CONTENT - BHEL - Industrial Systems Group

CONTENT - BHEL - Industrial Systems Group

CONTENT - BHEL - Industrial Systems Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

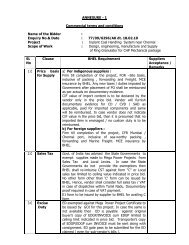

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

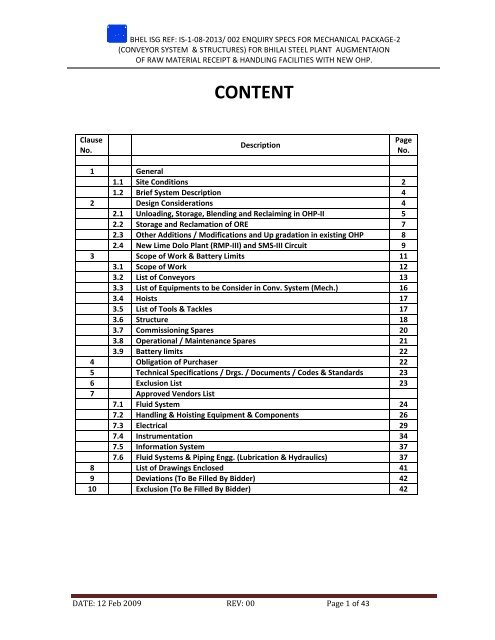

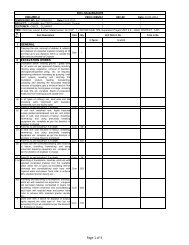

<strong>CONTENT</strong><br />

Clause<br />

No.<br />

Description<br />

Page<br />

No.<br />

1 General<br />

1.1 Site Conditions 2<br />

1.2 Brief System Description 4<br />

2 Design Considerations 4<br />

2.1 Unloading, Storage, Blending and Reclaiming in OHP‐II 5<br />

2.2 Storage and Reclamation of ORE 7<br />

2.3 Other Additions / Modifications and Up gradation in existing OHP 8<br />

2.4 New Lime Dolo Plant (RMP‐III) and SMS‐III Circuit 9<br />

3 Scope of Work & Battery Limits 11<br />

3.1 Scope of Work 12<br />

3.2 List of Conveyors 13<br />

3.3 List of Equipments to be Consider in Conv. System (Mech.) 16<br />

3.4 Hoists 17<br />

3.5 List of Tools & Tackles 17<br />

3.6 Structure 18<br />

3.7 Commissioning Spares 20<br />

3.8 Operational / Maintenance Spares 21<br />

3.9 Battery limits 22<br />

4 Obligation of Purchaser 22<br />

5 Technical Specifications / Drgs. / Documents / Codes & Standards 23<br />

6 Exclusion List 23<br />

7 Approved Vendors List<br />

7.1 Fluid System 24<br />

7.2 Handling & Hoisting Equipment & Components 26<br />

7.3 Electrical 29<br />

7.4 Instrumentation 34<br />

7.5 Information System 37<br />

7.6 Fluid <strong>Systems</strong> & Piping Engg. (Lubrication & Hydraulics) 37<br />

8 List of Drawings Enclosed 41<br />

9 Deviations (To Be Filled By Bidder) 42<br />

10 Exclusion (To Be Filled By Bidder) 42<br />

DATE: 12 Feb 2009 REV: 00 Page 1 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

1 GENERAL<br />

1.1 Site Conditions<br />

Location<br />

Bhilai Steel Plant (BSP), SAIL is located at Bhilai in Durg District of the state of Chhatisgarh in the central<br />

region of India. The site lies between 21.5 0 North latitude and 81.22 0 East longitude. The nearest<br />

convenient rail head is Durg which is about 12 Km west of Bhilai. Bhilai/ Durg stations are on the<br />

Howrah‐ Mumbai rail lie of SEC Railway of the Indian Railways.<br />

The location of the Bhilai is as follows:<br />

From New Dheli, the national capital : 1359 Km<br />

From Kolkatta : 868 Km<br />

From Chennai : 1269 Km<br />

From Mumbai : 1100 Km<br />

The distance from state capital Raipur to Bhilai Steel Plant is 30 Km. it is well connected by rail and road<br />

network. The nearest national highways are NH‐6 and NH‐43 crossing trough Raipur.<br />

Meteorological Data<br />

In the absence of Metrological data at Bhilai / Durg, the data of the state capital Raipur, 30 Km away,<br />

are considered. The meteorological details at Raipur are given below:<br />

Ambient Temperature<br />

Absolute maximum : 47.7 0 C<br />

Absolute minimum : 3.9 0 C<br />

Highest of mean monthly : 45.2 0 C<br />

Ambient Air<br />

Ambient air quality : <strong>Industrial</strong><br />

Relative Humidity<br />

Maximum : 100%<br />

Minimum : 7%<br />

Climate : Tropical Humid<br />

Rainfall<br />

Heaviest rainfall in 24 hours : 370.3 mm<br />

Annual Average : 1288.2 mm<br />

Wind<br />

Predominant wind direction : SW to NE (October ‐ February) West – East (Mar – Sep)<br />

Mean wind speed : 6.8 Km / hr<br />

Max. wind speed : 45 Km / hr<br />

DATE: 12 Feb 2009 REV: 00 Page 2 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

Altitude<br />

Average altitude of the land is 300 m above MSL<br />

Temperature inside shop premises is generally taken as 5 0 C above ambient, unless otherwise specified.<br />

Infrastructure Facilities outside the Plant<br />

Railway<br />

Bhilai Steel Plant connected to Indian Railways network Via Bhilai / Durg Stations are SEC Railway on<br />

the Howrah‐Mumbai line. The track gauge of SEC railways as well as of the Plant tracks are standard<br />

broad gauge i.e 1676 mm.<br />

Road<br />

The Plant is well connected to the country by road. National highways NH‐6 and NH‐43 both pass<br />

trough Raipur.<br />

Sea Port<br />

The nearest sea port is Vishakhapattanam, approximately 550 Km away from the site by rail.<br />

Air Traffic<br />

The nearest Air port connected to the National is Mana at Raipur, 30 Km away.<br />

Infrastructure Facilities Inside the Plant<br />

Railway<br />

The track gauge for entire Plant corresponds to the Indian railway standard broad gauge i.e 1676 mm<br />

Road<br />

Main road and Side roads of the Plants shall have road ways of 7.0 m and 4.0 m width respectively and the<br />

temporary roads provided during the construction stage shall be designed to cater the needs of<br />

movement of heavy construction vehicles.<br />

General Rules and Regulations<br />

All plant units with respect to their location, layout, general arrangement and design of equipment,<br />

structural design, etc. shall be safe to the personnel and conform to the relevant statutory requirements<br />

issued by Chattisgarh Government and the Government of India but not limited to the following.<br />

‐ Chattisgarh State Factory Rules/Acts.<br />

‐ Indian Electricity Rules/Acts<br />

‐ Electricity Regulatory Commission Act<br />

‐ Indian Petroleum Regulations/Acts<br />

‐ Indian Boiler Regulations/Acts<br />

‐ Indian Explosives Acts<br />

‐ Gas Cylinders Rules/Acts<br />

‐ Carbide of Calcium Rules/Acts<br />

‐ Static and mobile Pressure Vessels Codes (unifired) Rules/Acts<br />

DATE: 12 Feb 2009 REV: 00 Page 3 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

‐ Fire Protection Manual issued by Tariff Advisory Committee (India)<br />

‐ Pollution Control Regulations/Acts<br />

Pollution control measures shall be provided considering the latest norms and international standards.<br />

These should satisfy the stipulations of Central Pollution Control Board and Department of Environment<br />

and Forest, Government of India.<br />

In the event the requirement of this specification exceeds the requirement stipulated in the corresponding<br />

standards, regulation, safety code, the specification shall govern.<br />

In the event of conflict between the standard, regulations and codes, the most stringent one shall govern<br />

and the decision of the Purchaser shall be final.<br />

1.2 Brief System Description<br />

The turnkey package of this TS comprises of the following sub‐systems:<br />

• New Ore Handling Plant (OHP‐II) including receiving, unloading, Stacking & Reclaiming and finally<br />

transporting of Raw Material required for Blast Furnace #8, Sinter Plant‐III.<br />

• New conveyor line for New Lime Dolomite plant RMP3 and for proposed SMS‐III.<br />

• Modifications/ up‐gradations of existing equipment, including:<br />

o An additional series of conveyor from OHP I to JH‐20 parallel to existing route.<br />

o Up gradation of capacity of existing shuttle conveyors J9BRSC1.<br />

New Ore Handling Plant (OHP‐II)<br />

The raw material to be handled by the proposed system is mainly, Iron Ore Lump, Iron Ore Fines, Lime<br />

Stone (BF grade), Lime Stone (SMS grade), Dolomite (BF grade), Dolomite (SMS grade), Quartzite,<br />

Manganese ore. These raw materials are mainly required for Blast Furnace, Sinter Plant, Lime‐Dolomite<br />

Plant, SMS. All the raw materials will be received at the plant boundary by rail. The type of Wagon will be<br />

BOXN, BOXNHA, BOY, BOBRN, BOST, BOBS, BOXNEL, BOYL which will transport the raw materials<br />

depending upon the location of loading and type of raw materials.<br />

As per flow diagram/ design considerations, Bidder shall consider the all inter connecting facilities<br />

between existing & proposed systems while designing the proposed junction towers / conveyor. Also<br />

bidder shall consider any modifications / strengthening of existing junction towers/ conveyor / chutes and<br />

complete replacement of chutes in case necessary. Bidder must visit the BSP site for assessment /<br />

feasibility of modification, strengthening & replacement works to be carried out in the existing facilities<br />

before submission of offer to <strong>BHEL</strong>.<br />

2. DESIGN CONSIDERATIONS<br />

(The design considerations shall be the part of scope of work. Any thing missing in clause.3 i,e in scope of<br />

work but required as per clause.2 design considerations / flow diagram, then the bidder shall consider the<br />

same into their scope)<br />

The Ore Handling Plant (OHP‐II) has been planned based on the following assumption:<br />

