Beckosol 1700-M-60 Product Bulletin - Reichhold

Beckosol 1700-M-60 Product Bulletin - Reichhold

Beckosol 1700-M-60 Product Bulletin - Reichhold

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

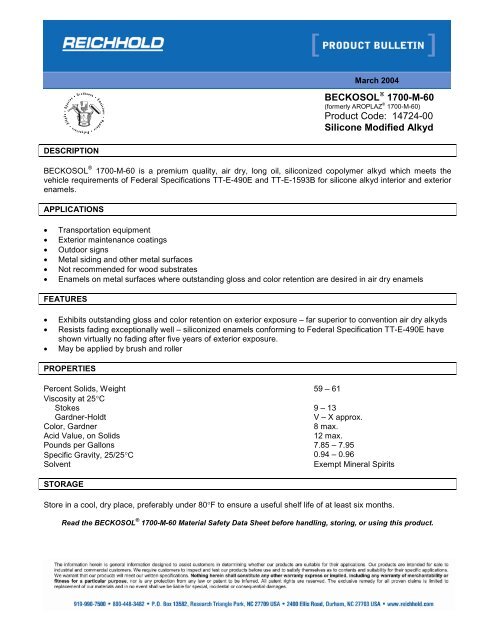

March 2004<br />

BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong><br />

(formerly AROPLAZ ® <strong>1700</strong>-M-<strong>60</strong>)<br />

<strong>Product</strong> Code: 14724-00<br />

Silicone Modified Alkyd<br />

DESCRIPTION<br />

BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong> is a premium quality, air dry, long oil, siliconized copolymer alkyd which meets the<br />

vehicle requirements of Federal Specifications TT-E-490E and TT-E-1593B for silicone alkyd interior and exterior<br />

enamels.<br />

APPLICATIONS<br />

• Transportation equipment<br />

• Exterior maintenance coatings<br />

• Outdoor signs<br />

• Metal siding and other metal surfaces<br />

• Not recommended for wood substrates<br />

• Enamels on metal surfaces where outstanding gloss and color retention are desired in air dry enamels<br />

FEATURES<br />

• Exhibits outstanding gloss and color retention on exterior exposure – far superior to convention air dry alkyds<br />

• Resists fading exceptionally well – siliconized enamels conforming to Federal Specification TT-E-490E have<br />

shown virtually no fading after five years of exterior exposure.<br />

• May be applied by brush and roller<br />

PROPERTIES<br />

Percent Solids, Weight 59 – 61<br />

Viscosity at 25°C<br />

Stokes 9 – 13<br />

Gardner-Holdt<br />

V – X approx.<br />

Color, Gardner<br />

8 max.<br />

Acid Value, on Solids<br />

12 max.<br />

Pounds per Gallons 7.85 – 7.95<br />

Specific Gravity, 25/25°C 0.94 – 0.96<br />

Solvent<br />

Exempt Mineral Spirits<br />

STORAGE<br />

Store in a cool, dry place, preferably under 80°F to ensure a useful shelf life of at least six months.<br />

Read the BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong> Material Safety Data Sheet before handling, storing, or using this product.

