WCP Magazine Dec 2014

WCP Magazine Dec 2014

WCP Magazine Dec 2014

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Our controllers are able to operate in ambient air temperature up to 40C. By this I mean that the control<br />

will operate normally even if the air temperature during the day reaches 40C. The control will also operate<br />

happily in temperatures to minus 5c. Electronics are far better coping with cold than heat.<br />

As part of our testing a control was fitted to a pump running at maximum for long periods the Temperature<br />

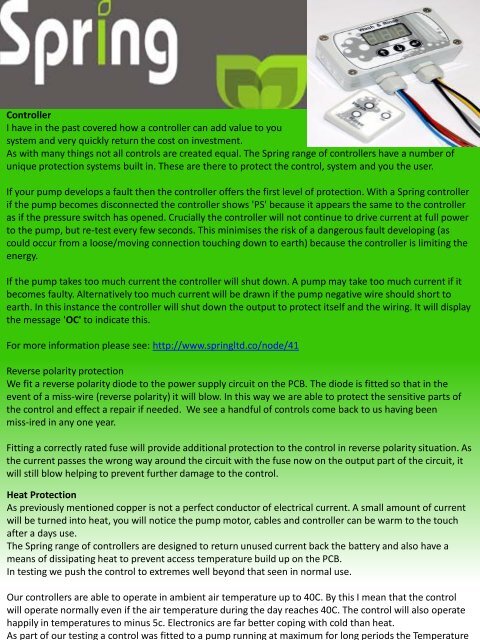

Controller<br />

I have in the past covered how a controller can add value to you<br />

system and very quickly return the cost on investment.<br />

As with many things not all controls are created equal. The Spring range of controllers have a number of<br />

unique protection systems built in. These are there to protect the control, system and you the user.<br />

If your pump develops a fault then the controller offers the first level of protection. With a Spring controller<br />

if the pump becomes disconnected the controller shows 'PS' because it appears the same to the controller<br />

as if the pressure switch has opened. Crucially the controller will not continue to drive current at full power<br />

to the pump, but re-test every few seconds. This minimises the risk of a dangerous fault developing (as<br />

could occur from a loose/moving connection touching down to earth) because the controller is limiting the<br />

energy.<br />

If the pump takes too much current the controller will shut down. A pump may take too much current if it<br />

becomes faulty. Alternatively too much current will be drawn if the pump negative wire should short to<br />

earth. In this instance the controller will shut down the output to protect itself and the wiring. It will display<br />

the message 'OC' to indicate this.<br />

For more information please see: http://www.springltd.co/node/41<br />

Reverse polarity protection<br />

We fit a reverse polarity diode to the power supply circuit on the PCB. The diode is fitted so that in the<br />

event of a miss-wire (reverse polarity) it will blow. In this way we are able to protect the sensitive parts of<br />

the control and effect a repair if needed. We see a handful of controls come back to us having been<br />

miss-ired in any one year.<br />

Fitting a correctly rated fuse will provide additional protection to the control in reverse polarity situation. As<br />

the current passes the wrong way around the circuit with the fuse now on the output part of the circuit, it<br />

will still blow helping to prevent further damage to the control.<br />

Heat Protection<br />

As previously mentioned copper is not a perfect conductor of electrical current. A small amount of current<br />

will be turned into heat, you will notice the pump motor, cables and controller can be warm to the touch<br />

after a days use.<br />

The Spring range of controllers are designed to return unused current back the battery and also have a<br />

means of dissipating heat to prevent access temperature build up on the PCB.<br />

In testing we push the control to extremes well beyond that seen in normal use.