A. Size of Raw Material<br />

1. Lump Iron Ore : ‐40 mm<br />

DATE: 12 Feb 2009 REV: 00 Page 4 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

2. Iron ore fines : ‐ 8 mm<br />

3. Lime Stone (BF/SP grade) : ‐60 mm<br />

4. Dolomite (BF/SP grade) : ‐60 mm<br />

5. Quartzite : ‐50 mm<br />

6. Lime Stone (SMS grade) : ‐25 mm<br />

7. Dolomite (SMS grade) : ‐25 mm<br />

8. Pellets : ‐18 mm<br />

9. Manganese Ore : ‐25 mm<br />

10. Coke Breeze : ‐25 mm<br />

B. No of Days of Working per year: 330 days<br />

C. Maximum material carrying capacity of each wagon shall be as per IS: 10095‐1982 reaffirmed 2001.<br />

Iron‐ore‐lump will be received in Track‐Hopper & all other material in Wagon Tipplers. One Track Hopper<br />

with two tracks has been considered for materials received in BOBS/ BOBRN wagons (mainly iron‐ore),<br />

whereas wagon tippler with side arm charger has been considered for unloading the materials received in<br />

BOXN/BOST/ BOXNHA/BOY/BOBS, BOXNEL, BOYL wagons.<br />

2.1 UNLOADING, STORAGE, BLENDING AND RECLAIMING IN OHP‐II<br />

One number Wagon tippler WT no.B1 along with a Track Hopper TH‐B1 with two parallel tracks on it have<br />

been envisaged for unloading Iron ore (lump and fines), Limestone & Dolomite (both BF grade and Sinter<br />

Plant grade), Mn‐ore, Quartzite etc.<br />

The Wagon Tippler shall be of Rota‐side type capable of unloading BOXN and proposed BOXNHA and<br />

BOBS, BOY wagons as per IS:10095‐1982, reaffirmed 2001. The rated unloading capacity shall be 20<br />

Tips/hour. Adequate system of handling sticky rakes such as vibrator/ air blaster shall be provided.<br />

25.0 t wagon axle load and 110 t gross weight of wagons (BOX, BOXN, BOXN HA ,BOXN HS, BOXN EL,<br />

BOYEL) to be considered for design of Wagon Tippler and track hopper. 2 nos. Weighbridges included in<br />

bidder's scope. The location of Weigh Bridge shall presently be considered at entry of pre hopper yard.<br />

However as the total railway track is being engineered by RITES , the location of weigh bridge may<br />

undergo change in detailed engineering stage.<br />

The placement of rakes shall be done by Side arm chargers capable of handling a full rake BOXN, BOXNHA,<br />

BOBS, BOY, BOXN EL, BOYEL wagons.<br />

One (1) no. track hopper with two rail tracks with length of 210 m excluding maintenance bay and holding<br />

capacity of 6000.0 T considering material of bulk density of 1.6 t/ cu.m. shall be included in bidder’s scope.<br />

The side angle of hopper with vertical shall be minimum 60 deg. hopper shall have four compartments.<br />

Track hopper envisaged to accommodate minimum 18 BOBS wagons. Bidder to confirm to maintain<br />

sufficient height of the track hopper superstructure to take care of OHE.<br />

2 nos. Electric hoist of 10.0 t capacity shall be provided for maintenance of Paddle Feeder at both ends of<br />

Track Hopper building. Two nos. double door pressurized cabin shall be provided for paddle feeder inside<br />

the track hopper tunnel. Anti‐derailment device/ check rail shall be provided in the track hopper subject to<br />

approval of RITES. Supply/ Laying of 60 kg/ m rail with continuous MS insert plate within track hopper<br />

building only are also in the scope of bidder. Further rail laying will be done BSP.<br />

DATE: 12 Feb 2009 REV: 00 Page 5 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

In addition to the above, one dedicated compressor station at track hopper TH‐3 for unloading of BOBRN<br />

wagons is to be provided. Compressed air connection to BOBRN wagons to be provided at 15 mts interval.<br />

The details of requirement of compressed air, the pressure and type shall be obtained from RDSO. Other<br />

points as applicable for compressed air station shall be considered as per TS for compressed air facilities<br />

indicated elsewhere.<br />

Provision of adequate illumination should be there on both pre & post tippler as well as on Merry Go<br />

Round circuit.<br />

Two belt feeders below Wagon Tippler shall discharge the raw material on either of two conveyors i.e. Z1‐<br />

C1 or Z1‐C2 which, in turn will discharge the material at Junction House JH‐Z1. From Jn House JH‐Z1,<br />

conveyors Z3‐C1 & Z3‐C2 will carry the material and discharge at JH‐Z3. There will be three incoming<br />

conveyors in Junction House JH‐Z3. The tail end of two conveyors Z3‐C1 & Z3‐C2 will start from JH‐Z1 and<br />

Belt conveyor Z3‐C3 from JH‐Z2. Junction house JH‐Z2 shall be located in between the JH‐Z1 & JH‐Z3.<br />

The track hopper with four nos. paddle feeders of 1500 tph each, two on conveyors Z2‐C1 and two on<br />

conv. Z2‐C2 has been envisaged. From Jn. house Z2, either of three conveyors Z3‐C1, Z3‐C2 (coming from<br />

JH‐Z1) & Z3‐C3 (begin from JH‐Z2) shall carry the material upto Jn house Z3. Reversible shuttle conveyors<br />

Z2‐RSC1/2 at JH‐Z2 will facilitate to discharge the material on either of any three conveyors. Each conveyor<br />

(Z2‐RSC1 & 2) shall be able to feed any of three conveyor Z3‐C1, Z3‐C2 & Z3‐C3. Also the space for future<br />

reversible shuttle conveyor shall be provided as shown in the flow diagram drg.. Therefore, JH‐Z2 shall be<br />

designed suitably so as to receive material from any of the conveyors coming from Track Hoppers and also<br />

load of future reversible shuttle conveyor shall be considered for structural design of junction house JH‐Z2.<br />

Non sticky liners/ polymer liners are to be fixed in the track hoppers to improve flowability.<br />

Suitable interchangeability shall be provided below Wagon Tipplers and Track Hoppers for the conveyors<br />

by providing Diverter gates.<br />

Bidder to provide jumbo gallery suitable for three nos. mobile trippers up to JH‐Z5 from JH‐Z4 over<br />

conveyors Z6‐C1, Z6‐C2 and Z6‐C3. Out of three trippers, two nos. (Over conv. Z6‐C2 and Z6‐C3 ) shall<br />

extend upto JH‐Z6 and one no. shall have provision of extension to junction house coming in future .<br />

Hence, junction house JH‐Z6 shall be designed by considering the space & load of future conveyors.<br />

Maintenance hoist of minimum 5t cap shall be provided for the trippers. Each of the three conveyors Z6‐<br />

C1, Z6‐C2 and Z6‐C3 shall be capable of feeding the stacking conv. Z4B‐C1as well as itself in JH‐Z4 and<br />

stacking conv. Z5B‐C1 as well as itself in JH‐Z5. Each of the two conveyors Z6‐C2 and Z6‐C3 shall be capable<br />

of feeding the stacking conv. Z6B‐C1 as well as future conveyor in Junction House –JH‐Z6.<br />

The raw material can be either transported via. Jn House Z4, Z5 or Z6 to the respective stacking conveyors<br />

Z4B‐C1, Z5B‐C1 & Z6B‐C1 for stockpiling or can be fed directly to the reclaiming conveyors Z7‐C1/ Z7‐C2<br />

which means convey material directly from the WT/ Track Hopper to:<br />

(a) To the Blast Furnace#8 Stock House<br />

(b) To the Base Mix Fuel & Flux crushing circuit of Sinter Plant‐III. JH‐Z11 shall be designed accordingly.<br />

In Jn House Z3, three nos. Reversible Shuttle conveyors no. Z3‐RSC1, 2 & 3 can feed any one of conveyor<br />

no. Z4‐C1, C2 & C3. One yard conveyor Z4A‐C1 and at Junction House JH‐Z4, three conveyors Z5‐C1, Z5‐C2<br />

& Z5‐C3 shall receive the material from above conveyors. Conveyor Z5‐C1, C2 & C3 shall further carry the<br />

material and discharge on yard conveyor Z5A‐C1 & Z6‐C1 & C2 at Junction House JH‐Z5. Any one of<br />

conveyor Z6‐ C2 & C3 will discharge the material on yard Conveyor Z6A‐C1 at Junction house JH‐Z6.<br />

DATE: 12 Feb 2009 REV: 00 Page 6 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

Suitable interchangeability shall be provided at Junction house JH‐Z4, 5, 6 & 11 for the conveyors by<br />

providing Diverter gates.<br />

The Stacking conveyors Z4A‐C1, Z5A‐C1 & Z6A‐C1 can form a stockpile 30m wide, 350m long and 10.5 m<br />

(maximum) high with the help of Twin boom stackers.<br />

Suitable number of electrically operated Under‐Slung Cranes, Hoists etc. shall be provided in all floors of<br />

Junction Houses and building for maintenance of equipment. In‐Line Magnetic Separators, Metal<br />

