Read the full case study here - Association for Project Management

Read the full case study here - Association for Project Management

Read the full case study here - Association for Project Management

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

APM <strong>Project</strong> <strong>Management</strong> Awards<br />

WINNER’S<br />

CASE STUDY<br />

Category<br />

Winner<br />

Overseas <strong>Project</strong> of <strong>the</strong> Year 2008<br />

Arup <strong>for</strong> The Water Cube, Beijing.<br />

Sponsor<br />

The project<br />

Introduction<br />

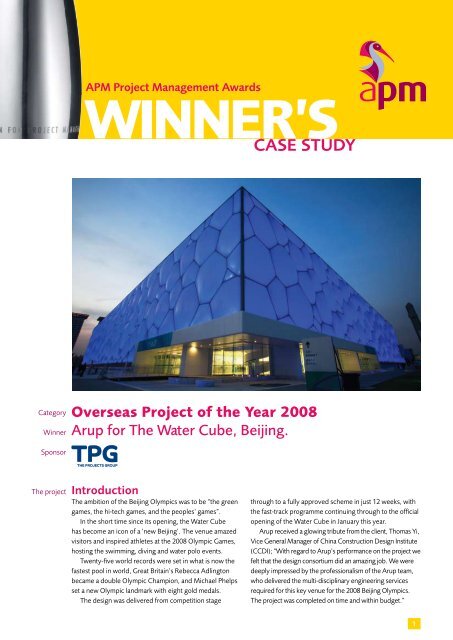

The ambition of <strong>the</strong> Beijing Olympics was to be “<strong>the</strong> green<br />

games, <strong>the</strong> hi-tech games, and <strong>the</strong> peoples’ games”.<br />

In <strong>the</strong> short time since its opening, <strong>the</strong> Water Cube<br />

has become an icon of a ‘new Beijing’. The venue amazed<br />

visitors and inspired athletes at <strong>the</strong> 2008 Olympic Games,<br />

hosting <strong>the</strong> swimming, diving and water polo events.<br />

Twenty-five world records were set in what is now <strong>the</strong><br />

fastest pool in world, Great Britain’s Rebecca Adlington<br />

became a double Olympic Champion, and Michael Phelps<br />

set a new Olympic landmark with eight gold medals.<br />

The design was delivered from competition stage<br />

through to a <strong>full</strong>y approved scheme in just 12 weeks, with<br />

<strong>the</strong> fast-track programme continuing through to <strong>the</strong> official<br />

opening of <strong>the</strong> Water Cube in January this year.<br />

Arup received a glowing tribute from <strong>the</strong> client, Thomas Yi,<br />

Vice General Manager of China Construction Design Institute<br />

(CCDI); “With regard to Arup’s per<strong>for</strong>mance on <strong>the</strong> project we<br />

felt that <strong>the</strong> design consortium did an amazing job. We were<br />

deeply impressed by <strong>the</strong> professionalism of <strong>the</strong> Arup team,<br />

who delivered <strong>the</strong> multi-disciplinary engineering services<br />

required <strong>for</strong> this key venue <strong>for</strong> <strong>the</strong> 2008 Beijing Olympics.<br />

The project was completed on time and within budget.”<br />

1

APM <strong>Project</strong> <strong>Management</strong> Awards<br />

WINNER’S<br />

CASE STUDY<br />

APM’s judges agreed that <strong>the</strong> Water Cube made a<br />

worthy winner; “Arup has managed to deliver, on time<br />

and to budget, a truly inspirational and enduring project<br />

<strong>for</strong> <strong>the</strong> Chinese people within a complex technical and<br />

