BLIND BOLT - Electronic Fasteners Inc

BLIND BOLT - Electronic Fasteners Inc

BLIND BOLT - Electronic Fasteners Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

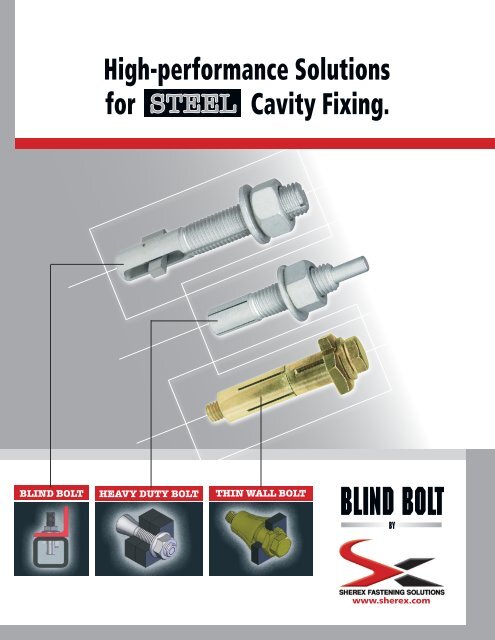

High-performance Solutions<br />

for<br />

STEEL<br />

Cavity Fixing.<br />

<strong>BLIND</strong> <strong>BOLT</strong><br />

HEAVY DUTY <strong>BOLT</strong><br />

THIN WALL <strong>BOLT</strong><br />

<strong>BLIND</strong> <strong>BOLT</strong><br />

by<br />

www.sherex.com

B L I N D B O L T<br />

n DACRALON CORROSION RESISTANT FINISH STANDARD<br />

n SAFE AND SIMPLE TO INSTALL<br />

n NO SPECIAL TOOLS REQUIRED FOR INSTALLATION<br />

n NO OVERSIZED HOLES NEEDED<br />

n CAN BE REMOVED WITHOUT DAMAGE<br />

n VERSATILE FIXING CAVITY<br />

n AVAILABLE IN STAINLESS STEEL<br />

PRODUCT SPECIFICATIONS: HIGH TENSILE STEEL<br />

THREAD HOLE PRODUCT QTY SOCKET Fixing Thickness ANCHOR DEPTH WEIGHT<br />

SIZE SIZE CODE BOX SIZE Min. Max. CLEARANCE CLEARANCE Per Box (lb)<br />

5/16-18 UNC .315 - .343 BBS-3125-2.0 50 1/2 0.406 0.813 0.75 1.063 2.25<br />

3/8-16 UNC .375 - .406 BBS-3750-2.375 40 9/16 0.625 1.156 1.000 1.313 3.15<br />

3/8-16 UNC .375 - .406 BBS-3750-5.0 20 9/16 2.063 3.656 1.000 1.313 3.8<br />

1/2-13 UNC .511 - .531 BBS-5000-2.755 20 3/4 0.500 1.188 1.125 1.375 3<br />

5/8-11 UNC .620 - .656 BBGS-6250-3.54** 20 15/16 0.688 1.563 1.563 1.813 6<br />

3/4-10 UNC .752 - .781 BBGS-7500-4.3** 10 1 1/8 1.500 3.250 1.813 2.25 6<br />

7/8-9 UNC .875 - .906 BBGS-8750-5.5** 10 1 5/16 2.000 3.188 1.875 2.313 7<br />

1.0-8 UNC .998 - 1.031 BBGS-1000-5.1** 5 1 1/2 0.875 2.375 2.125 2.406 5<br />

Performance Data: High Tensile Steel- 40,000 PSI TENSILE STRENGTH<br />

THREAD HOLE PRODUCT STRESS <strong>BOLT</strong> ULTIMATE TENSILE ULTIMATE SHEAR MAX TORQUE<br />

SIZE SIZE CODE AREA (IN 2 ) STEEL GRADE STRENGTH (LBF) STRENGTH (LBF) (ft/lbs)<br />

5/16-18 UNC .315 - .343 BBS-3125-2.0 .052 High Tensile Steel 2,000 2,300 9<br />

3/8-16 UNC .375 - .406 BBS-3750-2.375 .077 High Tensile Steel 3,000 3,500 17<br />

