Made in Germany VARIOMASTER Cleaning & Filling

Made in Germany VARIOMASTER Cleaning & Filling

Made in Germany VARIOMASTER Cleaning & Filling

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Masch<strong>in</strong>endatenblatt<br />

TWIN <strong>VARIOMASTER</strong> II<br />

Re<strong>in</strong>igen Clean<strong>in</strong>g & Befüllen Fill<strong>in</strong>g <strong>Made</strong> <strong>in</strong> <strong>Germany</strong>

Masch<strong>in</strong>endatenblatt<br />

- Patented clean<strong>in</strong>g process<br />

- Patented condensate monitor<strong>in</strong>g<br />

- Inductive flowmeter for fill<strong>in</strong>g level control<br />

- Siemens touchpanel<br />

- Festo pneumatic with manual start-up valve<br />

TWIN <strong>VARIOMASTER</strong> II<br />

- Good accessibility of all components<br />

- Variable equipment for different keg sizes<br />

- Small ma<strong>in</strong>tenance effort<br />

- Stop-valves for all media<br />

Re<strong>in</strong>igen Clean<strong>in</strong>g & Befüllen Fill<strong>in</strong>g<br />

<strong>Made</strong> <strong>in</strong> <strong>Germany</strong>

Masch<strong>in</strong>endatenblatt<br />

Description<br />

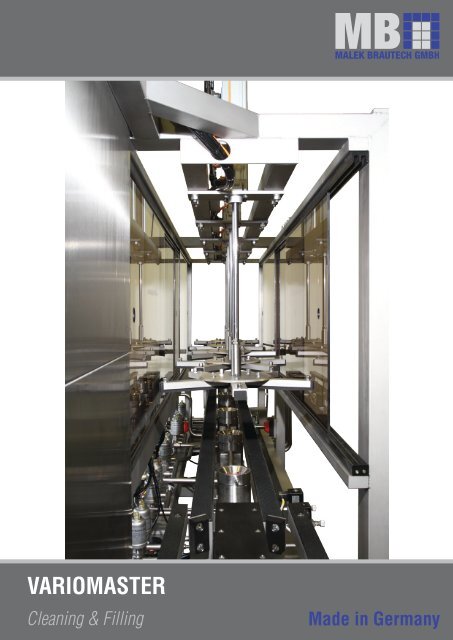

The <strong>VARIOMASTER</strong> is a fully-automatic mach<strong>in</strong>e for clean<strong>in</strong>g and fill<strong>in</strong>g of kegs.<br />

The mach<strong>in</strong>e is made of a rugged sta<strong>in</strong>less steel frame (1.4301) with brushed surface positioned on four levell<strong>in</strong>g feet.<br />

The treatment heads comb<strong>in</strong><strong>in</strong>g compact design with large flow cross sections for high liquid rates. Sta<strong>in</strong>less steel<br />

pneumatic valves with position <strong>in</strong>dicators ensure safe operation and the early detection of any leaks.<br />

Our patented clean<strong>in</strong>g system for counter flow r<strong>in</strong>s<strong>in</strong>g is also a component <strong>in</strong>cluded <strong>in</strong> the basic equipment, as well as<br />

our patented condensate monitor<strong>in</strong>g and an <strong>in</strong>ductive flowmeter that controls the fill<strong>in</strong>g level. Due to the use of exclusively<br />

high quality components and materials the ma<strong>in</strong>tenance required, is reduced to a m<strong>in</strong>imum.<br />

Maximum Product Safety<br />

Even the best type of product gets through defilement unenjoyable. That is why it is important not only dur<strong>in</strong>g the brew<strong>in</strong>g<br />

process, but also dur<strong>in</strong>g the fill<strong>in</strong>g process to ma<strong>in</strong>ta<strong>in</strong> the highest hygienic standards and controls. Beside the<br />

high quality standard of our mach<strong>in</strong>es, our special focus rema<strong>in</strong>s on the product safety dur<strong>in</strong>g the clean<strong>in</strong>g and fill<strong>in</strong>g<br />

process. To ensure this, the <strong>VARIOMASTER</strong> mach<strong>in</strong>es are already basically equipped with different types of process<br />

control devices. For example: center spear open<strong>in</strong>g control, electronic level sensors and our patented condensate<br />

monitor<strong>in</strong>g system for a neutrality check before the fill<strong>in</strong>g process. Optionally our aseptic fill<strong>in</strong>g head is also available<br />

which besides ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g the highest hygienic composition additionally sterilizes the product valve after each fill<strong>in</strong>g<br />

cycle.<br />

Features<br />

- Automatic step <strong>in</strong>dication<br />

- Electronic probe monitor<strong>in</strong>g and liquid control<br />

- Keg open<strong>in</strong>g monitor<strong>in</strong>g functions on all stations<br />

- Temperature monitor<strong>in</strong>g on the fill<strong>in</strong>g station<br />

- Control air monitor<strong>in</strong>g function<br />

- Sta<strong>in</strong>less steel electrical and pneumatic cab<strong>in</strong>et<br />

- Patented clean<strong>in</strong>g process<br />

- Patented condensate monitor<strong>in</strong>g before the fill<strong>in</strong>g process<br />

- Automatic program selection function for:<br />

- Keg clean<strong>in</strong>g and fill<strong>in</strong>g<br />

- Keg clean<strong>in</strong>g<br />

- Beer pre- and post-run<br />

- Empty<strong>in</strong>g of fill<strong>in</strong>g head<br />

- Steam<strong>in</strong>g of fill<strong>in</strong>g head<br />

- CIP clean<strong>in</strong>g from customer‘s CIP system or as agreed<br />

Optional Equipment: Aseptic fill<strong>in</strong>g head (registered property rights)<br />

TWIN <strong>VARIOMASTER</strong> II<br />

Re<strong>in</strong>igen Clean<strong>in</strong>g & Befüllen Fill<strong>in</strong>g<br />

<strong>Made</strong> <strong>in</strong> <strong>Germany</strong>

Specifications<br />

Capacity: S<strong>in</strong>gle l<strong>in</strong>e: ca. 60 Kegs/h (50 liter)<br />

Double l<strong>in</strong>e: ca. 120 Kegs/h (50 liter)<br />

PLC: Siemens S7-300 with touchpanel<br />

Pneumatic: Festo<br />

Models:<br />

<strong>VARIOMASTER</strong><br />

Clean<strong>in</strong>g & Fill<strong>in</strong>g<br />

L<br />

899<br />

1955<br />

2351<br />

Type Stations Clean<strong>in</strong>g media Length<br />

Clean<strong>in</strong>g Steriliz<strong>in</strong>g Steriliz<strong>in</strong>g and<br />

Pre-stress<strong>in</strong>g<br />

Fill<strong>in</strong>g<br />

(L)<br />

3R-SV-F 3 0 1 1 Caustic or acid 3.865 mm<br />

4R-SV-F 4 0 1 1 Caustic and acid 4.365 mm<br />

4R-S-SV-F 4 1 1 1 Caustic and acid 4.865 mm<br />

All above mentioned mach<strong>in</strong>e types are also available as double l<strong>in</strong>es.<br />

Special models are available <strong>in</strong> customer request.<br />

899<br />

2351<br />

Status: 10/2012, modifications and errors excepted<br />

<strong>Made</strong> <strong>in</strong> <strong>Germany</strong>

![twin2-en-1.1.pdf [1 MB] - Malek Brautech GmbH](https://img.yumpu.com/3394742/1/184x260/twin2-en-11pdf-1-mb-malek-brautech-gmbh.jpg?quality=85)