TDS - Axson North America, Inc

TDS - Axson North America, Inc

TDS - Axson North America, Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

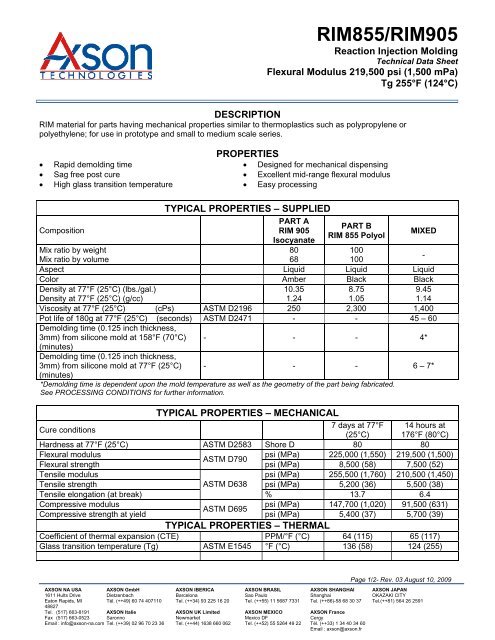

RIM855/RIM905<br />

Reaction Injection Molding<br />

Technical Data Sheet<br />

Flexural Modulus 219,500 psi (1,500 mPa)<br />

Tg 255°F (124°C)<br />

DESCRIPTION<br />

RIM material for parts having mechanical properties similar to thermoplastics such as polypropylene or<br />

polyethylene; for use in prototype and small to medium scale series.<br />

PROPERTIES<br />

• Rapid demolding time • Designed for mechanical dispensing<br />

• Sag free post cure • Excellent mid-range flexural modulus<br />

• High glass transition temperature • Easy processing<br />

Composition<br />

TYPICAL PROPERTIES – SUPPLIED<br />

PART A<br />

RIM 905<br />

Isocyanate<br />

80<br />

68<br />

PART B<br />

RIM 855 Polyol<br />

MIXED<br />

Mix ratio by weight<br />

100<br />

Mix ratio by volume<br />

100<br />

-<br />

Aspect Liquid Liquid Liquid<br />

Color Amber Black Black<br />

Density at 77°F (25°C) (lbs./gal.)<br />

10.35<br />

8.75<br />

9.45<br />

Density at 77°F (25°C) (g/cc)<br />

1.24<br />

1.05<br />

1.14<br />

Viscosity at 77°F (25°C) (cPs) ASTM D2196 250 2,300 1,400<br />

Pot life of 180g at 77°F (25°C) (seconds) ASTM D2471 - - 45 – 60<br />

Demolding time (0.125 inch thickness,<br />

3mm) from silicone mold at 158°F (70°C)<br />

(minutes)<br />

Demolding time (0.125 inch thickness,<br />

3mm) from silicone mold at 77°F (25°C)<br />

(minutes)<br />

- - - 4*<br />

- - - 6 – 7*<br />

*Demolding time is dependent upon the mold temperature as well as the geometry of the part being fabricated.<br />

See PROCESSING CONDITIONS for further information.<br />

TYPICAL PROPERTIES – MECHANICAL<br />

Cure conditions<br />

7 days at 77°F 14 hours at<br />

(25°C) 176°F (80°C)<br />

Hardness at 77°F (25°C) ASTM D2583 Shore D 80 80<br />

Flexural modulus psi (MPa) 225,000 (1,550) 219,500 (1,500)<br />

ASTM D790<br />

Flexural strength<br />

psi (MPa) 8,500 (58) 7,500 (52)<br />

Tensile modulus psi (MPa) 255,500 (1,760) 210,500 (1,450)<br />

Tensile strength ASTM D638 psi (MPa) 5,200 (36) 5,500 (38)<br />

Tensile elongation (at break)<br />

% 13.7 6.4<br />

Compressive modulus psi (MPa) 147,700 (1,020) 91,500 (631)<br />

ASTM D695<br />

Compressive strength at yield<br />

psi (MPa) 5,400 (37) 5,700 (39)<br />

TYPICAL PROPERTIES – THERMAL<br />

Coefficient of thermal expansion (CTE) PPM/°F (°C) 64 (115) 65 (117)<br />

Glass transition temperature (Tg) ASTM E1545 °F (°C) 136 (58) 124 (255)<br />

Page 1/2- Rev. 03 August 10, 2009<br />

AXSON NA USA AXSON GmbH AXSON IBERICA AXSON BRASIL AXSON SHANGHAI AXSON JAPAN<br />

1611 Hults Drive Dietzenbach Barcelona Sao Paulo Shanghai OKAZAKI CITY<br />

Eaton Rapids, MI Tél. (++49) 60 74 407110 Tel. (++34) 93 225 16 20 Tel. (++55) 11 5687 7331 Tel. (++86)-58 68 30 37 Tel.(++81) 564 26 2591<br />

