TW-Mill - Technowood

TW-Mill - Technowood

TW-Mill - Technowood

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The statical <strong>TW</strong>-<strong>Mill</strong><br />

Variant with fixed portal and moveable portal trolley<br />

Benefits of the portal<br />

trolley version<br />

• high efficiency due to automatic<br />

infeed and discharge<br />

• handling of all six sides of the<br />

component<br />

• linkup to further features possible<br />

(e.g. engine lathe)<br />

• all stops can be retracted<br />

• range of up to 2000mm<br />

(extensible)<br />

For the stationary version of <strong>TW</strong>-<strong>Mill</strong>, the portal remains fixed, the portal trolley<br />

executing the axle movement in X-direction. These so called „<strong>TW</strong>-Carriers“ lead the<br />

workpieces through under the portal with its milling and spindle units.<br />

All <strong>TW</strong>-Carriers are identical and designed as full-value servo axle, allowing for<br />

exact positioning. To prevent massive friction when repositioning the trolleys the<br />

supporting area can be lowered. The stop as well as the tensioners of the <strong>TW</strong>-Carrier<br />

can be retracted as well. This results in a free surface which enables flexible<br />

infeed and discharge backwards and forwards.<br />

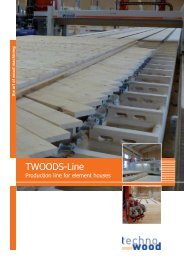

Of particular interest is the option for automatic infeed and discharge. Chain cross<br />

conveyors implement infeed of the components. The infeed can be used as driven<br />

discharge as well. Otherwise the processed components are discharged by gravity<br />

via slanted roller rail with stop at its end.<br />

Machining examples<br />

• drill holes<br />

• cuts<br />

• outline milling<br />

• window openings<br />

• short pieces<br />

• tenons and mortises<br />

• calibration<br />

• dovetail tenon/mortise<br />

• hags cut<br />

• dowel pin connection<br />

• skew notch<br />

• tapered skew notch<br />

• rebate with saw<br />

• jag<br />

• deburring<br />

• ... and so on and so on<br />

Die <strong>TW</strong>-<strong>Mill</strong> lässte viele Optionen zu - z.B.<br />

den Einsatz eines Drehbanks<br />

Bauteile werden via Querförderer automatisch<br />

auf die <strong>TW</strong>-Carrier eingefördert<br />

Die Fixierung von geraden Bauteilen erfolgt<br />

nach der Einförderung ebenfalls automatisch