Polyurethane Timing Belts - BRECOflex CO., LLC

Polyurethane Timing Belts - BRECOflex CO., LLC

Polyurethane Timing Belts - BRECOflex CO., LLC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

POLYURETHANE TIMING BELTS<br />

TIMING BELT MATERIALS<br />

<strong>BRE<strong>CO</strong>flex</strong> <strong>CO</strong>., L.L.C. manufactures high precision timing belts with the most advanced materials available.<br />

Extremely wear resistant polyurethane materials and high tensile braided steel tension members or Kevlar ®<br />

tension members are selected for their unique properties. The combination of the superior materials results in<br />

timing belts with a fine balance of high strength and high flexibility. <strong>BRE<strong>CO</strong>flex</strong> <strong>CO</strong>., L.L.C. offers the best<br />

performing timing belts available in the market place.<br />

Strength and Flexibility – The Perfect Combination<br />

<strong>Polyurethane</strong><br />

<strong>Polyurethane</strong> is the obvious choice for high strength timing belts. <strong>BRE<strong>CO</strong>flex</strong> <strong>CO</strong>., L.L.C. offers many<br />

polyurethane polyester elastomers to meet various application requirements.<br />

NOTE: Certain materials may require minimum quantities.<br />

All of our many specially selected polyurethane materials offer the following properties:<br />

• extremely wear resistant<br />

• extensive temperature range<br />

• resistant to petroleum, oils and fats<br />

• ozone and sunlight resistant<br />

• no lubrication required<br />

• high tooth shear strength<br />

• high tear resistance<br />

• allows belt processing with no<br />

loss in material properties<br />

• non-marking<br />

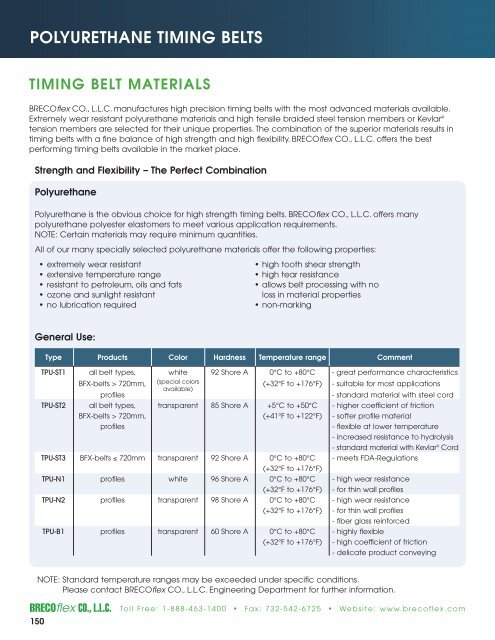

General Use:<br />

Type Products Color Hardness Temperature range Comment<br />

TPU-ST1 all belt types, white 92 Shore A 0°C to +80°C - great performance characteristics<br />

BFX-belts > 720mm, (special colors (+32°F to +176°F) - suitable for most applications<br />

available)<br />

profiles<br />

- standard material with steel cord<br />

TPU-ST2 all belt types, transparent 85 Shore A +5°C to +50°C - higher coefficient of friction<br />

BFX-belts > 720mm, (+41°F to +122°F) - softer profile material<br />

profiles<br />

- flexible at lower temperature<br />

- increased resistance to hydrolysis<br />

- standard material with Kevlar ® Cord<br />

TPU-ST3 BFX-belts ≤ 720mm transparent 92 Shore A 0°C to +80°C - meets FDA-Regulations<br />

(+32°F to +176°F)<br />

TPU-N1 profiles white 96 Shore A 0°C to +80°C - high wear resistance<br />

(+32°F to +176°F) - for thin wall profiles<br />

TPU-N2 profiles transparent 98 Shore A 0°C to +80°C - high wear resistance<br />

(+32°F to +176°F) - for thin wall profiles<br />

- fiber glass reinforced<br />

TPU-B1 profiles transparent 60 Shore A 0°C to +80°C - highly flexible<br />

(+32°F to +176°F) - high coefficient of friction<br />

- delicate product conveying<br />

NOTE: Standard temperature ranges may be exceeded under specific conditions.<br />

Please contact <strong>BRE<strong>CO</strong>flex</strong> <strong>CO</strong>., L.L.C. Engineering Department for further information.<br />

150<br />

Toll Free: 1-888-463-1400 • Fax: 732-542-6725 • Website: www.brecoflex.com