Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SIDE-GRIP PILE DRIVERS FOR TUBULAR PILES<br />

Driven tubular piles, casings, wood piles and stone columns are some examples of applications for<br />

<strong>Movax</strong> Tube Driver. The side gripping vibro driver has found its way to various site environments<br />

including rail, marine and general construction.<br />

Tube Driver utilises the side grip clamps to lift and rotate the pile to driving location. Secure grip<br />

keeps the tube in control during driving and AutoC control system enables fast and accurate piling<br />

work.<br />

<strong>Movax</strong> Tube Driver has been also successfully used as assisting machine before finishing with a<br />

drop hammer or a bigger vibro. Superior handling added with a capability to pre-drive the pile<br />

increases productivity.<br />

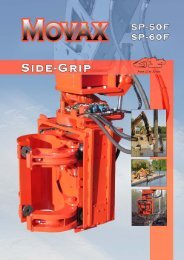

SP-70F4W<br />

From 25 to 40 ton<br />

SP-70F4W Side-Grip vibratory pile driver is capable<br />

of clamping the piles up to 720 mm in diameter. Its<br />

field proven high frequency vibratory technology is<br />

inherited from SP-70F4 sheet piler version. Additional<br />

clamps are available for all standard tube<br />

piles smaller than 720mm. SP-70WF4 is also suitable<br />

for timber piles.<br />

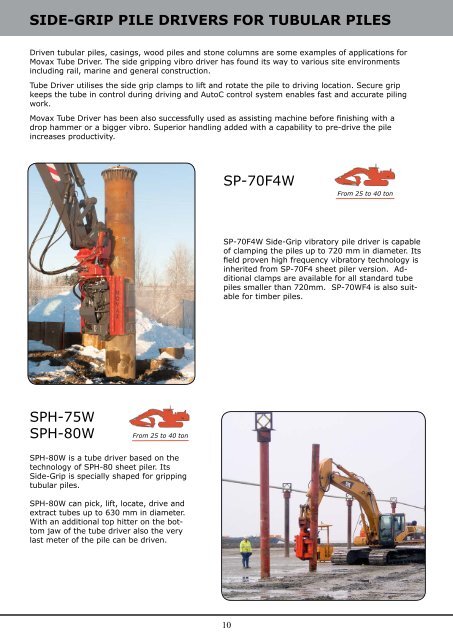

SPH-75W<br />

SPH-80W<br />

From 25 to 40 ton<br />

SPH-80W is a tube driver based on the<br />

technology of SPH-80 sheet piler. Its<br />

Side-Grip is specially shaped for gripping<br />

tubular piles.<br />

SPH-80W can pick, lift, locate, drive and<br />

extract tubes up to 630 mm in diameter.<br />

With an additional top hitter on the bottom<br />

jaw of the tube driver also the very<br />

last meter of the pile can be driven.<br />

10