NA-LUBE® BL-1232 EL - King Industries, Inc.

NA-LUBE® BL-1232 EL - King Industries, Inc.

NA-LUBE® BL-1232 EL - King Industries, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

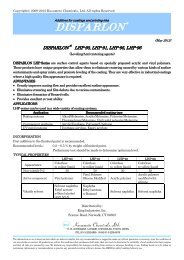

<strong>NA</strong>-LUBE ® <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Environmentally Friendly Ashless Additive Package<br />

for Ester Based Systems<br />

For information about the<br />

European Ecolabel, visit<br />

www.Ecolabel.eu

NEW <strong>NA</strong>-LUBE ® <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Environmentally Driven...Performance Proven<br />

Throughout the world, environmentally friendly lubricants are being developed to replace<br />

older technologies that are non-renewable and are contaminates when released<br />

into soil or water. Almost universally, the challenge formulators face when developing<br />

these new, replacement products is maintaining or surpassing the performance<br />

characteristics of the original.<br />

A particular area of focus for new greener lubricants has been hydraulic fluids, given<br />

their propensity to leak and the ensuing ground and water contamination. Here too,<br />

the challenge has been finding additives and additive packages that are eco-friendly<br />

and deliver the performance needed. In that regard <strong>King</strong> <strong>Industries</strong> is proud to introduce<br />

<strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong>, an ashless, multifunctional additive package specifically<br />

designed for use in ester based systems including hydraulic fluids. Additive Package<br />

<strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> has been evaluated against the European Ecolabel criteria for<br />

lubricants (Commission Decision 2011/381/EU). Based on that evaluation, <strong>NA</strong>-LUBE<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong>, when used as a single additive, qualifies for use in a final product eligible<br />

for the European Eco-Label in a concentration up to 1.8% by weight.<br />

<strong>NA</strong>-LUBE ® <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> Classification<br />

E<strong>EL</strong><br />

Classification<br />

% based on maximum treat<br />

rate of 1.8% by weight*<br />

Biodegradation C 1.80%<br />

Aquatic toxicity D 0.58%<br />

Aquatic toxicity E 0.38%<br />

Aquatic toxicity F 0.52%<br />

Substances not required to be<br />

assessed<br />

Renewability<br />

0.33%<br />

0%<br />

C = Non-Biodegradable and Non-Bioaccumulative<br />

D = Not Toxic<br />

E = Harmful<br />

F = Toxic<br />

* When used in combination with other additives, then the maximum treat level needs<br />

to be redefined.<br />

Eco-Label: Formulators of final products will need to provide additional information (e.g.<br />

performance test results, toxicity and biodegradability data on base oils and any other<br />

additives, components) in order to use the European Eco-Label on the final product.<br />

Regulatory Labeling: The incorporation of this additive into a formulation does not require<br />

any additional regulatory labeling.<br />

For more information about the EU Ecolabel, visit www.Ecolabel.eu

<strong>NA</strong>-LUBE ® <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> Typical Properties<br />

Environmentally friendly multifunctional, ashless additive package<br />

Appearance<br />

Clear amber, slightly viscous liquid<br />

Sulfur Content 8.20%<br />

Nitrogen Content 2.75%<br />

Phosphorus Content 0.90%<br />

Viscosity @ 40°C<br />

ASTM D 445, DIN 51 550<br />

Viscosity @ 100° C<br />

ASTM D 445, DIN 51 550<br />

Density @ 25°C<br />

ASTM D 4052<br />

Weight per Gallon @ 25°C<br />

Flash Point, COC<br />

ASTM D 92, DIN 51376<br />

Mineral Oil Content<br />

180 mm 2 /s (cSt)<br />

11 mm 2 /s (cSt)<br />

0.99 g/ml<br />

8.25 lbs.<br />

170°C<br />

None<br />

NOTE: The above data are not specifications.<br />

<strong>NA</strong>-LUBE ® <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> Applications<br />

<strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> is a multifunctional, ashless additive package that<br />

imparts excellent antiwear and anti-corrosion protection. It was specifically<br />

designed for use in ester based hydraulic systems where corrosion protection<br />

and filterability are key performance requirements. Examples of its performance<br />

in both saturated and unsaturated esters follow.<br />

<strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> is recommended for use in “total loss lubricants”, including<br />

chain saw oils, hydraulic fluids and concrete release agents.<br />

<strong>NA</strong>-LUBE ® <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> Advantages<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Confirmed by SMK to be in compliance for use in a final product eligible for<br />

the EU Ecolabel<br />

Low impact to water and soil during usage<br />

Requires no labeling risk-phrases<br />

Excellent antiwear performance<br />

Outstanding anti-corrosion protection<br />

Exceptional filterability<br />

Extended elastomer compatibility<br />

Complete additive package

<strong>NA</strong>-LUBE ® <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> Performance With Saturated Esters<br />

The test data that follow show the performance improvements and seal compatibility<br />

with a number of common elastomers when <strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> was tested in two<br />

different saturated esters.<br />

Typical performance results are shown below:<br />

Base Fluid<br />

Specification<br />

DIN ISO 15380<br />

Priolube 1973<br />

Saturated Ester<br />

Radialube ® 7588<br />

Saturated Ester<br />

Treat Level, % Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Steel Corrosion<br />

(ASTM D665 - 24 hours, 60°C)<br />

Procedure A (distilled H 2O)<br />

Procedure B (synthetic sea water)<br />

Pass<br />

Pass<br />

Demulsibility<br />

(ASTM D 1401) @ 130°F (54°C)<br />

Oil-Water-Emulsion<br />

Time (minutes) 30<br />

Fail<br />

Fail<br />

43-37-0<br />

15<br />

Pass<br />

Pass<br />

40-40-0<br />

15<br />

Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Fail<br />

Fail<br />

43-37-0<br />

25<br />

Pass<br />

Pass<br />

41-38-0<br />

25<br />

FZG A/8.3/90<br />

(ASTM D 5182, DIN 51 354 Part 2)<br />

Damage Load Stage 10 min. n/d >12 n/d 12<br />

Four Ball Wear (ASTM D 4172)<br />

1 hour, 22°C, 15kg, 1500rpm (mm)<br />

1 hour, 22°C, 30kg, 1500rpm (mm)<br />

1 hour, 75°C, 40kg, 1500rpm (mm)<br />

n/d<br />

0.49<br />

0.57<br />

0.48<br />

n/d<br />

0.54<br />

0.59<br />

0.40<br />

V 104C Vane Pump<br />

(DIN EN ISO 20 763)<br />

Reported Wear Loss Ring (mg)<br />

Wear Loss Vanes (mg)<br />

120 max.<br />

30 max.<br />

n/d 4.6<br />

7.5<br />

n/d<br />

n/d<br />

Copper Corrosion (ASTM D 130)<br />

3 hours, 100°C 2 max. 1b 1a 1b 1a<br />

AFNOR Filtration Dry (E 68690)<br />

FI 1.05 1.04 1.09 1.08<br />

AFNOR Filtration Wet (E 68691)<br />

FI 1.28 1.08 1.33 1.12<br />

Filterability Dry (DIN ISO 13357-2)<br />

FI1 (%)<br />

FI2 (%)<br />

80 min.<br />

60 min.<br />

99.5<br />

98.9<br />

95.4<br />

87.7<br />

99.1<br />

96.3<br />

96.9<br />

84.8<br />

Filterability Wet (DIN ISO 13357-2)<br />

FI1 (%)<br />

FI2 (%)<br />

70 min.<br />

50 min.<br />

92.5<br />

83.6<br />

93.8<br />

85.9<br />

95.0<br />

82.0<br />

91.7<br />

79.1<br />

Hydrolytic Stability<br />

(Beverage Bottle) (ASTM D 2619)<br />

Copper Loss (mg/cm 2 )<br />

Total Acidity-Water Layer (mg/KOH)<br />

Copper Appearance (ASTM D 130)<br />

0.05<br />

1.2<br />

1b<br />

0.01<br />

2.9<br />

3a<br />

0.05<br />

1.5<br />

1b<br />

-0.03<br />

2.9<br />

2c<br />

RPVOT (ASTM D 2272)<br />

150°C, H 2O, O 2, Cu Catalyst<br />

Lifetime (minutes)