3/8-16 UNC .375 - .406 BBS-3750-5.0 .077 High Tensile Steel 3,000 3,500 17<br />

1/2-13 UNC .511 - .531 BBS-5000-2.755 .141 High Tensile Steel 5,600 6,100 40<br />

5/8-11 UNC .620 - .656 BBGS-6250-3.54** .226 High Tensile Steel 8,000 10,000 85<br />

3/4-10 UNC .752 - .781 BBGS-7500-4.3** .334 High Tensile Steel 13,300 15,000 155<br />

7/8-9 UNC .875 - .906 BBGS-8750-5.5** .462 High Tensile Steel 18,000 20,000 220<br />

1.0-8 UNC .988 - 1.031 BBGS-1000-5.1** .606 High Tensile Steel 24,000 26,000 340<br />

Special designs and features are now available. Contact your representative for details.<br />

FITTING INSTRUCTIONS<br />

STEP 1<br />

Insert bolt into<br />

predrilled hole<br />

with marker<br />

pointing up.<br />

STEP 2<br />

Rotate bolt<br />

a half turn.<br />

STEP 3<br />

Secure bolt<br />

with supplied<br />

flange nut.<br />

**We strongly recommend the use of our safety gauges when installing these Blind Bolts<br />

WARNING: DO NOT EXCEED MAXIMUM TORQUE SETTINGS. ENSURE<br />

ANCHOR IS IN THE FULLY OPEN POSITION BEFORE APPLYING<br />

TORQUE OR THE PIN WILL SHEAR.<br />

Shear strength was determined across the threaded area. Should the shear<br />

plane fall below the minimum fixing thickness (across the hollow section)<br />

shear strength will be reduced and must be recalculated. Performance<br />

data listed is the ultimate failure load. Sherex recommends an appropriate<br />

factor of safety when incorporating the Blind Bolt products into your<br />

application. Additional testing available upon request.<br />

Sherex offers a wide range of standard sizes,<br />

and as always, we welcome special sizes.<br />

Part Number Explanation: BBS-3125-2.0<br />

BB S 3125 2.0<br />

Product style: Material: Thread Size Length<br />

BB Blind Bolt<br />

S - 4135 Chromoly Steel<br />

BBG G is for Grooved SS - A2 / 302 Stainless Steel<br />

For additional test data and special designs, please visit our website:<br />

www.sherex.com<br />

These bolts have not been designed to meet any ASTM standards for externally threaded fasteners. ANCHOR PURPOSES ONLY!

H E A V Y D U T Y ( H D ) B O L T<br />

n HIGH CORROSION RESISTANT PLATING STANDARD<br />

n QUICK AND EASY TO INSTALL<br />

n NO OVERSIZED HOLES REQUIRED<br />

n INCREASED ASSEMBLY EFFICIENCY<br />

n VIBRATION PROOF LOCKING MECHANISM<br />

Heavy Duty (HD) Bolt by Sherex is a fast, cost effective, high performance steel fixing. It was developed for situations where<br />

access to one side of the joint is restricted.<br />

PRODUCT SPECIFICATIONS: HIGH TENSILE STEEL<br />

THREAD HOLE PRODUCT QTY SOCKET Fixing Thickness WEIGHT<br />

SIZE SIZE CODE BOX SIZE Min. Max. Per Box (lb)<br />

1/2-13 UNC .500 - .516 HDS-5000-2.40 20 1/2 0.200 1.38 2.44<br />

5/8-11 UNC .612 - .625 HDS-6250-3.00 20 5/8 0.200 1.38 5.78<br />

3/4-10 UNC .738 - .750 HDS-7500-3.40 10 3/4 0.200 1.38 5.18<br />

PERFORMANCE DATA: HIGH TENSILE STEEL<br />

- 50,000 PSI TENSILE STRENGTH<br />

THREAD HOLE PRODUCT STRESS <strong>BOLT</strong> ULTIMATE TENSILE ULTIMATE SHEAR<br />

