ADCA-BM 32

ADCA-BM 32

ADCA-BM 32

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

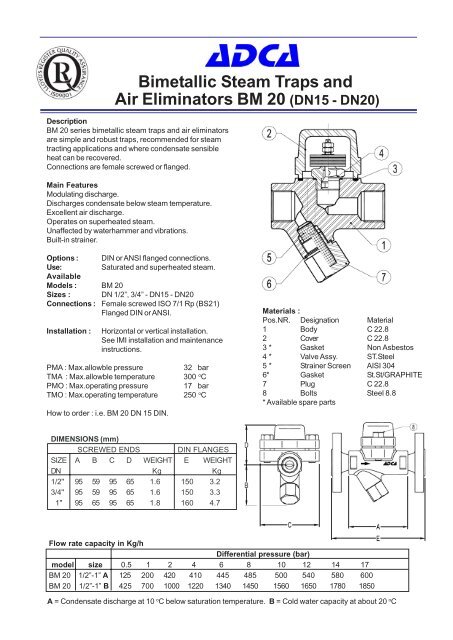

Bimetallic Steam Traps and<br />

Air Eliminators <strong>BM</strong> 20 (DN15 - DN20)<br />

Description<br />

<strong>BM</strong> 20 series bimetallic steam traps and air eliminators<br />

are simple and robust traps, recommended for steam<br />

tracting applications and where condensate sensible<br />

heat can be recovered.<br />

Connections are female screwed or flanged.<br />

Main Features<br />

Modulating discharge.<br />

Discharges condensate below steam temperature.<br />

Excellent air discharge.<br />

Operates on superheated steam.<br />

Unaffected by waterhammer and vibrations.<br />

Built-in strainer.<br />

Options : DIN or ANSI flanged connections.<br />

Use:<br />

Saturated and superheated steam.<br />

Available<br />

Models : <strong>BM</strong> 20<br />

Sizes : DN 1/2”, 3/4” - DN15 - DN20<br />

Connections : Female screwed ISO 7/1 Rp (BS21)<br />

Flanged DIN or ANSI.<br />

Installation :<br />

Horizontal or vertical installation.<br />

See IMI installation and maintenance<br />

instructions.<br />

PMA : Max.allowble pressure<br />

TMA : Max.allowble temperature<br />

PMO : Max.operating pressure<br />

TMO : Max.operating temperature<br />

How to order : i.e. <strong>BM</strong> 20 DN 15 DIN.<br />

<strong>32</strong> bar<br />

300 o C<br />

17 bar<br />

250 o C<br />

Materials :<br />

Pos.NR. Designation Material<br />

1 Body C 22.8<br />

2 Cover C 22.8<br />

3 * Gasket Non Asbestos<br />

4 * Valve Assy. ST.Steel<br />

5 * Strainer Screen AISI 304<br />

6* Gasket St.St/GRAPHITE<br />

7 Plug C 22.8<br />

8 Bolts Steel 8.8<br />

* Available spare parts<br />

DIMENSIONS (mm)<br />

SCREWED ENDS DIN FLANGES<br />

SIZE A B C D WEIGHT E WEIGHT<br />

DN Kg Kg<br />

1/2" 95 59 95 65 1.6 150 3.2<br />

3/4" 95 59 95 65 1.6 150 3.3<br />

1" 95 65 95 65 1.8 160 4.7<br />

Flow rate capacity in Kg/h<br />

Differential pressure (bar)<br />

model size 0.5 1 2 4 6 8 10 12 14 17<br />

<strong>BM</strong> 20 1/2”-1” A 125 200 420 410 445 485 500 540 580 600<br />

<strong>BM</strong> 20 1/2”-1” B 425 700 1000 1220 1340 1450 1560 1650 1780 1850<br />

A = Condensate discharge at 10 o C below saturation temperature. B = Cold water capacity at about 20 o C

abcde<br />

<strong>ADCA</strong><br />

INSTALLATION AND MAINTENANCE INSTRUCTIONS<br />

<strong>BM</strong> - BIMETALIC STEAM TRAPS<br />

BSS – <strong>BM</strong>20 – <strong>BM</strong><strong>32</strong><br />

GENERAL<br />

1. These instructions must be carefully read before any work involving products supplied by<br />

VALSTEAM <strong>ADCA</strong> ENGINEERING S.A. is undertaken.<br />

2. The installation procedure is a critical stage in a life of a steam trap and care should be taken<br />

to avoid damage to the trap or equipment.<br />

Warning!<br />

-At start up, the presence of small particles in the water (dirt, scale, weld splatters, etc) may<br />

cause an unperfected closure of the seat. If this occurs, proceed to an accurate cleaning.<br />

