Stora Enso Global Responsibility Report 2012 - GlobeNewswire

Stora Enso Global Responsibility Report 2012 - GlobeNewswire

Stora Enso Global Responsibility Report 2012 - GlobeNewswire

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Environment<br />

E<br />

Better use of the combined heat and power (CHP) potential of our mills<br />

can increase the power-to-heat ratio of our internal energy production.<br />

This means that for each MWh of heat that we produce, we should<br />

aim to maximise the amount of electricity generated. The Group’s<br />

overall power-to-heat ratio decreased from 23% in 2011 to 20% in<br />

<strong>2012</strong> mainly due to a prolonged stoppage at our gas turbine power<br />

plant at Anjala Mill.<br />

In <strong>2012</strong> we started to apply a new approach to energy efficiency management<br />

by initiating the implementation of a new software tool for<br />

energy savings at our mills. The tool primarily covers electricity, steam<br />

and the efficiency of heat exchangers, and it may also be expanded to<br />

cover water use. During <strong>2012</strong> the new software has been piloted at our<br />

Sachsen Mill in Germany. If it proves useful it will also be subsequently<br />

installed at other mills.<br />

issues, who work together systematically to find ways to improve the<br />

efficiency of energy use, referring to the targets set for each business<br />

area. During <strong>2012</strong> we conducted basic energy audits at nine mills. In<br />

2013 the focus will switch to follow-up audits, and Group-wide special<br />

topic campaigns will be introduced. We will also further intensify our<br />

assessments of investment proposals with potential to improve our<br />

mills’ energy efficiency, as well as the sharing of best practices on<br />

energy use.<br />

Our centralised energy efficiency fund contains a total of 10 million<br />

euros that can be allocated for energy saving investments. The fund<br />

was set up in 2008 to support our mills’ energy efficiency projects, and<br />

it supported 37 projects during <strong>2012</strong>. These projects should generate<br />

total energy savings amounting to at least 310 000 MWh per year<br />

when in full effect.<br />

To coordinate and steer our energy efficiency work and promote the<br />

spread of related information, we created the new position of Energy<br />

Efficiency Manager in 2011. In <strong>2012</strong> we took the next step by making<br />

our “energy hunters”, who have been assigned to find energy saving<br />

opportunities at our mills, into a permanent team.<br />

To further improve our energy use we have created a network of three<br />

forums for our Nordic and Continental European paper and board<br />

mills. These forums involve mill personnel with responsibility for energy<br />

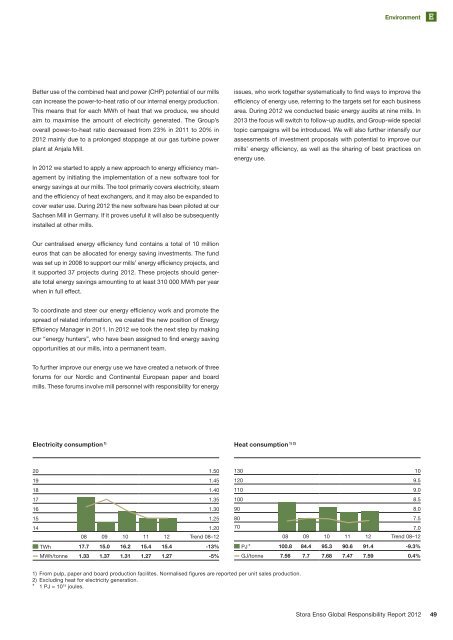

Electricity consumption 1) Heat consumption 1) 2)<br />

130 10<br />

20 1.50<br />

19 1.45<br />

18 1.40<br />

17 1.35<br />

16 1.30<br />

15 1.25<br />

14 1.20<br />

08 09 10 11 12 Trend 08–12<br />

TWh 17.7 15.0 16.2 15.4 15.4 -13%<br />

MWh/tonne 1.33 1.37 1.31 1.27 1.27 -5%<br />

120 9.5<br />

110 9.0<br />

100 8.5<br />

90 8.0<br />

80 7.5<br />

70 7.0<br />

08 09 10 11 12 Trend 08–12<br />

PJ * 100.8 84.4 95.3 90.6 91.4 -9.3%<br />

GJ/tonne 7.56 7.7 7.68 7.47 7.59 0.4%<br />

1) From pulp, paper and board production facilites. Normalised figures are reported per unit sales production.<br />

2) Excluding heat for electricity generation.<br />

* 1 PJ = 10 15 joules.<br />

<strong>Stora</strong> <strong>Enso</strong> <strong>Global</strong> <strong>Responsibility</strong> <strong>Report</strong> <strong>2012</strong> 49