SIZE SIZE CODE AREA (IN 2 ) STEEL GRADE STRENGTH (LBF) STRENGTH (LBF)<br />

1/2-13 UNC .500 - .516 HDS-5000-2.40 .141 High Tensile Steel 7,000 7,500<br />

5/8-11 UNC .612 - .625 HDS-6250-3.00 .226 High Tensile Steel 8,000 12,000<br />

3/4-10 UNC .738 - .750 HDS-7500-3.40 .334 High Tensile Steel 14,000 18,000<br />

These bolts have not been designed to meet any ASTM standards for externally threaded fasteners. ANCHOR PURPOSES ONLY!<br />

FITTING INSTRUCTIONS<br />

STEP 1<br />

Insert bolt into predrilled hole.<br />

STEP 2<br />

Drive pin flush with bolt end.<br />

STEP 3<br />

Secure bolt with supplied flange nut.<br />

WARNING: IT IS IMPORTANT THAT THE CORRECT<br />

HOLE SIZE IS USED. ANY VARIATION WILL LEAD<br />

TO INCORRECT DATA VALUES.<br />

Part Number Explanation: HDS-5000-2.40<br />

HD S 5000 2.40<br />

Product style: Material: Thread Size Length<br />

HD Heavy Duty S - 4135 Chromoly Steel<br />

For additional test data, please visit our website: www.sherex.com

T H I N W A L L ( T W ) B O L T<br />

n QUICK AND EASY TO INSTALL<br />

n LARGE GRIP AREA<br />

n EXCELLENT FOR CURVED SURFACES<br />

n ELIMINATES PROTRUDING STUD<br />

n FINISHED WITH ZINC YELLOW DICHROMATE<br />

n INCREASED ASSEMBLY EFFICIENCY<br />

n USED IN SHEET STEEL APPLICATIONS<br />

n EXTENSION PARTS ARE AVAILABLE<br />

The Thin Wall (TW) Bolt range is designed to clamp thin wall steel applications in any location. After installation, a neat low profile head<br />

is left, with no stud. The bolt has strong shear capacity and the tensile strength is the same as the clamping bolt. These bolts come<br />

with a standard Zinc and Yellow Passivate finish.<br />

PRODUCT SPECIFICATIONS: LOW CARBON STEEL<br />

THREAD HOLE PRODUCT QTY SCREW SOCKET BASE NUT Fixing Thickness WEIGHT<br />

SIZE size CODE BOX SIZE WRENCH SIZE Min. Max. Per Box (lb)<br />

5/16-18 UNC .315 - .343 TWS-3125-400 100 Phillips Head 1/2 0.080 0.400 2.60<br />

3/8-16 UNC .394 - .422 TWS-3750-400 100 3/8 11/16 0.080 0.400 5.66<br />

1/2-13 UNC .495 - .531 TWS-5000-400 100 1/2 3/4 0.080 0.400 11.60<br />

11/16-UNC .667 - .688 TWS-6875-400 100 11/16 7/8 0.080 0.400 16.60<br />

These bolts have not been designed to meet any ASTM standards for externally threaded fasteners. ANCHOR PURPOSES ONLY!<br />