-Do not touch the equipment without appropriate protection during working operation because it<br />

may conduct heat if the used fluid is at high temperature.<br />

-Before starting maintenance be sure that the equipment is not pressurized or hot.<br />

-The equipments must be used within the working temperature and pressure limits laid down for<br />

them, otherwise they may fail (refer to nameplate and/or IS- Information Sheet).<br />

-Do not remove the nameplate attached to the equipment. Serial number and other useful<br />

information is stamped on it.<br />

INSTALLATION<br />

1. Before to install remove plastic covers placed on flanges or connection ends. The equipment<br />

has an arrow or Inlet/Outlet designations. Be sure that it will be installed on the appropriate<br />

direction.<br />

2. Install the steam trap in the point of the system, where the condensate tends to collect. It can<br />

be installed in any position. An <strong>ADCA</strong> strainer can be installed upstream of the trap as<br />

additional protection.<br />

LIMITING CONDITIONS BSS <strong>BM</strong>20 <strong>BM</strong><strong>32</strong><br />

PMA: Max. allowable pressure 45 bar <strong>32</strong> bar <strong>32</strong> bar<br />

TMA: Max. allowable temperature 300 ºC 300 ºC 300 ºC<br />

PMO: Max. operating pressure 20 bar 17 bar 22 bar<br />

TMO: Max. operating temperature 250 ºC 250 ºC 250 ºC<br />

MAINTENANCE<br />

1. We recommend that the steam traps are serviced as necessary. Steam traps should be<br />

checked periodically (at least yearly), to verify that they are operating correctly and to clean<br />

the internal parts and strainer screen.<br />

2. When reassembling make sure that all gasket faces are clean and always use a new gasket.<br />

Tighten cover bolts uniformly in a diagonal sequence.<br />

3. For further information refer to the relevant IS (Information Sheet) or consult our Sales Office.<br />

VALSTEAM <strong>ADCA</strong><br />

We reserve the right to change the design and material of this product without notice.<br />

Produced in accordance with Article 3, paragraph 3 of the PED - European Pressure Equipment Directive - 97/23/EC. IMI 1.423 E 12.05

abcde<br />

<strong>ADCA</strong><br />

CE Marking :<br />

This product have been designed for use on steam and water which are in Group 2 of the PED-<br />

European Pressure Equipment Directive 97/23/EC and it comply with those requirements.<br />

The product fall within category SEP and must not be CE marked.<br />

PARTS LIST FOR BSS 20:<br />

CODE DESIGNATION<br />

TRAP SIZE<br />

DN<br />

POS.NR. QTY.<br />

A.95.5010.015 Valve regulator & gasket ½” 3 1 set<br />

A.95.5010.115 Strainer screen ½” 5 1 set<br />

Recommended tightening torques:<br />

POS.NR.<br />

TRAP SIZE<br />

DN<br />

Nm<br />

1-2 ½” 140<br />

3 ½” 50-55<br />

PARTS LIST FOR <strong>BM</strong> 20:<br />

CODE DESIGNATION<br />

TRAP SIZE<br />

DN<br />

POS.NR. QTY.<br />

A.95.5081.015 Valve regulator & gasket ½” - 3/4'' 3, 4 1 set<br />

A.95.5100.115 Strainer screen & gasket ½” - 3/4'' 5, 6 1 set<br />

Recommended tightening torques:<br />

POS.NR.<br />

TRAP SIZE<br />

DN<br />

Nm<br />

4 ½” - 3/4'' 120<br />

7 ½” - 3/4'' 90<br />

VALSTEAM <strong>ADCA</strong><br />

We reserve the right to change the design and material of this product without notice.<br />

Produced in accordance with Article 3, paragraph 3 of the PED - European Pressure Equipment Directive - 97/23/EC. IMI 1.423 E 12.05

abcde<br />

<strong>ADCA</strong><br />

PARTS LIST FOR <strong>BM</strong> <strong>32</strong>:<br />

CODE DESIGNATION<br />

TRAP SIZE<br />

DN<br />

POS.NR. QTY.<br />

A.95.5100.015 Valve regulator & gasket ½” - 1'' 3, 4 1 set<br />

A.95.5100.115 Strainer screen & gasket ½” - 1'' 5, 7 1 set<br />

Recommended tightening torques:<br />

POS.NR.<br />

TRAP SIZE<br />

DN<br />

Nm<br />

4 ½” - 1'' 120<br />

6 ½” - 1'' 90<br />

LOSS OF GUARANTEE: Total or partial disregard of above instructions involves loss of any right to guarantee.<br />

VALSTEAM <strong>ADCA</strong><br />

We reserve the right to change the design and material of this product without notice.<br />

Produced in accordance with Article 3, paragraph 3 of the PED - European Pressure Equipment Directive - 97/23/EC. IMI 1.423 E 12.05