cultural management environment, by establishing a clear<br />

vision and roadmap that all stakeholders aligned to. Clarity<br />

of communication was essential and Arup mitigated this<br />

key risk via interface management techniques aligned to<br />

<strong>the</strong> technical and commercial interdependencies, in an<br />

innovative manner.”<br />

The scale of <strong>the</strong> project was neatly summed up by<br />

Joanna Kennedy, Arup, who when accepting <strong>the</strong> award<br />

on behalf of Arup’s Australasian practice, described it as<br />

a “major collaboration” involving 20 different disciplines<br />

over four different countries.<br />

Background<br />

The Water Cube was <strong>the</strong> result of an international design<br />

competition with 10 short-listed participants, judged by a<br />

panel of architects, engineers and pre-eminent Chinese<br />

academics. The Arup + PTW + CCDI design was selected as<br />

<strong>the</strong> clear winner of <strong>the</strong> competition both by <strong>the</strong> international<br />

jury and <strong>the</strong> people of China <strong>the</strong>mselves, although <strong>the</strong><br />

outcome could have been quite different but <strong>for</strong> some<br />

tough decision-making by <strong>the</strong> Water Cube team.<br />

The Aquatics Centre was required to be <strong>the</strong> best<br />

Olympic swimming venue and <strong>the</strong>n a popular and<br />

well-used leisure and training facility after <strong>the</strong> games. It<br />

was to cost no more than US$100M be<strong>for</strong>e <strong>the</strong> Olympics<br />

and US$10M <strong>for</strong> its conversion to legacy mode.<br />

The Olympic requirements included a 50metre<br />

competition pool, a 33metre diving pool and a 50metre<br />

warm up pool. The main pool hall was to have 17,000 seats<br />

<strong>for</strong> <strong>the</strong> games and <strong>the</strong>n be reduced to 7,000 seats with<br />

o<strong>the</strong>r facilities added in order to make <strong>the</strong> Aquatics Centre<br />

a viable long-term legacy. The construction was to start<br />

be<strong>for</strong>e <strong>the</strong> end of 2003 and to be completed at least six<br />

months be<strong>for</strong>e <strong>the</strong> Olympics to allow a sufficient period <strong>for</strong><br />

trial competitive events.<br />

In 2003, as <strong>the</strong> fast track development program got<br />

underway, <strong>the</strong> team from Arup, PTW Architects, and China<br />

Construction Design International (CCDI) agreed that <strong>the</strong><br />

Aquatics Centre design should portray <strong>the</strong> way in which<br />

humanity relates to water, and devoted half of <strong>the</strong> available<br />

design competition period developing a design with a wave<br />

shaped roof depicting <strong>the</strong> power of <strong>the</strong> surf.<br />

Following <strong>the</strong> unveiling of <strong>the</strong> spectacular glowing<br />

Bird’s Nest design <strong>for</strong> <strong>the</strong> National Stadium by <strong>the</strong> team<br />

at Herzog & de Meuron and Arup just four weeks be<strong>for</strong>e<br />

<strong>the</strong> competition deadline <strong>the</strong> Aquatics Centre team<br />

realised <strong>the</strong>ir design could not win and made <strong>the</strong> difficult<br />

decision to scrap <strong>the</strong> wave design and swiftly agreed <strong>the</strong><br />

component parts of <strong>the</strong> Water Cube concept.<br />

The National Stadium is on <strong>the</strong> neighbouring site to <strong>the</strong><br />

Aquatics Centre, <strong>the</strong> two sites separated by a protected<br />

historic axis to Beijing’s Forbidden City, factors that led <strong>the</strong><br />

team to develop a complimentary design to <strong>the</strong> Bird’s Nest.<br />