Base Fluid<br />

Specification<br />

DIN ISO 15380<br />

Priolube 1973<br />

Saturated Ester<br />

Treat Level, % Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Radialube ® 7588<br />

Saturated Ester<br />

Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Air Release Properties (DIN 51381)<br />

50°C (minutes) 10 max. 4 4 4 4<br />

Foam Test* (ASTM D 892)<br />

Sequence I 25°C<br />

Sequence II 93°C<br />

Sequence III 25°C<br />

* <strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> does not contain a<br />

foam inhibitor<br />

150-0<br />

75-0<br />

150-0<br />

20-0<br />

0-0<br />

20-0<br />

140-0<br />

10-0<br />

20-0<br />

365-0<br />

30-0<br />

300-0<br />

110-0<br />

20-0<br />

290-0<br />

Seal Compatibility<br />

(DIN 53521 / 53538, Part 1)<br />

SRE-NBR / 7 days / 100°C<br />

Relative Volume Change, %<br />

Relative Change Shore A Hardness<br />

Change in Elongation at Break,%<br />

Chg. In Tensile Strength at Break, %<br />

Linde Corrosion Test<br />

(VDMA 24570)<br />

Metal Loss (g/m 2 )<br />

Brass CuZn35Mn2Si<br />

Guss Bronze CuPb15Sn8<br />

Sinter Bronze CuPbSn8<br />

Steel 100Cr6<br />

-3 to 10<br />

+/- 10<br />

30 max.<br />

30 max.<br />

8.2<br />

-4<br />

-60.6<br />

60.7<br />

Priolube is a trademark of Croda International, Radia is a trademark of Oleon NV.<br />

n/d<br />

9.3<br />

-6<br />

-18.8<br />

-24.0<br />

1<br />

1<br />

1<br />

0<br />

26.0<br />

-15<br />

-25.0<br />

-16.4<br />

n/d<br />

28.0<br />

-14<br />

-32.7<br />

26.8<br />

2<br />

2<br />

2<br />

0<br />

Extended Seal Compatibility<br />

Base Fluid<br />

Specification<br />

DIN ISO 15380<br />

Priolube 1973<br />

Saturated Ester<br />

Radialube 7588<br />

Saturated Ester<br />

Treat Level, % Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Seal Compatibility<br />