Detectors, Belt‐ Weigh‐Scales, Air‐Blasters/ Bin Vibrators shall be provided to make the system complete<br />

and the operation/ maintenance smooth.<br />

As per flow diagram/ design considerations, Bidder shall consider the all inter connecting facilities<br />

between existing & proposed systems while designing the proposed junction towers / conveyor. Also<br />

bidder shall consider any modifications / strengthening of existing junction towers/ conveyor / chutes and<br />

complete replacement of chutes in case necessary. Bidder must visit the BSP site for assessment /<br />

feasibility of modification, strengthening & replacement works to be carried out in the existing facilities<br />

before submission of offer to <strong>BHEL</strong>.<br />

2.2 STORAGE AND RECLAMATION OF ORE<br />

From the Wagon Tipplers WT‐B1 and the Track Hopper TH‐B1, the raw material is sometimes fed directly<br />

to the consuming plant in case of emergency. However, this shall not happen under normal circumstances,<br />

when the three Twin‐boom stackers over conveyors Z4B‐C1, Z5B‐C1 & Z6B‐C1 store the raw material in<br />

the designated place of the yard in bed nos. 1 to 6. Flexibility shall be in built in the Jn House Z4, Z5, & Z6<br />

to ensure stacking is trouble free.<br />

Bed blending system shall be possible with the stacker running to and fro on the length of the pile ‐or‐ on<br />

a length between two defined position in case more than one material is stored in a bed marked by travel<br />

limit switches, which through a relay sequencing circuit, with time control reverses the traveling gear after<br />

the travel in each direction covering the desired length of the pile. After a layer of some pre ‐determined<br />

amount is deposited in one traveling direction of the stacker, probes fitted on the stacker boom gives it a<br />

“raise” signal as soon as a net height of material is formed. The next layer is then formed.<br />

Iron ore may require stockpile formation as described above for blending and uniformity. However, the<br />

emphasis on blending shall be for iron ore fines‐ which shall be blended while stacking.<br />

Four nos. Bucket‐wheel reclaimers have been envisaged for bed no. 1 to 6.<br />

All stacking line conveyors feeders and stackers etc. shall have a rated capacity of 1500 tph & a designed<br />

capacity of 1800 tph.<br />

All reclaim line equipment shall have a rated capacity of 1500 tph and a designed capacity of 1800 tph in<br />

the ore handling area.<br />

Reclamation takes place by the conveyors Z7‐C3 (Bed no. 1), Z4A‐C1 (Bed 2or 3), Z5A‐C1 (Bed no.4 or 5)<br />

and Z6A‐C1 (Bed no. 6) and the reclaimed material via Jn House Z4A, B, Z5A, B, Z6A and Z6B shall reach Jn<br />

House Z7. Two reclaim conveyors Z7‐C1 and Z7‐C2 between Z6A to Z7 will receive all the materials from<br />

yard for further transportation.<br />

Reclamation from OHP takes place for the following circumstances:‐<br />

DATE: 12 Feb 2009 REV: 00 Page 7 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

Feeding of iron ore lump, dolomite, limestone, manganese, quartzite, pellet etc. to BF#8 stock house.<br />

Transporting Limestone/ Dolomite (SP grade) and iron‐ore fines to Base Blending Yard for Sinter Plant‐III.<br />

Two streams of belt conveyors shall reclaim the material from new OHP‐B yard to above places. Belt<br />

conveyor Z7‐C1 & C2 shall carry the material and transport thru Z8‐C1, C2, Z9‐C1, C2, Z10‐C1, C2 to Z11‐<br />

C1& C2 to Junction house JH‐Z11. Junction House‐Z11 can discharge the material either to existing<br />

conveyors R103/ R104 of Sinter Plant‐III or proposed conveyor Z12‐C1/ C2 of BF#8, with the help of<br />

reversible conveyors Z11‐RC1 or Z11‐RC2. To receive the material from Z11‐RC1 & C2, suitable<br />

modification in existing gallery of R103 & R104 is required. Also a junction house JH‐Z11 with two<br />

reversible conveyors & tail end of belt conveyors Z12‐C1 & C2 shall be erected above these conveyors.<br />

Further, conveyor Z12‐C1 & C2 and then Z13‐C1 & C2 shall move towards stock house of BF#8 and<br />

discharge at JH‐Z15 onto belt conveyors Z15‐C1 & Z15‐C2.<br />

A junction house JH‐Z14 shall be provided in between the junction houses JH‐Z13 & JH‐Z15. Two series of<br />

belt conveyors shall discharge the Sinter at the Junction House Z14 over belt conveyor Z15‐C1 & C2.<br />

Junction House JH‐Z14 shall be in the scope of Purchaser i.e. BSP.<br />

Suitable Junction houses with RCC floors, diverter gates & galleries shall be provided to transfer the<br />

material from one conveyor to another. The scope of bidder shall finish at JH‐Z15 with complete drive and<br />

discharge (including reversible shuttle conveyor) facilities. The receiving belt conveyor below Z15‐C1 & C2<br />

shall be in the scope of Purchaser i.e. BSP. However, JH‐Z15 shall have a provision (inserts/ foundation<br />

bolts) to erect outgoing conveyors to Stock House.<br />

As per flow diagram/ design considerations, Bidder shall consider the all inter connecting facilities<br />

between existing & proposed systems while designing the proposed junction towers / conveyor. Also<br />

bidder shall consider any modifications / strengthening of existing junction towers/ conveyor / chutes and<br />

complete replacement of chutes in case necessary. Bidder must visit the BSP site for assessment /<br />

feasibility of modification, strengthening & replacement works to be carried out in the existing facilities<br />

before submission of offer to <strong>BHEL</strong>.<br />

2.3 OTHER ADDITIONS/ MODIFICATIONS AND UPGRADATION IN EXISTING OHP<br />

(REF. DRG. NO. MEC/S/9101/11/17/0/00/00/061.B01/ R1)<br />

2.3.1. An Additional series of conveyor from OHP to J‐20<br />

Another proposed conveyor No J9‐C1 parallel to J9‐C3/J9‐C4, besides conveyors R‐102, shall start from Jn.<br />

House JH‐9B and shall discharge the material in a proposed conveyor J9H‐C1 in existing JH‐9, which in turn<br />

feeds to conveyor J10‐C2 in new Junction house JH‐9H . Conv J10‐C2 can feed proposed conveyor J11‐C3,<br />

J11‐RC2, J14‐C2/ J12‐C2 (Exst’g), J15‐C2. Conv J15‐C2 shall feed new reversible conv. J15‐RC1 in junction<br />

house JH‐15, which in turn can feed either existing SMS‐II feeding conv. J15A‐C1 or new conv. J15B‐C1.<br />

Conv. J15B‐C1 or another new conv. J15B‐C2 which shall receive sinter from existing conv. SS‐10 shall feed<br />

new conveyor J16‐C3 in new junction house JH‐15B which in turn shall discharge onto new conv. J16‐C3A<br />

in new junction house JH‐16A. Conv. J16‐C3A shall discharge onto new conv. J17‐C3 in JH‐16A which shall<br />

convey material to conveyor J17A‐C1 in JH‐17 (exst’g). Conveyor J17A C1 (Capacity 1500 tph) shall<br />

discharge to either of the two conveyors J20‐C3 or J17B‐C1 through a adjustable flap gate in junction<br />

house J17A. further J17B‐C1 shall discharge the material over J42‐C2 in JH‐17B. The capacity of the<br />

outgoing conveyors J20‐C3 and J17B‐C1/ J42‐C2 shall be 500tph and 1000tph respectively. Conveyor J20‐<br />

C3 shall be provided with one no. belt weigh scale and have provision of discharging onto existing sinter<br />

carrying conveyor J27‐C5 (Exst’g) in junction house JH‐20 (Exst’g). Conveyor J42‐C2 shall have provision of<br />

discharging onto existing conveyor J44‐C5 in junction house J42 (Exst’g).<br />

DATE: 12 Feb 2009 REV: 00 Page 8 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

Necessary modification/strengthening shall be carried out in junction house J42 to take care of additional<br />

loads by new conveyor. Suitable electrical interlock shall be provided between the conveyors J27‐C5 &<br />

J20‐C3 in junction house JH‐20 to trip all the incoming conveyors in case feed rate exceeds capacity<br />

(500tph) of the corresponding downstream conveyor J27‐C5. Similar interlock shall also be provided<br />

between J44‐C5 & J44‐C2 in junction house JH‐42 to avoid any spillage/chute blockage.<br />

These additional conveyors with gate will facilitate a new additional route for BF # 7.<br />

All above conveyor shall run adjacent to the existing conveyor/ galleries at same elevation, conveyor<br />

profiles may be decided accordingly. Junction houses JH‐9H, JH‐10A, JH‐15B, JH‐16A, JH‐ 17A and JH‐17B<br />

shall be new Junction houses. For inter connecting conveyor no. J11‐C3, J11‐RC2, J14‐C2, J15‐C2, J15‐RC1,<br />

J15B‐C1, J15B‐C2 , J17‐C3, J17A‐C1, J20‐C3 & J42‐C2, the existing junction houses (JH‐10, JH‐11, JH‐14, JH‐<br />

15, JH‐ 17, JH‐20 and JH‐42) shall be suitably modified to suit proposed conveyor transfer points/crossing<br />

over.<br />

As per flow diagram/ design considerations, Bidder shall consider the all inter connecting facilities<br />

between existing & proposed systems while designing the proposed junction towers / conveyor. Also<br />

bidder shall consider any modifications / strengthening of existing junction towers/ conveyor / chutes and<br />

complete replacement of chutes in case necessary. Bidder must visit the BSP site for assessment /<br />

feasibility of modification, strengthening & replacement works to be carried out in the existing facilities<br />

before submission of offer to <strong>BHEL</strong>.<br />

2.3.2. Up gradation of Reclaiming conveyors<br />

The capacity up‐gradation and utilization of reclaim conveyors are of utmost importance to ensure smooth<br />

operation in the OHP. The list of conveyors in the reclaiming circuit that shall be upgraded to 1500 tph are<br />

given in table below.<br />

Sl. Conveyor No. Existing belt Existing Proposed belt Proposed<br />

No<br />

width capacity width capacity<br />

1 J9B ‐ RSC‐1 1400 mm 500 m 3 / hr 1400 mm 1500 TPH<br />

Accordingly all necessary modifications/ replacement in drive unit, technology structure, gallery structure<br />

and in junction house shall be considered by the bidder.<br />

The capacity of all Belt conveyors shall be 1500tph for all raw materials viz.<br />

iron ore, limestone, dolomite with 1400mm belt width and belt speed shall be 2.0 m/s with a troughing<br />

angle of 35 deg.. Bulk density of raw material shall be considered as 2.2 t/m3 for power calculation / load<br />

data of structures and 1.6 t/m3 for volumetric capacity calculation of conveyor.<br />