They concluded that a cube concept would appeal to <strong>the</strong><br />

typical Chinese way of understanding beauty – a subtle,<br />

thought-provoking design representing <strong>the</strong> beauty and<br />

serenity of calm, untroubled water.<br />

The two opposing shapes sit toge<strong>the</strong>r in harmony;<br />

<strong>the</strong> Water Cube is blue against <strong>the</strong> Stadium’s red, water<br />

versus fire, square versus round, male versus female,<br />

earth versus heaven.<br />

2

APM <strong>Project</strong> <strong>Management</strong> Awards<br />

WINNER’S<br />

CASE STUDY<br />

While <strong>the</strong> structural solution based on <strong>the</strong> <strong>for</strong>mation<br />

of soap bubbles is unique, o<strong>the</strong>r technical ambitions<br />

contributed to its iconic <strong>for</strong>m.<br />

The Water Cube is an insulated greenhouse, which<br />

maximises <strong>the</strong> use of solar energy <strong>for</strong> both heating<br />

and lighting.<br />

The use of ETFE (ethylene tetrafluoroethylene – a kind<br />

of plastic) in lieu of glass creates a superior acoustic<br />

environment, reduces <strong>the</strong> weight of material supported<br />

by <strong>the</strong> structure, improves seismic per<strong>for</strong>mance, and is<br />

self cleaning and recyclable. The roof collects and re-uses<br />

all rainwater that falls on <strong>the</strong> building.<br />

Despite <strong>the</strong> building’s apparent complexity because<br />

<strong>the</strong> structure is based on a repetitive geometry, <strong>the</strong><br />

sub-components repeat across <strong>the</strong> building. T<strong>here</strong><br />

are only four different nodal geometries, three typical<br />

member lengths, and 22 different ETFE pillow shapes,<br />

greatly reducing <strong>the</strong> time and costs of production and<br />

installation.<br />

The design sets a new precedent <strong>for</strong> engineering<br />

approvals <strong>for</strong> <strong>the</strong> Chinese Olympic venues. Without<br />

per<strong>for</strong>mance-based fire engineering (a first <strong>for</strong> China)<br />

<strong>the</strong> Water Cube as we know it would not exist. The<br />

building is <strong>the</strong> result of integrating <strong>the</strong> technical<br />

requirements of all <strong>the</strong> relevant engineering disciplines,<br />

not <strong>the</strong> result of a single dominant one.<br />

Due to its complexity (<strong>the</strong> structure consists of 22,000<br />

steel members and 12,000 nodes), <strong>the</strong> entire project<br />

had to be conceived and modelled during <strong>the</strong> last three<br />

weeks of <strong>the</strong> design competition in three dimensions.<br />

Numerous new techniques and pieces of software<br />

were developed specifically <strong>for</strong> <strong>the</strong> Water Cube<br />

project. This new software was used to generate <strong>the</strong><br />

geometry, create a physical prototype, optimise <strong>the</strong><br />

structural per<strong>for</strong>mance, analyse acoustics, smoke<br />

spread, and pedestrian egress, and to provide<br />

construction documentation in a <strong>full</strong>y automated<br />

four dimensional sequence.<br />

The challenges<br />

In winning, <strong>the</strong> Arup team had created a significant<br />

challenge <strong>for</strong> itself. The competition concept had<br />

enormous wow-factor, and was based on solid engineering<br />

principles, but many of <strong>the</strong> concepts were so cutting<br />

edge that multiple streams of research and development<br />

were still needed to prove <strong>the</strong> design both internally and<br />

to design partners, and to sell technical aspects to <strong>the</strong><br />

Chinese approval authorities.<br />

Despite <strong>the</strong> complexities involved, <strong>the</strong> Water Cube<br />

always had one absolute given – a fixed end date. It was<br />

up to Arup’s project management team to deal with major<br />

timing issues along <strong>the</strong> way, most notably delivering <strong>the</strong><br />

physical venue design well in advance of knowing who<br />

would operate <strong>the</strong> Water Cube be<strong>for</strong>e and after <strong>the</strong> games,<br />

and how <strong>the</strong>y may want to reconfigure <strong>the</strong> building.<br />

T<strong>here</strong> were no easy answers to <strong>the</strong>se issues, however<br />

