of CFT becomes a<br />

formality at such places. Although the SOPs on<br />

positioning of CFTs and responsibilities as per<br />

AFO 126/98 have been laid out in SSOs of all the<br />

flying stations, it is everyone’s responsibility to<br />

ensure that a compromise on safety in a hurry to<br />

complete the ground run doesn’t happen.<br />

Identifying SNCOs of different trades and<br />

streams as independent Safety Inspectors within<br />

the units to report directly and confidentially<br />

with UFS&IOs or on the lines of QAS sections in<br />

BRDs can directly contribute in enhancing<br />

the safety environment of any workplace<br />

without compromising on discipline<br />

a n d service ethos in the best<br />

i n t e r e s t of aerospace safety. Tech<br />

flights should<br />

ensure more and more<br />

technicians are multi-skilled in<br />

fire safety operations<br />

to support the CFT crew<br />

and also should explore<br />

the feasibility of<br />

introducing rapid<br />

i n t e r v e n t i o n<br />

vehicles with<br />

extinguishing<br />

media which<br />

can be used<br />

to ensure safety<br />

during ground runs<br />

and can be manned<br />

independently and self sufficiently by the multiskilled<br />

technicians themselves. Thus the criticality<br />

in manning additional CFTs during flying hours<br />

and repositioning the CFTs from tech flight to tech<br />

flight and sqn to sqn can be avoided. The growing<br />

incidents of MT accidents in flying environments<br />

is a matter of concern and one reason is surely lack<br />

of safety consciousness and supervisory control<br />

among each and every individual.<br />

I have learnt one thing from the situation that<br />

I have faced from the above incident - the need<br />

to polish the skills and keeping in touch with the<br />

operating procedures as per the requirement<br />

of work place, balanced with a cool, composed,<br />

mind can only help us to react situationally in<br />

emergencies and to ensure safety. The need to<br />

create a safe environment at every work place is<br />

each and every air warriors responsibility. With<br />

lot of stress on our training policies based on<br />

modular patterns and restructuring, if the desired<br />

result needs to be borne, then I feel we need to<br />

redefine our HR recruitment by including the<br />

psychological testing like the one followed in SSBs<br />

which can help in identifying the right people for<br />

the right job with a positive attitude. The work<br />

culture inculcated in the young stage based on<br />

procedures and policies will go a long way in<br />

developing a sound and disciplined professional<br />

in the future. “Supervision means Superior Vision”.<br />

-WO Kishore Kumar S<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 27

ON 03 Jul 11, 907514-F Cpl SK Yadav, Ops Asst was detailed as Surveillance Technician<br />

and was manning Alpha Channel at the SU. At 1650 hrs, the civil aircraft with Chief<br />

Minister of the State on board, requested climb from its planned flight level 020 to 060.<br />

Aware of the degrading weather conditions of the sector he reconfirmed from the aircraft<br />

whether the climb was due to bad weather. On confirmation, he immediately reported<br />

the matter to the Sector Director Sqn Ldr R Sharma. After assessing the situation, SD<br />

cleared the climb and instructed ST to advice the pilot about enroute and destination bad<br />

weather. Further, taking view of the prevalent weather condition and in consultation with<br />

the SD, Cpl Yadav advised the pilot to abandon the mission and land at nearest diversion.<br />

He also coordinated the priority landing of the aircraft by doing necessary liaison with<br />

civil agencies at the nearest base.<br />

Cpl SK Yadav displayed keen observation, promptness and high professionalism and<br />

prevented a possible incident/accident involving Chief Minister of the state.<br />

Good Show Cpl SK Yadav<br />

(R Marwaha)<br />

Air Cmde<br />

PDAS<br />

On 11 Jul 11, Sqn Ldr Santharam Sure (26282-B) F (P) was authorized to fly an air<br />

experience sortie with a Medical Officer. While opening power for takeoff, he heard<br />

some abnormal noise from the engine. It was similar to the noise of cockpit pressurization<br />

valve fluttering, which subsided below 80% RPM. However, Sqn Ldr S Sure observed that<br />

the noise was different from a normal running of an engine, and he aborted the sortie<br />

and switched off without making any power changes till switch off. Post flight inspection<br />

revealed corrosive pitting of stator blades of the turbine, which was noticed only after the<br />

removal of the engine for inspection.<br />

Sqn Ldr S Sure displayed keen observation and prompt decision thereby avoiding a<br />

possibly disastrous situation.<br />

Good Show Sqn Ldr Santharam Sure<br />

(R Marwaha)<br />

Air Cmde<br />

PDAS<br />

32 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

On 29 On 29 Jun 11, 785748-R Cpl Amitava Datta AFSO was detailed to supervise<br />

the MES personnel for repair of inverter at Runway Controller hut. During the<br />

progress of the task he observed that the arrester barrier was slightly lowered. Taking<br />

necessary clearance from the tower, he proceeded to the barrier and found that the<br />

barrier was of lesser height. He requested tower to lower and raise the barrier again.<br />