As per flow diagram/ design considerations, Bidder shall consider the all inter connecting facilities<br />

between existing & proposed systems while designing the proposed junction towers / conveyor. Also<br />

bidder shall consider any modifications / strengthening of existing junction towers/ conveyor / chutes and<br />

complete replacement of chutes in case necessary. Bidder must visit the BSP site for assessment /<br />

feasibility of modification, strengthening & replacement works to be carried out in the existing facilities<br />

before submission of offer to <strong>BHEL</strong>.<br />

2.4 NEW LIME DOLO PLANT (RMP III) AND SMS III CIRCUIT<br />

Existing conveyor R‐101/ R‐102 shall be utilized to convey raw material required for Lime/Dolo Calcination<br />

plant RMP III and of SMS‐III by tapping the conveyor from Jn house J‐N102 (With suitable modification in<br />

DATE: 12 Feb 2009 REV: 00 Page 9 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

the Jn House) and taking a new route to the proposed Lime/ Dolo calcinations plant/ SMSIII. Any civil /<br />

structural modification works related to installation of new conveyors in existing junction house JN#102<br />

shall be bidder’s scope.<br />

The SMS grade limestone, dolomite and iron ore in existing OHP‐I shall be reclaimed via. Jn House N101,<br />

N102. Belt Conveyors R101/102 coming from OHP‐I shall now mostly carry Lime stone and dolomite. In JH‐<br />

N102, two reversible conveyor R103A & R104A are having a provision for taking material to Sinter plant III<br />

as well as proposed Lime Plant. A discharge chute below R103A & R104A to feed at the tail end of<br />

proposed belt conveyor L1‐C1 shall be provided at Junction house JH‐N102. Belt conveyor L1‐C1 shall<br />

discharge the material on L2‐C1 in junction house JHL2. Conv. L2‐C1 discharges onto conveyor L3C1 which<br />

discharges onto L4‐C1 in JH‐L3. Conv. L3‐C1 in turn discharge material at Junction House JH‐L4 to any of<br />

the two conveyors i.e. L5‐C1 & L7‐C1 with the help of diverter Gate.<br />

Thereafter, conveyor L7‐C1 will carry the material and transfer onto conveyor L9‐C1. Conveyor L9‐C1 will<br />

carry the material up to Surge Bin building JH‐L9 through reversible shuttle conv. JL9‐RSC1. Surge bin<br />

building JH‐L9 shall have 3 nos. bunkers of geometric capacity 190 cub m each for storing iron ore<br />

lump/limestone /bauxite. Suitable rod gate and motorized rack and pinion gates shall be fitted at the<br />

bottom of bunkers.3 nos. VVF controlled vibro feeders of 350 tph capacity each shall withdraw material<br />

from bunker and discharge it onto conveyor L10‐C1 which shall convey up to Junction house JH‐L10 for<br />

onward transportation to Surge Bin Building for SMS‐III (Surge bin bldg not in bidder’s scope) through SMS<br />

feeding conveyor. Conveyor L10‐C1 complete with discharge facilities and junction house JH‐L10 shall be in<br />

the scope of Bidder and SMS feeding conveyor shall be in the scope of purchaser.<br />

The other conveyor L5‐C1 shall receive material from conveyor L4‐C1 and discharge at JH‐L5 on to conv.<br />

L6‐C1 which shall convey up to junction house JH‐L6 and discharge onto lime plant feeding conveyor for<br />

onward transport to Lime & Dolomite calcination plant RMP III. Conveyor L6‐C1 complete with discharge<br />

facilities and junction house JH‐L6 shall be in the scope of Bidder. However, lime plant feeding conveyor<br />

shall be in the scope of purchaser i.e. BSP.<br />

Calcined lime/dolomite is received from the day bins of lime/dolo product storage building of RMP III onto<br />

conveyor L8‐C1.Conv. L8‐C1 discharges onto conv. L9‐C2 in JH‐L8 which in turn discharges onto conveyor<br />

L10‐C1 in Surge Bin building JH‐L9. This finished product of RMP III is transported to the junction house JH‐<br />

L10 by conveyors L10‐C1 which shall also carry limestone, bauxite, iron ore fines received directly from<br />

OHP I yard to SMS III. The scope of bidder starts from tail end on conveyor L8‐C1 including skirt boards etc.<br />

A fixed hopper of 8 cub m capacity on conveyor L10‐C1 near JH‐L9 with VVF controlled vibro feeder of 350<br />

tph capacity shall also be used to transport coke fines as and when required in the storage bins of the bulk<br />

material charging system of SMS III. Any other material e.g limestone/ DRI can also be transported under<br />

emergency conditions through fixed hopper.<br />

As per flow diagram/ design considerations, Bidder shall consider the all inter connecting facilities<br />

between existing & proposed systems while designing the proposed junction towers / conveyor. Also<br />

bidder shall consider any modifications / strengthening of existing junction towers/ conveyor / chutes and<br />

complete replacement of chutes in case necessary. Bidder must visit the BSP site for assessment /<br />

feasibility of modification works, strengthening & replacement to be carried out in the existing facilities<br />

before submission of offer to <strong>BHEL</strong>.<br />

2.5. Two separate Automatic Sampling system complete with sample cutter, collection, sizing, crushing<br />

and grinding shall be provided for the RMHS system.<br />

DATE: 12 Feb 2009 REV: 00 Page 10 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

3. SCOPE OF WORK & BATTERY LIMITS.<br />

1) Bidder shall consider all the equipments / facilities / requirements as per flow diagram, design<br />

consideration clause, Technical specs., General technical specs. and Layout in their scope including<br />

onboard electricals except civil works & auxiliaries DE, DS, VS, AC system, Electricals (except<br />

onboard electricals) and major equipments mentioned in exclusions list.<br />

2) As per flow diagram/ design considerations, Bidder shall consider the all inter connecting facilities<br />

between existing & proposed systems while designing the proposed junction towers / conveyor<br />

system. Also bidder shall consider any modifications / strengthening of existing junction towers/<br />

conveyors / chutes and complete replacement of chutes in case necessary. Bidder must visit the<br />

BSP site for assessment / feasibility of modification works, strengthening & replacement to be<br />

carried out in the existing facilities before submission of offer to <strong>BHEL</strong>.<br />

VERY IMPORTANT NOTE: ‐<br />

1) ANY OTHER ITEMS/ SYSTEMS/ SUB‐SYSTEMS WHICH ARE NOT LISTED IN THE EXCLUSIONS LIST BUT<br />

ARE REQUIRED FOR SYSTEM AS PER FLOW DIAGRAMS, DESIGN CONSIDERATIONS CLAUSE,<br />

TECHNICAL SPECS., GENERAL TECHNICAL SPECS. AND ARE REQUIRED FOR SMOOTH & TROUBLE<br />

FREE SAFE OPERATION OF THE PALNT MUST BE CONSIDERED BY THE BIDDER IN THEIR SCOPE<br />

WITHOUT FAIL.<br />

2) BIDDER SHOULD CONSIDER ALL NECESSARY REQUIREMENTS FOR INTERFACING & INTEGRATING<br />

OF OTHER EQUIPMENTS & SYSTEMS WHICH ARE NOT IN THE SCOPE OF BIDDER, NAMELY<br />

TWINBOOM STACKERS, BUCKET WHEEL RECLAIMERS, WAGON TIPPER & SIDE ARM CHARGER,<br />

PADDLE FEEDERS, DUST SUPPRESSION SYSTEM AND DUCT EXTRACTION SYSTEM ETC.<br />

3) BIDDER SHOULD CONSIDER IN THEIR PLC / AUTOMATION / CONTROL SYSTEM, ALL NECESSARY<br />

REQUIREMENTS (IN PUTS / OUT PUTS) FOR INTERFACING & INTEGRATING OF OTHER EQUIPMENTS<br />

& SYSTEMS WHICH ARE NOT IN THE SCOPE OF BIDDER, NAMELY TWINBOOM STACKERS, BUCKET<br />

WHEEL RECLAIMERS, WAGON TIPPER & SIDE ARM CHARGER, PADDLE FEEDERS, DUST<br />

SUPPRESSION SYSTEM AND DUCT EXTRACTION SYSTEM.<br />

4) TABLE OF ELECTRICAL SCOPE LIST SHALL BE REFERED FOR THE SCOPE / BATTERY LIMITS OF<br />

ELECTRICAL WORKS.<br />

• Complete design, manufacture, shop floor joint testing/ inspection, shop painting, transportation<br />

to site, un‐loading at site, storage & security at site, local transportation to erection spot, erection<br />

& commissioning, P.G.Testing, final painting at site and handing over to customer. Also bidder<br />

shall consider any items/ facilities which are not specifically mention in this specs. but are<br />

required for the smooth, safe and trouble free operation of the system.<br />

• Initial fills & consumables till handing over of equipments/ systems to the customer.<br />

• Operation & maintenance of equipments / system till handing over to customer. Any problems /<br />

accidents occurred before handing over to customer shall be rectified by the bidder.<br />

• Two years operation & maintenance spares for the equipments / systems which are in bidder’s<br />

scope.<br />

• Commissioning spares and insurance spares for all equipments which are in bidder’s scope.<br />

• Arrangement of all erection equipment viz. cranes, hoists, winches, etc, and safety appliances, any<br />

temporary structural supports as required for erection of plant & equipment. Cross checking of<br />

civil foundation works done by other agency during civil construction to avoid mismatches during<br />

equipment erection. Appointment of safety officer by the bidder shall be included.<br />