<strong>the</strong> key to success was a combination of involving Arup’s<br />

specialist designers and project managers with expertise<br />

in Olympic sites. These specialists provided a real<br />

understanding of how Olympic events will be operated,<br />

how <strong>the</strong> many operational streams must be linked, how to<br />

balance <strong>the</strong> needs of stakeholders, and how <strong>the</strong> venue sits<br />

within <strong>the</strong> wider Olympic organisational framework.<br />

The design and construction of <strong>the</strong> Water Cube, while<br />

pushing back <strong>the</strong> boundaries of innovation, is essentially<br />

business as usual <strong>for</strong> Arup. Arup is renowned <strong>for</strong> taking on<br />

large and complex designs and bringing <strong>the</strong>m to fruition.<br />

However, <strong>the</strong> actual project management of an Olympic<br />

venue <strong>for</strong> Arup is anything but business as usual.<br />

Communication<br />

The binding thread in <strong>the</strong> success of <strong>the</strong> Water Cube<br />

project was <strong>the</strong> quality and depth of communication<br />

both internally and externally. As well as day-to-day team<br />

communication and in<strong>for</strong>mation management processes,<br />

Arup’s communication strategy established <strong>the</strong> vision and<br />

key messages, and how <strong>the</strong>se would be integrated into<br />

daily project life.<br />

The strategy produced by Arup’s project managers<br />

went beyond planning <strong>the</strong> <strong>for</strong>mal internal and external<br />

methods of communication – it encompassed <strong>the</strong> need<br />

<strong>for</strong> <strong>the</strong> continuous incorporation of lessons learnt in<br />

dealing with stakeholders in a different location, and<br />

with a different culture and language. In doing so it<br />

provided a vehicle <strong>for</strong> relationship management and<br />

stakeholder engagement.<br />

At <strong>the</strong> implementation plan workshop, Arup’s project<br />

management team focused initially on <strong>the</strong> need to articulate<br />

and communicate a very clear project vision <strong>for</strong> <strong>the</strong> Water<br />

Cube design. This was intended to have multiple benefits.<br />

Most simply, <strong>the</strong> vision would provide improved clarity and<br />

autonomy to <strong>the</strong> design team members.<br />

This would help achieve a quality outcome in a very<br />

short period of time, by allowing parallel streams of activity<br />

to converge quickly and accurately. It was also hoped<br />

that having a robust vision would greatly help achieve<br />

alignment and buy-in from o<strong>the</strong>r project stakeholders.<br />

International aspects<br />

- <strong>the</strong> management<br />

of difference<br />

More challenging <strong>for</strong> Arup’s project management<br />

team than <strong>the</strong> technical aspects of <strong>the</strong> Water Cube,<br />

and ultimately far more rewarding, was learning and<br />

understanding <strong>the</strong> business culture and context in China.<br />

It was not only ‘<strong>for</strong>eign’ to Arup at <strong>the</strong> start of <strong>the</strong> project,<br />

but also highly difficult to read, so <strong>the</strong>y held some specific<br />

internal sessions with Chinese team members to agree<br />

3

APM <strong>Project</strong> <strong>Management</strong> Awards<br />

WINNER’S<br />

CASE STUDY<br />

<strong>the</strong>ir approach to <strong>the</strong> early ‘management of difference’.<br />

This partly focused on maintaining leverage over<br />

commercial arrangements, but mainly looked at how to<br />

minimise and manage <strong>the</strong> risks of <strong>the</strong> specific differences<br />

in norms, practices and expectations through <strong>the</strong> project<br />

lifecycle.<br />

The complex and dynamic nature of <strong>the</strong> Chinese<br />

market, particularly in <strong>the</strong> context of <strong>the</strong> Olympics, meant<br />

that <strong>the</strong> risks associated with delivering <strong>the</strong> Water Cube<br />

