Testing Virtual ECUs - Power Systems Design

Testing Virtual ECUs - Power Systems Design

Testing Virtual ECUs - Power Systems Design

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

28<br />

SPECIAL REPORT : AUTOMOTIVE ELECTRONICS<br />

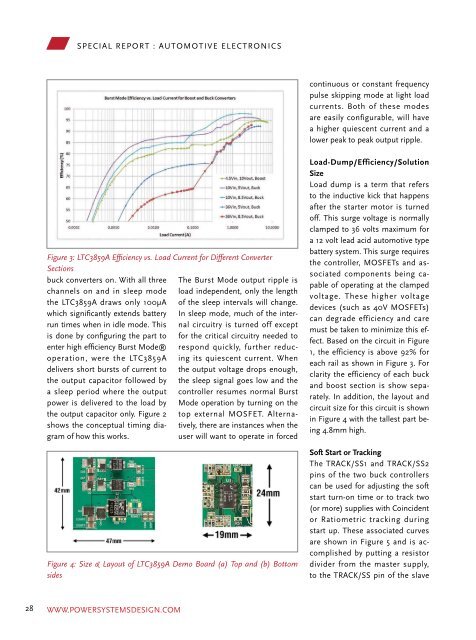

Figure 3: LTC3859A Efficiency vs. Load Current for Different Converter<br />

Sections<br />

buck converters on. With all three<br />

channels on and in sleep mode<br />

the LTC3859A draws only 100µA<br />

which significantly extends battery<br />

run times when in idle mode. This<br />

is done by configuring the part to<br />

enter high efficiency Burst Mode®<br />

operation, were the LTC3859A<br />

delivers short bursts of current to<br />

the output capacitor followed by<br />

a sleep period where the output<br />

power is delivered to the load by<br />

the output capacitor only. Figure 2<br />

shows the conceptual timing diagram<br />

of how this works.<br />

The Burst Mode output ripple is<br />

load independent, only the length<br />

of the sleep intervals will change.<br />

In sleep mode, much of the internal<br />

circuitry is turned off except<br />

for the critical circuitry needed to<br />

respond quickly, further reducing<br />

its quiescent current. When<br />

the output voltage drops enough,<br />

the sleep signal goes low and the<br />

controller resumes normal Burst<br />

Mode operation by turning on the<br />

top external MOSFET. Alternatively,<br />

there are instances when the<br />

user will want to operate in forced<br />

Figure 4: Size & Layout of LTC3859A Demo Board (a) Top and (b) Bottom<br />

sides<br />

continuous or constant frequency<br />

pulse skipping mode at light load<br />

currents. Both of these modes<br />

are easily configurable, will have<br />

a higher quiescent current and a<br />

lower peak to peak output ripple.<br />

Load-Dump/Efficiency/Solution<br />

Size<br />

Load dump is a term that refers<br />

to the inductive kick that happens<br />

after the starter motor is turned<br />

off. This surge voltage is normally<br />

clamped to 36 volts maximum for<br />

a 12 volt lead acid automotive type<br />

battery system. This surge requires<br />

the controller, MOSFETs and associated<br />

components being capable<br />

of operating at the clamped<br />

voltage. These higher voltage<br />

devices (such as 40V MOSFETs)<br />

can degrade efficiency and care<br />

must be taken to minimize this effect.<br />

Based on the circuit in Figure<br />

1, the efficiency is above 92% for<br />

each rail as shown in Figure 3. For<br />

clarity the efficiency of each buck<br />

and boost section is show separately.<br />

In addition, the layout and<br />

circuit size for this circuit is shown<br />

in Figure 4 with the tallest part being<br />

4.8mm high.<br />

Soft Start or Tracking<br />

The TRACK/SS1 and TRACK/SS2<br />

pins of the two buck controllers<br />

can be used for adjusting the soft<br />

start turn-on time or to track two<br />

(or more) supplies with Coincident<br />

or Ratiometric tracking during<br />

start up. These associated curves<br />

are shown in Figure 5 and is accomplished<br />

by putting a resistor<br />

divider from the master supply,<br />

to the TRACK/SS pin of the slave<br />

At higher temperatures, or in cases<br />

where the internal power dissipation<br />

causes excessive self heating<br />

on chip, the over temperature<br />

shutdown circuitry will shut down<br />

the LTC3859A. When the junction<br />

temperature exceeds approximately<br />

170°C, the over temperature<br />

circuitry disables the on-board<br />

bias LDO, causing the bias supply<br />

POWER SYSTEMS DESIGN JULY/AUGUST 2011<br />

Figure 5: LTC3859A Output Voltage Tracking: (a) Coincident Tracking and (b) Ratiometric Tracking<br />

supply.<br />

to drop to zero volts and effective ler. Combined with two synchro-<br />

shutting down the entire LTC3859A nous step-down controllers, ideal<br />

in an orderly manner. Once the for powering many automotive<br />

junction temperature drops back electronic devices, the LTC3859A<br />

to approximately 155°C, the LDO maintains regulation for all output<br />

turns back on.<br />

voltages during an engine restart.<br />

Conclusion<br />

The LTC3859A provides a solution<br />

by boosting the battery voltage to<br />

a safe operating level with is onboard<br />

synchronous boost control-<br />

Author: Bruce Haug<br />

Senior Product Marketing Engineer<br />

Linear Technology Corporation<br />

www.linear.com<br />

WWW.POWERSYSTEMSDESIGN.COM WWW.POWERSYSTEMSDESIGN.COM<br />

29