On raising of the barrier, he measured the center height and found it to be less than<br />

the required minimum barrier height. Sensing the danger, he declared arrester barrier<br />

as unserviceable and requested for assistance of CCR party. On inspection by CCR<br />

party it was revealed that the stanchion on the eastern side was struck.<br />

Cpl A Datta displayed keen observation and professional approach and prevented<br />

a potentially disastrous situation.<br />

Good Show Cpl Amitava Datta<br />

(R Marwaha)<br />

Air Cmde<br />

PDAS<br />

On 27 Jun 2011, 768211-H Sgt AK Saini Eng/Fit was detailed to carry out Post Flight<br />

on Searcher MK II RPA. During Post Flight check, he noticed a minute crack on<br />

water pump driving belt. Further investigations revealed a crack of 3mm width on<br />

top layer of the belt. If it would have gone unnoticed it could have resulted in failure<br />

of oil pump leading to overheating and seizure of engine.<br />

Sgt AK Saini displayed a high Degree of professionalism and averted a possible<br />

accident/incident.<br />

Good Show Sgt AK Saini<br />

(R Marwaha)<br />

Air Cmde<br />

PDAS<br />

INDIAN AIR FORCE 2 0 1 2 F e b r u a r y Aerospace Safety 33

On 29 Aug 11, Flt Lt GPS Brar (28714-G) and Flt Lt M Rana (29251-K) were authorized to fly an<br />

RTR mission in an AVRO ac. During the preflight inspection the aircrew noticed a small<br />

paint scratch resembling a crack on the port wing between engine nacelle and fuselage.<br />

Aircrew brought it to the notice of DSS personnel and asked for further investigation. On<br />

investigation a 1” crack was found on upper surface of the wing. A detailed investigation<br />

subsequently revealed a crack on the supporting stringer as well and few loose rivets. If<br />

unnoticed, this crack would have resulted into a catastrophic disaster.<br />

Flt Lt Brar and Flt Lt Rana have displayed a high degree of professionalism and keen<br />

observation thereby preventing a potential accident/incident.<br />

Well Done Flt Lt GPS Brar & Flt Lt M Rana<br />

(R Marwaha)<br />

Air Cmde<br />

PDAS<br />

ON 13 Aug 11, Flt Lt Rohan Atul Atre (29880-G) F (P), was authorized to carry out ground<br />

run on Mi-17 IV helicopter, after 50 hrs servicing and MGB change, along with 775533-<br />

F Sgt Rajesh Chako Flt Engr. During start-up, they heard unusual noise coming from engine<br />

and MGB bed. Flt Lt Atre promptly asked Flt Eng to carry out a switch off. The origin of the<br />

noise could not be established at unit level. After thorough inspection carried out by the<br />

special rectification team, it was ascertained that abnormal noise was present. However,<br />

after removing the port engine it was found out that No.1 gene was unserviceable and the<br />

shaft giving drive to the gene had broken.<br />

Flt Lt A Atre and Sgt Rajesh Chako displayed keen sense of observation thereby isolating<br />

the weak link in the chain of events which could have led to a possible catastrophe.<br />

Well Done Flt Lt Rohan Atul Atre &Sgt Rajesh Chako<br />

(R Marwaha)<br />

Air Cmde<br />

PDAS<br />

34 Aerospace Safety F e b r u a r y 2 0 12<br />

INDIAN AIR FORCE

ON 11 Aug 11, 743927-H Cpl Sandip Kumar Ghosh Rad/Fit was detailed for guard<br />

duty. During the course of his duty he heard an unusual sound from the RPA parked<br />

in the blast pen. He rushed to the site and noticed high intensity sparks emanating<br />

from the forward payload compartment of the Heron RPA. He immediately raised<br />

an alarm and took assistance from the other air warrior on guard duty. 742787-H Cpl<br />

Lindo Antony Rad/Fit reacted to the situation immediately and assisted Cpl SK Ghosh<br />

in extinguishing the fire and got the situation under control.<br />

Cpl S K Ghosh and Cpl Lindo Antony displayed dedication to duty, situational<br />

awareness, prompt action and good team effort thereby averting a incident/<br />

accident.<br />

Well Done Cpl SK Ghosh and Cpl Lindo Antony<br />

(R Marwaha)<br />

Air Cmde<br />

PDAS<br />

ON 22 Aug 11, Sqn Ldr MK Khan (27008-R) F (P) was detailed to fly an A&E check<br />

sortie on a Dornier aircraft. After carrying out the complete air test profile, while<br />

rejoining the pilot heard an audio warning on the headset which was coupled with<br />