WSP Construction Design - WSP Group

WSP Construction Design - WSP Group

WSP Construction Design - WSP Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>WSP</strong> <strong>Construction</strong> <strong>Design</strong>

A characteristic feature of good construction design is that no unexpected disruptions occur.<br />

<strong>Design</strong>ing buildings is one thing – handling complete projects is entirely something else. You can<br />

keep track of our work throughout the project period, from the initial idea to the property<br />

management stage. The earlier you involve us, the greater the responsibility we can take.<br />

Tighter deadlines and changing methods<br />

Building design is becoming increasingly sophisticated. Projects<br />

are carried out with ever tighter time limits and new<br />

methods of construction are being developed. This makes<br />

great demands on planning and design methodology.<br />

Right team for each project<br />

Expert personnel are <strong>WSP</strong>’s greatest and most important resource.<br />

With the backing of skilled staff and a strong organisation,<br />

we are always able to put together the team best suited<br />

to each project. This applies both to large, extensive projects<br />

and to smaller and quicker assignments. We adapt our efforts<br />

to maximise customer benefit.<br />

Competitions – a good way of gauging our own<br />

capability<br />

For a knowledge-based company, competitions are a good way<br />

of gauging its own capability. Therefore we are proud to be<br />

able to point out projects we have gained through challenging<br />

and creative solutions, which have increased the added<br />

value of the buildings through innovative technology and a<br />

comprehensive perspective.<br />

The compact building process<br />

We live in a time of rapid change. This is one reason why<br />

people today often want to be able to take step-by-step decisions<br />

on parts of the project along the way. Present day reality<br />

also means that it is almost always considered essential to<br />

minimise the total project time, i.e. the time from investment<br />

decision to completion. The aim is to increase certainty and<br />

reduce risk-taking.<br />

The compact building process is a reality today, and will<br />

be even more so in the future. It makes it necessary for high<br />

quality work to be done in both decision planning and project<br />

management. It also entails a model of implementation<br />

for the design and construction on site as well as monitoring<br />

and controlling project cost development. <strong>WSP</strong> has the experience,<br />

methodology, developed support documents and routines<br />

to meet the requirements for short times, successive<br />

decisionmaking and optimum project result.<br />

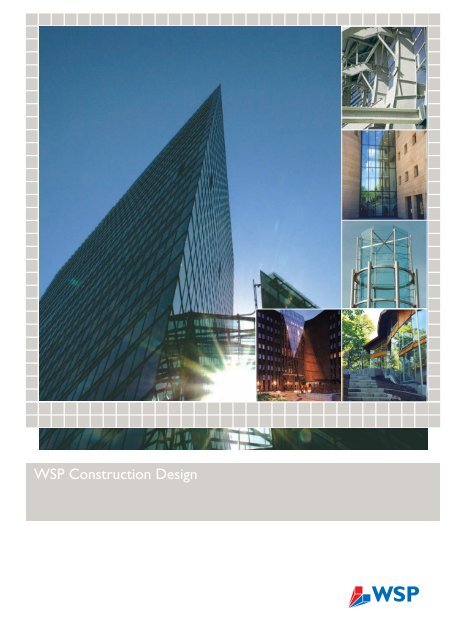

On the front cover, some prize-winning projects:<br />

1<br />

6<br />

2<br />

3<br />

4<br />

5<br />

1. Kista Science Tower, White Arkitekter<br />

(Photo: Mark Earthy/Pressens Bild)<br />

2. Stockholm Globen Arena, Bergs Arkitekter<br />

3. Malmö City Library, Henning Larsen Tegnestue<br />

4. Stockholm, Southern Link ventilation system,<br />

Tengbom Arkitekter, artist Leif Bolter<br />

5. Frescati Aula Magna, Ralph Erskine<br />

6. Stockholm, Ericsson, Main Entrance<br />

Bjurström & Brodin Arkitekter<br />

Kista Science Tower.<br />

A 32-storey, 158 metre high and just over 41 000 sq.m. large offi ce building. The building has a triangular shape and double-glazed facades,<br />

and is a new landmark for Kista.<br />

2

Working on assignment<br />

The essential requirements of the project are the<br />

point where our work begins<br />

During our planning of the assignment, we identify the essential<br />

requirements of the project and the client’s expectations.<br />

These are transformed into optimal solutions on the<br />

basis of given functional and technical requirements as well<br />

as environmental demands within specified financial and time<br />

constraints. During the course of the design work we make<br />

sure that the demands are worked into the documents.<br />

Assignment control at all stages<br />

This approach forms the basis for how we conduct our assignments.<br />

It means that you, as the client, obtain a solution<br />

that has the necessary potential for ensuring that a finished<br />

structure or building will meet stipulated demands and preferences.<br />

With an established and jointly approved quality and<br />

environmental plan, assignment and cost control are conducted<br />

on the one hand with in-house developed software for<br />

follow-up and assignment reporting, and on the other hand<br />

with routines linked to <strong>WSP</strong>’s financial system. The reporting<br />