could not be underestimated. Beijing’s lack of regulatory<br />

transparency and regional differences, as well as a<br />

relationship-based business culture were among<br />

<strong>the</strong> factors Arup identified that made China a challenging<br />

project environment.<br />

Arup’s project management team looked at a diverse<br />

range of risks, trying to understand and plan <strong>the</strong>ir<br />

approach to <strong>the</strong> project in <strong>the</strong> unfamiliar context of China’s<br />

legal, social, cultural, economical and technological<br />

environment. O<strong>the</strong>r than <strong>the</strong> commercial risk of delayed<br />

payment, <strong>the</strong> key risks identified were social – how<br />

China’s business culture might affect <strong>the</strong> relationships and<br />

dynamics within <strong>the</strong> international Water Cube team, and<br />

with <strong>the</strong> external stakeholders involved in approving <strong>the</strong><br />

design concept.<br />

Social risks such as cultural misunderstandings could<br />

have completely derailed or significantly delayed <strong>the</strong><br />

Water Cube project. Relationship building is fundamental<br />

in Chinese business, so understanding Guanxi – a <strong>for</strong>m of<br />

social networking – and how to au<strong>the</strong>ntically cultivate and<br />

manage it was vital to <strong>the</strong> Arup project management team.<br />

O<strong>the</strong>r important factors in <strong>the</strong> approach included:<br />

Emphasising Arup’s international reputation and <strong>the</strong><br />

depth and diversity of its activities and locations.<br />

Ensuring that all interactions with Chinese stakeholders<br />

involved giving <strong>the</strong>m <strong>the</strong> highest possible quality of<br />

service, both in terms of <strong>the</strong> material issued and <strong>the</strong><br />

Arup staff directly involved with <strong>the</strong>m.<br />

It was important to involve well-respected senior<br />

engineers from Arup’s Beijing and Hong Kong offices at<br />

key stages of <strong>the</strong> approvals process. Their influence and<br />

local knowledge of <strong>the</strong> Chinese legislation, coupled with<br />

Arup’s involvement in o<strong>the</strong>r high profile Olympic projects<br />

in Beijing, were leveraged to convince some conservative<br />

authorities to accept a range of innovative approaches to<br />

<strong>the</strong> engineering design that didn’t follow <strong>the</strong> prescriptive<br />

rules of <strong>the</strong> Chinese building codes.<br />

This was <strong>the</strong> number one risk in <strong>the</strong> early stages of <strong>the</strong><br />

project, and <strong>the</strong> <strong>for</strong>mal approval of <strong>the</strong> engineering design<br />

in early 2004 set a major precedent and direction <strong>for</strong> o<strong>the</strong>r<br />

Olympic projects.<br />

Arup’s specialist project managers were very specific<br />

during contract negotiations to clearly define <strong>the</strong> scope of<br />

services and <strong>the</strong> interfaces with Chinese design partners,<br />

and were robust in contract negotiations that removed<br />

some of <strong>the</strong> post-Olympic payment milestones that were<br />

unrelated to Arup’s scope. The result was a financial<br />

success despite <strong>the</strong> considerable risks of working on<br />

such a fast track project, with international partners and<br />

stakeholders, on a project involving such groundbreaking<br />

design techniques and materials.<br />

By deliberately resolving any potential conflicts early,<br />

Arup were able to sign a contract and facilitate a smooth<br />

and seamless handover to <strong>the</strong>ir Chinese partners with<br />

clearly understood and accepted interfaces.<br />

4

APM <strong>Project</strong> <strong>Management</strong> Awards<br />

WINNER’S<br />

CASE STUDY<br />

Interface management<br />

Some of <strong>the</strong> challenges faced included <strong>the</strong> integration and<br />

<strong>the</strong> coordination of <strong>the</strong> many interfaces <strong>for</strong> <strong>the</strong> project<br />

involving multiple stakeholders with conflicting demands.<br />

Coordinating <strong>the</strong> requirements <strong>for</strong> athletes, officials,<br />