FITTING INSTRUCTIONS<br />

STEP 1<br />

Insert bolt into predrilled hole.<br />

STEP 2<br />

Hold base nut with a wrench.<br />

(TW Installation Tool shown)<br />

STEP 3<br />

Turn bolt head until fastener is secure.<br />

NOW AVAILABLE!<br />

TW INSTALLATION TOOL–<br />

Installs all TW sizes<br />

TAMPER-PROOF HEADS<br />

Contact your<br />

SHEREX REPRESENTATIVE<br />

for additional information<br />

and pricing!!<br />

WARNING: THIN WALL SERIES IS NOT INTENDED<br />

FOR HEAVY DUTY APPLICATIONS.<br />

Sherex offers a wide range of standard sizes and, as always, we<br />

welcome special sizes.<br />

Part Number Explanation: TWS-3125-400<br />

TW S 3125 400<br />

Product style: Material: Thread Size Length<br />

TW Thin Wall S - Low Carbon Steel<br />

For additional test data, please visit our website: www.sherex.com

A P P L I C A T I O N S<br />

Safe, Quick and Easy installation<br />

for hundreds of blind-sided<br />

installation applications!<br />

Construction<br />

Railway<br />

The anchor system was used to tie mast climber<br />

work platforms into tubular steel, making onsite<br />

welding unnecessary. Blind Bolts therefore were<br />

faster and easier to install, saving time and money.<br />

Scaffolding<br />

Blind Bolts have achieved certified acceptance as a<br />

high-performance fixing solution for installing AWS<br />

units onto steel railroad ties.<br />

Marinas<br />

Blind Bolts being used for holding critical masonry,<br />

and scaffolding.<br />

Blind Bolts are ideal for many marine fixing applications<br />

including harbors, mooring points, etc...<br />

Blind Bolts save both<br />

time and expense!<br />

For additional applications, please visit www.sherex.com<br />

400 Riverwalk Pkwy, Suite 600 • Tonawanda, NY 14150 • Phone: 866-474-3739 • Fax: 716-875-0358 • info@sherex.com • www.sherex.com

<strong>BLIND</strong> <strong>BOLT</strong> by<br />

SHEREX<br />

Three High-performance Solutions<br />

for STEEL Cavity Fixing.<br />

<strong>BLIND</strong> <strong>BOLT</strong><br />

n DACRALON CORROSION RESISTANT<br />

FINISH STANDARD<br />

n SAFE AND SIMPLE TO INSTALL<br />

n NO SPECIAL TOOLS REQUIRED FOR<br />

INSTALLATION<br />

n NO OVERSIZED HOLES NEEDED<br />

n CAN BE REMOVED WITHOUT DAMAGE<br />

n VERSATILE FIXING CAVITY<br />

n AVAILABLE IN STAINLESS STEEL<br />

<strong>BLIND</strong> <strong>BOLT</strong>S by SHEREX are revolutionary<br />

fastening devices used in steel applications<br />

where there is no backside access.<br />

The <strong>BLIND</strong> <strong>BOLT</strong> provides an innovative<br />

solution without the need for welding, or<br />

expensive tools. Components can be<br />

successfully attached by simply inserting<br />

the Blind Bolt, and tightening the nut.<br />

HEAVY DUTY (HD) <strong>BOLT</strong><br />

n HIGH CORROSION RESISTANT<br />

PLATING STANDARD<br />

n QUICK AND EASY TO INSTALL<br />

n NO OVERSIZED HOLES REQUIRED<br />

n INCREASED ASSEMBLY EFFICIENCY<br />

n VIBRATION PROOF LOCKING MECHANISM<br />

TECHNICAL SPECIFICATIONS<br />

Anchor Clearance<br />

Min.<br />

Fixing<br />

Clearance<br />

Screw Driver Slot<br />

THIN WALL (TW) <strong>BOLT</strong><br />

n QUICK AND EASY TO INSTALL<br />

n LARGE GRIP AREA<br />

n EXCELLENT FOR CURVED SURFACES<br />

n ELIMINATES PROTRUDING STUD<br />

n FINISHED WITH ZINC YELLOW DICHROMATE<br />

n INCREASED ASSEMBLY EFFICIENCY<br />

n USED IN SHEET STEEL APPLICATIONS<br />

n EXTENSION PARTS ARE AVAILABLE<br />

Non-load<br />

Bearing<br />

Pivot Pin<br />

Depth Clearance<br />

Max. Fixing<br />

Clearance<br />

Direction Marker<br />

UNITED STATES PATENT #6685408<br />

CANADIAN PATENT #2363549<br />

GREAT BRITAIN PATENT #1159536<br />

400 Riverwalk Pkwy, Suite 600 • Tonawanda, NY 14150 • Phone: 866-474-3739 • Fax: 716-875-0358 • info@sherex.com • www.sherex.com