ASTM E 84 Surface Burning Characteristics of ... - Usg-me.com

ASTM E 84 Surface Burning Characteristics of ... - Usg-me.com

ASTM E 84 Surface Burning Characteristics of ... - Usg-me.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ELECTRONIC DRAFT COPY<br />

<strong>ASTM</strong> E <strong>84</strong> <strong>Surface</strong> <strong>Burning</strong> <strong>Characteristics</strong><br />

<strong>of</strong> "Standard White" Ceiling Tile<br />

A Report To:<br />

USG Middle East Ltd.<br />

2nd Industrial City<br />

7410 Alkharj Road<br />

Dammam<br />

34326-4201<br />

Kingdom <strong>of</strong> Saudi Arabia<br />

Phone: +966 3 812 0995<br />

fax: +966 3 812 1029<br />

E-mail:<br />

zmalek@usg<strong>me</strong>.<strong>com</strong><br />

Web:<br />

www.usg.<strong>com</strong><br />

Attention:<br />

Mr. Ziad Malek<br />

Submitted by:<br />

Fire Testing<br />

Report No. 11-002-181<br />

4 Pages<br />

Date: April 5, 2011

<strong>ASTM</strong> E <strong>84</strong> <strong>Surface</strong> <strong>Burning</strong> <strong>Characteristics</strong> <strong>of</strong> "Standard White" Ceiling Tile Page 2 <strong>of</strong> 4<br />

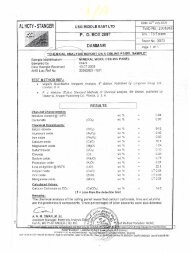

For: USG Middle East Ltd. Report No. 11-002-181<br />

ACCREDITATION To ISO/IEC 17025 for a defined Scope <strong>of</strong> Testing by the Standards Council <strong>of</strong> Canada<br />

Exova<br />

SPECIFICATIONS OF ORDER<br />

Determine the Fla<strong>me</strong> Spread and Smoke Developed Indices based upon a single test conducted in<br />

accordance with <strong>ASTM</strong> E <strong>84</strong>-10b, as per Exova Warringtonfire ME P.O. #DFL0343 PO dated April 4, 2011.<br />

SAMPLE IDENTIFICATION<br />

(Exova sample identification number 11-002-S0181)<br />

15 mm thick ceiling tile (product referenced "Standard", colour reference "White") having a weight per unit area<br />

<strong>of</strong> 3.5 kg/m².<br />

TEST PROCEDURE<br />

The <strong>me</strong>thod, designated as <strong>ASTM</strong> E <strong>84</strong>-10b, "Standard Method <strong>of</strong> Test for <strong>Surface</strong> <strong>Burning</strong> <strong>Characteristics</strong> <strong>of</strong><br />

Building Materials", is designed to determine the relative surface burning characteristics <strong>of</strong> materials under<br />

specific test conditions. Results are expressed in terms <strong>of</strong> Fla<strong>me</strong> Spread Index (FSI) and Smoke Developed (SD).<br />

Although the procedure is applicable to materials, products and assemblies used in building construction for<br />

develop<strong>me</strong>nt <strong>of</strong> <strong>com</strong>parative surface spread <strong>of</strong> fla<strong>me</strong> data, the test results may not reflect the relative surface<br />

burning characteristics <strong>of</strong> tested materials under all building fire conditions.<br />

SAMPLE PREPARATION<br />

The test sample consisted <strong>of</strong> 6 sections <strong>of</strong> material, each approximately 0.5 inches (13 mm) in thickness by<br />

21 inches (533 mm) in width by 47.25 inches (1200 mm) in length. The sections were butted together to form<br />

the requisite speci<strong>me</strong>n length. Prior to testing, the sample was conditioned at a temperature <strong>of</strong> 73 ± 5°F (23 ±<br />

3°C) and a relative humidity <strong>of</strong> 50 ± 5%.<br />

The testing was perfor<strong>me</strong>d on: 2011-03-18<br />

SUMMARY OF TEST PROCEDURE<br />

The tunnel is preheated to 150 ± 5°F (66 ± 2.8°C), as <strong>me</strong>asured by the floor-embedded thermocouple located<br />

23.25 feet (7087 mm) downstream <strong>of</strong> the burner ports, and allowed to cool to 105 ± 5°F (40.5 ± 2.8°C), as<br />