VIPs, written press, broadcasters, work<strong>for</strong>ce, sponsors,<br />

spectators, and of course <strong>the</strong> operator, is complex and<br />

requires delicate balance.<br />

Arup’s project management team had <strong>the</strong> challenge of<br />

coordinating 20 specialist Arup engineering disciplines,<br />

ensuring <strong>the</strong>y were properly integrated, and that <strong>the</strong><br />

complex interfaces of <strong>the</strong> Water Cube were properly<br />

understood and documented.<br />

Developing on previous Arup project management<br />

work at London’s Heathrow Terminal 5, <strong>the</strong> project<br />

management team introduced an interface management<br />

strategy which divided component parts of <strong>the</strong> Water<br />

Cube into volumes defined by physical and time<br />

boundaries which were described in a project volume<br />

register and each volume assigned an owner.<br />

An interface occurred when anything touched or<br />

crossed a boundary. Initially all high (key) and low level<br />

interfaces were identified and captured on a register, and<br />

regular interface management and coordination meetings<br />

held involving all parties. The principle began working<br />

very well internally, and was quickly expanded to include<br />

external interfaces w<strong>here</strong> Arup required in<strong>for</strong>mation from<br />

ano<strong>the</strong>r team or third party – e.g. <strong>the</strong> interior designers, or<br />

utility supplies from off site. These external interfaces were<br />

classified as:<br />

Physical – a point or plane common to two or more<br />

parties at which a physical interdependency exists, e.g.<br />

<strong>the</strong> location of an underground service or duct route.<br />

Functional – a relationship between two parties at<br />

which per<strong>for</strong>mance independency exists, eg power<br />

requirements or data connectivity.<br />

Organisational and contractual – a relationship between<br />

two parties in which a delineation in scope or contractual<br />

responsibility exists, e.g. <strong>the</strong> development of details by<br />

Arup’s Chinese design partners CCDI based on Arup’s<br />

scheme designs, or interfaces between civil engineering<br />

and architectural landscaping documentation.<br />

Operational – a relationship between two parties at<br />

which delineation in operational responsibility exists,<br />

e.g. maintenance <strong>for</strong> equipment under warranty with <strong>the</strong><br />

ongoing maintenance and replacement by <strong>the</strong> operator,<br />

and <strong>the</strong> short term responsibilities <strong>for</strong> Olympic overlay<br />

compared to pre-Olympics mode and <strong>the</strong>n legacy mode.<br />

The management of interfaces became one of <strong>the</strong> most<br />

important functions of <strong>the</strong> project management team<br />

during <strong>the</strong> Water Cube design and in <strong>the</strong> longer term,<br />

Arup believes <strong>the</strong> results will also generate significant<br />

savings in construction cost compared to current practice.<br />

Safety in design<br />

Measured by international standards, construction site<br />

safety records in China are poor. At <strong>the</strong> implementation<br />

plan workshop, Arup’s project management team made<br />

a strong commitment to explore <strong>the</strong> risk-prone activities<br />

likely to occur in <strong>the</strong> construction of <strong>the</strong> Water Cube,<br />

and to potentially improve safety by following a ‘Safety in<br />

Design’ approach. This included producing documentation<br />

that would improve safety awareness, suggesting planned<br />

and logical methods <strong>for</strong> construction and maintenance.<br />

Using <strong>the</strong> UK Construction Design and <strong>Management</strong><br />

(CDM) Regulations, and draft NSW legislation, this<br />

approach was intended to ensure that unusual hazards<br />

and risks (such as post-Olympic alterations to <strong>the</strong> internal<br />

fit-out, and working-at-height hazards involved in<br />

maintenance of light fittings or adjusting broadcasting<br />

equipment) were eliminated or controlled at <strong>the</strong> design<br />

stage w<strong>here</strong>ver possible.<br />

The final hazard risk register was included with tender<br />

documentation along with recommendations that it be<br />

incorporated into <strong>the</strong> safety management plans <strong>for</strong> <strong>the</strong><br />

