Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

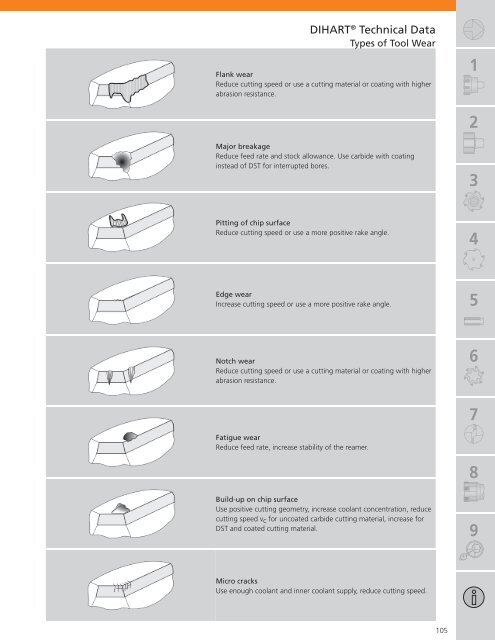

DIHART ® Technical Data<br />

Types of Tool Wear<br />

Flank wear<br />

Reduce cutting speed or use a cutting material or coating with higher<br />

abrasion resistance.<br />

1<br />

2<br />

Major breakage<br />

Reduce feed rate and stock allowance. Use carbide with coating<br />

instead of DST for interrupted bores.<br />

3<br />

Pitting of chip surface<br />

Reduce cutting speed or use a more positive rake angle.<br />

4<br />

Edge wear<br />

Increase cutting speed or use a more positive rake angle.<br />

5<br />

Notch wear<br />

Reduce cutting speed or use a cutting material or coating with higher<br />

abrasion resistance.<br />

6<br />

7<br />

Fatigue wear<br />

Reduce feed rate, increase stability of the reamer.<br />

8<br />

Build-up on chip surface<br />

Use positive cutting geometry, increase coolant concentration, reduce<br />

cutting speed vc for uncoated carbide cutting material, increase for<br />

DST and coated cutting material.<br />

9<br />

Micro cracks<br />

Use enough coolant and inner coolant supply, reduce cutting speed.<br />

105