SUGGESTED FORMULATIONS<br />

Navy Haze Gray Exterior Semi-Gloss<br />

#26270<br />

A-733 Conforms to TT-E-490E<br />

Lbs. Gals. Material<br />

166. 5.05 Rutile Titanium Dioxide, TiPure R-902 (1)<br />

3. 0.21 Lampblack<br />

90. 3.80 Micronized Magnesium Silicate,<br />

(2)<br />

Asbestine 325<br />

90. 4.00 Calcium Carbonate, Snowflake (3)<br />

50. 2.11 3000 Mesh Mica, C3000 (4)<br />

4. 0.50 Suspension and Antisag Agent, MPA<br />

<strong>60</strong>% in Xylene (5)<br />

4. 0.50 4% Calcium Naphthenate<br />

280. 35.00 BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong><br />

Mix on high-speed mill to 150°F. Then grind on roller mill:<br />

184. 23.00 BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong><br />

163. 25.02 Mineral Spirits<br />

2. 0.25 6% Cobalt Naphthenate<br />

2. 0.25 6% Manganese Naphthenate<br />

1. 0.13 Anti-Skinning Agent<br />

2. 0.18 Anti-Floating Additive, #1 Paint Additive (6)<br />

1041. 100.00 TOTAL<br />

High Gloss White<br />

Lbs. Gals. Material<br />

270.0 8.20 Rutile Titanium Dioxide (1)<br />

6.0 0.42 Suspension and Sag Control Agent (2)<br />

230.0 28.70 BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong><br />

Grind to 7 Hegman. Then letdown with:<br />

283.0 35.40 BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong><br />

169.0 25.93 Mineral Spirits<br />

2.8 0.35 6% Cobalt Naphthenate<br />

4.2 0.52 6% Calcium Naphthenate<br />

1.0 0.13 Anti-Skinning Agent<br />

968.8 100.00 TOTAL<br />

Analysis:<br />

18.2 Pigment Volume Concentration, Percent<br />

0.8/1.0 Pigment/Binder Weight Ratio<br />

65 – 70 Consistency, KU<br />

Suppliers:<br />

(1) DuPont (2) Elementis<br />

Analysis:<br />

33.3 Pigment Volume Concentration, Percent<br />

16.3 Hiding Pigment, Percent<br />

22.1 Extender Pigment, Percent<br />

27.3 Vehicle Solids, Percent<br />

65.7 Total Solids, Percent<br />

67 – 77 Consistency, KU<br />

40 – 50 Gloss, <strong>60</strong>°<br />

Suppliers:<br />

(1) Du Pont (4) English<br />

(2) International Talc (5) Kronos<br />

(3) Thompson-Weinman (6) Dow Chemical<br />

BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong> (14724-00)<br />

2

TYPICAL PERFORMANCE DATA<br />

Zinc Oxide Compatibility<br />

Increase of approximately 16 KU when tested<br />

according to TT-R-266d procedure<br />

Solvent Tolerance<br />

Mineral Spirits Infinite<br />

Film Compatibility<br />

Percent Modifier on Total Solids Giving Clear Film<br />

Modifier 10 25 50 75<br />

Long Oil Alkyds — C C C<br />

BECKOSOL ® 10-0<strong>60</strong><br />

Medium-Oil Alkyds — C C C<br />

BECKOSOL ® 11-035<br />

Short-Oil Alkyds — I I I<br />

BECKOSOL ® 12-054<br />

Thermoplastic Acrylics C C — —<br />

Acryloid B-67, 45% in Xylol, C C — —<br />

Rohm & Haas Melamine<br />

Resins Cymel 247-10, Cytec<br />

C = Compatible<br />

I = Incompatible<br />

Drier Recommendations<br />

Metal Based on Vehicle Solids<br />

Air Dry 0.03 – 0.05% Co<br />

0.03 – 0.05 Mn<br />

0.0 – 0.05 Ca<br />

Drying Data<br />

Checking at 50% Solids, 1.5 Mil Application.<br />

Driers as Metals Based on Vehicle Solids:<br />

0.05% Co, 0.05% Mn, 0.05% Ca<br />

Set-to-Touch, Hours 1 – 2<br />

Zapon Dry, 500g, Hours 2½ – 3½<br />

Sward Hardness, 24 Hours 18<br />

Viscosity, Stokes<br />

Typical Viscosity Reduction<br />

100<br />

10<br />

1<br />

0.1<br />

70<br />

<strong>60</strong><br />

50<br />

40<br />

Percent Solids by Weight<br />

Warning: Lead (Pb) should not be allowed to contact silicones as<br />

drier salts or in any other way.<br />

BECKOSOL ® <strong>1700</strong>-M-<strong>60</strong> (14724-00)<br />

3