FKM 2 / 42 days / 80°C<br />

Relative Volume Change, %<br />

Relative Change Shore A Hardness<br />

Change in Elongation at Break,%<br />

Chg. in Tensile Strength at Break, %<br />

-3 to 10<br />

+/- 10<br />

30 max.<br />

30 max.<br />

1.4<br />

0<br />

-2.4<br />

2.76<br />

1.7<br />

0<br />

3.2<br />

12.8<br />

3.2<br />

-3<br />

-4.8<br />

11<br />

3.3<br />

-2<br />

-4.8<br />

12.1<br />

Seal Compatibility<br />

NBR 1 / 42 days / 80°C<br />

Relative Volume Change, %<br />

Relative Change Shore A Hardness<br />

Change in Elongation at Break,%<br />

Chg. in Tensile Strength at Break, %<br />

-3 to 10<br />

+/- 10<br />

30 max.<br />

30 max.<br />

7.2<br />

-4<br />

-21.9<br />

-32.1<br />

9.2<br />

-7<br />

-8<br />

-6.2<br />

25.3<br />

-16<br />

-28.4<br />

-20.1<br />

26.5<br />

-16<br />

-20.9<br />

-9.6<br />

Seal Compatibility<br />

NBR 2 / 42 days / 80°C<br />

Relative Volume Change, %<br />

Relative Change Shore A Hardness<br />

Change in Elongation at Break,%<br />

Chg. in Tensile Strength at Break, %<br />

-3 to 10<br />

+/- 10<br />

30 max.<br />

30 max.<br />

1.5<br />

-1<br />

-3.4<br />

-12.8<br />

2.8<br />

-2<br />

-12.5<br />

-22.7<br />

11.8<br />

-8<br />

-12.5<br />

-22.7<br />

12.9<br />

-8<br />

-16.3<br />

-14.1<br />

Seal Compatibility<br />

EPDM 1 / 42 days / 80°C<br />

Relative Volume Change, %<br />

Relative Change Shore A Hardness<br />

Change in Elongation at Break,%<br />

Chg. in Tensile Strength at Break, %<br />

-3 to 10<br />

+/- 10<br />

30 max.<br />

30 max.<br />

77.2<br />

-19<br />

-55.4<br />

-32.2<br />

72.7<br />

-18<br />

-48.6<br />

-3<br />

19.7<br />

-10<br />

-22.6<br />

-4.3<br />

20.3<br />

-10<br />

-20.3<br />

-0.9<br />

Seal Compatibility<br />

HNBR 1 / 42 days / 80°C<br />

Relative Volume Change, %<br />

Relative Change Shore A Hardness<br />

Change in Elongation at Break,%<br />

Chg. in Tensile Strength at Break, %<br />

-3 to 10<br />

+/- 10<br />

30 max.<br />

30 max.<br />

9<br />

-5<br />

-38.3<br />

-48.3<br />

9.5<br />

-5<br />

-2.9<br />

-1.7<br />

20.8<br />

-10<br />

-8<br />

-4.2<br />

22.1<br />

-12<br />

-9.1<br />

-3.9

<strong>NA</strong>-LUBE ® <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> Performance:<br />

Saturated vs. Unsaturated Esters<br />

Using the baseline data obtained from the previous example in saturated esters,<br />

<strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> was further evaluated using an unsaturated ester. As shown,<br />

here too, its addition improved a number of critical performance characteristics.<br />

Base Fluid<br />

Specification<br />

DIN ISO 15380<br />

Priolube 1973<br />

Saturated Ester<br />

Priolube 2089<br />

Unsaturated Ester<br />

Treat Level, % Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Steel Corrosion<br />