of completed and remaining work is normally done on a<br />

monthly basis in hours and costs, and can be adapted to suit<br />

the client’s requirements.<br />

<strong>WSP</strong> is quality certified in accordance with SS-EN ISO<br />

9001:2000 and environmentally certified to SS-EN ISO<br />

14001. Our work on assignments follows specially developed<br />

environmental methods and a list of environmental aspects.<br />

The same model for implementation – from start of assignment<br />

to completion – makes it possible to achieve the right quality and<br />

cost effectiveness.<br />

The assignment process routines and aids are based on experience<br />

within <strong>WSP</strong> and meets the requirements of the standards<br />

SS-EN ISO 9001 and 14001.<br />

Our routines, aids and templates for carrying out the assignment.<br />

3

Our project types and skills<br />

Our experience of both new construction and conversion can be applied in all stages of the project -<br />

experience we have acquired over a long period of time by working on a large range of projects,<br />

all the way from the early stages, through participation in competitions and not least through high-qualifi ed<br />

conversion projects, such as inner-city and industrial projects.<br />

Our project types, skills and top-level expertise are summarised below.<br />

Top-level expertise<br />

• Structural and construction engineering design of steel,<br />

concrete (incl. prestressed), timber, brick, stone, glass and<br />

plastic structures.<br />

• Building dynamics with regard to frame structures,<br />

machine foundations and vibration-free foundations.<br />

• Building engineering and building physics with regard to<br />

load-bearing capacity, build ability, durability, effect of fire,<br />

moisture and environmental issues.<br />

• Risk analysis of larger building complexes and tunnels, e.g.<br />

with respect to transport of hazardous goods and fire<br />

analyses.<br />

• Structural engineering and design calculations, of tall<br />

buildings, including wind-tunnel studies (CFD analysis),<br />

dynamic analysis (wind, human comfort, passive and active<br />

mass damping and optimisation of the stability of frame<br />

structures).<br />

• Roof and terrace damage investigations.<br />

Our services<br />

• <strong>Design</strong> of buildings and civil engineering structures.<br />

• Building design, building technology and building physics.<br />

• Conversion and renovation engineering.<br />

• Building statics and dynamics.<br />

• Technical surveys and damage investigations.<br />

• Technical development in projects for the construction<br />

industry.<br />

• R&D.<br />

• Fire protection documentation and fire protection<br />

engineering.<br />

• Risk/impact assessment.<br />

• Quality responsibility in accordance with the Planning<br />

and Building Act, PBL.<br />

• Air-raid shelter expertise.<br />

• 3D design and 3D analysis.<br />

• Foundation preservation techniques, <strong>WSP</strong> Terrasond.<br />

In close co-operation with <strong>WSP</strong> Management, we also offer:<br />

• <strong>Design</strong> management.<br />

• <strong>Construction</strong> management.<br />

• Technical inspection.<br />

• Performance specifications.<br />

• Costings.<br />

General building construction<br />

• Offices<br />

• Institutes of higher education and<br />

universities<br />

• Business and conference centres<br />

• Hotels and apartment blocks<br />

• Retail<br />

• Research facilities<br />

• Hospitals and health centres<br />

• Museums, libraries and churches<br />

• Cinema complexes<br />

• Banks and police stations<br />

• Public swimming baths<br />

• Refurbishment/conversion of arts centres<br />

and listed buildings<br />

Industrial buildings<br />

Heavy industry<br />

• Forest industry<br />

• Mining and minerals industry<br />

• Steel industry<br />

• Energy installations<br />

• Water and sewage treatment<br />

plants<br />

• Petrochemical industry<br />

• Chemical industry<br />

Light industry<br />

• Pharmaceutical industry<br />

• Food industry<br />

• Electronic industry<br />

Other types of industry<br />

• Manufacturing industry<br />

• Automotive industry<br />

• Distribution centres<br />

Infrastructure<br />

• Stadia and Arenas<br />

• Airports<br />

• Train and bus terminals<br />

• Travel centres<br />

• Metro/underground stations<br />

• Rescue centres<br />

• Command centres<br />

• Rock cavern facilities<br />

• Hangars<br />

• Decking over structures, bridges<br />

and tunnels<br />

4

Rational implementation, building methods and effective<br />

design work are based on continuous R&D<br />

We are constantly developing within our assignments and in the R&D projects that we conduct either inhouse<br />

or in co-operation with institutes of higher education and universities. Our concentration on development<br />