various package contractors on site.<br />

The people factor<br />

To remove potential pinch points from specific key staff<br />

becoming overloaded, and to allow technical staff more<br />

freedom, Arup’s project managers established<br />

semi-independent teams with <strong>the</strong>ir own leadership,<br />

to progress in parallel streams.<br />

The four teams included design, product research,<br />

stakeholder engagement and commercial issues such as<br />

scope, contract and fees. For example, Arup established<br />

clean interfaces that would allow <strong>the</strong> finalisation of <strong>the</strong><br />

structural geometry and research into <strong>the</strong> ETFE facade<br />

per<strong>for</strong>mance to proceed without holding up <strong>the</strong> general<br />

space planning of <strong>the</strong> building. Leadership <strong>for</strong> key<br />

stakeholder meetings was separate from commercial<br />

negotiations, so that one did not compromise <strong>the</strong> o<strong>the</strong>r.<br />

Following <strong>the</strong> success of <strong>the</strong> Water Cube<br />

implementation model, it has now become standard<br />

practice on all of Arup’s major projects. Having specialist<br />

project managers providing leadership, while still providing<br />

freedom to technical staff, significantly improved <strong>the</strong><br />

design process and embedding project management into<br />

<strong>the</strong> business was more easily accepted as <strong>the</strong> specialist<br />

project managers on <strong>the</strong> Water Cube also had technical<br />

engineering backgrounds. In this way <strong>the</strong> specialist project<br />

managers were able to contribute at all levels, ra<strong>the</strong>r than<br />

ever being perceived as a ‘non-technical’ overhead.<br />

Developing <strong>the</strong> tools to deliver<br />

The Water Cube was a catalyst <strong>for</strong> <strong>the</strong> development of<br />

a range of bespoke project management planning and<br />

monitoring tools. Such tools were needed to deliver such<br />

5

APM <strong>Project</strong> <strong>Management</strong> Awards<br />

WINNER’S<br />

CASE STUDY<br />

a large multidisciplinary project, delivered across different<br />

offices, and with a program that demanded reporting,<br />

monitoring and action to happen in real time.<br />

A range of project management tools established<br />

<strong>for</strong> <strong>the</strong> Water Cube have since been developed fur<strong>the</strong>r<br />

through internal funding and are now being rolled out on<br />

all major Arup projects in <strong>the</strong> Australasia Region. These<br />

include simple protocols <strong>for</strong> shared servers and email filing<br />

between multiple offices, technical management of project<br />

interfaces, safety in design and construction sequencing,<br />

through to more complex programming applications that<br />

interface with Arup’s global cost monitoring system to<br />

provide detailed <strong>for</strong>ecasting and per<strong>for</strong>mance reporting<br />

capabilities such as resource management and earned<br />

value management.<br />

In fact, following on from <strong>the</strong> momentum and success<br />

of <strong>the</strong> Water Cube, <strong>the</strong>re is now a dedicated systems<br />

development & integration team based within Arup’s<br />

Brisbane project management team that services both<br />

internal major projects and also success<strong>full</strong>y provides<br />

<strong>the</strong>se services direct to external clients, through licensing<br />

agreements and tailored systems development.<br />

Conclusions<br />

Stretching with <strong>the</strong>ir involvement in <strong>the</strong> design competition<br />

in 2003, through to <strong>the</strong> emerging dynamics of working<br />

between Chinese and Australian teams, <strong>the</strong> Water<br />

Cube has been an incredible learning and development<br />

experience <strong>for</strong> Arup. The Water Cube has acted as catalyst<br />

in advancing and codifying Arup’s approach to a number of<br />

key areas of project management knowledge.<br />

In particular, <strong>the</strong>se included:<br />

Establishing and leading winning teams,<br />

Managing relationships with stakeholders across<br />

cultures,<br />

<strong>Project</strong> management processes required on major<br />

multidisciplinary projects,<br />

Technological improvements in modelling capability.<br />

These have since been used to great effect on many<br />

o<strong>the</strong>r Arup projects internationally. Watching <strong>the</strong> Olympic<br />

