Catalog Supplement for 2006 - JRP

Catalog Supplement for 2006 - JRP

Catalog Supplement for 2006 - JRP

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

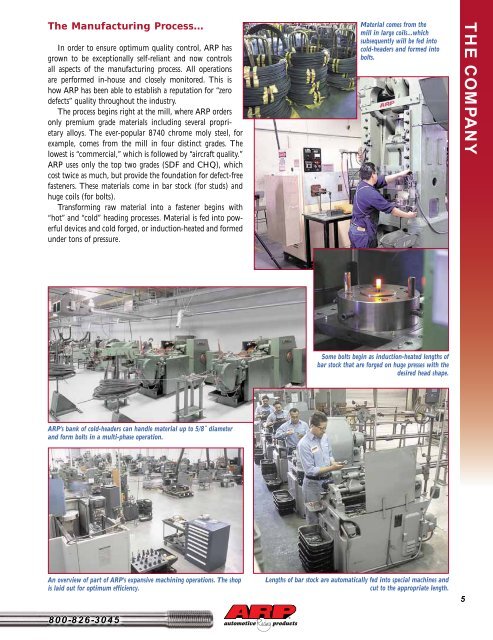

The Manufacturing Process…<br />

In order to ensure optimum quality control, ARP has<br />

grown to be exceptionally self-reliant and now controls<br />

all aspects of the manufacturing process. All operations<br />

are per<strong>for</strong>med in-house and closely monitored. This is<br />

how ARP has been able to establish a reputation <strong>for</strong> “zero<br />

defects” quality throughout the industry.<br />

The process begins right at the mill, where ARP orders<br />

only premium grade materials including several proprietary<br />

alloys. The ever-popular 8740 chrome moly steel, <strong>for</strong><br />

example, comes from the mill in four distinct grades. The<br />

lowest is “commercial,” which is followed by “aircraft quality.”<br />

ARP uses only the top two grades (SDF and CHQ), which<br />

cost twice as much, but provide the foundation <strong>for</strong> defect-free<br />

fasteners. These materials come in bar stock (<strong>for</strong> studs) and<br />

huge coils (<strong>for</strong> bolts).<br />

Trans<strong>for</strong>ming raw material into a fastener begins with<br />

“hot” and “cold” heading processes. Material is fed into powerful<br />

devices and cold <strong>for</strong>ged, or induction-heated and <strong>for</strong>med<br />

under tons of pressure.<br />

Material comes from the<br />

mill in large coils...which<br />

subsequently will be fed into<br />

cold-headers and <strong>for</strong>med into<br />

bolts.<br />

THE COMPANY<br />

Some bolts begin as induction-heated lengths of<br />

bar stock that are <strong>for</strong>ged on huge presses with the<br />

desired head shape.<br />

ARP’s bank of cold-headers can handle material up to 5/8˝ diameter<br />

and <strong>for</strong>m bolts in a multi-phase operation.<br />

An overview of part of ARP’s expansive machining operations. The shop<br />

is laid out <strong>for</strong> optimum efficiency.<br />

800-826-3045<br />

Lengths of bar stock are automatically fed into special machines and<br />

cut to the appropriate length.<br />

5