• Specialized training of Purchaser’s / Consultant’s personnel for operation, maintenance, for<br />

smooth handing over the plant.<br />

DATE: 12 Feb 2009 REV: 00 Page 11 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

• Bidder shall deploy qualified site in‐Charge , Engineers, Supervisors, Skilled / Unskilled Labour to<br />

site for E & C works. The no. of persons shall be decided mutually by BSP / <strong>BHEL</strong> / Successful<br />

Bidder for timely completion of the project.<br />

3.1 SCOPE OF WORK<br />

The broad turnkey scope of work shall be as per the following. However items described in technical<br />

specification should also be considered by the bidders in their scope.<br />

Design, engineering, manufacture, inspection, shop & primary coat of paint, transportation to site,<br />

unloading at site, safe storage & security at site, local transportation to erection site, any site fabrication,<br />

erection, commissioning and P.G test of complete conveyor system, all conveyor gallery structure &<br />

trestles, miscellaneous structure and all junction tower structure and other equipments as described in<br />

brief description & design considerations clause (i.e Clause 1 & 2 above) and as per system requirement.<br />

All the equipments / systems which are in the bidders scope shall be supplied along with onboard<br />

electricals. Refer list of electrical scope table for details.<br />

Scope for conveyor system & other auxiliary equipment covers the following<br />

• Conveyor technology structure (stringer, short support, deck plate, seal plate, idler frames etc.).<br />

• All types of idlers.<br />

• All types of pulleys.<br />

• Complete gravity take‐up unit including counter weight guiding pipes / beams.<br />

• Conveyor belting ( Excluding boom conveyor belt in stacker / reclaimer ).<br />

• Chutes & Liners, Flap gates and chute vibrators if any.<br />

• Complete motorized flap gate actuator assembly, limit switches and actuator stand.<br />

• Complete conveyor drive (Coupling, Motor, Gear box, brakes, Base frame, hold back etc.)<br />

• Internal scraper & external scraper.<br />

• Skirt board & hoods at tail end & head end.<br />

• Safety switches ( Emergency, Belt sway, Pull cord, chute jamming detector, belt slip etc).<br />

• Belt weigher system.<br />

• Metal detector system.<br />

• Traveling Trippers & bunker sealing arrangement.<br />

• Any modification in the chutes / structure of existing plant for interfacing the proposed new<br />

system with existing system OR complete replacement of chute, as per flow diagram / system<br />

description as required.<br />

• Inline magnetic separators,<br />

• Coal sampling system,<br />

• Hoists,<br />

• Mobile belt changing device,<br />

• Belt vulcanizing device,<br />

• ROD gate, Diverter gate,<br />

• Sump pump,<br />

• Belt feeder,<br />

• Air blaster,<br />

• Bin vibrator,<br />

• One no. dedicated compressed air system including all pipes, fittings, hose and associated electrics<br />

at track hopper TH‐3 for unloading of BOBRN wagons from both tracks.<br />

DATE: 12 Feb 2009 REV: 00 Page 12 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

• Complete structural works (Structure for conveyor gallery, conveyor gallery trestle, conveyor<br />

gravity take‐up, junction towers, monorails / supports, rails for traveling tripper, rails for<br />

reclaimer machines, rails for stacking machines etc.)<br />

As per flow diagram/ design considerations, Bidder shall consider the all inter connecting facilities<br />

between existing & proposed systems while designing the proposed junction towers / conveyor. Also<br />

bidder shall consider any modifications / strengthening of existing junction towers/ conveyor / chutes<br />

and complete replacement of chutes in case necessary. Bidder must visit the BSP site for assessment /<br />

feasibility of modification, strengthening & replacement works to be carried out in the existing facilities<br />

before submission of offer to <strong>BHEL</strong>.<br />

Preparation and approval of erection survey / alignment schemes, grouting clearances, painting<br />

clearances, testing of welds, pressure testing protocols and other related site protocols.<br />

Deputation of representatives of<br />

equipment suppliers and technology suppliers to site for supervision of erection, testing and<br />

commissioning.<br />

Applying final finish coat of paint as per approved procedure & shades before handing over, first fill of<br />

lubricant & oil, special tools & tackles, mobile equipment, handling & hoisting equipment etc.<br />

Supply of all commissioning spares and insurance spares. A list of such commissioning spares & insurance<br />

spares shall be indicated separately as indicated in schedule chapter . Bidder shall quote separately for<br />

two years spares along with the main offer.<br />

Progress reporting as per agreed formats, providing documentary evidence of purchase orders on sub<br />

vendors with addresses of contact persons, attending all site progress review / engineering review<br />

meetings at BSL, Bhilai or at MECON / <strong>BHEL</strong>, Ranchi, opening an equipped site office with coordinator over<br />

seeing all activities.<br />

Arrangement of all erection equipment viz. cranes, hoists, winches, etc, and safety appliances, any<br />

temporary structural supports as required for erection of plant & equipment. Appointment of safety<br />

officer by the bidder shall be included.<br />

Specialized training of Purchaser’s / Consultant’s personnel for operation, maintenance, for smooth<br />

handing over the plant.<br />

Testing and cold trial run of systems/ sub ‐ systems and integrated testing shall be carried out by the<br />

successful Bidder on continuous basis for complete system along with associated facilities followed by<br />

commissioning. On successful commissioning of the various sub‐systems, PG test of the entire plant shall<br />

be carried out as elaborated in the relevant chapter.<br />

Receiving delivery of items at site, their proper storage, and handling at site, watch and ward services,<br />

removal of debris to a location specified by the Purchaser etc.<br />

Site shall be handed over to the Purchaser in clean and orderly manner to the satisfaction of the site<br />

engineers after commissioning of the project.<br />

Getting Purchaser’s/ consultant’s approval for the drawings prepared by the successful Bidder, obtaining<br />

required approval from statutory authorities, providing adequate personnel, equipment, tools & tackles<br />

for timely completion of the project.<br />

3.2. LIST OF CONVEYORS<br />

3.2.1. OHP‐II Pertaining to raw material feeding of BF no 8 & SP‐III<br />

DATE: 12 Feb 2009 REV: 00 Page 13 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

(Length & lift of conveyors specified below are indicative only. Bidder shall decide exact length & lift<br />

during detail engineering based on system / layout requirement)<br />

Sl no Conveyor number Rated Capacity (tph) Tentative Length/lift Qty<br />

(m)<br />

/no)<br />

1 Z1C1 1500 114.09/12.2 1<br />

2 Z1C2 1500 114.09/12.2 1<br />

3 Z3C1 1500 261.725/18.4 1<br />

4 Z3C2 1500 261.725/18.4 1<br />

5 Z3C3 1500 90.475/4.5 1<br />

6 Z3RSC1 1500 5.8/0 1<br />

7 Z3RSC2 1500 5.8/0 1<br />

8 Z3RSC3 1500 5.8/0 1<br />

9 Z2C1 1500 427.7/23 1<br />

10 Z2C2 1500 427.7/23 1<br />

11 Z2RSC1 1500 5.8/0 1<br />

12 Z2RSC2 1500 5.8/0 1<br />

13 Z4C1 1500 236.9/9 1<br />

14 Z4C2 1500 236.9/9 1<br />

15 Z4C3 1500 236.9/9 1<br />

16 Z5C1 1500 88.7/8 1<br />

17 Z5C2 1500 88.7/8 1<br />

18 Z5C3 1500 88.7/8 1<br />

19 Z6C1 1500 88.7/8 1<br />

20 Z6C2 1500 88.7/8 1<br />

21 Z6C3 1500 88.7/8 1<br />

22 Z7C3 1500 469.5/7 1<br />

23 Z4B‐C1 1500 469.5/7 1<br />

24 Z4A‐C1 1500 503/7 1<br />

25 Z5B‐C1 1500 469.5/7 1<br />

26 Z5A‐C1 1500 503/7 1<br />

27 Z6B‐C1 1500 469.5/7 1<br />

28 Z6A‐C1 1500 503/7 1<br />

29 Z7C1 1500 270/7 1<br />

30 Z7C2 1500 273/7 1<br />

31 Z8C1 1500 391.865/6 1<br />

32 Z8C2 1500 394.875/6 1<br />

33 Z9C1 1500 695/9.4 1<br />

34 Z9C2 1500 692/9.4 1<br />

35 Z10C1 1500 1133/6.5 1<br />

36 Z10C2 1500 1136/6.5 1<br />

37 Z11C1 1500 380.6/10.5 1<br />

38 Z11C2 1500 380.6/10.5 1<br />

39 Z11RC1 1500 8/0 1<br />

40 Z11RC2 1500 8/0 1<br />

41 Z12C1 1500 377/0 1<br />

(Nos<br />

DATE: 12 Feb 2009 REV: 00 Page 14 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