(ASTM D665 - 24 hours, 60°C)<br />

Procedure A (distilled H 2O)<br />

Procedure B (synthetic sea water)<br />

Pass<br />

Pass<br />

Demulsibility<br />

(ASTM D 1401) @ 130°F (54°C)<br />

Oil-Water-Emulsion<br />

Time (minutes) 30<br />

Fail<br />

Fail<br />

43-37-0<br />

15<br />

Pass<br />

Pass<br />

40-40-0<br />

15<br />

Fail<br />

Fail<br />

44-34-2<br />

30<br />

Pass<br />

Pass<br />

41-39-0<br />

20<br />

FZG A/8.3/90<br />

(ASTM D 5182, DIN 51 354 Part 2)<br />

Damage Load Stage 10 min. n/d >12 n/d 12<br />

Four Ball Wear (ASTM D 4172)<br />

1 hour, 22°C, 15kg, 1500rpm (mm)<br />

1 hour, 22°C, 30kg, 1500rpm (mm)<br />

1 hour, 75°C, 40kg, 1500rpm (mm)<br />

n/d<br />

0.49<br />

0.57<br />

0.48<br />

n/d<br />

0.55<br />

0.60<br />

0.52<br />

V 104C Vane Pump<br />

(DIN EN ISO 20 763)<br />

Reported Wear Loss Ring (g)<br />

Wear Loss Vanes (g)<br />

120 max.<br />

30 max.<br />

n/d 4.6<br />

7.5<br />

n/d<br />

n/d<br />

Copper Corrosion (ASTM D 130)<br />

3 hours, 100°C 2 max. 1b 1a 1b 1a<br />

AFNOR Filtration Dry (E 68690)<br />

FI 1.05 1.04 1.08 1.12<br />

AFNOR Filtration Wet (E 68691)<br />

FI 1.28 1.08 1.35 1.18<br />

Filterability Dry (DIN ISO 13357-2)<br />

FI1 (%)<br />

FI2 (%)<br />

80 min.<br />

60 min.<br />

99.5<br />

98.9<br />

95.4<br />

87.7<br />

96.8<br />

94.0<br />

96.7<br />

85.8<br />

Filterability Wet (DIN ISO 13357-2)<br />

FI1 (%)<br />

FI2 (%)<br />

70 min.<br />

50 min.<br />

92.5<br />

83.6<br />

93.8<br />

85.9<br />

86.8<br />

82.5<br />

92.5<br />

83.1<br />

Hydrolytic Stability<br />

(Beverage Bottle) (ASTM D 2619)<br />

Copper Loss (mg/cm 2 )<br />

Total Acidity-Water Layer (mg/KOH)<br />

Copper Appearance (ASTM D 130)<br />

0.05<br />

1.2<br />

1b<br />

0.01<br />

2.9<br />

3a<br />

0.06<br />

1.9<br />

1b<br />

0.01<br />

13.3<br />

3b<br />

RPVOT (ASTM D 2272)<br />

150°C, H 2O, O 2, Cu Catalyst<br />

Lifetime (minutes)

Base Fluid<br />

Specification<br />

DIN ISO 15380<br />

Priolube 1973<br />

Saturated Ester<br />

Treat Level, % Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Priolube 2089<br />

Unsaturated Ester<br />

Neat With 1.8%<br />

<strong>BL</strong>-<strong>1232</strong> <strong>EL</strong><br />

Air Release Properties (DIN 51381)<br />

50°C (minutes) 10 max. 4 4 3 4<br />

Foam Test* (ASTM D 892)<br />

Sequence I 25°C<br />

Sequence II 93°C<br />

Sequence III 25°C<br />

* <strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong> <strong>EL</strong> does not contain a<br />

foam inhibitor<br />

150-0<br />

75-0<br />

150-0<br />

20-0<br />

0-0<br />

20-0<br />

140-0<br />

10-0<br />

20-0<br />

10-0<br />

0-0<br />

10-0<br />

60-0<br />

10-0<br />

10-0<br />

Seal Compatibility<br />

(DIN 53521 / 53538, Part 1)<br />

SRE-NBR / 7 days / 100°C<br />

Relative Volume Change, %<br />

Relative Change Shore A Hardness<br />

Change in Elongation at Break,%<br />

Chg. Tensile Strength at Break, %<br />

-3 to 10<br />

+/- 10<br />

30 max.<br />

30 max.<br />

8.2<br />

-4<br />

-60.6<br />

60.7<br />

9.3<br />

-6<br />

-18.8<br />

-24.0<br />

8.5<br />

-6<br />

-44.7<br />

-44.3<br />

9.9<br />

-7<br />

-24.5<br />

-28.5<br />

Priolube is a trademark of Croda International, Radialube ® is a registered trademark of Oleon NV.<br />

Contact Information:<br />

Visit Us At: www.kingindustries.com<br />

USA/Headquarters:<br />

<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>., Science Road, Norwalk, CT 06852<br />

(203) 866-5551 lad@kingindustries.com<br />

Europe Technical Sales Office<br />

<strong>King</strong> International, Noordkade 64, 2741 EZ Waddinxveen, The Netherlands<br />

+31-182-631360 info@kingintl.nl<br />

Asia - Pacific Rim Technical Support<br />

Dr. Zhiqiang Alex He, 42 JLYY - Rich Mond Hill, Bo Ai 7th Road,<br />

Zhongshan, Guangdong, China 528403<br />

+760-88229866 alex.he@kingindustries.com<br />

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of product evaluations),<br />

including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance<br />

and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. Such testing has not necessarily been<br />

done by <strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>. ("<strong>King</strong>"). The facts, recommendations and suggestions herein stated are believed to be reliable; however, no guaranty or warranty<br />

of their accuracy is made. EXCEPT AS STATED, THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS OR OTHER-<br />

WISE. KING SHALL NOT BE H<strong>EL</strong>D LIA<strong>BL</strong>E FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES. Any statement inconsistent<br />

herewith is not authorized and shall not bind <strong>King</strong>. Nothing herein shall be construed as a recommendation to use any product(s) in conflict with patents covering<br />

any material or its use. No license is implied or granted under the claims of any patent. Sales or use of all products are pursuant to Standard Terms and<br />

Conditions stated in <strong>King</strong> sales documents.

LAD <strong>NA</strong>-LUBE <strong>BL</strong>-<strong>1232</strong><strong>EL</strong> feb2011