is important to be able to create final solutions with a focus on totality in terms of implementation<br />

period, quality, function and cost.<br />

Development takes place continuously in the<br />

following areas:<br />

• Implementation models<br />

• Procurement and payment models<br />

• Short implementation periods<br />

• Project management<br />

• Efficient design<br />

• Technical solutions<br />

• Environmental issues<br />

• Dynamic analyses<br />

• Material issues, steel and concrete<br />

• 3D design<br />

Velocity (mm/s)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

6289H<br />

1<br />

0<br />

0<br />

25<br />

50<br />

75<br />

100<br />

12.5<br />

37.5<br />

62.5<br />

87.5<br />

112.5<br />

Freq (Hz)<br />

Dynamic FEM analysis of a machinery foundation.<br />

125<br />

Technical reports, directions, thesis and notices<br />

form part of the quality assurance work.<br />

Flat slab constructions with patented<br />

shear reinforcement, which results in<br />

smaller quantities of reinforcement and<br />

endows the structure with great ductility.<br />

Efficient execution as the reinforcement is<br />

separated into different layers.<br />

Radical conversions require special building<br />

methods, a developed implementation<br />

plan and follow-up procedure with<br />

active design during the period of construction.<br />

Analysis of wind pressures and wind loads<br />

occurring in the wind tunnel (CFD analysis)<br />

for Kista Science Tower.<br />

5

We also have capacity and ample experience in<br />

extremely large and complex projects.<br />

Musi Pulp Mill, Sumatra<br />

A new complete pulp mill producing<br />

500,000 tonnes a year. The construction design<br />

was accomplished in 12 months in Indonesia<br />

with local sub-consultants under the<br />

direction of <strong>WSP</strong>.<br />

Swedish Match<br />

New snuff factory in Kungälv, 23,000 sq.m.<br />

An EPCM (engineering, procurement, construction,<br />

management) assignment for <strong>WSP</strong><br />

including technical design of construction,<br />

ground, environment, electricity, control and<br />

automation.<br />

Käppala waste water treatment<br />

plant<br />

An extensive infrastructure project in which<br />

large resources and specialist skills were<br />

required for the design of both building related<br />

and process-related parts of the construction.<br />

SSAB, Oxelösund<br />

The rolling plate mill was converted into<br />

one of the most efficient in the world while<br />

operation continued. The structural design<br />

required considerable adaptation to the<br />

building work with respect to timetable,<br />

temporary structures and loads.<br />

Physics centre<br />

<strong>WSP</strong> assisted with the winning competition<br />

entry. The extreme requirements for the<br />

cleanliness and freedom from vibrations of<br />

the premises made great demands on the<br />

building and structural design of the facility.<br />

Architect, Henning Larsens Tegningstue, Copenhagen.<br />

City Cronan<br />

Offices 48,000 sq.m. 50 apartments. A conversion<br />

and extension project where the<br />

frame structure and erection in stages has<br />

been adapted to the locations and the loadbearing<br />

capacity of traffic and service tunnels<br />

underneath. The inner courtyard has a<br />

glazed roof with a steel structure of minimalist<br />

design. Reflex Arkitekter, Stockholm<br />

Arlanda Nord 2002<br />

Pier F, the Passage building and the new Terminal<br />

North building, a new expansion of<br />

Arlanda Airport for increased capacity and<br />

adaptation to the Schengen Agreement.<br />

Steel frame structure and bracing-free filigran<br />

steel-concrete composite floor structures.<br />

Large roof truss cantilevers, doubleglazed<br />

facades, suspended floor structure in<br />

roof truss. KHR Arkitekter Copenhagen.<br />

Rönnskär +200<br />

Boliden has carried out an upgrading of the<br />

entire melting plant and an increase in capacity<br />

to make it one of the most modern<br />

plants in the world, with regard also to<br />

environmental issues. The upgrade has been<br />

completed in stages while operation continues,<br />

with frame structure solutions adapted<br />

accordingly. <strong>WSP</strong> has been responsible<br />

for building design, geo-engineering and fire<br />

protection dimensioning.<br />

Högdalen BIO6 CHP plant<br />

New biofuel-fired boiler 95 MW and refuse<br />

incineration boiler 75 MW, as well as reception<br />

hall, flue-gas scrubbing turbine and ash<br />

silo building. The expansion has been carried<br />

out in stages within an energy facility already<br />

in heavy use. <strong>WSP</strong> has been responsible for<br />

building design and geo-engineering.<br />

6

3D design – the natural choice in our projects<br />

3D design is today an obvious and necessary choice for designers, contractors and clients/users. Obvious<br />

because the co-ordination advantages for all the disciplines involved are significant and necessary because<br />

today’s strained time schedules, with design and construction running in parallel, demand zero faults and the<br />

capacity to be able to rapidly localise the consequences of, for example, a change.<br />