<strong>me</strong>asured by the floor-embedded thermocouple located 13 feet (3962 mm) from the burners. At this ti<strong>me</strong> the<br />

tunnel lid is raised and the test sample is placed along the ledges <strong>of</strong> the tunnel so as to form a continuous<br />

ceiling 24 feet (7315 mm) long, 12 inches (305 mm) above the floor. Three 8 foot (2438 mm) sections <strong>of</strong><br />

0.25 inch (6 mm) ce<strong>me</strong>nt board are then placed on the back side <strong>of</strong> the sample end-to-end, to protect the<br />

tunnel lid, and the lid is then lowered into place.

<strong>ASTM</strong> E <strong>84</strong> <strong>Surface</strong> <strong>Burning</strong> <strong>Characteristics</strong> <strong>of</strong> "Standard White" Ceiling Tile Page 3 <strong>of</strong> 4<br />

For: USG Middle East Ltd. Report No. 11-002-181<br />

SUMMARY OF TEST PROCEDURE (continued)<br />

Upon ignition <strong>of</strong> the gas burners, the fla<strong>me</strong> spread distance is observed and recorded every 15 seconds.<br />

Fla<strong>me</strong> spread distance versus ti<strong>me</strong> is plotted, ignoring any fla<strong>me</strong> front recessions. Calculations are based<br />

on <strong>com</strong>parison with fla<strong>me</strong> spread characteristics <strong>of</strong> select red oak, determined in calibration trials and<br />

arbitrarily established as 100. If the area under the curve (A) is less than or equal to 97.5 min·ft, FSI = 0.515·A;<br />

if greater, FSI = 4900/(195-A). Smoke Developed is determined by <strong>com</strong>paring the area under the obscuration<br />

curve for the test sample to that <strong>of</strong> inorganic reinforced ce<strong>me</strong>nt board and red oak, arbitrarily established as<br />

0 and 100, respectively.<br />

Exova<br />

TEST RESULTS<br />

SAMPLE FSI SD<br />

"Standard White" Ceiling Tile 5 120<br />

Observations <strong>of</strong> <strong>Burning</strong> <strong>Characteristics</strong><br />

- The sample ignited approximately 0.5 minutes after exposure to the test fla<strong>me</strong>.<br />

- The fla<strong>me</strong> front propagated to a maximum distance <strong>of</strong> 1.5 feet (0.5 <strong>me</strong>tres) at approximately<br />

0.75 minutes.<br />

- Smoke Developed was recorded during the test (see ac<strong>com</strong>panying chart).<br />

Authorities having jurisdiction usually refer to these categories:<br />

Fla<strong>me</strong>-Spread Index<br />

Smoke Develop<strong>me</strong>nt<br />

Class 1 or A 0 - 25 450 Maximum<br />

Class 2 or B 26 - 75 450 Maximum<br />

Class 3 or C 76 - 200 450 Maximum<br />

Note: This is an electronic copy <strong>of</strong> the report. Signatures are on file with the original report.<br />

Robert A. Carleton,<br />

Fire Testing.<br />

Ian Smith,<br />

Fire Testing.<br />

Note:<br />

This report and service are covered under Exova Canada Inc. Standard Terms and Conditions <strong>of</strong> Contract which<br />

may be found on the Exova website (www.exova.<strong>com</strong>), or by calling 1-866-263-9268.

<strong>ASTM</strong> E <strong>84</strong> <strong>Surface</strong> <strong>Burning</strong> <strong>Characteristics</strong> <strong>of</strong> "Standard White" Ceiling Tile Page 4 <strong>of</strong> 4<br />

For: USG Middle East Ltd. Report No. 11-002-181<br />

FLAME SPREAD INDEX<br />

"Standard White" Ceiling Tile<br />

20<br />

Exova<br />

18<br />

16<br />

RED OAK (FSC=100)<br />

SAMPLE<br />

Fla<strong>me</strong> Spread in Feet<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Ti<strong>me</strong> in Minutes<br />

SMOKE DEVELOPED<br />

100<br />

"Standard White" Ceiling Tile<br />

90<br />

80<br />

RED OAK (SD=100)<br />

SAMPLE<br />

% Light Absorption<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Ti<strong>me</strong> in Minutes<br />

FSI<br />

SD<br />

5 120