42 Z12C2 1500 374/0 1<br />

43 Z13C1 1500 205.3/3 1<br />

44 Z13C2 1500 202.3/3 1<br />

45 Z15C1 1500 323/24.5 1<br />

46 Z15C2 1500 323/24.5 1<br />

3.2.2. NEW CONVEYOR J12A‐C1 & AN ADDITIONAL LINE PARALLEL TO J9 SERIES CONVEYORS UP TO<br />

JH‐27.<br />

(Length & lift of conveyors specified below are indicative only. Bidder shall decide exact length & lift<br />

during detail engineering based on system / layout requirement)<br />

Sl no Conveyor number Rated Capacity (tph) Tentative Length/lift<br />

(m)<br />

Qty<br />

(Nos/no)<br />

1 J9B‐RSC1 1500 21/3 1<br />

2 J9‐C1 1500 262/16 1<br />

3 J9H‐C1 1500 14.4/0 1<br />

4 J10‐C2 1500 120.3/12.4 1<br />

5 J11‐C3 1500 115.7/0 1<br />

6 J11‐RC2 1500 21/0 1<br />

7 J14‐C2 1500 310/9.2 1<br />

8 J15‐C2 1500 190/12.25 1<br />

9 J15‐RC1 1500 10.5/0 1<br />

10 J15B‐C1 1500 10.5/0 1<br />

11 J15B‐C2 1500 10.5/0 1<br />

12 J16‐C3 1500 268.3/12.7 1<br />

13 J16‐C3A 1500 7.3/0 1<br />

14 J17‐C3 1500 332/0 1<br />

15 J17A‐C1 1500 111.65/16.7 1<br />

16 J20‐C3 500 54.05/5 1<br />

17 J17B‐C1 1000 76/11 1<br />

18 J42‐C2 1000 20/0 1<br />

3.2.3 NEW CONVEYOR LINE FROM JUNCTION HOUSE JN‐102 TO LIME PLANT OF SMS‐II<br />

(Length & lift of conveyors specified below are indicative only. Bidder shall decide exact length & lift<br />

during detail engineering based on system / layout requirement)<br />

Sl no Conveyor no Rated Capacity (tph) Length/lift (m) Qty (Nos/no)<br />

1 L1C1 1500 162/10 1<br />

2 L2C1 1500 467/4 1<br />

3 L3C1 1500 37/4 1<br />

4 L4C1 1500 194/8 1<br />

5 L5C1 1500 86/4 1<br />

6 L6C1 1500 106.1/10 1<br />

7 L7C1 1500 108/4 1<br />

8 L8C1 1500 129.2/4 1<br />

9 L9C1 1500 218/11 1<br />

DATE: 12 Feb 2009 REV: 00 Page 15 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

10 L9C2 1500 70.9/4 1<br />

11 L9RSC1 1500 7/0 1<br />

12 L10C1 1500 560.6/47 1<br />

The all above belt conveyors shall include belting, all types of pulleys and idlers, drive unit, drive<br />

base frame, head frame, tail frame, take‐up units, stringer channel with supporting post, deck<br />

plate, discharge chute, skirt board with sealing system, external scraper, internal scraper,<br />

electrical protection switches, fasteners between equipment and its support etc<br />

Drive unit shall consist of motor, gear box, high speed coupling (between motor and gear box),<br />

low speed coupling (between gear box and drive pulley), brake and/or hold back built‐in with<br />

gear box, mounted on base plate preferably common for all the above.<br />

Conveyor system, safety switches like pull cord switches, belt sway switches and emergency<br />

stop switches shall be in the bidder scope.<br />

3.3. List of equipments to be considered in conveyor system (Mechanical) package.<br />

Bidder should consider the following equipment & associated auxiliaries, Hoists, commissioning spares<br />

and all services as described in conveyor system as the part of conveyor system package.<br />

3.3.1 Equipments (BOQ)<br />

Sl Equipment description Location Qty<br />

no<br />

1 EOT crane ‐20/5 t with maintenance WTB‐B1<br />

1 no<br />

crane<br />

2 ILMS 1& 2‐Suspended magnetic (PH) on conveyor Z1C1/Z1C2 2 nos<br />

separator<br />

3 ILMS 3& 4‐Suspended magnetic (PH) on conveyor Z2C1/C2 2 nos<br />

separator<br />

4 MD‐Metal detector Various location 6 nos<br />

5 Mobile belt changing device 2 nos<br />

6 RPG‐Rack & pinion gate Various location 2 nos<br />

7 ROD gate Various location 2 nos<br />

8 DG‐Diverter gate Various location 21 nos<br />

9 BWS‐Belt weigh scale Various location 14 nos<br />

10 Belt feeder (VVVF drive) Wagon tippler 2 nos<br />

11 Belt vulcanizing machine suitable for<br />

1 no<br />

1400 B<br />

12 Chute with liners Tiscral/ Sailhard/ Various location<br />

Lot<br />

UHMWPE)<br />

13 Portable submersible pump 4 nos<br />

14 Travelling Tripper 5 Nos.<br />

15 Automatic Sampling System complete<br />

with sample cutter, collection, sizing,<br />

crushing, grinding for RMHS system<br />

2 Nos.<br />

DATE: 12 Feb 2009 REV: 00 Page 16 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

16 AB (Air Blaster / Bin Vibrator) WT/ TH etc. 6 Nos.<br />

17 BV (Air Blaster / Bin Vibrator) Wt / TH etc. 6 Nos.<br />

18 Compressed air system for track hopper Track hopper<br />

1 set<br />

wagon unloading system.<br />

19 Hoists Various places 1 Lot<br />

3.4. HOISTS<br />

Bidder shall consider hoists at various places of proposed plant (JHs/ WT/ Track hopper etc.) as per<br />

system requirement. In case of existing junction houses, if the existing hoists are not able to cater for the<br />

newly incorporated system equipments, then new hoists shall be provided in such places of existing<br />

system.<br />

3.5. List of Tools & Tackles:<br />

1 Spanners<br />

a) Open end spanners metric sizes 6‐75mm ‐ 4 sets<br />

b) Adjustable spanner 10 inch ‐ 4 Nos.<br />

c) Box spanners metric sizes 8‐32mm & 23‐50mm ‐ 2 sets each.<br />

d) Ring spanners metric sizes 24‐56 ‐ 4 sets<br />

e) Socket head spanner with universal drive size ¾” – 1” ‐ 4 sets<br />

2 Vice grips 5” & 8” ‐ 2 Nos. each<br />

3 Digital Dial indicators ( up to 0.001 mm) with fixing accessories ‐ 4 sets<br />

4 Ball peen Hammers 2, 5, 10kg ‐ 4 Nos. each<br />

5 Nylon faced hammers 1 kg. ‐ 4 No<br />

Sledge hammer of 5kg & 10 kg ‐ 2 Nos. each<br />

6 Hydraulic bearing extractor of reputed make to suit LHS equipment ‐ 2 sets<br />

7 All type of pliers of different size of reputed make (Taparia,Everest) to suit LHS Equipment ‐ 3 Nos. in<br />

each<br />

i Cutting Pliers<br />

ii Nose pliers<br />

iii Internal circlip pliers<br />

iv External circlip pliers<br />

8 Hydraulic flange puller of reputed make to suit LHS equipment ‐ 2 sets<br />

9 Screw Drive 18”, 12”, 8”, 6” ‐ 4 Nos. each<br />

10 Spirit level 12” ‐ 2 Nos.<br />

11 Plumb bob ‐ 2 Nos.<br />

12 Belt Pullers of sizes 1.5 Ton, 5ton, & 8 Ton ‐ 2 sets each<br />

13 Pressure hoses 10T, 50T and 100T ‐ Each 2 Nos.<br />

14 4” dia. Portable motor operated grinding machine with flexible grinder ‐ 2 Nos.<br />

15 Self supporting, Extendable aluminium ladder with max. height of 6 m ‐ 4 Nos.<br />

16 a) Grease gun with hose & adapter ‐ 5 Nos.<br />

b) Bucket grease pump with hose & adapter ‐ 3 Nos.<br />

17 Roughing tools & spare flexible shafts ‐ 2 sets<br />

18 Slings & ‘D’ shackle ‐ 2 sets of each size<br />

19 Grip clamps for belts ‐ 12 Nos.<br />

20 Thermo meters (0‐180 deg.) ‐ 10 Nos.<br />

21 100VA (415V/40V) transformer for control boxes ‐ 2 Nos.<br />

22 Hydraulic pumps with manifold for vulcanizing hydraulic presses and flexible Hoses ‐ 1 Set<br />

DATE: 12 Feb 2009 REV: 00 Page 17 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

23 Control boxes suitable for heater plate ‐ 2 Nos.<br />

24 Pins & sockets, cable for connecting sockets and Junction boxes ‐ 2 Nos. each<br />

25 Buffing machine 1800 RPM ‐ 1 No.<br />

26 Splice knife 2” suitable for EP belts ‐ 12 Nos.<br />

27 Filing vice ‐ 10 Nos.<br />

28 Fluid coupling withdrawal device (for each type) ‐ 2 Nos.<br />

29 Fluid coupling mounting device ( for each type ) ‐ 2 Nos.<br />

30 3 jaw puller(17.5T) ‐ 2 Nos.<br />

31 Ultrasonic thickness meter for measuring plate thickness ‐ 2 Nos.<br />

32 Torque wrenches of 4 different ranges ‐ 2 sets of each<br />

7‐35 kg‐m<br />

14‐56 kg‐m<br />

49‐109 kg‐m<br />

75‐200 kg‐m<br />

33 Suitable hexagonal adapter sets for hollow shafts connections with drives. Each set consisting of 1 No.<br />

of each size 12, 14, 17, 19, 22 ‐ 2 sets<br />

34 Fast aligning equipment for alignment ‐ 2 Nos.<br />

35 Hydraulic jack (50t & 10t) Pc 2 type ‐ 2 Nos. each<br />

36 Lifting eye bolt including D shackles of 2,3,5,10 Tonnes sling ropes ( 5 Nos. each of sizes ½”, ¾”, 1” – 2<br />

mts long ‐ 1 set each.<br />

37 Pipe wrenches – 6” ,12” & 18” ‐ 4 Nos.<br />

38 Vibration analyzer ( IRD make for measuring Vibration & noise level) ‐ 2 Nos.<br />

39 Digital tachometer 0‐3000 RPM ‐ 2 Nos.<br />

40 Try squres ‐ 2 Nos.<br />

41 Straight edges ‐ 2 Nos.<br />

42 Steel Scales – 300, 500 & 1000 ‐ 2 Nos. each<br />

43 Bore dial guage 0 – 10 mm with LC 0.01 ‐ 2 sets<br />

44 Feeler guage ‐ 5 sets<br />

45 Screw guage – 150 to 600 mm ‐ 2 Nos.<br />

46 Digital Vernier caliper – 300 / 600 mm ‐ 2 Nos.<br />

47 Hand drill – Electrical ½” & 1” ‐ 2 nos. each<br />

48 Crimping tool (hand operated) – 5 mm to 16 mm ‐ 2 Nos.<br />

49 Crimping tools (Hand operated) – 16 mm to 240 mm ‐ 2 Nos.<br />

50 Mekaster tool kit ‐ 4 Nos.<br />

51 Platform Trolley ( Sl. No. 3 of M & E)<br />

52 10” size flat, round, half round bastard / fine piles ‐ 2 Nos.<br />

53 Outside Micrometer, range upto 150 mm ‐ 2 Nos.<br />

54 Inside Micrometer, range upto 150 mm ‐ 2 Nos.<br />

55 Steel Tape (3m, 30m) ‐ 2 nos. each<br />

56 Internal & external Calliper (0.15m, 0.5m, 1m) ‐ 2 sets each<br />

57 Manual Hoist of cap. 3t and 5t ‐ 4nos. each<br />

3.6. STRUCTURE<br />

The following list is indicative only. Bidder shall consider conveyor galleries & trestles for all the<br />

conveyors of proposed system as required and also for conv. J9B‐RSC1 (if required).<br />