48827<br />

Tel. (517) 663-8191 AXSON Italie AXSON UK Limited AXSON MEXICO AXSON France<br />

Fax (517) 663-0523 Saronno Newmarket Mexico DF Cergy<br />

Email : info@axson-na.com Tel. (++39) 02 96 70 23 36 Tel. (++44) 1638 660 062 Tel. (++52) 55 5264 49 22 Tél. (++33) 1 34 40 34 60<br />

Email : axson@axson.fr

RIM855/RIM905<br />

Reaction Injection Molding<br />

Technical Data Sheet<br />

Flexural Modulus 219,500 psi (1,500 mPa)<br />

Tg 255°F (124°C)<br />

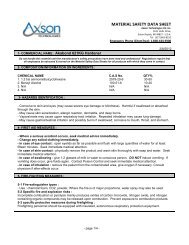

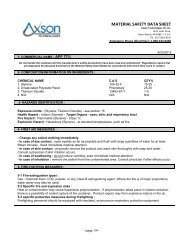

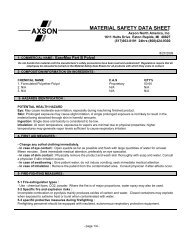

PROCESSING CONDITIONS<br />

Part B contains fillers which tend to settle during storage; remix to ensure a homogeneous product. Part B may be<br />

remixed through the use of an agitator on a dispensing machine or by hand; after remixing be sure to protect the<br />

material from moisture contamination through the use of a qualified dry blanket like <strong>Axson</strong> <strong>North</strong> <strong>America</strong>’s dry gas<br />

blanket. Both parts (polyol and isocyanate) must be mixed at a temperature higher than 65°F (18.5°C) according to<br />

the mix ratio above. Casting must be conducted in molds free of any trace of moisture. For further information<br />

please consult AXSON’s technical staff or AXSON’s technical data sheet about ANCILLARY PRODUCTS.<br />

Prior to unsupported post cure: Once demolded, ensure that the part has obtained a rigid state prior to<br />

unsupported post cure. Example: 1/8 inch part from 158°F (70°C) silicone mold may be post cured without support<br />

roughly 4 minutes after demolding, whereas a 1/8 inch part from a room temperature silicone mold can be post<br />

cured without support roughly 6 minutes after demolding. The time required prior to unsupported post cure is<br />

dependent upon the mold temperature as well as the geometry of the part being fabricated.<br />

Optimum properties of the material are obtained after a 14 hour post cure at 176°F (80°C)<br />

STORAGE CONDITIONS<br />

Shelf life is 1 year (12) months when stored at 77°F (25°C) in original, unopened containers.<br />

HANDLING PRECAUTIONS<br />

Possibly irritating to the respiratory system and to skin. Always wear appropriate personal protection. Avoid<br />

fumes, use only in a well ventilated area. If skin contact occurs, wash immediately with soap and water; if<br />

irritation develops contact a physician. In the event of an eye splash, wash the contaminated eye with water for<br />

at least 15 minutes and immediately seek medical help. If ingested, contact a physician.<br />

Consult the MSDS for further information.<br />

GUARANTEE<br />

The information presented in this technical data sheet are based on results of tests conducted under precise conditions. It is the responsibility of<br />

the user to determine the suitability of AXSON products, under their own conditions, before commencing with application. AXSON refuses any<br />

guarantee concerning the compatibility of a product with any particular application. AXSON disclaims all responsibility for damage from any<br />

incident which results from the use of these products. The guarantee conditions are regulated by our general sale conditions.<br />

Page 2/2- Rev. 03 August 10, 2009<br />

AXSON NA USA AXSON GmbH AXSON IBERICA AXSON BRASIL AXSON SHANGHAI AXSON JAPAN<br />

1611 Hults Drive Dietzenbach Barcelona Sao Paulo Shanghai OKAZAKI CITY<br />

Eaton Rapids, MI Tél. (++49) 60 74 407110 Tel. (++34) 93 225 16 20 Tel. (++55) 11 5687 7331 Tel. (++86)-58 68 30 37 Tel.(++81) 564 26 2591<br />

48827<br />

Tel. (517) 663-8191 AXSON Italie AXSON UK Limited AXSON MEXICO AXSON France<br />

Fax (517) 663-0523 Saronno Newmarket Mexico DF Cergy<br />

Email : info@axson-na.com Tel. (++39) 02 96 70 23 36 Tel. (++44) 1638 660 062 Tel. (++52) 55 5264 49 22 Tél. (++33) 1 34 40 34 60<br />

Email : axson@axson.fr