events in <strong>the</strong> Water Cube has been a rewarding and<br />

humbling experience <strong>for</strong> <strong>the</strong> Arup team. T<strong>here</strong> is a genuine<br />

sense of authorship with <strong>the</strong> team members, and <strong>the</strong>re<br />

have been many presentations and discussions about why<br />

<strong>the</strong> project was so special.<br />

Of all <strong>the</strong> key messages though, <strong>the</strong> one that has<br />

emerged above all o<strong>the</strong>rs is <strong>the</strong> total, equitable and<br />

transparent partnership between Arup, PTW Architects,<br />

and CCDI.<br />

The Water Cube is a unique project brought about<br />

by a set of circumstances that perhaps may never repeat<br />

<strong>the</strong>mselves. Olympic venues are always special, but <strong>the</strong><br />

nature of Beijing’s aspirations to emerge on <strong>the</strong> global<br />

stage meant that <strong>the</strong> Water Cube became a representation<br />

to four billion viewers of a new Beijing.<br />

The fact that Beijing invited international designers to be<br />

part of <strong>the</strong> Olympics at all was unusual, and set <strong>the</strong> tone <strong>for</strong><br />

a genuine collaboration on <strong>the</strong> Water Cube w<strong>here</strong> western<br />

and eastern perspectives worked toge<strong>the</strong>r with mutual<br />

respect and openness.<br />

The project management of <strong>the</strong> Water Cube has created<br />

a lasting legacy <strong>for</strong> Beijing, and a lasting legacy <strong>for</strong> Arup’s<br />

project management team.<br />

6

APM <strong>Project</strong> <strong>Management</strong> Awards<br />

WINNER’S<br />

CASE STUDY<br />

The APM <strong>Project</strong> <strong>Management</strong> Awards have been celebrating<br />

project management excellence since 1993 and <strong>the</strong> broad range<br />

of categories is designed to make entry possible <strong>for</strong> projects and<br />

companies of all sizes and complexity.<br />

Joana Kennedy OBE, Director<br />

of Ove Arup & Partners Ltd<br />

collecting <strong>the</strong> 2008 Overseas<br />

<strong>Project</strong> of <strong>the</strong> Year Award <strong>for</strong><br />

<strong>the</strong> Watercube, Beijing<br />

The awards reflect <strong>the</strong> invaluable contribution project managers<br />

make in all sectors of society and <strong>the</strong> event provides an opportunity<br />

<strong>for</strong> industry professionals to meet with colleagues and entertain<br />

guests as well as celebrate at one of <strong>the</strong> year’s most exciting events.<br />

Highly regarded in <strong>the</strong> project management industry, <strong>the</strong> awards<br />

reflect <strong>the</strong> dedication and talent that helps to shape <strong>the</strong> project<br />

management community and <strong>the</strong> world around us. The finalists,<br />

winners and sponsors of <strong>the</strong> awards attract national publicity <strong>for</strong><br />

<strong>the</strong>ir achievement and involvement. Winning an award provides<br />

invaluable recognition and kudos to <strong>the</strong> careers of winners.<br />

For more details on <strong>the</strong> awards and how to enter or attend, visit<br />

www.apm.org.uk/awards.asp or email awards@apm.org.uk<br />

7

<strong>Association</strong> <strong>for</strong> <strong>Project</strong> <strong>Management</strong><br />

Ibis House, Regent Park<br />

Summerleys Road<br />

Princes Risborough<br />

Buckinghamshire, HP27 9LE<br />

Telephone 0845 458 1944<br />

International +44 (0)1844 271640<br />

Facsimile +44 (0)1844 274509<br />

Email<br />

Web<br />

info@apm.org.uk<br />

www.apm.org.uk