DATE: 12 Feb 2009 REV: 00 Page 18 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

1 Rails for Traveling trippers & twin 1 Lot<br />

boom stackers machines, Bucket<br />

wheel reclaimers machines, Paddle<br />

feeders.<br />

2 Conveyor galleries, trestles, gravity<br />

take‐up structures & conveyor crossover<br />

1 Lot<br />

structure for all conveyors<br />

listed in conveyor list clause 3.2.1,<br />

3.2.2 & 3.2.3 and also per system<br />

requirement.<br />

3 Monorails for all hoists 1 Lot<br />

Miscellaneous structure like stair<br />

4<br />

case, hand rails, walk way 1 Lot<br />

chequered plates/ gratings, ladders,<br />

equipments supporting structure<br />

etc. as per system requirement.<br />

LIST OF STRUCTURAL JUCTION HOUSE:<br />

NEW JUNCTION HOUSES<br />

1 JH‐Z2 to ZH‐Z15 (except 13 nos.<br />

JH‐Z1, 14)<br />

2 JH‐Z4A 1 no<br />

3 JH‐Z4B 1 no<br />

4 JH‐Z5A 1 no<br />

5 JH‐Z5A 1 no<br />

6 JH‐Z5B 1 no<br />

7 JH‐Z6A 1 no<br />

8 JH‐Z6B 1 no<br />

9 JH‐15B 1 no<br />

10 JH‐16A 1 no<br />

11 JH‐17A 1 no<br />

12 JH‐17B 1 no<br />

13 JH‐9A 1 no<br />

14 JH‐10A 1 no<br />

15 JH‐L1 to JH‐L10 10 nos.<br />

17 Wagon tippler shed 1 no<br />

18 Track hopper shed 1 no<br />

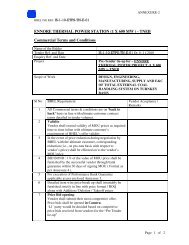

ELECTRICAL SCOPE LIST<br />

B – <strong>BHEL</strong>, V – Vendor, AB – Air Blaster, BV – Bin Vibrator, TTR – Travelling Tripper, AF – Apron Feeder,<br />

BF – Belt Feeder, RGD – Rod Gate, DG – Diverter/ Flap Gate, MD – Metal Detector, ILMS – Magnetic<br />

Separator, BWS – Belt Weighing System.<br />

Sl.<br />

No.<br />

Description<br />

EOT/<br />

Hoist<br />

ILMS<br />

MD<br />

RDG/DG<br />

Gates<br />

BWS<br />

BF<br />

Sampling<br />

System<br />

AB/<br />

BV<br />

Conv.<br />

AF<br />

TTR<br />

DATE: 12 Feb 2009 REV: 00 Page 19 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

1 Motor V ‐ ‐ V ‐ V V V V V<br />

2 VVVF ‐ ‐ ‐ ‐ ‐ V ‐ ‐ B ‐<br />

3 HT Cable ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ B ‐<br />

4 Transformers ‐ V ‐ ‐ ‐ ‐ ‐ ‐ B ‐<br />

5 Bus Ducts ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ B ‐<br />

6 MCC ‐ ‐ ‐ ‐ ‐ B B B B ‐<br />

7 Field Devices V V V V V ‐ V V V V<br />

8<br />

LT Power<br />

Cable<br />

V V V B B B B B B V<br />

9<br />

Control/ Fest<br />

Cable<br />

V V V B B B V ‐ B V<br />

10 Illumination ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ B B<br />

11 PLC / MMI ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ B ‐<br />

12 Control Desk ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ B ‐<br />

13<br />

Control<br />

Panel<br />

V V V ‐ V ‐ V ‐ ‐ V<br />

14<br />

Power JB /<br />

Control JB<br />

V V V ‐ V ‐ V V ‐ V<br />

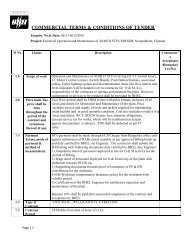

3.7. COMMISSIONING SPARES<br />

(Bidders shall consider the following minimum commissioning spares in their scope. Commissioning<br />

spares for all other equipments like belt weigher, traveling tripper, metal detector, vibro feeders,<br />

vibratory grizzly feeders, ILMS, belt feeders, etc. which are in the bidders’ scope shall also be<br />

considered).<br />

Note: ‐ Spares for any equipment / system which are covered under this package but not mentioned in the<br />

list below shall be considered by the bidder into their scope and the same shall be subjected to customer<br />

BSP approval during project execution.<br />

A<br />

FOR CONVEYOR OF ALL BELT WIDTH INCLUDING SHUTTLE CONVEYOR<br />

1. Roller of idlers<br />

GEAR BOXES(Including drives of stackercum<br />

reclaimer, wagon tippler,pusher car,CBMS )<br />

1% of<br />

total<br />

quantity of each type<br />

1. Oil seals 1 set of each type<br />

2. Input shaft with matching gear wheel assembly 1 set of each type<br />

GEAR COUPLING<br />

1. Seal kit for gear coupling 1 set of each type<br />

H DIVERTOR GATE<br />

1 Limit switch 12 nos.<br />

2 Oil seals of actuator 12 nos.<br />

I<br />

RACK & PINION GATE<br />

DATE: 12 Feb 2009 REV: 00 Page 20 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

1 Limit switch 4 nos of each type<br />

J<br />

FOR ALL FLUID COUPLINGS<br />

1 Fusible plug 2 nos. of each type<br />

2 Resilient plate 2 nos. of each type<br />

3 Multidisc plate 1 no of each type<br />

K<br />

FOR ALL SG/US EOT CRANES<br />

a) MECHANICAL<br />

1. Oil seals and gaskets for<br />

i) Hoist gear box 1 set for each type<br />

ii) CT gear box<br />

1 set for each type<br />

iii) LT gear box<br />

1 set for each type<br />

2. Brake shoes 1 set for each type<br />

b) ELECTRICAL<br />

1. Indicating lamp with holder 1 no of each type<br />

2. Power contactor-contacts 1 no of each type<br />

3. Power contactor-coil 1 no of each type<br />

4. Auxiliary contactor-contacts 1 no of each type<br />

5. Auxiliary contactor-coil 1 no of each type<br />

6. Push button 1 no of each type<br />

7. Power fuses 5 % of each rating<br />

8. Control fuses 10% of total quantity(for each<br />

type)-Minm 1 no.<br />

9. Control switches 1 no of each type<br />

10. Brake coil 1 no of each type<br />

L<br />

FOR ALL ELECTRIC HOISTS<br />

a) MECHANICAL<br />

1. Oil seals and gaskets for<br />

i) Hoist gear box 1 set for each type<br />

ii) CT gear box<br />

1 set for each type<br />

2. Brake shoes 1 set for each type<br />

b) ELECTRICAL<br />

1. Indicating lamp with holder 1 no of each type<br />

2. Power contactor 20% of each rating -Minm 1 no.<br />

3. Overload relay 20% of each rating -Minm 1 no.<br />

4. Fuses 30% of each rating -Minm 1 no.<br />

5. Relay/Timers 20% of each rating -Minm 1 no.<br />

6. Push button 20% of each rating -Minm 1 no.<br />

7. Brake coil 20% of each rating -Minm 2 no.<br />

3.8. OPERATIONAL / MAINTENANCE SPARES<br />

Bidder shall consider two years operational/ maintenance spares for all the equipments/ systems which<br />

are in the scope bidder and the list of spares shall be furnished along with offer.<br />

3.9. BATTERY LIMITS<br />

DATE: 12 Feb 2009 REV: 00 Page 21 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

An overall battery limit of the Raw Material Handling System has been described in the “Brief System<br />

Description” along with the Flow Diagram – Drawing No. MEC/S/9101/11/17/0/00/00/061.B01/R2 for<br />

OHP‐II.<br />

1. Battery limits for New Ore Handling Plant (OHP-II) comprises of the following:<br />

• New Ore Handling Plant (OHP‐II) –From new Wagon Tippler WT # B1 and new track hoppers to the<br />

Ore storage bed for Stacking, reclaiming & transportation to various units, including<br />

Lump Ore, limestone, dolomite etc. from OHP‐II to New Blast Furnace #8. (Through Junction house Z 15).<br />

Iron Ore fines, limestone & dolomite to both modules of Sintering Plant‐III. (Through Junction house Z 11)<br />

from OHP II.<br />

2. Proposed modifications/ up‐gradations are:‐<br />

• An additional series of conveyor from OHP‐I to new junction house J‐20 (it is existing)<br />