3D in practice<br />

The concept of 3D design includes, as a<br />

natural component, 3D scanning which<br />

is a fantastic aid in representing reality<br />

in three dimensions. The generated 3D<br />

model of reality is integrated into the<br />

design model in order to be able to localize<br />

collision points directly or quite<br />

simply to adapt the design to suit existing<br />

conditions.<br />

A terrain model in 3D with levels for<br />

ground surface, rock and different types<br />

of soil is inserted into a 3D model in<br />

order later to analyse necessary excavation<br />

requirements and volumes.<br />

Complicated structures and dynamically<br />

loaded structures require analysis<br />

and dimensioning in 3D. Within <strong>WSP</strong>,<br />

we use ANSYS, STAAD, Robot Millennium<br />

and Strusoft. The advantage<br />

of these programs is that you can export<br />

data from and import data to the 3D<br />

model.<br />

In large complex projects within the<br />

process industry, co-operation between<br />

building consultants, process consultants<br />

and other players is an important part<br />

of the design work, and the principal<br />

model is built in PDMS. Our 3D<br />

model in Tekla Structures is exported to<br />

PDMS with a conversion program that<br />

retains intelligence in the 3D model.<br />

<strong>WSP</strong> is Sweden’s largest user of the<br />

3D program Tekla Structures, which is<br />

a multi-material CAD tool with large<br />

built-in intelligence. The above activities<br />

are compiled in the Tekla model and<br />

therefore provide excellent input at all<br />

stages of the design work.<br />

Kungsbron, Stockholm<br />

Office block<br />

Advantages and potential<br />

• Bills of quantities can be generated for all materials. This includes the content<br />

of reinforcement and the area of formwork for concrete, the weight of prefabricated<br />

elements and the volumes of rock and soil excavation.<br />

Vällingby, Stockholm<br />

Load-bearing structure for glazed roof<br />

• Production planning for the erection of structural frames, which is important<br />

for crane positioning, scaffolding and stockpiles.<br />

• Overview of time schedules. By means of so-called 4D technology the progress<br />

of construction can be followed on a day-by-day or week-by-week basis.<br />

Critical points can be illustrated directly.<br />

• Help with reinforcement. Complicated concrete reinforcement areas can be<br />

illustrated to clarify complicated cross-sections.<br />

• CNC control of machinery for steel structures. Basic input is mailed directly<br />

to the steel supplier workshop, which then can start entering the information<br />

into its machine.<br />

• A faster descision-making process. Operational staff concerned can use the<br />

model on the web to give their views on the position of service points, stockpiles,<br />

lifting areas, etc.<br />

PDMS, Jiang Lin, China<br />

Pulp mill, Pipe bridge<br />

7

<strong>WSP</strong> is a global company that offers qualified consultancy services for the public sector and<br />

the environment. With more than 100 offices around the world, and 6 000 employees, <strong>WSP</strong> is<br />

one of the largest consulting companies in Europe, and amongst the ten largest in the world.<br />

Operations are concentrated primarily in England and Sweden, but also extend to the rest of<br />

Europe, the United States, Africa and Asia.<br />

For our customers, this means being able to enjoy the benefits of our unique specialist expertise<br />

and our wide range of services. We maintain a strong local presence on each market,<br />

while, at the same time, our network of specialists contributes the skills, expertise and resources<br />

needed to achieve the best solutions. In Sweden, <strong>WSP</strong> is a nationwide consultancy company<br />

employing 1 900 people.<br />

Operations are conducted through the business areas:<br />

<strong>WSP</strong> Architecture<br />

<strong>WSP</strong> <strong>Construction</strong> <strong>Design</strong><br />

<strong>WSP</strong> Environmental<br />

<strong>WSP</strong> International<br />

<strong>WSP</strong> Management<br />

<strong>WSP</strong> Civils<br />

<strong>WSP</strong> Systems<br />

We operate in the following locations:<br />

Borlänge • Falköping • Gothenburg • Helsingborg • Kalmar • Karlstad • Kiruna • Kristianstad<br />

Linköping • Luleå • Lund • Malmberget • Malmö • Norrköping • Piteå<br />

Skellefteå • Stockholm • Sundsvall • Torsby • Umeå • Varberg • Ystad • Örebro<br />

• Örnsköldsvik • Östersund<br />

<strong>WSP</strong> <strong>Construction</strong> <strong>Design</strong><br />

Arenavägen 7<br />

SE- 121 88 Stockholm, Sweden<br />

Tel: +46 (0)8 688 60 00<br />

Fax: +46 (0)8 688 69 99<br />

www.wspgroup.se