NACURE® DNNSA Catalysts - King Industries, Inc.

NACURE® DNNSA Catalysts - King Industries, Inc.

NACURE® DNNSA Catalysts - King Industries, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

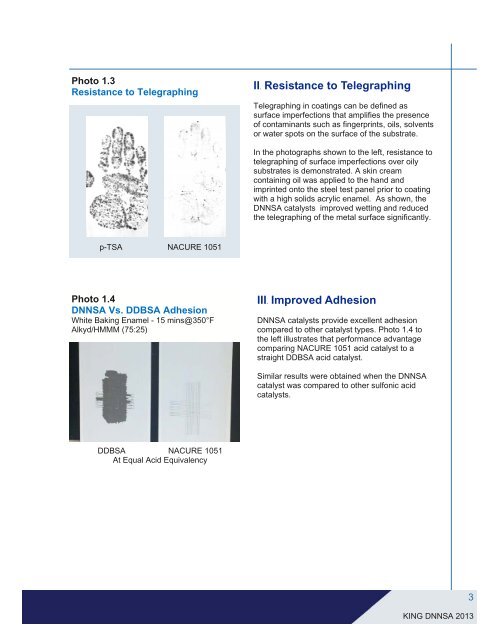

Photo 1.3<br />

Resistance to Telegraphing<br />

II. Resistance to Telegraphing<br />

Telegraphing in coatings can be defined as<br />

surface imperfections that amplifies the presence<br />

of contaminants such as fingerprints, oils, solvents<br />

or water spots on the surface of the substrate.<br />

In the photographs shown to the left, resistance to<br />

telegraphing of surface imperfections over oily<br />

substrates is demonstrated. A skin cream<br />

containing oil was applied to the hand and<br />

imprinted onto the steel test panel prior to coating<br />

with a high solids acrylic enamel. As shown, the<br />

<strong>DNNSA</strong> catalysts improved wetting and reduced<br />

the telegraphing of the metal surface significantly.<br />

p-TSA NACURE 1051<br />

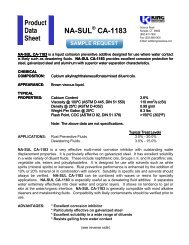

Photo 1.4<br />

<strong>DNNSA</strong> Vs. DDBSA Adhesion<br />

White Baking Enamel - 15 mins@350°F<br />

Alkyd/HMMM (75:25)<br />

III. Improved Adhesion<br />

<strong>DNNSA</strong> catalysts provide excellent adhesion<br />

compared to other catalyst types. Photo 1.4 to<br />

the left illustrates that performance advantage<br />

comparing NACURE 1051 acid catalyst to a<br />

straight DDBSA acid catalyst.<br />

Similar results were obtained when the <strong>DNNSA</strong><br />

catalyst was compared to other sulfonic acid<br />

catalysts.<br />

DDBSA NACURE 1051<br />

At Equal Acid Equivalency<br />

3<br />

KING <strong>DNNSA</strong> 2013