3. Feeding Limestone & dolomite to New Lime Dolo Plant RMP III and New Steel Melting Shop SMS III :<br />

This includes providing a discharge chute below belt conveyor R103A & R104A at Junction House JN‐102<br />

(With suitable modifications of JH‐102 which is in the scope of the Bidder) so as to feed new conveyor L1‐<br />

C1 as well as existing belt conveyors R105 & R106. Limestone/dolomite/iron ore received from existing<br />

OHP‐I will be supplied to the junction house JH‐L6 of proposed new RMP III as well as junction house JH‐<br />

L10 through surge bin building JH‐L9 before proposed new SMS‐III. The conveyor feeding raw material to<br />

RMP III from junction house JH‐L6 and feeding raw material to SMS III from JH‐L10 is not in bidder’s scope.<br />

However junction houses JH‐L6 and JH‐L10 are included in bidder’s scope but necessary provisions shall be<br />

made in JH‐6 & 10.<br />

4.0 Obligations of Purchaser<br />

Purchaser shall allot leveled land with an undulation of about +500mm from the predetermined level as<br />

per the layout drawing for installation of the Raw Material Handling System.<br />

Purchaser shall provide construction power, drinking water during construction on Chargeable basis and<br />

space for storage and site office as per general technical specifications (GTS). The Bidder shall indicate the<br />

details required by them in the prescribed format.<br />

Additional Points<br />

• The requirement of construction power and water shall be indicated.<br />

• List of activities to be performed by the Purchaser for completeness of the work shall be<br />

mentioned by the Bidder without fail along with offer.<br />

• The resource deployment for carrying out the job as suggested by the Bidder shall be mentioned.<br />

• Supply of the initial fill is in the Bidder’s scope.<br />

• The Bidder shall confirm the supply of all consumables required for erection, testing and<br />

successful commissioning of the system.<br />

• The Bidder shall also confirm the provision of commissioning spares required for all equipment.<br />

• The Bidder shall confirm the supply of all special tools and tackles required for erection, testing<br />

and successful commissioning of the system.<br />

• The Bidder shall furnish spares for two years normal operation/ maintenance of the offered<br />

equipment to ensure availability of the equipment. Price of such spares shall be quoted<br />

separately.<br />

DATE: 12 Feb 2009 REV: 00 Page 22 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

5. TECHNICAL SPECIFICATION / DRGS / DOCUMENTS / CODES & STANDARS<br />

Complete detailed specifications for all the equipments / systems & drawings and all other documents ,<br />

approved vendor list, P.G tests etc, shall be sent the responded bidders separately in the form of soft<br />

copies.<br />

6. EXCLUSIONS LIST.<br />

1) All civil works like RCC buildings, foundations for Junction towers, foundations for conveyor gallery<br />

trestles, equipment foundations/ insert plates etc.. However, bidder must furnish the add on<br />

optional price for including the civil design in their scope.<br />

2) All roads, drains, garland drains, pipe culverts in the plant area etc.<br />

3) Complete dry fog dust suppression system (DS DF). However, the bidder shall design the head end<br />

hood & tail end skirt board by considering the dry fog dust suppression system. Typical head end<br />

& typical tail end drgs. Shall be vetted by the designer of DS DF.<br />

4) Complete dust extraction system. However, the bidder shall design the head end hood & tail end<br />

skirt board by considering the dust extraction system. Typical head end & typical tail end drgs.<br />

Shall be vetted by the designer of DE system.<br />

5) Ventilation system for conveyor underground tunnels, underground junction houses, Electrical<br />

control / MCC rooms, Wagon tippler house and track hopper house.<br />

6) Any air conditioning for Wagon tippler operator room, control rooms etc.<br />

7) Wagon tipplers & side arm charger along with on board electrics.<br />

8) Twin boom stackers & on board electrics & boom conveyor belt. However, rails for stacker<br />

machines are included in bidder’s scope.<br />

9) Bucket wheel reclaimers & on board electrics. However, rails are included in bidder’s scope.<br />

10) Paddle feeders & on board electrics. However, rails for paddle feeders and compressed air system<br />

for wagon unloading are included in the bidder’s scope.<br />

11) Weigh bridges & on board electrics.<br />

12) Fire fighting system<br />

13) Electrics as mentioned in electrical scope list above.<br />

VERY IMPORTANT NOTE: ‐<br />

5) ALL OTHER ITEMS / SYSTEMS/ SUB‐SYSTEMS WHICH ARE NOT LISTED IN THE EXCLUSIONS LIST BUT<br />

ARE REQUIRED FOR SYSTEM AS PER FLOW DIAGRAM & DESIGN CONSIDERATIONS CLAUSE AND<br />

ARE REQUIRED FOR SMOOTH & TROUBLE FREE SAFE OPERATION OF THE PALNT MUST BE<br />

CONSIDERED BY THE BIDDER IN THEIR SCOPE WITHOUT FAIL.<br />

6) BIDDER SHOULD CONSIDER ALL NECESSARY REQUIREMENTS FOR INTERFACING & INTEGRATING<br />

OF OTHER EQUIPMENTS & SYSTEMS WHICH ARE NOT IN THE SCOPE OF BIDDER, NAMELY<br />

TWINBOOM STACKERS, BUCKET WHEEL RECLAIMERS, WAGON TIPPER & SIDE ARM CHARGER,<br />

PADDLE FEEDERS, DUST SUPPRESSION SYSTEM AND DUCT EXTRACTION SYSTEM.<br />

7) BIDDER SHOULD CONSIDER IN THEIR PLC / AUTOMATION SYSTEM, ALL NECESSARY<br />

REQUIREMENTS (IN PUTS / OUT PUTS) FOR INTERFACING & INTEGRATING OF OTHER EQUIPMENTS<br />

& SYSTEMS WHICH ARE NOT IN THE SCOPE OF BIDDER, NAMELY TWINBOOM STACKERS, BUCKET<br />

WHEEL RECLAIMERS, WAGON TIPPER & SIDE ARM CHARGER, PADDLE FEEDERS, DUST<br />

SUPPRESSION SYSTEM AND DUCT EXTRACTION SYSTEM.<br />

7.0 APPROVED VENDOR LIST<br />

DATE: 12 Feb 2009 REV: 00 Page 23 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

1.1 FLUID SYSTEM<br />

A. Water Supply Facilities<br />

Sl.<br />

No.<br />

1<br />

2<br />

3<br />

Item Description<br />

Horizontal<br />

Centrifugal Pumps<br />

Vertical Turbine<br />

Pumps<br />

Vertical Wet Pit<br />

Type Pumps<br />

4 Submersible Pumps<br />

Manufacturers<br />

Kirloskar Brothers, KSB, Beacon Weir, Khimline, Jyoti,<br />

Sintech, Ghaziabad.<br />

Kirloskar Brothers, Voltas, WPIL, Jyoti<br />

SU Motors, Kishore Pumps, Kirloskar Brothers, KSB.<br />

KSB, SU Motors, Kirloskar Brothers, Kishore Pumps,<br />

Darling, Beacon Weir.<br />

5 Slurry Pump Akay, Sam Engg., MBE, KBL, KSB Pumps, WARMAN.<br />

6 Dosing Pump<br />

7 Cooling Towers<br />

8 Pressure Filters<br />

Shapo Tools, Asia LMI (Madras), Positive Metering<br />

Pumps, Toshniwal, Milton Roy India.<br />

PCTPL, Shri Ram Tower Tech, Gammon, Himgiri,<br />

Southern Cooling Tower, BDT, GEA<br />

Thermax, Ion‐Exchange, Resin India, Driplex, Doshion,<br />

VA Tech Wabag, UEM, Aquatech<br />

9 Sluice Gates Jash Engineering, IVPL<br />

10<br />

Travelling Water<br />

Screen<br />

Macmet, Triveni, Otokiln, Mecgale (Nagpur), General<br />

Mechanical<br />

11 Sludge Scrapper Triveni, Neo – Parisrutan, Mata India, Geomiller<br />

12 Fire Hydrants<br />

13 Basket Strainers<br />

New Age Industries, Steelage Industires, ASCO,<br />

Strumech, Vijay Fire, Zenith<br />

Filteration Engrs, J.N Marshall, Masturlal Fabrication ,<br />

ARF Engg, Purolator Filters, ABB, Filters Mfd India<br />

14 Duplex Strainers Filteration Engrs., Otokiln, Superflo<br />

15<br />

Rubber Dismantling<br />

Joints<br />

BDX, CORI Engineers, D.Wren,<br />

16 Diesel Engine Cummins/Ashok Layland/Ruston<br />

17<br />

Softening & DM<br />

Plant<br />

18 R O Plants<br />

Doshi / Resin India / Thermax / Thermax Cullinyan / VA<br />

Tech / Ion Exchange /Triveni / GEA Energy <strong>Systems</strong>/<br />

Driplex Water Engg, Triveni,<br />

UEM India, VA Tech, GEA Energy <strong>Systems</strong>, Ion<br />

Exchange,<br />

Driplex Water Engg, Triveni,<br />

DATE: 12 Feb 2009 REV: 00 Page 24 of 43

<strong>BHEL</strong> ISG REF: IS‐1‐08‐2013/ 002 ENQUIRY SPECS FOR MECHANICAL PACKAGE‐2<br />

(CONVEYOR SYSTEM & STRUCTURES) FOR BHILAI STEEL PLANT AUGMENTAION<br />

OF RAW MATERIAL RECEIPT & HANDLING FACILITIES WITH NEW OHP.<br />

19<br />

20<br />

Effluent Treatment<br />

Plant<br />

Drinking water<br />

Treatment Plant<br />

21 Basalt Liners<br />

UEM India, VA Tech, GEA Energy <strong>Systems</strong>, Triveni,<br />

UEM India, VA Tech, GEA Energy <strong>Systems</strong>, Driplex<br />

Water<br />

Engg , Triveni,<br />

DEMECH, Vidyut Green Bank, Enviro Abrasian, Garden<br />